Académique Documents

Professionnel Documents

Culture Documents

Venteos de Explosion

Transféré par

James FloresTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Venteos de Explosion

Transféré par

James FloresDroits d'auteur :

Formats disponibles

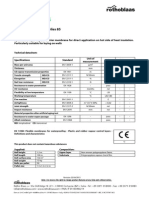

PRODUCT INFORMATION

EXPLOSION VENTING

EX-GO-VENT

Rectangular

Single Layer

Burst Panel

for

Explosion

Venting

at Low

Vacuum

Features

Standard burst pressure

pstat. = 0.1 barg @ 22 C*

= 1.45 psig @ 71.6 F*

In plants producing organic products considerable

volumes of fine dust are permanently present. In the

beginning it can be considered this fine dust is only combustible. However, enriched with oxygen this combustible material transforms into a highly explosive mixture.

If an ignition source is then introduced resulting in an explosion and fire, this will cause enormous consequential

damage for plant and personnel. Acc. to ATEX directive

94/9/EG manufacturers are obliged to reduce the risk of a

dust explosion.

Operating pressure or vacuum

standard 50 % from pstat.*

Temperature from

-40 C up to 180 C*

(-40 F up to 356 F)*

Material: 304 stainless steel, silicon

gasket (FDA compliant)

Customised dimensions, e.g.: Triangular, Sail

- or Trapezium shape, etc. in order to utilise full

capacity and optimise customer equipment

configuration

Mounting without using the usual counter frame

Explosion protection by certified explosion panels provides a cost effective and good engineered solution. i.e.:

If a dust explosion occurs the explosion pressure is

reduced to a harmless level within the plant.

GBPI-EGV-10011/2 valid from 2011-07-21 - Subject to revision without notice.

The

EX-GO-VENT

incorporating

bionic

structures

guarantees extraordinary stability suitable for most

standard applications. The flat, single layer explosion

panel has a perfect venting efficiency due to its low

specific weight. Unlike other manufacturers options, the

EX-GO-VENT is NOT torque dependent during installation. Typically, mounting is made directly on roofs,

bulkheads or round shaped equipment and provides a

guaranteed leak-tight sealing against arduous weather

Direct installation on plain walls as well

as on cylindrical equipment, e. g. cyclones,

filters, silos, etc.

Elimination of dead-space and product

accumulation, making it suitable for sterile

applications, e. g. in food industry

Mounting possible on cylindrical walls with

diameter 3.5 m (9.8 ft)

Round EX-GO-VENTs are also available

* For non-standard operating conditions, e. g.

higher operating pressure, vacuum, pulsation and

temperature please contact epd@rembe.de or

call + 49 (0) 29 61 - 74 05 - 0 to discuss your

requirements.

conditions or other water ingress.

Gallbergweg 21 59929 Brilon/Germany T + 49 (0) 29 61 - 74 05 - 0 F + 49 (0) 29 61 - 5 07 14 sales@rembe.de www.rembe.de

1/3 |

EX-GO-VENT

REMBE

P R O D U C T I N F O R M AT I O N E X P L O S I O N V E N T I N G

Filter system: Holtrop & Jansma, NL

Elevator with EX-GO-VENT panels

Applications

Explosion venting of silos,

filter, bucket elevators,

cyclones, grinders and more

GBPI-EGV-10011/2 valid from 2011-07-21 - Subject to revision without notice.

Your benefits

Perfect venting efficiency

Sanitary installation

Wide range of applications

Easy and quick mounting

EX-GO-VENT explosion panels protecting

a biomass handling facility

2/3 | EX-GO-VENT

Considerable cost reductions

due to integrated gasket and

mounting frame

REMBE

P R O D U C T I N F O R M AT I O N E X P L O S I O N V E N T I N G

[mm]

EX-GO-VENT installation:

quick and easy

Mo

v

of b emen

urs

t

ting in ca

se

Warning sign

Stamped lot-number

Hinge

Tag plate

Vessel wall

Quality and Certifications

GBPI-EGV-10011/2 valid from 2011-07-21 - Subject to revision without notice.

Certifications

All series

ATEX

(BVS 03 ATEX ZQS/E210)

KTA 1401 Nuclear Power

ESA - Aerospace

CML

ASME

GOST

Gospromnadzor

KOSHA

various international

inspections

Certification IAW

ATEX guideline 94/9 EG

Approval IAW ATEX certificate no.

FSA 04 ATEX 1538 X

Every batch

Manufacture and certified IAW

the requirements of EN14797

Burst test certificates with

each supply IAW EN10204-3.1

The REMBE team provides total support in sizing your

venting area requirements and recommending a cost effective solution suitable for your specific application(s). Sizing

Calculations are made IAW VDI guideline 3673, HBG-BGI

739, EN14491, or NFPA 68. Full sizing calculation details and

product information are provided with the order documentation.

3/3 | EX-GO-VENT

Single-Layer Explosion Vent

EX-GO-VENT

for low vacuum

Effective Vent Area

Max. Dimensions

of Wall Opening =

Nominal Venting Dimensions

130

229

150

180

270

200

247

205

340

314

305

345

315

247

330

340

400

410

404

305

354

375

440

470

490

500

300

386

454

570

450

600

590

605

575

610

457

650

520

370

653

600

710

620

586

500

750

620

800

457

610

645

720

760

840

920

457

920

586

1000

915

770

1020

790

586

920

740

740

750

1130

860

940

940

1110

920

1000

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

[in]

500

305

600

420

465

460

465

610

385

424

457

405

467

610

470

440

400

410

420

610

580

655

605

610

590

620

1000

920

760

620

800

600

620

605

645

610

890

650

820

1220

653

800

710

820

920

1100

840

1020

800

1500

1118

1130

1020

1114

920

920

2000

1020

1630

1000

1118

1340

1020

1340

1893

1254

1630

1893

1900

1130

1520

1440

1600

1460

1920

2000

5.1

9.0

5.9

7.1

10.6

7.9

9.7

8.1

13.4

12.4

12.0

13.6

12.4

9.7

13.0

13.4

15.7

16.1

15.9

12.0

13.9

14.8

17.3

18.5

19.3

19.7

11.8

15.2

17.9

22.4

17.7

23.6

23.2

23.8

22.4

24.0

18.0

25.6

20.5

14.6

25.7

23.6

28.0

24.4

23.1

19.7

29.5

24.4

31.5

18.0

24.0

25.4

28.3

29.9

33.1

36.2

18.0

36.2

23.1

39.4

36.0

30.3

40.2

31.1

23.1

36.2

29.1

29.1

29.5

44.5

33.9

37.0

37.0

43.7

36.2

39.4

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

[cm]

19.7

12.0

23.6

16.5

18.3

18.1

18.3

24.0

15.2

16.7

18.0

15.9

18.4

24.0

18.5

17.3

15.7

16.1

16.5

24.0

22.8

25.8

23.8

24.0

23.2

24.4

39.4

36.2

29.9

24.4

31.5

23.6

24.4

23.8

25.4

24.0

35.0

25.6

32.3

48.0

25.7

31.5

28.0

32.3

36.2

43.3

33.1

40.2

31.5

59.1

44.0

44.5

40.2

43.9

36.2

36.2

78.7

40.2

64.2

39.4

44.0

52.8

40.2

52.8

74.5

49.4

64.2

74.5

74.8

44.5

59.8

56.7

63.0

57.5

75.6

78.7

[sq in]

700

108.5

750

116.3

920

142.6

1250

1300

193.8

201.5

1350

209.3

1470

1500

1550

227.9

232.5

240.3

1600

1680

248.0

260.4

1860

2050

288.3

317.8

2850

2890

441.8

448.0

3000

465.0

3400

527.0

3600

558.0

3720

4100

4220

4260

4500

576.6

635.5

654.1

660.3

697.5

5000

5100

5400

5500

775.0

790.5

837.0

852.5

6320

6400

979.6

992.0

6800

1054.0

8450

1309.8

8500

1317.5

10000

10230

10300

10400

10500

1550.0

1585.7

1596.5

1612.0

1627.5

12750

13000

13500

15040

16000

17500

20000

1976.3

2015.0

2092.5

2331.2

2480.0

2712.5

3100.0

* Standard burst pressure pstat = 0.1 barg @ 22 C (71.6 F),

further sizes, gasket materials, burst pressures, etc. on request.

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- (GUNSMITHING) The .22 PistolDocument18 pages(GUNSMITHING) The .22 PistolMago Invisivel88% (25)

- Pure Sine Wave Inverter For House BackupDocument44 pagesPure Sine Wave Inverter For House BackupKrista Jackson100% (1)

- NextCloud OnlyOffice PDFDocument89 pagesNextCloud OnlyOffice PDFOmar Gallegos Vazquez100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Document57 pagesChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pages000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- MR ValvesDocument56 pagesMR ValvesIdris SiddiquiPas encore d'évaluation

- Dynaxe-En Double EccDocument15 pagesDynaxe-En Double Eccrajaj19800% (1)

- EBS Data MaskingDocument31 pagesEBS Data MaskingNawab ShariefPas encore d'évaluation

- Foamglass - Data SheetDocument2 pagesFoamglass - Data SheetdidapopescuPas encore d'évaluation

- Pipe InsulationDocument50 pagesPipe InsulationSam WeberPas encore d'évaluation

- C#.Net Interview Questions and AnswersDocument11 pagesC#.Net Interview Questions and AnswersManoj ManuPas encore d'évaluation

- Coal Cement IndustryDocument11 pagesCoal Cement IndustrySanjay GorePas encore d'évaluation

- ASTM Data and ControlDocument141 pagesASTM Data and ControlYohanes Ronny100% (1)

- Application & Technical Manual 10 Penetration SealsDocument62 pagesApplication & Technical Manual 10 Penetration SealskenwongwmPas encore d'évaluation

- Dry Gas Seals Type 28Document6 pagesDry Gas Seals Type 28ewok2030100% (1)

- Explosion ProtectionDocument20 pagesExplosion Protectionzirimia100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Quest CCS ProjectDocument10 pagesQuest CCS ProjecttruehemingwayPas encore d'évaluation

- SAES-A-102 Ambient Air Quality and Source Emissions StandardsDocument21 pagesSAES-A-102 Ambient Air Quality and Source Emissions StandardsFlorante NoblezaPas encore d'évaluation

- Model 2100bDocument4 pagesModel 2100bkeyur1109Pas encore d'évaluation

- Q-Rohr - 3: Indoor Flameless Explosion VentingDocument4 pagesQ-Rohr - 3: Indoor Flameless Explosion VentingSanjay GorePas encore d'évaluation

- Sigraflex UniversalDocument6 pagesSigraflex UniversalJan SmitPas encore d'évaluation

- Sika Tricomer (Eng)Document12 pagesSika Tricomer (Eng)ilijarskPas encore d'évaluation

- Bauder Thermofolbrochure May2010Document12 pagesBauder Thermofolbrochure May2010Deana WhitePas encore d'évaluation

- Breather/Drain Plugs: SeriesDocument1 pageBreather/Drain Plugs: SeriesGolfkung PairojPas encore d'évaluation

- Recotec Rotafil enDocument16 pagesRecotec Rotafil enJordan RileyPas encore d'évaluation

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoPas encore d'évaluation

- Bursting Discs Breather Valves Signalling UnitsDocument16 pagesBursting Discs Breather Valves Signalling Unitssmab2162094Pas encore d'évaluation

- Wintech Test Engineering BrochureDocument8 pagesWintech Test Engineering BrochureWintechEngineeringPas encore d'évaluation

- Crouse Hinds Control StationsDocument127 pagesCrouse Hinds Control StationsLaurence MalanumPas encore d'évaluation

- Roxtec UG Cable SealDocument4 pagesRoxtec UG Cable SealMarkPas encore d'évaluation

- 936057f PDFDocument2 pages936057f PDFSebastiaan OostPas encore d'évaluation

- Fike VentingDocument6 pagesFike Ventingjpdavila205Pas encore d'évaluation

- AFICO Heavy Density Pipe Insulation - NewDocument4 pagesAFICO Heavy Density Pipe Insulation - NewNickolas HeadPas encore d'évaluation

- Technical Data Design Sheets - Tornado Da Fa PDFDocument14 pagesTechnical Data Design Sheets - Tornado Da Fa PDFMilena Lemus FonsecaPas encore d'évaluation

- Proofex GPDocument2 pagesProofex GPkalidindivenkatarajuPas encore d'évaluation

- Energychain CatalogueDocument72 pagesEnergychain CatalogueigusukPas encore d'évaluation

- Fire Damper - FDDocument7 pagesFire Damper - FDZaw Moe KhinePas encore d'évaluation

- BR Matacryl RB - GBDocument4 pagesBR Matacryl RB - GBNevena DelibasicPas encore d'évaluation

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document12 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Lê Duy MinhPas encore d'évaluation

- Leak Detection With VSP-leak Detection Units and Vacuum BoxesDocument5 pagesLeak Detection With VSP-leak Detection Units and Vacuum BoxesChinbat ShirchinPas encore d'évaluation

- Dgs-Ep-E E4 Dgs-Dry Gas Seals 02.14Document4 pagesDgs-Ep-E E4 Dgs-Dry Gas Seals 02.14cincaohijauPas encore d'évaluation

- Euro Therma TR27 2ppDocument2 pagesEuro Therma TR27 2ppbakkakraljPas encore d'évaluation

- Rothoblaas - Vaporvlies 85.technical Data Sheets - enDocument2 pagesRothoblaas - Vaporvlies 85.technical Data Sheets - enAndrei GheorghicaPas encore d'évaluation

- Polyiso InsulationDocument2 pagesPolyiso Insulationarbor02Pas encore d'évaluation

- C Ce 0432 CPD 221051 enDocument54 pagesC Ce 0432 CPD 221051 enKhuyến Nguyễn VănPas encore d'évaluation

- Wood-Aluminium Transom-Mullion Construction Batimet TM60 SE Formale Anforderungen An Die Konstruktionen Formal Requirements For ConstructionDocument4 pagesWood-Aluminium Transom-Mullion Construction Batimet TM60 SE Formale Anforderungen An Die Konstruktionen Formal Requirements For ConstructionLiew Yau WeiPas encore d'évaluation

- Help With Nickel Alloy Welding - GA5Document5 pagesHelp With Nickel Alloy Welding - GA5chompink6900Pas encore d'évaluation

- Cellular GlassDocument2 pagesCellular GlassPaolo NgPas encore d'évaluation

- Gylon GasketingDocument12 pagesGylon GasketingjohnsaballaPas encore d'évaluation

- Ex D Enclosures Understanding The StandardsDocument4 pagesEx D Enclosures Understanding The StandardsFarid HazwanPas encore d'évaluation

- Fabric Expansion JointsDocument20 pagesFabric Expansion JointsBradley NelsonPas encore d'évaluation

- 830 SpecDocument2 pages830 Specmonarchy1103Pas encore d'évaluation

- WBS Socket Detailing 2010 10Document10 pagesWBS Socket Detailing 2010 10mcnortyPas encore d'évaluation

- Fugenbandprofile en Ansicht PDFDocument8 pagesFugenbandprofile en Ansicht PDFHadianto JkPas encore d'évaluation

- KAT-B 2452 EROXplus Edition1 07-02-2014 EN PDFDocument11 pagesKAT-B 2452 EROXplus Edition1 07-02-2014 EN PDFphamvantranllmPas encore d'évaluation

- 5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBDocument4 pages5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBSivareddy InduriPas encore d'évaluation

- Technor Explosion Proof EnclosuresDocument6 pagesTechnor Explosion Proof EnclosuresTh NattapongPas encore d'évaluation

- ThermPanManufactureInst 05Document1 pageThermPanManufactureInst 05imeqingenieriaPas encore d'évaluation

- KoolDuct Technical Data Sheet UKDocument2 pagesKoolDuct Technical Data Sheet UKsiva_nagesh_2Pas encore d'évaluation

- Pennguard InformationDocument2 pagesPennguard Informationhuynhthanhtamga1981Pas encore d'évaluation

- Coverseals enDocument6 pagesCoverseals enNCvetarskyPas encore d'évaluation

- Tech Bulletin 4 Cladding InstallationDocument4 pagesTech Bulletin 4 Cladding InstallationAbu NijamPas encore d'évaluation

- Eternit PločeDocument28 pagesEternit PločedarkopavicPas encore d'évaluation

- Proc HindDocument8 pagesProc HindWulan GlhPas encore d'évaluation

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiPas encore d'évaluation

- Sentinel GLDocument2 pagesSentinel GLdimitrios25Pas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- 2013 OSPE Salary Survey PDFDocument20 pages2013 OSPE Salary Survey PDFdarinscottjohnsonPas encore d'évaluation

- BCM NotesDocument25 pagesBCM NotesAman AgrawalPas encore d'évaluation

- Noise and VibrationDocument14 pagesNoise and VibrationABHISHEK V GOWDAPas encore d'évaluation

- Tps 53014Document27 pagesTps 53014nebiyu mulugetaPas encore d'évaluation

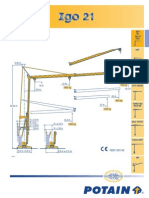

- Potain Igo 21 PDFDocument4 pagesPotain Igo 21 PDFMarco CruzPas encore d'évaluation

- STK412 150 Sanyo PDFDocument4 pagesSTK412 150 Sanyo PDFroger.Pas encore d'évaluation

- Battery CatalogueDocument6 pagesBattery CataloguerantaroPas encore d'évaluation

- CS1 Course OutlineDocument2 pagesCS1 Course Outlineapi-27149177Pas encore d'évaluation

- Nirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVDocument2 pagesNirma University Institute of Technology B.Tech. in Mechanical Engineering Semester IVKartik aminPas encore d'évaluation

- Potsdam Village Police Dept. Blotter April 12, 2018Document2 pagesPotsdam Village Police Dept. Blotter April 12, 2018NewzjunkyPas encore d'évaluation

- Aero 3 - 8 Anna's SyllabusDocument110 pagesAero 3 - 8 Anna's SyllabusShiva UPas encore d'évaluation

- CND - Clinical Round ChecklistDocument2 pagesCND - Clinical Round ChecklistMona Ismail AlsomaliPas encore d'évaluation

- Spirex": Onepiece Spiral Flexible CouplingDocument1 pageSpirex": Onepiece Spiral Flexible CouplingHazim HazimPas encore d'évaluation

- Lab 2Document8 pagesLab 2Hamid SaeedPas encore d'évaluation

- Steering Wheel Slip - Check: Pruebas y AjustesDocument2 pagesSteering Wheel Slip - Check: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURAPas encore d'évaluation

- Wind Energy Unit-EEEDocument6 pagesWind Energy Unit-EEEpfalencarPas encore d'évaluation

- MMPB 730 RerollDocument4 pagesMMPB 730 RerollLuis Padilla SandovalPas encore d'évaluation

- How To Draw and Read Line Diagrams Onboard Ships?: ShareDocument9 pagesHow To Draw and Read Line Diagrams Onboard Ships?: ShareShaif uddin rifatPas encore d'évaluation

- Check List For Chilled Water Secondary Pump: Sl. No Description RemarksDocument2 pagesCheck List For Chilled Water Secondary Pump: Sl. No Description Remarkssiruslara6491Pas encore d'évaluation