Académique Documents

Professionnel Documents

Culture Documents

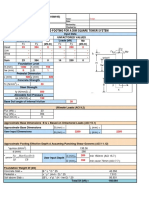

RCC Bund Wall With Shear Key

Transféré par

nhulugallaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RCC Bund Wall With Shear Key

Transféré par

nhulugallaDroits d'auteur :

Formats disponibles

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

4.5

SR NO

Design of Concrete Bund Wall for

Wet Crude Tank 21-TK-001.

TABLE OF CONTENTS

1.0

Design Data

2.0

Design Philosophy

3.0

Design Of Wall

4.0

Design Of Base Slab

APPENDIX - I

Typical details of Cantilever Wall

PAGE NO

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

1.0 DESIGN DATA :

1.1 Geometrical Data :

Height of soil filling, ( H2 )

Depth of base, ( W b )

Depth of retaining wall below finished

ground level, ( H )

Free Board ( F )

Total Height of retaining wall, ( H1 )

Depth of soil, ( D )

Top of raft from GL of tank ( D1)

Width of heel slab ( Bh )

Thickness of wall at bottom, ( B )

Width of toe slab ( Bt )

1.6

=

=

0.5

2.1

=

=

5.25

2.1

m

m

1.6

=

=

2.7

0.5

m

m

0.6

Thickness of wall at top, ( B1 )

0.3

Thickness of wall at H2 from raft top(Bc)

=

=

0.433

2.7

m

m

0.5

Clear distance between face of shear

key & face of toe slab ( Dst )

0.6

Height of shear key, ( Hs )

0.2

18

kN/m3

Clear distance between face of shear

key & face of heel slab ( Dsh )

Width of shear key, ( Bs )

0.5

( considered at rest condition as per geotechnical report)

Net Allowable Bearing capacity of soil

=

125

KN/m2

Angle of internal friction, (

=

32

Coefficient of active earth pre. ( Ka )

( 1-SIN ) / ( 1+SIN )

=

Coefficient of passive earth pre. ( KP )

( 1+SIN ) / ( 1-SIN )

=

=

=

Tank

Farm

area

H1

H

H2

D1

D

B

Bh

Bt

Hs

Dsh

Dst

B

s

0.31

3.25

N/mm2

N/mm2

Dia of Reinforcement in wall ( dwall )

20

mm

Dia of Reinforcement in base ( dbase )

=

=

=

20

75

24

mm

mm

KN/m3

8.77

KN/m3

Density of retained liquid, ( w )

Bc

1.75

1.75

1.3 Material Data: ( As Per JI-180-000-ECV-SPE-001 )

Grade of Concrete ( Fck )

30

=

Yield Strength of reinforcement ( Fy )

414

=

Clear Cover to Reinforcement ( c )

Unit Weight of Concrete ( c )

Wb

1.2 Soil Data : ( As Per JI-180-000-ECV-SPE-001 )

Unit weight of soil,( )

=

Coefficient of soil pressure, ( Ko )

=

Factor of safety against sliding

Factor of safety against overturning

B1

2.0 DESIGN PHILOSOPHY :

Here, Bund wall has been desinged as a cantilever retaining wall for 1 m length and for that following critical

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

cases has been considered

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

Case 1 ) Empty on tank side & soil pressure and wind on other side of retaining wall.

In this case cantilever wall has been analyzed for the active earth pressure from one side only,

while checking for the stability, wt of earth from both the side has been considered.

Case 2 )

Hydrostatic pressure due to stored liquid during spillages or tank burst conditions.

In this case cantilever wall has been analyzed for the submerged liquid pressure from tank side

only passive earth pressure on the other side of retaining wall to the possible extent of 2/3

height of overburden soil. While checking for the stability, wt of earth from both the side & wt of

liquid form tank side has been considered.

The stability and base pressure check for the retaining wall have been carried out to decide the

size and other details of the assumed retaining wall. The structural calculations are carried out later.

3.0 DESIGN OF WALL :

3.1 BM Calculation For Case 1 :

a)

Active earth pressure ( Pa )

=

=

Shear at base of stem due to active

earth pressure ( Va )

Moment at base of stem due active

earth pressure ( Ma )

Qw

8.870 KN/m2

Pa * H2 / 2

7.096 kN/m

Pa * H2 / 2 * H2 / 3

3.785

kNm/m

0.76

KN/m2

Shear at base of stem due to wind

pressure ( Vw )

Qw * (H1-H)

Moment at base of stem due to Wind

pressure ( Mw )

2.394 kN/m

Qw * (H1-H) * ((H1-H)/2+H2)

b)

Wind pressure ( Qw )

*Ka*H2

Pa

( Refer Civil & Structural design

philosophy JI-180-000-ECV-SPE-001)

c)

Passive earth pressure, ( Pp )

=

=

Shear at base of stem due to passive

earth pressure ( Vp )

Moment at base of stem due to

passive earth pressure ( Mp )

d)

Additional Shear ( Vadd )

7.601

kNm/m

*Kp*D1

0.000 KN/m2

Pp * D1 / 2

( Passive pressure for moment

calculation has been ignored so

as to be on conservative side )

0.000 kN/m

Pp * D1 / 2 * D1 / 3

0.000

kNm/m

0.00

kN/m

( Due to Walkway at top )

Additional Moment ( Madd )

0.53

kNm/m

( Due to Walkway at top )

Total shear at base ( V1 )

=

=

Va + Vw + Vadd - Vp

9.49

kN/m

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

Total moment at base ( M1 )

M

+

M

+

M

M

=

a

w

add

p

=

11.92

kNm/m

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

3.2 BM Calculation For Case 2 :

a)

Contained Liquid pressure ( Pw )

=

=

Shear at base of stem due to liquid

pressure ( Vl )

Moment at base of stem due to liquid

pressure ( Ml )

b)

Active earth pressure ( Pa )

Qw

=

=

Ka * D1

Moment at base of stem due to active

earth pressure ( Ma )

=

=

=

=

Shear at base of stem due to passive

earth pressure ( Vp )

Moment at base of stem due to

passive earth pressure ( Mp )

4.549 KN/m2

Ka*D12/2

3.639 kN/m

Ka*D13/6

1.941

0.000 KN/m

Pp * H2 / 2

0.76

Qw * F

( Passive pressure for moment

calculation has been ignored so

as to be on conservative side )

kNm/m

KN/m2

0

kN/m

Qw * F * (F/2 + (H1-F-W b))

kNm/m

0.00

kN/m

( Due to Walkway at top )

Additional Moment ( Madd )

0.53

kNm/m

( Due to Walkway at top )

Total shear at base ( V2 )

=

=

Total moment at base ( M2 )

=

=

Pp

0.000 kN/m

Pp * H2 / 2 * H2 / 3

Moment at base of stem due to wind

pressure ( Mw )

Pw

kNm/m

0.000

Pa

*Kp*H2

Shear at base of stem due to wind

pressure ( Vw )

e)

Additional Shear ( Vadd )

98.937 kN/m

Pw * (H1-W b-F)2/6

156.650 kNm/m

d)

Wind pressure ( Qw )

41.658 KN/m2

Pw * (H1-W b-F)/2

Shear at base of stem due to active

earth pressure ( Va )

c)

Passive earth pressure ( Pp )

w*(H1-W b-F)

Vl + Va + Vw + Vadd - Vp

102.58 kN/m

Ml + Ma + Mw + Madd - Mp

159.12

kNm/m

3.3 Rebar Calculation :

Design factored bending

moment ( Mu )

=

=

1.4 * ( Maximum of M1 & M2 )

222.77

kNm

( Load factor for soil pressure is

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

1.4, as per BS:8110-Part I )

(

B

*

1000

)

(d

/2)

c

Effective depth ( d )

=

wall

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

=

415

mm

Now as per clause 3.4.4.4 of BS 8110 ( Part - I )

k

=

=

=

z

Take z

Required Ast1

As per table 3.25 of BS : 8110 ( Part - I )

Min reinforcement for flexure ten Ast2

Mu / fcu bd2

30

0.043

222.77

x 1000

<

x 106

x 415

0.156

=

=

=

=

=

=

=

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

415 x [ 0.5 + sqrt( 0.25 394.06 mm

&

0.95 x d

394.25 mm

Minimum Of Above two values

394.06 mm

=

=

M / [0.95*fy*z]

1437.36 mm2/m

=

=

=

0.13 % of Area of concrete

0.13

x 1000

x 500

mm2/m

650

x 415

0.043

/ 100

As per table 3.25 of BS : 8110 ( Part - I ) clause 3.9.4.19

Min reinforcement for crack control Ast3

=

0.25 % of Area of concrete

=

=

=

From the above required Astreq1

Required 20 mm bar at a spacing of 218 mm c/c

Provide 20 mm bar at a spacing of

150

Area of steel provided Astprov1

=

pt provided

0.25

1250

625

x 1000

mm2

mm2

1437.36 mm2/m

x 500 / 100

on both face

on each face

Max of Ast1, Ast2 & Ast3

mm c/c

2093

0.42 %

mm2

3.4 Distribution Steel :

Provide Min Reinforcement As Dist. Steel, As per table 3.25 of BS : 8110 ( Part - I )

Distribution steel, Adist

=

0.13 % of Area of concrete

=

=

Dia of distribution rebar

Provide 16 mm bar at a spacing of

Area of steel provided Astprov1

3.5 Check For Shear :

Maximum design shear at face ( Vf )

=

250

=

0.13

650

16

mm c/c

804

x 1000

mm2/m

mm

mm2

Maximum Of V1 & V2

x 500

/ 100

/0.9)]

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By :GK

=

102.58 kN

Shear V at face of the support ( Vu1 )

1.4 * Vf

=

( Load factor for soil pressure is

=

Shear stress at face of support, ( v1 )

=

=

Maximum allowed shear stress ( vmax )

143.61

Vu1/bd

kN

0.35

N/mm

4.38

N/mm2

Max( 0.8fcu , 5 )

1.4, as per BS:8110-Part I )

or

5 N/mm2

v1 < vmax, O.K. (Clause 3.7.7.2)

100Ast / bd

From BS 8110, Part 1 Table 3.8, ( vc )

Revise value of ( vc )

=

=

0.50

0.43

N/mm

vc*( fck /25 )1/3

For fck = 25 N/mm2

For fck = 30 N/mm2

0.46

N/mm

Since vc > v1, Hence section is SAFE in shear

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of RCC Bund Wall For

Rev No

:

Wet Crude Tank 21-TK-001.

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

GK

3.6 Calculation Of Crack Width

Maximum allowable crack width

0.3

mm (Per BS 8110-2 : 1985 clause 3.2.4)

1 ) Crack width for drying shrinkage / thermal movement :

fcu

=

=

Characteristic strength of reinforced concrete

30

N/mm2

fy

Characteristic strength of reinforcing steel as per table 3.1 of BS 8110

( As per design philosophy 0.9fy )

414

N/mm2

=

Thermal strain r

R

=

=

=

=

=

0.8*t**R ( Refer equation 14 of clause 3.8.4.2 of BS 8110-2)

0.6

( Per Table 3.3 of BS 8110-2)

Coefficient of thermal expansion of mature concrete

0.000012 Table 7.3 of BS 8110 ( Part 2 )

Fall in temperatue between hydration peak and ambient

20

( per Table 3.2 of BS 8110-2)

Thermal strain r

Design surface crack width, W 1

Where,

acr

0.0001152

=

3*acr*r/(1+2*((acr-cmin)/(h-x)))

=

=

=

=

=

=

=

=

=

Dist from point considered to the surface of the nearest long bar

Sqrt( S/22+ (c+/2)2 ) - (/2)

acr

113.31 mm

Size of each reinforcing bar

20

Depth of wall = B

500

Spacing of reinforcement

150

As

=

=

Area of steel

2093.333

W1

D

S

0.034

mm

<

0.3

mm

2 ) Crack width in flexure :

Crack width, ( W 2 )

3*acr*m/(1+2*(acr - cmin)/(h-x))

Where,

acr

=

=

=

2

1

=

=

=

113.31

mm

average strain at the level where the cracking is being considered

1 -2

0.001

bt*(h-x)*(a'-x)/3*Es*As*(d-x)

0.0004

fs/Es*((h-x)/(d-x))

for crack width of 0.3mm

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

:

0

Wet Crude Tank 21-TK-001.

Prep. By :

Dipak

Checkd. By :

GK

=

0.001

Moment in section, M

=

159.1203 kNm

( Unfactored moment)

Stress in steel, fs

M/(A

*(d-S'/2))

=

s

=

=

=

192.8955 N/mm2

OK

Overall depth of member

500

mm

bt

=

=

Width of section at the centroid of tensile steel

1000

mm

Es

a

=

=

=

=

=

=

Modulus of elasticity of reinforcement

200000 N/mm2

Distance from the compression face to the point at which the

crack width is being calculated

effective depth ( d )

415

mm

Effective depth

D - cmin - /2

=

=

415

mm

cmin

=

=

Minimum cover to tensile steel

75

mm

=

=

=

=

=

=

=

=

=

=

Mu / fcu bd2

z

z

S'

x

W2

=

=

= D

0.043

<

0.156

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

394.06 mm

&

394.06 mm

Depth of stress block

41.87498 mm

depth of neutral axis

(d-z)/0.45

46.52776 mm

3*acr*m/(1+2*(acr - cmin)/(h-x))

0.240 mm

<

&

394.25

0.3

0.95 x d

mm

mm

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : Design of RCC Bund Wall For

Rev No

:

Wet Crude Tank 21-TK-001.

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Dipak

GK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

Sign Convention :

Clockwise Moment

Anti clockwie Moment

+Ve

-Ve

Horizontal left to right direction

Horizontal right to left direction

+Ve

-Ve

4.0 DESIGN OF BASE SLAB :

4.1 Stability Analysis For Case 1 :

( Moment has been calculated with respect to A )

a)

Active earth pressure ( Pa )

=

=

*Ka*H

KN/m2

kN

Shear at base due to active earth

pressure ( Va )

Moment at base due active

pressure ( Ma )

12.225

Pe*H2/6

8.557

Qw

11.642

Pe*H/2

kNm

A

Pe

b)

Wind pressure ( Qw )

Pp

=0

KN/m2

=

0.76

( Refer Civil & Structural design philosophy JI-180-000-ECV-SPE-001)

Qw * (H1-H)

Shear at base due to wind

=

pressure ( Vw )

Moment at base due to Wind

pressure ( Mw )

c)

Passive earth pressure, ( Pp )

=

=

Shear at base due to passive earth

pressure ( Vp )

Moment at base due to passive earth

pressure ( Mp )

d)

Additional Shear ( Vadd )

Additional Moment ( Madd )

Check Against Overturning :

Overturning moment ( Mo )

2.394 kN

Qw * (H1-H) * ((H1-H)/2+H)

8.798

Kp*(D+Hs)

( Passive pressure

has been neglected )

0

KN/m2

1/2*Pp(D+Hs)

0.000 kN

1/6*Pp(D+Hs)2

0.000

1.1

=

=

kNm

kNm

kN

kNm

Mp - Ma - Mw - Madd

-18.46

kNm

W1

( 5.25 - 0.50 ) x 0.30 x 24

W 1'

1/2 x ( 5.25 - 0.30 ) x ( 0.50 - 0.30 ) x 24

W2

0.60 x 1.60 x 18

W 2'

1/2 x ( 0.50 - 0.43 ) x 1.60 x 18

0.96

kN

34.2

kN

11.4

kN

17.28

kN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

W3 =

( 2.70 + 0.50 + 0.60) x 0.50 x 24

45.6

kN

W4

2.70 x 1.60 x 18

W key =

0.50 x 0.20 x 24

Additional Axial Force ( W add )

W

77.76

kN

2.4

kN

4.4

kN

W 1 + W 2 +W 3 + W 1' + W 2' + W 4 + W key + W add

=

=

194.0048 kN

B1 = 0.30

Wadd

Bc = 0.43

GL

W2'

W1

H1 = 5.25

GL

W2

W1'

H2 = 1.60

W4

D1 = 1.60

B = 0.60

Bh = 2.70

Bt = 0.60

Wb = 0.50

W3

Dsh = 2.70

Wkey

Dst = 0.60

Hs = 0.20

Bs = 0.50

Restoring moment ( Mr )

=

W 1*(Bh+0.5*B1) + W 2*(Bh+B+0.5*Bt) + W 3*(Bh+Bt+B)/2 + + W add*(Bh+0.5*B1)

W 1' *(Bh+B1+(B-B1)/3) + W 2' * (Bh+B1+(B-Bc)*2/3) + W 4*Bh/2 + W key*( Dsh+Bs/2)

407.08

F.O.S

Check Against Sliding :

Shear at base ( Vb )

kNm/m

=

=

Mr / Mo

22.058

>

1.75

=

=

Vp - Ve - Vw - Vadd

Total weight of wall and soil, ( W )

Coeff of friction between soil and

concrete ( )

Restoring force

=

=

=

=

=

194.00 kN

Tan(2/3)

0.391

*W

75.769 kN

F.O.S

=

=

Restoring force / Shear at base

5.18

>

1.75

Calculation Of Base Pressure :

Total width of base ( L )

Width of base slab ( B )

Base area ( A )

Section modulas of base slab ( Z )

=

=

=

=

=

=

-14.619

3.8

1

BL

3.8

B L2 / 6

2.407

OK

kN

m

m

m2

m3

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

W

=

194.00 kN

Mr

=

407.08 kNm

Mo

=

=

-18.46

kNm

( Mr - Mo ) / W

2.004

=

=

x

0.104

=

=

Wxe

20.176

kNm

Pressure

P1

W /A

59.44

KN/m2

P2

Eccentricity ( e )

Moment due to eccentricity ( Me )

L/2

<

0.63

(L/6)

OK

Me / Z

42.67031 KN/m2

>

<

0

162.8

Comp

OK

PRESSURE DIAGRAM

Down pressures :

Tank side pressure

( Earth + Base Slab )

=

=

Other side pressure

( Earth + Base Slab )

=

=

(xD1) + (cxW b)

40.80 KN/m2

(xH2) + (cxW b)

40.80

KN/m2

2.004

1.9

Base Pressure :

P2

1.9

2.70

0.50

42.67

0.60

54.58

56.79

P1

59.44

Downward Pressure :

40.80

40.80

Effective Depth d

Tank farm side :

a ) Shear force at wall face

0.415

42.67 x

21.13

2.70

40.80 x

kN

+

2.70

11.91 x

2.70 /2

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

b ) Shear at d distance from

the wall face

i.e. = 2.70 - 0.415 = 2.285

42.67 x

15.79

2.285

40.80 x

kN

+

2.285

10.08 x

2.285 /2

c ) Shear at 1.5d distance

=

from the wall face

i.e. = 2.70 - ( 1.5 x 0.415 ) = 2.078

=

42.67 x

-

2.078

40.80 x

+

2.078

9.17 x

2.078 /2

d ) BM

42.67 x

11.91 x

40.80 x

21.29

2.70 x

2.70 x

2.70 x

kNm

2.70 /2

2.70 /6

2.70 /2

+

-

40.80 x

56.79 x

-10.39

0.60

0.60

kNm

40.80 x

-3.37

0.185

58.62 x

kN

c ) Shear at 1.5d distance

=

from the wall face

i.e. = 0.60 - ( 1.5 x 0.415 ) = -0.022

40.80 x

-

-0.023

59.54 x

=

Earth side :

a ) Shear force at wall face

=

=

b ) Shear at d distance from

the wall face

i.e. = 0.60 - 0.415 = 0.185

13.41

0.42

d ) BM

40.80 x

56.79 x

2.65 x

-3.20

kN

2.65 x

0.60 /2

0.185

0.82 x

0.185 /2

-0.023

-0.10 x

-0.023 /2

0.60 /2

0.60 /2

0.60 /3

kN

0.60 x

0.60 x

0.60 x

kNm

Design BM & Shear For Base Slab For Case1 :

BM at face of wall, ( Mf1 )

21.29

kNm

Shear at wall face, ( Vf11)

21.13

kN

Shear at d dist. from wall face ( Vf12)

15.79

kN

Shear at 1.5d dist. from wall face ( V f13)

13.41

kN

Shear & BM for Shear Key For Case1 :

Shear key has been analyzed for the passive pressure, as it is the pressure which comes in action

and bends shear key when retaining wall is subjected to active pressure.

Shear for shear key at the face of

base slab ( Vs1 )

Moment for shear key at the face of

base slab ( Ms1 )

( 1/2 x 122.96 x 0.20 x 0.20 )

+ ( 1/3 x 11.71 x 0.20 x 0.20 )

2.62

kNm

( 122.96 x 0.20 ) + ( 1/2 x 11.71 x 0.20 )

25.76

kN

122.96

2300

A

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

200

Pp = 134.67

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of RCC Bund Wall For

Wet Crude Tank 21-TK-001.

Sign Convention :

Clockwise Moment

Anti clockwie Moment

-Ve

+Ve

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Dipak

Checkd. By : GK

Horizontal left to right direction

Horizontal right to left direction

-Ve

+Ve

6.2 Stability Analysis For Case 2 :

( Moment has been calculated with respect to B )

Qw

a)

Contained Liquid pressure ( Pw )

=

=

Shear at base due to liquid

pressure ( Vl )

Moment at base due to liquid

pressure ( Ml )

b)

Active earth pressure ( Pa )

=

=

=

=

Shear at base due to active earth

pressure ( Va )

Moment at base due to active earth

pressure ( Ma )

c)

Passive earth pressure ( Pp )

=

=

=

Moment at base due to passive earth

pressure ( Mp )

Shear at base due to wind

pressure ( Vw )

Moment at base due to wind

pressure ( Mw )

e)

Additional Shear ( Vadd )

Additional Moment ( Madd )

Check Against Overturning :

Overturning moment ( Mo )

46.0425 KN/m2

/2*Pw*(H1-F)

120.86 kN/m

/6*Pw*(H1-F)2

211.51

=

=

Pw

Pp

B

5.97

KN/m2

1/2*Ka*D2

6.27

kN/m

1/6*Ka*D3

4.39

kNm/m

*Kp*(H+Hs)*2/3

89.783 KN/m2

1/2*Pp*(H+Hs)*2/3

( Passive pressure for 2/3 ht

has been considered )

68.833 kN/m

1/6*Pp*(H+Hs)2*(4/9)

35.182

kNm/m

KN/m2

=

=

0.76

Qw * F

=

=

0

kN/m

Qw * F * (F/2 + (H1-F))

kNm/m

kN/m

0.53

=

=

Pa

kNm/m

Ka*D

Shear at base due to passive earth

pressure ( Vp )

d)

Wind pressure ( Qw )

w*(H1-F)

kNm/m

Mp - Mw - Ml - Ma - Madd

-181.24 kNm/m

W1

( 5.25 - 0.50 ) x 0.30 x 24

34.2

kN

W2

0.60 x 1.60 x 18

17.28

kN

W3

( 2.70 + 0.50 + 0.60) x 0.50 x 24

45.6

kN

W4

2.70 x 1.60 x 18

77.76

kN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of RCC Bund Wall For

Wet Crude Tank 21-TK-001.

W5

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Dipak

Checkd. By : GK

( 5.25 - 2.10 - 0.00) x 2.70 x 8.77

W 1' =

1/2 x ( 0.50 - 0.30 ) x ( 5.25 - 0.50 ) x 24

11.4

kN

W 2' =

1/2 x ( 0.50 - 0.43 ) x 1.60 x 18

0.97

kN

2.4

kN

4.30

kN

W key =

0.50 x 0.20 x 24

Additional Axial Force ( W add )

W

74.5889 kN

W 1 + W 2 +W 3 + W 1' + W 2' + W 4 + W 5 + W key + W add

=

=

268.49896 kN

B1 = 0.30

Wadd

F = 0.00

Bc = 0.43

WL

GL

W2'

W5

3.15

W1

H1 = 5.25

W2

W1'

H2 = 1.60

W4

D1 = 1.60

B = 0.50

A

Bh = 2.70

Bt = 0.60

Wb = 0.50

W3

Dsh = 2.70

Wkey

Dst = 0.60

Hs = 0.20

Bs = 0.50

Restoring moment ( Mr )

= W 1*(Bt+(B-B1)+ B1/2) + W 2*Bt/2 + W 3*(Bh+B+Bt)/2 + W add*(Bt+(B-B1)+ B1/2) + W key*(Dst+Bs/2)

W 4*(Bt+B+Bh/2) + W 5*(Bt+B+Bh/2) + W 1' *(Bt+(B-B1)*(2/3)) + W 2' *( Bt+(B-Bc)/3)

=

512.66

kNm/m

F.O.S

Check Against Sliding :

Shear at base, ( Vb )

=

=

Mr / Mo

2.829

>

1.75

=

=

Vp - Vw - Vl - Va - Vadd

Total weight of liquid,wall and soil ( W )

Coeff of friction between soil and

concrete, ( )

Restoring force

=

=

=

=

=

268.499 kN

tan(2/3)

0.390337

*W

104.805 kN

F.O.S

=

=

Restoring force / Shear at base

1.798

>

1.75

Calculation Of Base Pressure :

Total width of base ( L )

Width of base slab ( B )

Base area ( A )

=

=

=

=

OK

-58.297 kN

3.8

1

BL

3.8

m

m

m2

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of RCC Bund Wall For

Wet Crude Tank 21-TK-001.

Section modulas of base slab ( Z )

W

Mr

=

=

=

B L2 / 6

2.406667 m3

268.499 kN

512.6575 kNm

Mo

=

=

-181.24

kNm

( Mr - Mo ) / W

1.235

=

=

x

-0.665

=

=

Wxe

-178.55

Pressure

P1

W /A

-3.53

KN/m

P2

144.85

KN/m2

Eccentricity ( e )

Moment due to eccentricity ( Me )

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Dipak

Checkd. By : GK

L/2

>

0.63

(L/6)

NOT OK

0

162.8

Tension

OK

kNm

Me / Z

<

<

PRESSURE DIAGRAM

Down pressures :

Tank side pressure

( Earth+liquid+ Base Slab)

=

=

Other side pressure

( Earth + Base Slab )

=

=

(xD1) + (cxW b) + (wx(H1-D1-W b-F))

68.43 KN/m2

(xH2) + (cxW b)

40.80

KN/m2

1.235

1.9

Base Pressure :

P1

1.9

2.70

0.50

-3.53

101.90

0.60

121.42

P2

144.85

Downward Pressure :

68.43

40.80

Effective Depth d

Tank farm side :

a ) Shear force at wall face

0.415

68.43 x

-3.53 x

51.96

=

b ) Shear at d distance from

the wall face

68.43 x

-3.53 x

2.70

2.70

105.43 x

2.70 /2

2.285

2.285

89.22 x

2.285 /2

kN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of RCC Bund Wall For

Wet Crude Tank 21-TK-001.

i.e. = 2.70 - 0.415 = 2.285

62.49

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Dipak

Checkd. By : GK

kN

c ) Shear at 1.5d distance

=

from the wall face

i.e. = 2.70 - ( 1.5 x 0.415 ) = 2.078

=

68.43 x

-3.53 x

d ) BM

68.43 x

2.70 x

-3.53 x

2.70 x

105.43 x

2.70 x

134.19 kNm

2.70 /2

2.70 /2

2.70 /6

121.42 x

0.60

23.43 x

0.60 /2

55.40 kN

+

-

137.62 x

0.185

7.22 x

0.185 /2

18.58 kN

+

-

145.73 x

-0.023

-0.88 x

-0.023 /2

-2.35

kN

+

-

=

Earth side :

a ) Shear force at wall face

=

=

b ) Shear at d distance from

the wall face

i.e. = 0.60 - 0.415 = 0.185

c ) Shear at 1.5d distance

from the wall face

i.e. = 0.60 - ( 1.5 x 0.415 )

= -0.022

d ) BM

=

=

=

Design BM & Shear For Base Slab For Case2 :

BM at face of wall, ( Mf2 )

65.24

2.078

2.078

81.12 x

2.078 /2

kN

121.42 x

0.60 x

23.43 x

0.60 x

40.80 x

0.60 x

17.32 kNm

40.80 x

40.80 x

40.80 x

0.60 /2

0.60 /3

0.60 /2

134.19

kNm

Shear at wall face, ( Vf21)

55.40

kN

Shear at d dist. from wall face ( V f22)

62.49

kN

Shear at 1.5d dist. from wall face ( V f23)

65.24

kN

0.60

0.185

-0.023

+

-

Shear & BM for Shear Key For Case 2 :

Shear key has been analyzed for the passive pressure, as it is the pressure which comes in action

and bends shear key when retaining wall is subjected to active pressure.

Shear for shear key at the face of base

slab ( Vs2 )

Moment for shear key at the face of

base slab ( Ms2 )

( 1/2 x 81.98 x 0.20 x 0.20 )

+ ( 1/3 x 7.81 x 0.20 x 0.20 )

1.74

kNm

( 81.98 x 0.20 ) + ( 1/2 x 7.81 x 0.20 )

17.18

kN

81.98

2300

A

200

Pp = 89.78

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

Sign Convention :

Clockwise Moment

Anti clockwie Moment

-Ve

+Ve

Horizontal left to right direction

Horizontal right to left direction

-Ve

+Ve

6.3 Rebar Calculation For Base Slab :

Max Design BM & Shear From Case 1 & Case 2 :

BM at face of wall, ( Mf )

134.19

kNm

Max Of ( Mf1,Mf2 )

Shear at wall face, ( Vf1 )

55.40

kN

Max Of ( Vf11,Vf21 )

Shear at d dist. from wall face ( Vf2)

62.49

kN

Max Of ( Vf12,Vf22 )

Shear at 1.5d dist. from wall face ( Vf3)

65.24

kN

Max Of ( Vf13,Vf23 )

Design factored bending

moment ( Mu )

1.4 * ( Mf )

Effective depth ( d )

=

=

187.87 kNm

1.4, as per BS:8110-Part I )

( W b * 1000 ) - (dbase/2) - c

415

( Load factor for soil pressure is

mm

Now as per clause 3.4.4.4 of BS 8110 ( Part - I )

k

=

=

=

Mu / fcu bd2

30

0.036

187.87

x 1000

<

x 106

x 415

0.156

=

=

=

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

415 x [ 0.5 + sqrt( 0.25 397.50 mm

&

=

=

0.95 x d

394.25

Take z

=

=

Minimum of above two values

394.25 mm

Required Ast1

=

=

M / [0.95*fy*z]

=

=

=

0.13 % of Area of concrete

0.13

x 1000

x 500

650

mm2/m

Minimum reinforcement :

As per table 3.25 of BS : 8110 ( Part - I )

Min rebar for flexure tension Ast2

x 415

0.036

mm

1211.60 mm2/m

/ 100

As per table 3.25 of BS : 8110 ( Part - I ) clause 3.9.4.19

Min rebar for crack control Ast3

=

0.25 % of Area of concrete

=

=

=

From the above required Astreq1

0.25

1250

625

x 1000

mm2

mm2

1211.60 mm2/m

Required 20 mm bar at a spacing of 259 mm c/c

Provide 20 mm bar at a spacing of

150

mm c/c

x 500

/ 100

on both face

on each face

Max of Ast1, Ast2 & Ast3

/0.9)]

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

Area of steel provided Astprov1

=

2093

mm2

pt provided

0.42 %

6.4 Distribution Steel For Base Slab:

Provide Min Reinforcement As Dist. Steel, As per table 3.25 of BS : 8110 ( Part - I )

Distribution steel, Adist

=

0.13 % of Area of concrete

=

=

Dia of distribution rebar

Provide 12 mm bar at a spacing of

Area of steel provided Astprov1

0.13

650

=

150

12

mm c/c

754

=

=

1.4 * ( Vf1 )

x 1000

mm2/m

x 500

/ 100

mm

mm2

6.5 Check For Shear For Base Slab:

Shear V at face of the support ( Vu1 )

77.56 kN

1.4 * ( Vf2 )

Shear V at d distance from the

support ( Vu2 )

Shear V at 1.5d distance from the

support ( Vu3 )

=

=

91.34

Shear stress at face of support, ( v1 )

=

=

=

Vu1/bd

Maximum allowed shear stress

( vmax ) = Max( 0.8fck , 5 )

87.48 kN

1.4 * ( Vf3 )

0.19

4.382

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

( Load factor for soil pressure is

kN

N/mm

N/mm2

1.4, as per BS:8110-Part I )

or

5 N/mm2

v1 < vmax, O.K. (Clause 3.7.7.2)

Actual shear stress at d dist.

from support ( v2 )

Vu2/bd

=

=

0.21

Vu3/bd

N/mm

Actual shear stress at 1.5d dist.

from support ( v3 )

0.22

N/mm

100Ast / bd

0.504

From BS 8110 Part 1 Table 3.8 ( vc )

Revise value of ( vc )

=

=

0.510 N/mm

vc*( fcu /25 )1/3

For fcu = 25 N/mm2

For fcu = 30 N/mm2

0.542 N/mm

Since vc > v1, v2 & v3, Hence section is SAFE in shear

6.6 Rebar Calculation For Shear Key :

Max Design BM & Shear From Case 1 & Case 2 :

BM at face of wall, ( Ms )

=

2.62

kNm

Max Of ( Ms1,Ms2 )

Shear at wall face, ( Vs )

25.76

kN

Max Of ( Vs1,Vs2 )

Design factored bending

moment ( Mu )

1.4 * ( Ms )

Effective depth ( d )

=

=

3.66

kN

( Bs * 1000 ) - (dwall/2) - c

415

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

mm

Now as per clause 3.4.4.4 of BS 8110 ( Part - I )

k

=

=

Mu / fcu bd2

30

3.66

x 1000

x 106

x 415

x 415

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

=

0.001

<

0.156

z

=

=

=

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

415 x [ 0.5 + sqrt( 0.25 414.67 mm

&

=

=

0.95 x d

394.25

Take z

=

=

Minimum of above two values

394.25 mm

Required Ast1

=

=

M / [0.95*fy*z]

=

=

=

0.13 % of Area of concrete

0.13

x 1000

x 500

mm2

650

As per table 3.25 of BS : 8110 ( Part - I )

Min rebar for flexure tension Ast2

23.61

0.001

/0.9)]

mm

mm2/m

/ 100

As per table 3.25 of BS : 8110 ( Part - I ) clause 3.9.4.19

Min reinforcement for crack control Ast3

=

0.25 % of Area of concrete

From the above required Astreq1

=

=

=

0.25

1250

625

650.00

Required 20 mm bar at a spacing of 483 mm c/c

Provide 20 mm bar at a spacing of

150

mm c/c

Area of steel provided Astprov1

=

2093

pt provided

=

0.42 %

x 1000

mm2

mm2

x 500

/ 100

on both face

on each face

mm2

Max of Ast1, Ast2 & Ast3

mm2

6.7 Distribution Steel For Base Slab:

Provide Min Reinforcement As Dist. Steel, As per table 3.25 of BS : 8110 ( Part - I )

Distribution steel, Adist

=

0.13 % of Area of concrete

=

=

Dia of distribution rebar

Provide 16 mm bar at a spacing of

Area of steel provided Astprov1

=

250

0.13

650

16

mm c/c

804

=

=

1.4 * ( Vs )

=

=

=

Vu/bd

x 1000

mm2/m

x 500

/ 100

mm

mm2

6.8 Check For Shear For Base Slab:

Shear V at face of the support ( Vu )

Shear stress at face of support, ( v )

Maximum allowed shear stress

( vmax ) = Max( 0.8fck , 5 )

36.07

0.09

4.382

kN

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

N/mm

N/mm2

or

&

5 N/mm2

v < vmax, O.K. (Clause 3.7.7.2)

100Ast / bd

From BS 8110 Part 1 Table 3.8 ( vc )

Revise value of ( vc )

0.504

0.35

N/mm

vc*( fcu /25 )1/3

For fcu = 25 N/mm2

For fcu = 30 N/mm2

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

: JI-180-000-ECV-CAL-050

Subject : Design of RCC Bund Wall For

Rev No

: 0

Wet Crude Tank 21-TK-001.

Prep. By : Dipak

Checkd. By : GK

=

0.372 N/mm

Since vc > v, Hence section is SAFE in shear

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : Design of RCC Bund Wall For

Wet Crude Tank 21-TK-001.

Doc No

:

Rev No

:

Prep. By :

Checkd. By :

Appendix - I

EL 103.65

300

EL 103.7

EL 100.5

Tank Side

Earth Side

4750

1600

EL 100.50

1600

2700

500

600

2700

500

600

500

200

Sectional Elevation Of Wall

** All Dimensions Are In MM

( GA Detail Only )

Tank Side

Earth Side

Y16 @ 250 mmc/c

Y20 @ 150 mmc/c

Y12 @ 150 mmc/c

Y20 @ 150 mmc/c

Sectional Elevation Of Wall

( RC Detail Only )

JI-180-000-ECV-CAL-050

0

Dipak

GK

Vous aimerez peut-être aussi

- RCC Bund Wall Without Shear KeyDocument21 pagesRCC Bund Wall Without Shear Keynhulugalla100% (1)

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyPas encore d'évaluation

- For Detail of Section TB 0 332 316 004Document43 pagesFor Detail of Section TB 0 332 316 004MUKESH KUMARPas encore d'évaluation

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - Columnsfeiz asgarPas encore d'évaluation

- 11 CulvertDesign v22Document2 pages11 CulvertDesign v22Lee See VoonPas encore d'évaluation

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443Pas encore d'évaluation

- Cable Trench Design Calculation for 50 MW Solar PlantDocument4 pagesCable Trench Design Calculation for 50 MW Solar PlantAmol ChavanPas encore d'évaluation

- Burnt Oil Pit-R1Document6 pagesBurnt Oil Pit-R1Irshad KhanPas encore d'évaluation

- 9m Pole CalculationDocument6 pages9m Pole CalculationPankaj SherwalPas encore d'évaluation

- Pedestal DesignDocument2 pagesPedestal DesignRamadanPas encore d'évaluation

- FOUNDATION Blow Down Tank Design CalculationsDocument30 pagesFOUNDATION Blow Down Tank Design CalculationsvasudhaPas encore d'évaluation

- Block Partition Wall DesignDocument4 pagesBlock Partition Wall DesigntkofaiPas encore d'évaluation

- SS-5 SUBSTATION FLOOR SLAB DESIGN CHECKDocument7 pagesSS-5 SUBSTATION FLOOR SLAB DESIGN CHECKAsaru DeenPas encore d'évaluation

- Load Combination For Steel Design Per BS en 1990 EditionDocument2 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru Deen100% (1)

- Insert Plate DesignDocument24 pagesInsert Plate Designabhi arote100% (1)

- 071-CG-01 Stair Case Design Report For AveryDocument16 pages071-CG-01 Stair Case Design Report For AveryK Divakara RaoPas encore d'évaluation

- 15-Loads Calculation For Lattice Steel StructuresDocument29 pages15-Loads Calculation For Lattice Steel StructuresOmar SalahPas encore d'évaluation

- DesignDocument25 pagesDesignMelchorRdzPas encore d'évaluation

- Trench DesignDocument8 pagesTrench Designprasadnn2001Pas encore d'évaluation

- Cable Trench MainDocument17 pagesCable Trench MainAchin Achena100% (6)

- Design of The PoleDocument7 pagesDesign of The Polevirous08Pas encore d'évaluation

- 1 Design Basis 1.1 Material and Properties 1.1 Material and PropertiesDocument40 pages1 Design Basis 1.1 Material and Properties 1.1 Material and PropertiesDarshan PanchalPas encore d'évaluation

- Pile DesignDocument9 pagesPile DesignAmit Kumar PaulPas encore d'évaluation

- Foundation Notes:-: G.A. Drawing For 9 Mtrs. Octagonal Pole With 1M Double ArmDocument1 pageFoundation Notes:-: G.A. Drawing For 9 Mtrs. Octagonal Pole With 1M Double ArmP.Manna100% (1)

- Vent Stack Foundation CalDocument11 pagesVent Stack Foundation CalBenedict OgbaghaPas encore d'évaluation

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyPas encore d'évaluation

- Cable Trench Desiign Report 26.04.2020 PDFDocument50 pagesCable Trench Desiign Report 26.04.2020 PDFkkgcPas encore d'évaluation

- 1.60m Deep-35m Tower Foundation Design 9nov 2019-11.14Document3 pages1.60m Deep-35m Tower Foundation Design 9nov 2019-11.14Harold Jackson MtyanaPas encore d'évaluation

- 420 Transformer FDN For Panjarpur-6.0mtr26.5.06Document21 pages420 Transformer FDN For Panjarpur-6.0mtr26.5.06Zulkifli BasriPas encore d'évaluation

- Control Building Static Calculations: Design of Roof Beam 02 CalculationDocument21 pagesControl Building Static Calculations: Design of Roof Beam 02 Calculationisaacjoe77Pas encore d'évaluation

- Project No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved byDocument9 pagesProject No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved bysaravananPas encore d'évaluation

- Car ShelterDocument29 pagesCar ShelterMochammad Shokeh100% (1)

- Design KN/M.: 388 RelnforcedDocument6 pagesDesign KN/M.: 388 RelnforcedSubhajyoti DasPas encore d'évaluation

- Box Culvert Design Calculation 222Document9 pagesBox Culvert Design Calculation 222mal_sri6798Pas encore d'évaluation

- Design calculation for a burnt oil pitDocument5 pagesDesign calculation for a burnt oil pitIrshad KhanPas encore d'évaluation

- Design of Light Pole FoundationDocument2 pagesDesign of Light Pole Foundationabhinav100% (2)

- 2.0 Crack Width CheckDocument8 pages2.0 Crack Width CheckMoses LugtuPas encore d'évaluation

- Pile Foundation DesignDocument3 pagesPile Foundation Designamol100% (2)

- 2 PDFDocument1 page2 PDFSujit RasailyPas encore d'évaluation

- Project: Client: Made by Date Location: Subject: Checked Revision Job NoDocument2 pagesProject: Client: Made by Date Location: Subject: Checked Revision Job NothaoPas encore d'évaluation

- Calculation Sheet For Gantry CPF & Cluster Rev.0 (8015-0151-82-Po-45-0009-9784-S03-12054)Document36 pagesCalculation Sheet For Gantry CPF & Cluster Rev.0 (8015-0151-82-Po-45-0009-9784-S03-12054)tanujaayerPas encore d'évaluation

- ReportTank 12.0m DiaDocument17 pagesReportTank 12.0m DiasuheilbugsPas encore d'évaluation

- Design Doc. - Rt. WallDocument16 pagesDesign Doc. - Rt. WallAnindit MajumderPas encore d'évaluation

- Car Parking Shade Design ReportDocument28 pagesCar Parking Shade Design Reportsiso hegoPas encore d'évaluation

- Reference CalcDocument15 pagesReference CalcPoulomi BiswasPas encore d'évaluation

- Compressor Shelter: Velocity of PressureDocument3 pagesCompressor Shelter: Velocity of PressurerohitnrgPas encore d'évaluation

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Document22 pagesFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXPas encore d'évaluation

- Fire Pipe Trench-Doc TemplateDocument63 pagesFire Pipe Trench-Doc TemplateSivaAgathamudiPas encore d'évaluation

- Design Report - Pipe Support - R2 PDFDocument10 pagesDesign Report - Pipe Support - R2 PDFAkhilesh KajarekarPas encore d'évaluation

- Sample 10715Document16 pagesSample 10715remya.uPas encore d'évaluation

- DGS 1482-004 REV 2 - Geotechnical InvestigationDocument13 pagesDGS 1482-004 REV 2 - Geotechnical InvestigationcarloPas encore d'évaluation

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box Culvertrupesh417Pas encore d'évaluation

- 9m Pole FDN Design 18.2.2015Document2 pages9m Pole FDN Design 18.2.2015faizankhan23Pas encore d'évaluation

- Monorail Design Lateral LoadDocument46 pagesMonorail Design Lateral Loadshangz1511Pas encore d'évaluation

- Test Tank TK 1527 Equal DepthDocument20 pagesTest Tank TK 1527 Equal DepthnhulugallaPas encore d'évaluation

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comPas encore d'évaluation

- Transformer Foundation Along With Blast WallDocument11 pagesTransformer Foundation Along With Blast Wallkrmurali2000Pas encore d'évaluation

- 230kV Equipment FoundationDocument4 pages230kV Equipment FoundationMian M Khurram100% (1)

- Chequered PlateDocument23 pagesChequered Platesaravanan428680% (10)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

- Test Tank TK 1527 Equal DepthDocument20 pagesTest Tank TK 1527 Equal DepthnhulugallaPas encore d'évaluation

- Blast CalculationDocument35 pagesBlast CalculationnhulugallaPas encore d'évaluation

- Slab DesignDocument7 pagesSlab Designnhulugalla0% (1)

- Change VPN fix line numbers request letterDocument1 pageChange VPN fix line numbers request letternhulugallaPas encore d'évaluation

- Effective Length For Moment FrameDocument5 pagesEffective Length For Moment FramenhulugallaPas encore d'évaluation

- Anchor BlockDocument12 pagesAnchor BlocknhulugallaPas encore d'évaluation

- Crack Width BS 8110Document2 pagesCrack Width BS 8110nhulugallaPas encore d'évaluation

- STABILITY CHECK FOR BLOCK PEDESTAL CAPACITYDocument5 pagesSTABILITY CHECK FOR BLOCK PEDESTAL CAPACITYnhulugallaPas encore d'évaluation

- Beam DesignDocument7 pagesBeam DesignAlexs DiazPas encore d'évaluation

- Change VPN fix line numbers request letterDocument1 pageChange VPN fix line numbers request letternhulugallaPas encore d'évaluation

- Design of Shear KeyDocument13 pagesDesign of Shear Keynhulugalla100% (1)

- AutoDesk AutoCad 2008 3D TutorialDocument3 pagesAutoDesk AutoCad 2008 3D TutorialAries LukmawantoPas encore d'évaluation

- Salaries and Tax DEMODocument6 pagesSalaries and Tax DEMOnhulugallaPas encore d'évaluation

- Design Forces Applied To Beams: Table For Beam To Column Moment Connection (Type - MC)Document7 pagesDesign Forces Applied To Beams: Table For Beam To Column Moment Connection (Type - MC)nhulugallaPas encore d'évaluation

- Ji 187a Sa3 20 Ecv Cal 005 - SSDocument17 pagesJi 187a Sa3 20 Ecv Cal 005 - SSnhulugallaPas encore d'évaluation

- Design of Water Tanks-CE 05014 p3 6Document65 pagesDesign of Water Tanks-CE 05014 p3 6engineerkranthi4055100% (1)

- ACI Mix DesignDocument9 pagesACI Mix DesignAbdul Hamid BhattiPas encore d'évaluation

- Wet Dry Tank TN 021Document20 pagesWet Dry Tank TN 021nhulugallaPas encore d'évaluation

- Various Test On WorkabilityDocument93 pagesVarious Test On WorkabilityParul SinghPas encore d'évaluation

- Belajar Menggambar 3d Dengan Autocad 2007Document200 pagesBelajar Menggambar 3d Dengan Autocad 2007Iswant MacanPas encore d'évaluation

- Steel Design Vol 3 - EL-Sayed Bahaa MachalyDocument474 pagesSteel Design Vol 3 - EL-Sayed Bahaa Machalynhulugalla100% (3)

- Etabs TutorialDocument103 pagesEtabs TutorialGlenn Rey DomingoPas encore d'évaluation

- Test Tank TK 1527 Equal DepthDocument20 pagesTest Tank TK 1527 Equal DepthnhulugallaPas encore d'évaluation

- Design of Piled Raft Foundations For Tall BuildingsDocument7 pagesDesign of Piled Raft Foundations For Tall BuildingsnhulugallaPas encore d'évaluation

- 09 - (4th Civil) (Tanks) Circular TanksDocument97 pages09 - (4th Civil) (Tanks) Circular TanksSovich82100% (1)

- BlastDocument32 pagesBlastnhulugallaPas encore d'évaluation

- Beam Design in PR Braced Steel FramesDocument26 pagesBeam Design in PR Braced Steel FramesWaqar AhmedPas encore d'évaluation

- Pile Foundation DesignDocument82 pagesPile Foundation Designcuongnguyen89% (28)

- 3 Hours / 70 Marks: Seat NoDocument5 pages3 Hours / 70 Marks: Seat NoMadao111Pas encore d'évaluation

- Concreto Pretensado-NAWY - Cap 7 PDFDocument82 pagesConcreto Pretensado-NAWY - Cap 7 PDFCarlos Alberto Pacheco SierraPas encore d'évaluation

- Lecture - 37: Case Studies On Retrofitting and RehabilitationDocument38 pagesLecture - 37: Case Studies On Retrofitting and Rehabilitationu10ce073Pas encore d'évaluation

- Tutorial - 1-Design For Static and Fatigue StrengthDocument5 pagesTutorial - 1-Design For Static and Fatigue StrengthSouradeepBhattacharya50% (2)

- Peng2019 PDFDocument7 pagesPeng2019 PDFRoja AllampallyPas encore d'évaluation

- Jmert SPD d117Document8 pagesJmert SPD d117Atul SaxenaPas encore d'évaluation

- Penetration Tests: SPT, CPT and PLTDocument25 pagesPenetration Tests: SPT, CPT and PLTJigar MokaniPas encore d'évaluation

- Chapter 1 IntroductionDocument12 pagesChapter 1 IntroductionephPas encore d'évaluation

- ASMEThermal Shock Design Guidleines 2007Document9 pagesASMEThermal Shock Design Guidleines 2007Harold Edmundo Calvache VallejoPas encore d'évaluation

- Purlin section design beam displacement analysisDocument7 pagesPurlin section design beam displacement analysisIjaz AhmedPas encore d'évaluation

- Stone Column Design and Construction TechniquesDocument210 pagesStone Column Design and Construction TechniquesGeorge Christodoulidis100% (2)

- Soil Modulus and Undrained Cohesion of Clayey Soils From Stress-Strain ModelsDocument10 pagesSoil Modulus and Undrained Cohesion of Clayey Soils From Stress-Strain ModelsTerry CheungPas encore d'évaluation

- Permeability - 4 MtechDocument70 pagesPermeability - 4 MtechViky ShahPas encore d'évaluation

- Determining Stress Intensity Factors Analytically and NumericallyDocument50 pagesDetermining Stress Intensity Factors Analytically and NumericallyAdnen Laamouri100% (1)

- Excavacion PDFDocument25 pagesExcavacion PDFLuis Alejandro Godoy OrdenesPas encore d'évaluation

- CEG605.1 Advanced Soil Mechanics THDocument2 pagesCEG605.1 Advanced Soil Mechanics THameykatdarePas encore d'évaluation

- Lecture 2 Nature of Earthquake Ground MotionDocument28 pagesLecture 2 Nature of Earthquake Ground MotionJomar LampitokPas encore d'évaluation

- Civil Engineering SyllabusDocument172 pagesCivil Engineering SyllabusGeorgy XavierPas encore d'évaluation

- Leis2004 Hydrotest PDFDocument12 pagesLeis2004 Hydrotest PDFFebri SSPas encore d'évaluation

- Beams Reinforced For TensionDocument13 pagesBeams Reinforced For TensionChristian ActerPas encore d'évaluation

- Deep BeamDocument6 pagesDeep BeamHenra HalimPas encore d'évaluation

- Perhitungan Volume Semen Untuk PaperDocument3 pagesPerhitungan Volume Semen Untuk PaperSkolastikaPradiptaPas encore d'évaluation

- Diseño de Columnas de Concreto Basado en ACI 318-14Document1 pageDiseño de Columnas de Concreto Basado en ACI 318-14zenon mitha huarachiPas encore d'évaluation

- Structural Design of TimberDocument6 pagesStructural Design of Timberlewis kalataPas encore d'évaluation

- ACEE0232 - Poovarodom - A New Earthquake Resistant Design Standard For Buildings in ThailandDocument6 pagesACEE0232 - Poovarodom - A New Earthquake Resistant Design Standard For Buildings in ThailandVignesh T ShekarPas encore d'évaluation

- Getahun AsresDocument108 pagesGetahun AsresnasrPas encore d'évaluation

- Waves in Three-Dimensional Solid: A ElasticDocument22 pagesWaves in Three-Dimensional Solid: A ElasticaguiiahimPas encore d'évaluation

- AIJ Proposal (ACI SP123)Document19 pagesAIJ Proposal (ACI SP123)hbookPas encore d'évaluation

- 2 LaminarFlowPipes&Annuli NewtonianDocument24 pages2 LaminarFlowPipes&Annuli NewtoniankelrzPas encore d'évaluation

- Seismic Design Guide For Masonry BuildinsDocument68 pagesSeismic Design Guide For Masonry BuildinsleekyPas encore d'évaluation