Académique Documents

Professionnel Documents

Culture Documents

1l Datasheets Editable

Transféré par

ghostamirTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1l Datasheets Editable

Transféré par

ghostamirDroits d'auteur :

Formats disponibles

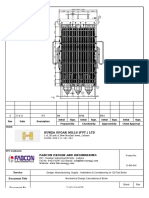

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

SCHEDULE - B

TECHNICAL PARTICULARS POWER PLANT EQUIPMENT

S. No.

Unit

DESCRIPTION

Value

1.0

STEAM

GENERATOR

AUXILIARIES

WITH

1.1

STEAM

FLOW

AT

SUPERHEATER OUTLET

FINAL

(kg/hr)

1.2

MAXIMUM

CONTINUOUS

GENERATION

AT

VWO

CONDITIONS

WITH

OFFERED

STEAM

PARAMETERS

AT

SUPERHEATER OUTLET

(kg/hr)

1.3

SUPERHEATER DESPERHEATING

SPRAY WATER FLOW

Kg/hr

1.4 a)

AUXILIARY STEAM FLOW FOR

SOOT BLOWING, OIL BURNER

ATOMIZATION ETC.

Kg/hr

b)

STEAM FOR AUXILIARY STEAM

TAP OFF

(Pr./Temp)

1.5

THERMAL EFFICIENCY OF THE

STEAM GENERATING UNITS AT

MCR

a)

DESIGN COAL

b)

WORST COAL

FINAL

(%)

(kg/cm2g)

1.6

STEAM PRESSURE AT

SUPERHEATER OUTLET

1.7

STEAM TEMPERATURE AT FINAL

SUPERHEATER OUTLET

(C)

1.8

REHEATER OUTLET STEAM FLOW

(KG/HR)

1.9

STEAM

TEMPERATURE

REHEATER INLET HEADER

AT

(C)

1.10

STEAM

TEMPERATURE

REHEATER OUTLET HEADER

AT

(C)

1.11

STEAM PRESSURE AT REHEATER

INLET HEADER

(kg/cm2g)

1.12

STEAM PRESSURE AT REHEATER

OUTLET HEADER

(kg/cm2g)

100%

80%

60%

BMCR

TGMCR TGMCR

TGMCR

50%

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

1.13 a)

b)

Value

(kg/cm2)

Pressure drop across Reheater

(kg/cm2)

Pressure drop in economizer

1.14

Pressure drop across cold reheat &

hot reheat lines

(kg/cm2)

1.15 a)

Feed

water

Economiser inlet

(C)

b)

temperature

at

Feed water temp. of economizer

outlet

1.16

Flue Gas Temperature

a)

Furnace Unit

b)

Primary Superheater inlet / outlet

c)

Secondary superheaters inlet / outlet

d)

Reheater inlet / outlet

f)

Economizer inlet / outlet

g)

ESP inlet / outlet

h)

ID Fan Inlet / Outlet

i)

Stack Inlet

1.17

Pressure Drop : mmWC

a)

Primary air side total pressure drop

through the system

b)

Secondary air side total pressure

drop

c)

Flue gas pressure drop through the

system

1.18

Acid Dew Paint Temperature

a)

For Design Coal

b)

For worst coal

1.19

Steam Purity (ppm)

a)

Total dissolved solid

b)

Silica

c)

Sodium

d)

Chloride

1.20

Recommended time to bring boiler on

Full Load

a)

After cold start

(oC)

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

b)

After 24 hrs. shut down

c)

After 8 hrs. shut down

d)

Hot restart (Less than 1 hour after

shut down)

e)

Control Point of Boiler

1.21

Cooling Water Requirement for

Boilers & Auxiliaries

a)

Quantity

M3/hr

b)

Pressure

Kg/cm2(g)

c)

Temperature

1.22

Instrument air

Requirement

a)

Quantity

M3/min

b)

Pressure

Kg/cm2(g)

1.23

Heat liberated by fuel:

1.24

Service

air

a)

Max. net heat input per plan

area of surface

(kcal/m2/hr)

b)

Max.

release rate

(kcal/m2/hr)

burner

i.

Furnace

temperature

ii.

1.25

&

(% MCR)

zone

heat

exit

gas

(C)

Boiler Exit gas temperature

(C)

Weight of fuel fired:

a)

Performance coal

b)

Worst coal

1.26

Type of steam generator:

1.27

Type of firing

1.28

Total auxiliary power consumption

a)

ID Fans

b)

FD Fans

c)

PA Fans

d)

Pluverizers

e)

Seal air fans

f)

Coal Feeders

:

(MW)

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

g)

ESP

h)

Total auxiliary power consumption

1.29

Combustion chamber volume

(cum)

1.30

Furnace dimensions (Width x Depth x

Height)

(Metres)

1.31

Heat surface areas:

(Sq.M)

a)

Water walls

b)

Superheaters

c)

Reheaters

d)

Economisers

e)

Air heater

f)

Steam coil air heater

g)

Temperature easurement

(Yes/No.)

for SH Tubes

h)

Temperature measuring for

RH Tubes

1.32

(Yes/No.)

Boiler drum:

a)

Elevation

b)

Overall dimensions

c)

Material

d)

Diameter / thickness

e)

Details of drum

temperature provision

metal

f)

Temperature

difference

across the drum metal thickness.

g)

Maximum

pressure

Kg/cm2

operating

h)

Design pressure

Hr/cm2

i)

Design Temperature

j)

Water capacity at MCR

between normal and lowest water

level

1.33

Number of Attemperators:

a)

Superheated steam

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

b)

1.34

Reheat steam

a)

Number

heaters

b)

heater

Value

&

Emergency

:

type

of

air

drive

for

air

1.35

Max. air leakage through air heater

1.36

Draft Plant

Forced

Primary

Draft

Air fans

Fans

a)

Make; Quantity; Type

b)

BMCR

Volumetric flow rate at 100%

(Nm3/sec.)

c)

Total pressure

(mmwc)

d)

Margins included in

i)

flow rate

ii)

Total pressure

iii)

redundancy

1.37

(%)

(%)

Equipment

e)

Efficiency

f)

Motor rating

g)

Speed

h)

Motor type

i)

Lubrication System

j)

Critical speeds

(%)

(kw)

Rpm

Soot-blowers:

a)

Quantity, type, location

b)

Steam conditions (pressure

& temperature quality)

:

:

c)

Time required for one cycle

of operation

1.38

Pulverisers:

a)

Quantity, type, make

Induced

fans

draft

Seal air

fans

Scanner

air fans

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

(rpm)

b)

Speed

c)

Design capacity

d)

Motor rating

(tphr)

(kw)

e)

Number of operating mills

and standby mills when fired with

f)

i)

Worst coal

ii)

Performance coal

CO monitoring & Fire

Detection

Provided

1.39

b)

c)

d)

e)

1.41

1.41.1

g)

Coal Feeders :

h)

Type, Quality, make

i)

Type of Control

a)

Quantity, type, make

b)

Capacity each

c)

Turn Down Ratio

Number & diameter of flue for each

unit

Height of the stack

Number of stacks provided

Velocity of flue gas at top

Is SS venturi provided at top?

Regenerative Air Preheaters

Type

Yes/No

Stacks

a)

System

Burners

1.40

:

: (kg/hr)

Coal

Fuel oil

Light oil

(HFO/LSHS)

(LDO)

Ignitors

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

1.41.2

Number

1.41.3

Mounting (Vertical / Horizontal)

1.41.4

Maximum Handling Capacity

a)

b)

1.41.5

Nm3/hr

Flue gas

Air

Flue gas temperature at heaters

outlet

1.41.6

Recommended average cold end

temp. at 100% BMCR to minimize

corrosion

1.41.7

Total effective heating surface area

a)

b)

1.41.8

Gas Side

Air Side

Pressure drop at BMCR,

a)

b)

1.41.9

mmwc

Air side

Gas side

On Load Cleaning

a)

b)

1.41.10

Type of Blower

Pressure of steam jet

Off Load Cleaning

a)

b)

1.41.11

Value

Medium (water / air)

Pressure quantity

Air heater Fire Preventive measure

Details

1.42

MOTORS/

1.42.1

HT Motors

Type

_____

a)

Pulverizer

b)

FD fan

c)

ID fan

d)

PA fan

Motor rating

Qty./

(kW)

(RPM)

Speed

Boiler

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

1.42.2

LT MOTORS

a)

Regenerative air heater

i) Emergency DC motor

ii) Air Motor

b)

Seal air fan

Nos. of fan

Redundancy level

c)

Scanner air fan

Nos. of fan

Redundancy level

d) Igniter air fan

Nos. of fan

Redundancy level

e)

f)

g)

Gravimetric feeder drives:

i)

For main drives

ii)

For clean out conveyor

Long retractable soot blower:

i)

For traverse

ii)

For rotating

Wall blower:

i)

For traverse

ii)

For rotating

h)

Regenerative air heater sootblower

i)

Furnace

probe

temperature

j)

Regenerative air heater lube

pump for support bearings

k)

Regenerative air heater lube oil

pump for guide bearings

l)

LDO pump motor

m) HFO pump motor

n)

FD fan lube oil pump

o)

ID fan lube oil pump

p)

PA fan lube oil pump

q)

Gullitone gates blower

startup

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

r)

Mills

s)

Any other items to be listed

1.43

SOOT BLOWERS

1.43.1

Cleaning Medium

a)

Pressure

: Kg/cm2g

b)

Temperature

: deg.C

c)

Source of cleaning medium

1.43.2

Number of groups of soot blowers

1.43.3

Total operating time per group min

1.43.4

Blowers

1.43.5

a)

Type and make

b)

Number of soot blowers

c)

Operating pressure

: Kg/cm2g

d)

Steam consumption rate

: T/hr

b)

Lance/swivel tube in high /

intermediate / low temperature

area

Nozzles

c)

Feed tube

d)

Blowing head

e)

Chain

CBD

BLOW DOWN VESSELS

1.44.1

Design code followed

1.44.2

Operating conditions

1.44.3

Furnace

Reheater

Economiser

Materials of Construction

a)

1.44

Value

a)

Pressure

: Kg/cm2g

b)

Temperature

: deg.C

Design conditions

a)

Pressure

: Kg/cm2g

b)

Temperature

: deg.C

1.44.4

Hydraulic test pressure

: Kg/cm2g

1.44.5

Corrosion allowance

: mm

IBD

Superheater

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

1.44.6

Shell diameter

:M

1.44.7

Shell height

:M

1.44.8

Materials of Construction

a)

Shell and head

b)

Nozzle necks

1.45

THERMAL INSULATION

1.45.1

Type of insulating material(s)

1.45.2

1.45.3

Maximum temp (deg.C) the insulating

materials can withstand

Insulating materials standard

1.45.4

Density of insulating materials

1.45.5

Thermal

conductivity

temperature of

a) 50

1.45.6

at

: kg/m3

mean

: Kcal/M/ hr

deg.C

: deg.C

b)

100

: deg.C

c)

150

: deg.C

d)

200

: deg.C

e)

250

: deg.C

f)

300

: deg.C

g)

350

: deg.C

h)

400

: deg.C

Steam Generating Plant & Auxiliaries,

Insulation & Casing Details

<--------Block------->

Mineral

Pourabl

fibre

e

mattres

insulatio

s

n

---------(mm/

Qty)

1.45.6.1

1.45.6.2

Furnace extended side backpass walls

Enclosure

a. Roof

b.

i)

Horizontal

ii)

Vertical

Extended side

i)

Horizontal

---------(mm/

Qty)

Segme

nted

blocked

calcium

silicate

---------(mm/

Qty)

Cement

GI

sheet

jacket

Other

(specify

details)

---------(mm/

Qty)

---------(mm/

Qty)

---------(mm/

Qty)

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

ii)

c.

Vertical

Bottom

i)

Horizontal

ii)

Vertical

1.46

HP & LP

SYSTEM

1.46.1

Quantity

1.46.2

Type

1.46.3

Medium to be handled

1.46.4

Capacity

1.46.5

Discharge pressure

1.46.6

Stroke Adjustment Range

1.46.7

Stroke adjustment

1.46.8

Material of Construction

1.46.8.1

Liquid end

1.46.8.2

Plunger

1.46.8.3

Drive end

1.46.9

End Connection

1.47

PIPING,

VALVES

SPECIALITIES

FOR

PIPING

1.47.1

1.47.1.1

1.47.1.2

Value

CHEMICAL

DOSING

Phosphate

AND

CRITICAL

Pipes & Fittings

Basic codes and standards

-

design

testing and inspection

Indicate the following for each pipe

class

Design pressure

: Kg/cm2g

Design temperature

: deg.C

Design flow

: T/hr

Design velocity

: M/sec

Primary rating

: lbs

Material of construction for

Hydrazine

Ammonia

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

i)

Pipes

ii)

Fittings

Value

Pipe sizes, mm (outside dia x

thickness) and/or (Max inside dia x

min thickness)

Tolerance for dia x min. thickness

Hydrostatic test pressure, at shop &

after erection (for piping systems

under purview of IBR shall also be

indicated)

: Kg/cm2g

Minimum duration of hydrostatic test

: minute

Reference standard

examination

for

ultrasonic

Type of rust inhibiter given before

shipment

Valve specification code

1.47.2

Gate/Globe/Check/Stop

Valves

Check

For each type (construction, pressure

class & body/bonnet material wise) of

valve, indicate the following

1.47.2.1

Pressure class, lbs

1.47.2.2

Nominal size

1.47.2.3

Construction

1.47.2.4

a.

Bonnet/cover

b.

Disc

c.

Ends

d.

Seat

Materials

a.

Body & bonnet/cover

b.

Stem/hinge pin

c.

Disc and seat ring

1.47.2.5

Type and details of end connections

1.47.2.6

Hydrostatic tests

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

a.

Shell test pressure

: Kg/cm2g

b.

Seat test pressure

: Kg/cm2g

1.48

STEAM PURITY

1.48.1

Total dissolved solids

1.48.2

Silica

1.48.3

Sodium

1.48.4

Chlorides

1.48.5

Copper

1.48.6

Iron

: ppm

2.0

ELECTROSTATIC PRECIPITATORS

:

A)

TYPE; MAKE

B)

COLLECTING ELECTRODES

MATERIAL, TYPE

C)

DISCHARGE ELECTRODES

MATERIAL, TYPE

D)

PRESSURE DROP ACROSS

ESP

E)

TEMPERATURE

ACROSS ESP

F)

QUANTITY, TYPE, RATING OF

TRANSFORMER RECTIFIER

UNITS

:

DROP

: (mg/Nm3)

G)

PARTICULATE

EMISSION

WITH WORST COAL FIRING

WITH

ALL

FIELDS

IN

SERVICE

:

H) PARTICULATE EMISSION WITH

DESIGN COAL FIRING WITH

ALL FIELDS IN SERVICE

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

J)

Value

PARTICULATE

EMISSION

WITH

DESIGN

COAL

FIRMING WITH ONE FIELD

OUT OF SERVICE

: (Nos.)

J)

ESP STREAMS PER BOILER

(m2/m3/sec)

K)

SPECIFIC COLLECTION AREA

L)

MIN. GAS TEMP. AT ESP

INLET

M)

MAX. FLUE GAS VELOCITY

N)

STORAGE CAPACITY

EACH HOPPER

O)

HOPPER VALLEY ANGLE

P)

MINIMUM

&

COLLECTOR

SPACING

M/s

Hr.

OF

MAXIMUM

PLATE

2.1

: (%)

COLLECTION EFFICIENCY

:

A)

ALL FIELDS IN SERVICE

B)

ONE FIELD OUT OF SERVICE

IN EACH ESP

C)

2-FIELDS OUT OF SERVICE

IN EACH ESP

:

D)

1

STREAM

OUT

OF

SERVICE;

AND

THE

OTHER

STREAM CARRYING 70% MCR

LOAD

Design coal

Worst coal

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

M3/s

E)

FLUE GAS FLOW

2.2

SCHEDULE OF WEIGHTS:

:

A)

STRUCTURAL STEEL

B)

PRESSURE PARTS

C)

MILLING PLANT

D)

DRAFT PLANT

E)

PIPEWORK

F)

DUCTING

G)

ESP

H)

ANY OTHER ITEMS

3.0

TURBINE

GENERATOR

AUXILIARIES

WITH

3.1

STEAM TURBINE

3.1.1

MAKE / TYPE

3.1.2

TYPE OF GOVERNING

3.1.3

(rpm)

SPEED

3.1.4

MW

RATED OUTPUT

3.1.5

MW

MAXIMUM CAPACITY

Kg/cm2(g)

3.1.6

STEAM PRESSURE BEFORE ESV

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

o

3.1.7

STEAM TEMP. BEFORE ESV

Kg/cm2(g)

3.1.8

LP EXHAUST PRESSURE WITH

DESIGN COOLING WATER INLET

TEMP.

3.1.9

HP TURBINE

a)

NO. OF STAGES

b)

NO. OF IMPULSE & REACTION

STAGES

3.1.10

I.P. TURBINE

a)

NO. OF STAGES

b)

NO. OF IMPULSE / REACTION

STAGES

3.1.11

L.P. TURBINE

a)

NO. OF STAGES

b)

:

NO. OF IMPULSE / REACTION

STAGES

3.2

LUBRICATING & GOVERNING OIL

SYSTEM

3.2.1

SHAFT DRIVEN OIL PUMP

a)

TYPE

b)

lit / minute

CAPACITY

kg/cm2(g)

c)

DISCHARGE PRESSURE,

d)

POWER CONSUMPTION

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

3.2.2

FULL CAPACITY AUXILIARY OIL

PUMP (AC MOTOR DRIVEN)

a)

TYPE

b)

Lit/min/

CAPACITY

Kg/cm2(g)

c)

DISCHARGE PRESSURE

d)

RPM

PUMP SPEED,

e)

KW

MOTOR RATING,

3.2.3

EMERGENCY OIL PUMP (DC Motor

Driven)

a)

TYPE

b)

Lit/m

CAPACITY

Kg/m2

c)

DISCHARGE PRESSURE

d)

RPM

PUMP SPEED

e)

KW

MOTOR RATING

3.2.4

:

JACKING OIL PUMP

a)

:

TYPE / NO.

Kg/cm2

b)

DELIVERY PRESSURE

c)

CAPACITY

d)

PUMP SPEED

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

e)

MOTOR RATING

3.2.5

TURNING GEAR

a)

TYPE OF DRIVE

b)

Rpm

TURNING GEAR SPEED

c)

HAND

BARRING

PROVIDED

FACILITY

3.3

CONDENSER:

:

A)

TYPE,

PASSES

NUMBER

OF

Kcal/hr

DESIGN HEAT LOAD AT VWO, 3%

MU)

Ata

C)

DESIGN BACK PRESSURE

D)

COOLING WATER FLOW

E)

COOLING SURFACE

: (cum/hr)

: (Sq.M)

F)

TUBE

DIA,

NUMBER,

THICKNESS & MATERIAL:

:

I)

CONDENSING SECTION

II)

AIR COOLER SECTION

G)

CLEANLINESS FACTOR

:

H)

CONDENSER WATER SIDE

PRESSURE DROP

:

I)

PERCENTAGE

PLUGGING MARGIN

OF

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

:

J)

CONDENSER

TUBE

(OUTSIDE DIA X THICKNESS)

:

K)

WATER

THROUGH TUBES

VELOCITY

:

L)

CW SIDE PRESSURE

:

M)

DESIGN

TEMPERATURE

CW

:

N)

WATER

PRESSURE

BOX

DESIGN

:

- VACUUM

:

O)

WATER

TEMPERATURE

BOX

DESIGN

TEMPERATURE RISE ACROSS THE

CONDENSER

(LxWxH)

Q)

OVERALL

CONDENSER

SIZE

OF

3.4

AIR

EXTRACTION

(VACUUM PUMP)

SYSTEM

a)

NUMBER

Nm3/hr

b)

MAXIMUM QUANTITY OF DRY AIR

EXTRACTED

c)

Min.

LIME REQUIRED

INITIAL VACUUM

TO

CREATE

d)

RATED KW OF DRIVE MOTOR

3.5

Gland

steam

condenser

LP Heaters

2

3

HP Heaters

5

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

3.5.1

: (Sq.M)

TYPE, SURFACE AREA PER UNIT

3.5.2

:

TUBE MATERIAL, NUMBER, DIA

3.5.3

A)

PRESSURE

ACROSS:

DROP

:

A)

STEAM SIDE

B)

WATER SIDE

B)

TEMPERATURE CHANGE

A)

STEAM SIDE

B)

WATER SIDE

3.6

DEAERATOR:

:

A)

TYPE

: (cum)

B)

STORAGE

CAPACITY /

MINUTES

TANK

:

C)

SIZE

SPRAY VALVES QUANTITY

:

D)

TRAYS

MATERIAL

QUANTITY,

E)

DISSOLVED

PERCENTAGE

OXYGEN

Kg/cm2

F)

DESIGN PRESSURE

G)

DESIGN TEMPERATURE

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

3.7

CONDENSATE PUMP

3.7.1

NUMBERS

CAPACITY

OFFERED

3.7.2

TYPE & MANUFACTURER

3.7.3

IS THE PUMP DIRECTLY DRIVEN

BY ELECTRIC MOTOR ?

3.7.4

PUMP PERFORMANCE

3.7.4.1

Tonnes / hr

(TMCR)

DESIGN CAPACITY

3.7.4.2

DISCHARGE

PRESSURE

DESIGN CAPACITY

AT

3.7.4.3

SUCTION PRESSURE

3.7.4.4

Kg/Sq.Cm

(a)

Kg/Sq.cm

(a)

MLC

TOTAL HEAD DEVELOPED BY THE

PUMP

3.7.4.5

OPERATING SPEED AND NUMBER

OF STAGES

3.7.4.6

NPSH REQUIREMENT AT FULL

CAPACITY

3.7.4.7

MLC

SHUT OFF HEAD

3.7.4.8

POWER CONSUMPTION KW AND

EFFICIENCY AT DESIGN CAPACITY

3.7.4.9

KW

POWER RATING PROVIDED

3.7.4.10

MAX. FLOW THROUGH THE PUMP

WITHOUT

OVERLOADING

PRIMEOVER TONNE/HR (PUMP

RUN OUT)

3.7.5

RECIRCULATION CONTROL

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

a)

TYPE

b)

MANUFACTURER

c)

T/hr

MINIMUM FLOW REQUIRED

3.7.6

MECHANICAL SEAL PROVIDED AT

ENDS

3.7.7

COOLING

ARRANGEMENT

MECHANICAL SEAL

OF

3.7.8

Tonnes

WEIGHT OF PUMP AND DRIVE

ASSEMBLY

INCLUDING

BASE

PLATE

3.7.9

MOTOR DETAILS

a)

KW

RATING

b)

RPM

SPEED

c)

VOLTAGE

d)

METHOD OF LUBRICATION

3.8

BOILER FEED PUMP

3.8.1

NO. OF PUMPS

3.8.2

TYPE OF PUMP

3.8.3

DESIGN PARAMETERS

3.8.3.1

Deg.C

TEMP. OF FEED WATER

Kg/m3

3.8.3.2

SPECIFIC

WATER

GRAVITY

OF

FEED

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

3.8.3.3

Value

Cu.m/hr

SUCTION FLOW

3.8.3.4

M/c

DYNAMIC HEAD

3.8.3.5

Rpm

SPEED

3.8.3.6

KW

POWER INPUT TO PUMP

3.8.3.7

EFFICIENCY OF PUMP

3.8.3.8

M/c

NPSH REQUIRED

3.8.3.9

M/c

SHUT OFF HEAD

3.8.3.10

Cu.m/hr

BFP BALANCING LEAK OFF FLOW

AT RATED SPEED

3.8.3.11

T/hr

MIN. FLOW THROUGH PUMP

3.8.4

CONSTRUCTIONAL FEATURES

3.8.4.1

CASING TYPE

3.8.4.2

IMPELLER TYPE

3.8.4.3

NO. OF STAGES

3.8.4.4

TYPE OF JOURNAL BEARINGS

3.8.4.5

TYPE OF THRUST BEARING

3.8.4.6

METHOD OF COOLING THRUST

BEARING AND JOURNAL BEARING

3.8.4.7

COUPLING TYPE

3.8.5

STRAINER MESH SIZE

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

Kg/sq.cm2

3.8.5.1

PRESSURE DROP

3.8.6

MECHANICAL SEAL

3.8.6.1

QTY/PUMP

3.8.6.2

TYPE OF SEAL

3.8.6.3

MAKE OF SEAL

3.8.7

BOOSTER PUMP

3.8.7.1

TYPE OF PUMP

3.8.7.2

NO. OF PUMPS

3.8.7.3

Rpm

RATED SPEED

3.8.7.4

Cu.m/hr

DESIGN FLOW

o

3.8.7.5

TEMPERATURE

3.8.7.6

M/c

HEAD DEVELOPED

3.8.7.7

KW

POWER INPUT AT RATED FLOW

3.8.7.8

EFFICIENCY AT DESIGN POINT

3.8.7.9

M/c

NPSH REQUIRED

3.8.7.10

DIRECTION OF RATOTATION OF

THE PUMP

3.8.7.11

TYPE OF JOURNAL BEARINGS

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

3.8.7.12

NO. OF BEARINGS

3.8.7.13

TYPE OF LUBRICATION

3.8.7.14

TYPE OF COUPLING

3.8.9

MECHANICAL SEAL

3.8.9.1

QTY./PUMP

3.8.9.2

TYPE OF SEAL

3.8.9.3

MAKE OF SEAL

3.8.10

BFP MOTOR DETAILS

3.8.10.1

KW

RATING

3.8.10.2

Rpm

SPEED

3.8.10.3

VOLTAGE

3.8.10.4

METHOD

OF

LUBRICATION

BEARING

3.8.11

BFP DRIVE TURBINE

3.8.11.1

No off

3.8.11.2

Type, Make & Model No.

3.8.11.3

Output Normal

KW

3.8.11.4

Output Max

KW

3.8.11.5

Normal Speed

RPM

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

Value

3.8.11.6

Speed Range

RPM

3.8.11.7

Motive Steam

3.8.11.7.1

Source :

3.8.11.7.1.

1

3.8.11.7.1.

2

3.8.11.7.1.

3

3.8.11.8

Start-up

3.8.11.9

Pressure

Kg/cm2

3.8.11.10

Temperature

3.8.11.11

Back Pressure

Kg/cm2(abs)

3.8.11.12

Details of connection with booster

pump

3.8.11.13

Details of connection with boiler feed

pump

3.8.11.14

Turbine controls / governing

3.8.11.15

Start up time ( from zero to full load)Seconds

Low Load

Full Load

Flow-t/h

3.9

SCHEDULE OF WEIGHTS:

:

A)

TURBINE GENERATOR WITH

AUXILIARIES

B)

REGENERATIVE FEED WATER

HEATERS WITH AUXILIARIES

C)

CONDENSER

AUXILIARIES

D)

PUMPS WITH AUXILIARIES

:

WITH

3.10

TURBINE LUBE OIL PURIFICATION

SYSTEM

3.10.1

Quantity, Make, Type

3.10.2

Capacity

: (LPH)

3.10.3

Purifier requirements

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Unit

DESCRIPTION

3.10.4

Value

Centrifuge; Type; Speed; Motor rating

3.10.5

:

:

ANTI-FLOOD TANK; CAPACITY &

MATERIAL

3.10.6

Heater; Type; Rating; Make; Material

and number of thermostats

3.10.7

Polishing filter;

Model & type

3.10.8

Pumps:

Capacity;

Make;

a)

Quantity; Capacity; Motor rating

b)

Material of construction:

i)Casing

ii)

Impeller/rotor

iii)

Shaft

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

4.0

WATER TREATMENT PLANT

4.1

Schedule of Water Pumps

S. No.

Item

Units

Parameters

Sea Water

1.

2.

3.

Total no. of pumps

Pump capacity

Pump total head excluding

losses in the pump

Pump speed (max.)

Type of pump

Location

Type of internal element

Liquid handled

Type of line bearing lubrication

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

Liquid for lubrication

Type of pump motor coupling

Thrust bearing location

Pump operating range

Power supply

Materials of construction

Pump column pipe

Pump bowl and discharge elbow

Impeller

Shaft

Line shaft coupling

Line shaft bearing

All hardware under water

Base plate

Shaft sleeve

Thrust bearing cooling system

pipes and valves

Nos.

M3/ hr

MWC

RPM

Filter water

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

4.2

Schedule of Clarification & Filtration System

S. No.

1.0

1.1

a.

b.

c.

d.

e.

1.2

a.

b.

c.

d.

e.

f.

g.

1.3

a.

b.

c.

1.4

a.

b.

c.

1.5

a.

b.

c.

d.

e.

f.

Description

Clarification Plant

Size of Raw Water inlet size

Material of Construction of Pipe

Valves

i)

Number of control valves

ii)

Type

iii) Size

Ends

Material of construction

i)

Body & disc

ii)

Valve spindle (Shaft)

iii) Bearing & Gland packing

iv) Valve seat

v) Disc seat

vi) Seal retaining ring

vii) Bolts and nuts

viii) Gear casing

ix) Gears

x) Pinions

xi) Pinion screw hardware

Cascade Aerator

Quantity offered

Capacity

Material of construction

Size x H

Number of steps

Number of treads

Number of risers

Stilling Chamber

Number

Material of Construction

Capacity

Parshall Flume

Number

Material of Construction

Capacity

Flash mixer

Number

Material of Construction

Capacity (displacement)

Detention time (approx.)

Free-board

Agitator

Protective cover of GI construction for

motors and gear drives.

Clariflocculator

a.

b.

c.

d.

e.

Number required

Type & Construction

Rated Effluent Capacity

Guaranteed Effluent Turbidity

Detention period :

i.

Flocculation zone

ii.

Clarifier zone

Rise rate

Surface flow rate at rated capacity

Velocity in launder

f.

g.

h.

Parameter

Sea Water Inlet Pipe and Valves

g.

1.6

Units

mm

No.

mm

No.

m3/hr

mxm

No.

Cum/hr

Cum/hr.

No.

Cum

Min

Cum/hr

NTU

minutes

minutes

m3/hr/m2

m3/hr/m2

m/sec.

Control

One

Isolating

Two

By-Pass

One

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

i.

j.

k.

l.

1.7

a.

b.

c.

d.

e.

f.

1.8

Description

Platform with railing

Rake bridge Material

Sludge

blow-off

constant

bleed

arrangement with telescopic device &

flushing connection.

Quantity of Flocculation Agitator

Chemical House

Number

Type

Ground Floor

First Floor

Handling Facility

Size

Dosing System

a.

b.

c.

d.

Numbers provided

MOC & Internal lining

Effective Capacity

Solution strength

e.

f.

g.

Agitator MOC

Dissolving basket MOC

Alum, Polyelectrolyte & Lime solution

dosing system - Capacity & head

M.O.C. for piping & valves

Sump

No. of sludge sump

Construction

Capacity

Size

Disposal Pumps

Numbers

Type

Rated Capacity

Head

Type of lubrication

Material of Construction

i.

Casing

ii.

Impeller

iii. Shaft

iv. Packing

v.

Flexible coupling

h.

1.8

a.

b.

c.

d.

1.9

a.

b.

c.

d.

e.

f.

vi.

g.

h.

i.

1.10

1.11

Bolts & Nuts

- In corrosive locations

- in other places

Electric supply

Enclosure & insulation

Speed of pump motor rating

Sludge Thickener

i)

Number

ii)

Capacity

iii) Inlet Solid Concentration

iv) Outlet concentration

v) Material of construction

Thickened Sludge Transfer Pumps

i) Number

ii) Type

iii) Capacity and head

iv) Liquid to be handled

v) Material of construction

a) Pump casing

b) Stator

Units

Parameter

No.

No.

Alum

Lime

Polyelectrolyte

No.

Cum.

%

Sludge

Filter Backwash

Sludge

Filter Backwash

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

1.12

1.17

a.

b.

c.

d.

e.

f.

1.18

a.

b.

c.

d.

e.

f.

Description

c) Shaft

d) Eccentric rotor

Centrifuge

i) Number

ii) Type

iii) Capacity

iv) Inlet Solid Concentration

v) Outlet concentration

vi) Material of construction

a) Bowl

b) Conveyor

c) Conveyor flieght

d) Flieght protection

e) Liquid discharge port

f) Solid discharge port

g) Feed nozzle

h) Recovery

vii) Discharge hopper with valves

Sumps

Capacity (effective)

Dimensions

Length

Breadth

Depth

Type

Level Control Equipment

Internal Lining including Roof

Water Proofing

Miscellaneous Water Pumps

g.

h.

i.

Numbers

Type

Capacity

Head

Type of lubrication

Material of Construction

i.

Casing

ii.

Impeller

iii. Shaft

iv. Shat sleeves

v.

Column pipe

vi. Packing

vii. Flexible coupling

viiii. Bolts & Nuts

- In corrosive locations

- in other places

Electric supply

Enclosure & insulation

Speed of pump motor rating

a.

b.

c.

d.

e.

f.

Chlorinator

Chlorine Tonner

Regulating Valves

Chlorinator

Capacity

Injector

Diffusers

1.19

Units

Parameter

Clarified Water

RO Stage I Permeate

Cum

m

m

m

Clarified

Water

Supply

Pumps

RO

RO

Stage I Stage

High

II

pressure Supply

pumps

Pump

s

Servic

e

Water

Pump

s

Cum/hr

mwc

rpm

kW

RW

No.

Potable

RO

Stage

II

Perme

ate

pump

DESEIN

S. No.

g.

h.

i.

Volume-II: General & Schedules

Schedule B (Mechanical)

Description

Chlorine Analysis

Leak detector

Safety equipment

Units

Parameter

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

4.3

Schedule of RO DM Section

Sl. No.

1.0

a

b

c

d

e

2.0

a

b

c

d

e

3.0

a

b

c

d

e

f

g

4.0

a

b

c

d

e

f

g

1

a

b

c

d

e

f

g

2

a

b

c

d

Description

PT PLANT

Dual Media Filter

Size of each unit (dia x

LOS)

Design flow rate (gross)

Pressure drop across the

unit inclusive of frontal

piping, fittings, valves &

instruments

Backwash flow rate

Air blowers capacity and

discharge pressure

Pressure Sand Filter

Size of each unit (dia x

LOS)

Design flow rate (gross)

Pressure drop across the

unit inclusive of frontal

piping, fittings, valves &

instruments

Backwash flow rate

Air blowers capacity and

discharge pressure

Coagulant dosing system

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Material of construction

Coagulant dosing system

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Material of construction

RO Stage I

Antiscalant dosing system

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Material of construction

SMBS Dosing

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Unit

Mxm

Cum/hr

Cum/hr

Cum/ min/ kg/ sq cm

Mxm

Cum/hr

Cum/hr

Cum/ min/ kg/ sq cm

ppm

Lph/ kg/sq cm

mxm

ppm

Lph/ kg/sq cm

mxm

ppm

Lph/ kg/sq cm

mxm

ppm

Lph/ kg/sq cm

Parameter

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

Sl. No.

e

f

g

3

a

b

c

d

e

4

a

b

c

d

e

f

5

a

b

c

d

e

f

g

h

6

6.1

6.2

6.3

6.4

6.5

1

a

b

c

d

e

f

g

2

a

b

c

d

e

f

g

3

a

b

c

Description

Tank dimensions

No. of tanks offered

Material of construction

Cartridge Filter

Quantity

Capacity per filter

Pressure drop across filter

under

50%

clogged

condition

Mesh size

Material of construction

RO modules

No. of streams

Capacity per stream

Material of construction of

membranes

Flow recovery

Salt rejection capacity

Make of membranes

Chemical cleaning system

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Type of cleaning chemical

Details of cartridge filter

RO Stage I Permeate

Sump

Quantity

Capacity

Dimensions

MOC

Painting details

RO Stage II

Antiscalant dosing system

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Material of construction

SMBS Dosing

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Material of construction

Cartridge Filter

Quantity

Capacity per filter

Pressure drop across filter

under

50%

clogged

Unit

mxm

microns

%

%

ppm

Lph/ kg/sq cm

mxm

ppm

Lph/ kg/sq cm

mxm

ppm

Lph/ kg/sq cm

mxm

Parameter

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

Sl. No.

d

e

4

a

b

c

d

e

f

5

a

b

c

d

e

f

g

h

6

6.1

6.2

6.3

6.4

6.5

1

a

b

c

d

e

i

ii

f

i

ii

g

i

ii

h

i

ii

i

i

ii

2

a

Description

condition

Mesh size

Material of construction

RO modules

No. of streams

Capacity per stream

Material of construction of

membranes

Flow recovery

Salt rejection capacity

Make of membranes

Chemical cleaning system

Dosing rate considered

Dosing pump capacity &

head

No. of pumps offered

Dosing pump material of

construction

Tank dimensions

No. of tanks offered

Type of cleaning chemical

Details of cartridge filter

RO Stage II Permeate

Sump

Quantity

Capacity

Dimensions

MOC

Painting details

Mixed Bed Units

Size of each unit (dia x

LOS)

Design flow rate(gross)

Gross output between

regenerations

Productive output between

regenerations

Resin make & models

Cation resin

Anion resin

Resin quantity

Cation resin

Anion resin

Regeneration levels

Cation resin

Anion resin

Derated

exchange

capacity

Cation resin

Anion resin

Regenerant capacity

Quantity of 30% HCL/

regeneration

Quantity of 98% NaOH/

regeneration

ACID

REGENERATION

SYSTEM

Acid transfer pumps

Capacity

Head

ALKALI REGENERATION

SYSTEM

Unit

microns

%

%

ppm

Lph/ kg/sq cm

mxm

Mxm

Cum/hr

Cum

Cum

Lit

Lit

Kg/cum

Kg/cum

Kg/cum

Kg/cum

cum

Cum

Cum/hr

Kg/sqcm

Parameter

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

Sl. No.

a

4

a

b

c

d

5

a

b

6

a

b

c

13.0

13.1

i)

ii)

iii)

iv)

v)

vi)

13.2

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

13.3

i)

ii)

iii)

iv)

Description

Alkali transfer pumps

Capacity

Head

DM Water STORAGE

TANK

Quantity

MOC

Dia X LOS

Capacity

CONTROL PANEL

Make

Dimensions

PLC

Make

Model no./ system type

Configuration and logic

Neutralising System

Neutralisation Pit

Number

Material of construction

Effective capacity of each

compartment

Isolation gate valves

Numbers required

Protection

Neutralised

Waste

Disposal Pumps

Number

Type

Capacity and total head of

each pump

Duty

RPM

Vibration

Lubrication

Noise Level

Drive motor

Suction condition

Material of Construction

- Casing

- Base Plate

- Impeller

- Shaft

- Shaft coupling

- Shaft sleeve

Ultration Filtration

Number of Modules

Capacity

Type of Membrane

Accessories Provided

Unit

Cum/hr

Kg/sqcm

Nos.

Mxm

Cum

Parameter

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

4.4

S. No.

SCHEDULE OF CW CHLORINATION SYSTEM

Description

1.0

a.

b.

c.

d.

e.

f.

2.0

a.

b.

c.

d.

e.

f.

g.

3.0

a.

b.

c.

d.

e.

f.

g.

H

i

4.0

a.

b.

c.

d.

e.

f.

Sea Water Booster Pump

Manufacturer

Type

Number of pumps

Capacity

Head

Material of Construction

Casing

Impeller

Shaft

Base Plate

Bolts & Nuts

Auto Self Cleaning Filter

Number

Manufacturer

Mesh Screen size

Material of Constrcution

Body

Screen

Pressure Drop at full flow when clean

across filter

Size, LOS x dia (m x m)

Weight of each filter

Electrolyser

Number

Type & Manufacturer

Capacity (each)

Available Cl2 content @ outlet

Life of electrodes

Range of operation

Material of Constrcution

Anode

Cathode

Shell

Gaskets

Design Pressure

Test Pressure

Size

Weight

Hypochlorite Dosing Pumps

Quantity

Capacity

Head

Material of construction

Casing

Impeller

Shaft

Make

Weight of pump assembly

Units

Cum/hr

MWC

Kg/ cm2 (g)

Kgs

kg/hr

Ppm

Years

%

Mxm

kgs

Cum/hr

Kg/ cm2 (g)

kgs

5.0

DILUTE HYDROCHLORIC ACID TANK

a.

b.

c.

d.

Quantity

Capacity

Manufacturer & type

Material of construction

6.0

HYPOCHLORITE STORAGE TANK

Cum

Parameter

CW & PT System Sea water Intake

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

a.

b.

c.

d.

Quantity

Capacity

Manufacturer & type

Material of construction

7.0

H2 DILUTION BLOWERS

a.

b.

c.

d.

e.

8.0

a.

b.

c.

d.

e.

f.

g.

Manufacturer

Quantity

Capacity

Discharge pressure

Material of Construction

Casing

Impeller

Shaft

Transformer Rectifiers

Manufacturer

Capacity

Quantity

Method of Control

Output DC Current

Output DC voltage

Cooling type

Units

Cum

Parameter

CW & PT System Sea water Intake

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

4.5

Schedules for Laboratory Equipment

S. No.

Description

Parameters

Water Analysis

1.01

a)

b)

c)

d)

1.02

a)

b)

c)

d)

1.03

a)

b)

c)

d)

1.04

a)

b)

c)

d)

1.05

a)

b)

c)

d)

1.06

a)

b)

c)

d)

1.07

a)

b)

c)

d)

1.08

a)

b)

c)

d)

1.09

a)

pH-meter

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Conductivity Meter

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Spectro Photometer

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Dissolved Oxygen Meter

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Turbidity meter

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Balances

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Flame Photometer

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Selective Ion-Analyser

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Oil Content Analyzer

Make

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

b)

c)

d)

1.10

a)

b)

c)

d)

1.11

a)

b)

c)

d)

1.12

a)

b)

c)

d)

1.13

a)

b)

c)

d)

1.14

a)

b)

c)

d)

1.15

a)

b)

c)

d)

1.16

a)

b)

c)

d)

1.17

a)

b)

c)

d)

1.18

Description

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Water Purification System

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Stirring hot plate

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Water Bath

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Refrigerator

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Vacuum Pump

Make

Model No.

Technical Leaflet & operating

attached.

Parameters

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

description

List of accessories included with the

instruments

Residual Chlorine Meter

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Jar Test Apparatus

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Portable Water Quality Checker

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Personal Computer

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

a)

b)

c)

d)

2.00

Coal Analysis

2.01

Coal Analyzer

a)

b)

c)

d)

2.02

a)

b)

c)

d)

2.03

a)

b)

c)

d)

2.04

a)

b)

c)

d)

2.05

a)

b)

c)

d)

2.06

a)

b)

c)

d)

2.07

a)

b)

c)

d)

3.00

Description

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Oxygen Bomb Calorimeter

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Carbon & Sulphur Analyzer

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Muffle Furnace

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Oven

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Lab Pulverizer

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Sieve Shaker

Make

Model No.

Technical Leaflet & operating

attached.

List of accessories included

instruments

Oil Analysis

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

description

with

the

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

3.01

Description

Red Wood Viscometer

a)

b)

c)

d)

3.02

a)

b)

c)

d)

3.03

a)

b)

c)

d)

3.04

a)

b)

c)

d)

3.05

a)

b)

c)

d)

3.06

a)

b)

c)

d)

3.07

a)

b)

c)

d)

3.08

a)

b)

c)

d)

4.00

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Automatic Flash Point Apparatus

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Dean & Stark Moisture Determination

Apparatus

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Flash Shaker

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Centrifuge

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Heating Mantle

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Automatic K-F (Karl-Fisher) Titrimeter

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Gas Chromatograph

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Meteorological & Pollution

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

4.01

a)

b)

c)

d)

4.02

a)

b)

c)

d)

4.03

a)

b)

c)

d)

4.04

a)

b)

c)

d)

4.05

a)

b)

c)

d)

4.06

a)

b)

c)

d)

4.07

a)

b)

c)

d)

4.08

a)

b)

c)

d)

4.09

a)

b)

Description

Electrical Amenograph

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Dew Point Meter

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Rain Gauge

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Mercury Barometer

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Maximum & Minimum Thermometer

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Dry & Wet bulb Thermometer

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

High Volume Sampler

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Stack Monitoring Kit

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Portable Gas Analyser

Make

Model No.

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

c)

d)

4.10

a)

b)

c)

d)

Description

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Stop Watch

Make

Model No.

Technical Leaflet & operating description

attached.

List of accessories included with the

instruments

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

4.6

Schedule of Condensate Polishing Unit

S. No.

1.0

1.1

1.1.1

1.1.2

Description

Chemical Consumption

Hydrochloric Acid (30% conc.)

Kgs/litre of cation resin

Amount of cation resin in one vessel, litres

1.1.3

1.2

Total for regeneration of one vessel

charge, kgs

Sodium Hydroxide (48% purity)

1.2.1

1.2.2

Kgs. Litre of anion resin

Amount of anion resin in one vessel, litres

1.2.3

Total for regeneration of one vessel

charge, kgs

Power Requirements

During Normal Operation KW

During Regeneration KW

Total energy consumption for regeneration

of one vessel charge KWH

2.0

2.1

2.2

2.2.1

2.2.2

Total energy consumption for regeneration

of one vessel charge KWH

2.2.3

Duration of the regeneration process

considered in 2.2 above

3.0

3.1

3.1.1

Effluent Quality

Normal Conditions

When operating under normal design

conditions with the influent quality no

worse than that indicated in Technical

Specifications, the effluent quality shall be

better than the following:

3.1.1.1

3.1.1.2

3.1.1.3

3.1.1.4

3.1.1.5

3.1.1.6

3.1.1.7

Total solids,

ppb

Silica,

ppb

Copper,

ppb

Iron,

ppb

Sodium,

ppb

Chloride,

ppb

Conductivity, after removal of ammonia

and amines, micro mhos/cm at 25C

3.1.1.8

3.1.2

Crude,

ppb

Service run between two successive

regenerations at the design flow and

above influent condition, while maintaining

this guaranteed effluent quality, hours

(minimum)

Start-up Conditions

3.2

3.2.1

3.2.2

3.3

With the influent quality no worse than

that indicated in Technical Specification,

total crud content of the effluent shall not

exceed, ppb

Useful service run between

two

successive regenerations, at the design

flow and the above influent condition, shall

not be less than, hours

Condenser Tube-Leakage Conditions

DESEIN

S. No.

3.3.1

3.3.2

4.0

4.1

4.2

4.3

4.3.1

4.3.2

4.3.3

5.0

6.0

6.1

6.1.1

6.1.2

6.1.3

6.1.4

6.1.5

6.2

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

7.0

7.1

7.2

8.0

8.1

8.2

8.3

8.4

8.5

Volume-II: General & Schedules

Schedule B (Mechanical)

Description

With the influent quality no worse than

indicated in the Technical Specifications,

sodium content of the effluent shall be

limited to ppb

Useful service run between

two

successive regenerations, at the design

flow and the above influent conditions,

shall not be less than, hours

Hydraulics

Design flow rate per vessel, M3/hr

Average velocity of condensate through

the resin bed at the above flow, m/min

Pressure drop across the service vessels

at the above design flow, shall not exceed

the following maximum values, kg/cm2

Vessel, excluding resign trap

Resin trop alone

Total

Resin Loss

Condensate Polishing Service Vessels

Capacity & Performance of Each Vessel

Service rate (m3/hr.)

Service Hydraulic rate (m/min)

Pressure Loss without resins, (kg/cm2)

Rinse Rate (m3/hr.)

Resin

sluice

Rate

(m3/hr.)

and

3

simultaneous Air (NM /hr.)

Vessel Details

Design Pressure kg/m2 (gauge)

Number of vessel per unit

Tank Size

Thickness

Vessel material

Lining Material & thickness

Vessel Supports

Freeboard (%)

Design code

Resin Details Each Vessel

Cation / Anion / Inert Resin

Manufacturer & Type

Total Exchange Capacity (kg/Caco3/m3)

Volume (litres)

Sieve analysis

Technical literature furnished

Total Resin Bed depth cms

Service Requirements

Instrument

air

consumption

for

instruments and controls (max.) (NM3/hr.)

Control power supply feeder rating

required (KW)

Max. Service air consumption (NM3/hr.)

Sealing water requirement for glands

sealed valves (m3/hr.)

Electrical & Power consumption (total) for

instruments & control panel

S. No.

9.0

Description

Condensate Polishing External

Regeneration

9.1

9.1.1

Capacity & Performance

Resin Scrub

Clean

RESIN SEPARATION

AND CATION

REGENERATION

ANION RESIN

REGENERATION

Dirty

MIXED RESIN

STORAGE

DESEIN

S. No.

9.1.2

9.1.3

9.1.4

9.1.5

9.1.6

9.1.7

9.1.8

S. No.

10.0

10.1

10.1.1

10.1.2

10.1.3

10.1.4

Volume-II: General & Schedules

Schedule B (Mechanical)

Description

Air (NM3/hr. and pressure in

kg/cm2(g))

Water Rinse (m3/hr.)

Backwash Rate (m3/hr.)

Slow Rinse (m3/hr.)

Fast Rinse (m3/hr.)

Regenerant Flow (m3/hr.)

Air Mix (NM3/hr.) and pressure

kg/cm2

Resin sluicing Rate (m3/hr.) and

simultaneous Air (NM3/hr.)

Resin Separation Flow Rate (m3/hr.)

10.2

10.2.1

10.2.2

10.2.3

10.2.4

Description

Hot Water Tank

Capacity & Performance

Capacity (litres)

Outlet Temp (C)

Recovery Time (Hr.)

Heat Input (kcal/hr)

Capacity as percentage of total diluent water

for alkali required for one regeneration

Vessel Details

Design Pressure

Tank Size (dia x shell side length)

Thickness (Head/shell)

Vessel Material

S. No.

Description

11.0

11.1

11.2

11.2.3

11.2.4

Air Blowers

Number of units

Blower

Type

Discharge Capacity NM3/hr at

mm. W.C.

Activated Carbon Filter

Capacity & Performance

Service Rate (m3/hr)

Pressure Drop (kg/m2)

Backwash rate (m3/hr) & duration

(minutes)

Rinse Rate (m3/hr) & duration

(minutes)

Vessel Details

Design Pressure (kg/m2g)

Tank size (dia x shell side length)

Activated Carbon Material

Surface area (m2/gram)

Characteristics

a) Bulk density kg/m3

b) Uniformity co-efficient

c) Abrasion number

d) Ash, %

Quantity in filter bed

a) Volume, M3

b) Bed depth, cms

Resin Transfer Pipeline

Number and size

Approximate length, meters

Pipe

Material

10.1.5

12.0

12.1

12.1.1

12.1.2

12.1.3

12.1.4

12.2

12.2.1

12.2.2

12.3

12.3.1

12.3.2

12.3.5

13.00

13.00.1

13.00.2

13.01

13.01.1

For Service Vessels

For regeneration

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

13.01.2

13.01.3

14.00

14.01

Wall thickness

Type of joints

Skids

Overall Dimensions

Length, mm

Width, mm

Height, mm

Control Panels

Dimension, mm

Mounting

14.02

S. No.

15.0

Description

Miscellaneous Tank

15.1

i)

ii)

iii)

iv)

v)

S. No.

16.0

16.1

Nos. supplied

Size, mm

Useful capacity, M3

Maximum capacity, M3

Material

of

construction

thickness, mm

Acid Dozing

ALKALI

STORAGE

&

Description

Neutralising System

i)

Neutralising Pit

a) Number provided

b) Material of construction

c) i) Useful capacity of each pit

(m3/each)

ii) Max. capacity of each pit

(m3/each)

d) Size (m)

e) Liquid Depth

f) Agitation system

i) Size of pipe (mm)

ii) Material

iii) Type of agitation system

iv) In case of air agitation system

a) Quantity of air required

NM3 per section of pit

Alkali Dozing

ACID

STORAGE

TANK

DM WATER

STORAGE

TANKS

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

Unit

1.0

SEA WATER INTAKE SYSTEM

1.1

SEA WATER INTAKE PUMPS

1.1.1

General

1.1.1.1

Type

1.1.1.2

Manufacturer

1.1.1.3

Model Number

1.1.2

Equipment Performance

1.1.2.1

Performance standard

1.1.2.2

Guaranteed Design Capacity

: (M/hr)

1.1.2.3

Guaranteed Total Head at pump

discharge flange at rated capacity

: (MLC)

1.1.2.4a)

Bowl head at rated capacity

: (MLC)

b)

Bowl head at rated speed and

closed discharge

: (MLC)

c)

Total head loss from suction bell

inlet to pump discharge flange at

rated capacity

: (MLC)

1.1.2.5

Range of operation

1.1.2.6

Pump rated speed

: (RPM)

1.1.2.7

Guaranteed pump efficiency at

rated capacity

: (%)

1.1.2.8

Tolerance on guaranteed design

a)

Capacity

: (Cu. M/hr)

b)

Total head

: (MWC)

c)

Efficiency

: (%)

1.1.2.9

Rub-away-speed (reverse) due to

reverse flow at rated head

: (rpm)

1.1.2.10

Are pumps and motors capable of

withstanding the reverse run-away

speed (mention the duration also)?

1.1.2.11

Expected noise level

1.1.2.12

Expected vibration limits

1.1.2.13

Power consumption

1.1.2.13.1

Guaranteed pump shaft

power at rated capacity

1.1.2.13.2

Power Consumption

condition at motor

input

: (KW)

at rated

terminals,

: (KW)

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

Unit

Parameters

(Guaranteed)

1.1.2.14

Pump specific speed

1.1.2.14.1

1.1.2.15

Suction specific speed

Minimum

submergence

(over

suction bell) required at rated

capacity

:

: (MLC)

1.1.2.16

Pump motor Critical speed

: (RPM)

a)

1st

b)

2nd

1.1.2.17

Mode of pump starting

1.1.2.18

Provision for impeller adjustment

available

Type of shaft coupling

1.1.2.19

i)

between impeller & line

shaft

ii)

between

shaft

line

&

head

1.1.2.20

Type of lubrication and cooling

1.1.2.21

Thrust bearing (s)

1.1.2.21.1

Location

1.1.2.21.2

Numbers provided

1.1.2.21.3

Type

1.1.2.21.4

Description

of

lubrication

Arrangement and lubricant

1.1.2.21.5

Coolant

1.1.2.22

Shaft Sealing Arrangement

1.1.2.22.1

Type

1.1.3

Material of Construction

1.1.3.1

Base Plate

1.1.3.2

Discharge casing

1.1.3.3

Column pipe

1.1.3.4

Suction bell

1.1.3.5

Impeller

1.1.3.6

Impeller shaft

1.1.3.7

Impeller wear ring

RPM x (Flow in

USGPM)1/2

NS

=

----------------------------

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

Unit

1.1.3.8

Casing wear rings

1.1.3.9

Impeller shaft

1.1.3.10

Line shaft and head shaft

1.1.3.11

Shaft sleeve

1.1.3.12

Shaft coupling

1.1.3.13

Shaft enclosing tube

1.1.3.14

Line & head shaft bearing

1.1.3.15

Impeller bearings

1.1.3.16

Stuffing box

1.1.4

INSPECTION AND TESTING

1.1.4.1

Material test

1.1.4.2

Hydro-static test pressure and

duration

: (Kg./ Sq.cmg)

(min)

1.1.4.3

Performance test

1.1.4.4

Test speed

: (RPM)

1.1.4.5

Cavitation test

1.1.4.6

Dynamic balancing test

1.1.5

Loading Data

1.1.5.1

Horizontal and vertical loads for

pump foundation design

: (Kg.f.)

1.1.5.2

Design load at thrust block

: (Kg.f.)

1.2

BUTTERFLY VALVES

1.2.1

General

1.2.1.1

Manufacturer & Model No.

1.2.1.2

Type

1.2.1.3

Size of the valve

1.2.1.4

Number offered

1.2.2

Equipment Performance

1.2.2.1

Maximum allowable flow

: (Cu. M/hr)

1.2.2.2

Pressure drop across the valve at

design flow

: (Kg/Sq.cmg)

1.2.2.3

Operating time from open to

: (mm NB)

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

Unit

close condition and vice-versa

1.2.2.4

Valve body & disc

1.2.2.4.1

Body construction

1.2.2.4.2

Whether the body is lined

1.2.2.4.3

Disc Construction

1.2.2.5

Valve seat

1.2.2.5.1

Material

1.2.2.5.2

No. of retaining ring segments

1.2.2.6

Valve shaft

1.2.2.6.1

Shaft attachment

1.2.2.6.2

Shaft diameter (mm)

1.2.3

Material of Construction

1.2.3.1

Valve body

1.2.3.2

Valve disc

1.2.3.3

Valve seat

1.2.3.4

Valve shaft

1.2.3.5

Shaft bearings

1.3

RUBBER EXPANSION JOINT

1.3.1.1

Nominal size

: (NB)

1.3.1.2

Type

1.3.2

Performance Capability

1.3.2.1

Axial elongation/contraction

: (mm)

1.3.2.2

Lateral deflection

: (mm)

1.3.2.3

Angular movement

: (degrees)

1.3.2.4

Torsional movement

: (degrees)

1.3.3

Design and Construction

1.3.3.1

Design standard

1.3.3.2

Design pressure

: (Kg./ Sq.cmg)

1.3.3.3

Design vacuum

: (Kg./ Sq.cmg)

1.3.3.4

Bursting pressure of

: (Kg./ Sq.cmg)

1.4

Sea Water Pumphouse

Parameters

DESEIN

S. No.

1.4.1

1.4.2

1.4.3

1.5

1.5.1

Volume-II: General & Schedules

Schedule B (Mechanical)

Description

Size

Size of forebay

Depth of Intake sump

Intake Well

Size of intake well

Unit

M xm xm

M xm xm

M

Parameters

DESEIN

Volume-II: General & Schedules

Schedule B (Mechanical)

S. No.

Description

Unit

CW Pumps

5.0

CW SYSTEM

5.1

CW & ACW PUMPS

5.1.1

General

5.1.1.1

Type

5.1.1.2

Manufacturer

5.1.1.3

Model Number

5.1.2

Equipment Performance

5.1.2.1

Performance standard

5.1.2.2

Guaranteed Design Capacity

: (M/hr)

5.1.2.3

Guaranteed Total Head at pump

discharge flange at rated capacity

: (MLC)

5.1.2.4a)

Bowl head at rated capacity

: (MLC)

b)

Bowl head at rated speed and

closed discharge

: (MLC)

c)

Total head loss from suction bell