Académique Documents

Professionnel Documents

Culture Documents

Predicting Gravity-Drainage Performance Using A Three-Dimensional Model

Transféré par

Hamidreza AnjidaniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Predicting Gravity-Drainage Performance Using A Three-Dimensional Model

Transféré par

Hamidreza AnjidaniDroits d'auteur :

Formats disponibles

Predicting

Gravity-Drainage

Performance

Using a Three-Dimensional

H. N. HALL

MEMBER AlME

Abstract

Reservoir and prod[tcing Awictetlstics

can :overn the

deci.riou 10 me either a one-, nvo- or tllvee-dittrensiotzal

nwdcl for I)]aking prcdic(ions for gravity-drainage re.rerwir.~. Examples of conditions rcqniring one-, IWO- and

rhree-ditt tensional calc[dtuion r are given. In 196 I rhe author prcsen!ed a me[hod for predicting t)tte.dit??el~.sior?al

gvavi[y-drainage performance. Titi.~ work iws been extended

m ohluin a [ilreeditnensional

nmdel, wilici~ is desctvi~ed

and

jor )ri~icil a saitlple proi)lenz is pre.rentrd.

Introduction

Marry pnpcrs on gravity drainage or gas-cap drive- have

been presented for conditions where the reservoir is treated

as a single arcaI segment so that, in effect, only one-dimensional flow is considered, Other authors- have given evidence showing that the one.dimensional concept would be

unsatisfactory to predict reservoir performance for cerutin

(ypcs of reservoirs. Experience has indicated that specific

reservoir and producing conditions govern whether one-.

two- or three-cfimensional concepts must be used as a basis

for reliable reservoir performance predictions,

Previously the author presented a paper outlining a

method for predicting the performatlce of gravity-drainage

reservoirs? That paper treated the reservoir as a single

areal segment so that it was applicable for only one-dimensional flow. The work has been extended to obtain a threedimensional model that can be used to predict performance

of gravity-drainage

reservoirs. Although capable of being

three-dimensional, it can be used equally weII for one. and

two-dimensional predictions.

This paper discusses those reservoir and producing conditions governing the choice of model, and also describes

a three-dimensional

model suitable for predicting reservoir

performance in the more complex situations.

Discussion

PAN AMERICAN

TULSA, OKLA.

Model

PEWtOIEUM

CORP.

to predict the movement of oil and gas with~n the reservoir. The word model is used here to connote the combination of both a physical model and a mathematical

model based on the physical model. Certain types of

reservoir situations may be predicted suitably with a onedimensional model, whereas two- and three-dimensional

models may be required for other situations. This section

illustrates reservoir conditions associated with the use of

a specific type of model.

Many types of reservoir structures are such that gravity

drainage possibly could be an important factor in oil production. Production practices, as well as the nature of the

structure, can influence the type of model that should be

used. Obviously, it is impossible to discuss all combinations of reservoir structure and production practices that

might be encountered in gravity-drainage

reservoirs, The

following arc typical examples of conditions where a choice

must be made among a one-, two- or three-dimensional

model to predict reservoir performance satisfactorily.

Conditions Requiriog a

One-Dinlensionttl Model

Fig. la shows contours for an asymmetrical anticline in

which gravity drainage might bc expected to be important.

Fig. Ib depicts a cross-section along Line A-A in Fig. 1a.

Existence of a gas cap is a good clue that gravity drainage

will be an important factor in producing oil from this

type of reservoir. However, it is not essential since a gas

cap will form as oil is produced from the reservoi!, If the

proper combination

of reservoir permeability and withdrawal rates is present, the reservoir will behave like a

The Choice of Model

To predict reservoir performance, it is necessary to represent the reservoir by a physical model. A mathematical

model, based on the assumed physical model, then is used

Original

manuscript

received

in Society of Petroleum

Engineers

office

Revised manuscript

received

March S1. 1968. Paper

(SPJ2

1878) was $wesentcd at SPIi 42nd Annuat

Fall hleeting held in Houston,

Tex,

Ott: 1-4, 1!!67. 0 Copyright

l!J68 A.nericwn

Institute

of Mininr!,

Metallurgical,

and Petroleum

Engineers,

Inc.

AUK.11, 1967.

References 8iven at end of

This paper

cover 1968.

will

be

printed

Paper.

in

Tran8actioms

volume

243,

which

will

l-a

STRUCTURAL CONTOUR

Fig. lTypical

l-b

SECTION A-A

reservoir, one-dimensional

model.

.-

tank in that the gas-oil contact will move down-structure

as a level discontinuity, and there will be no significant

regional pressure gradient throughout

the reservoir. Oil

displaced by movement of the gas-oil contact spreads out

evenly and, in the case of operations not using pressure

maintenance,

gas evolved throughout

the structure will

move upward uniformly through the oil column into the

gas cap. The dominant movement of gas is updip, and the

movement of oil is downdip, therefore, it is one-dimensional. These conditions would be expected where properties (such as porosity and permeability)

are uniform

throughout the reservoir, where well spacing is uniform

and where the producing rate from the field is Iow in

comparison with the gravity reference rate.

Fig. 2a shows how the reservoir is separated into vertical

blocks, (In this paper, %ertical blocks denotes blocks

stacked in a vertical direction and horizontal

blocks

refers to blocks lying in the same horizontal plane, ) The

final physical model of the reservoir to be used in onedimensional calculations is shown in Fig. 2b. The reservoir

is characterized by a series of stacked blocks. The area of

ddch

block is assigned in such a way that the pore volume

of each block corresponds to the actual portion of the

reservoir it represents.

Conditions Requiring a

Two-Dimensional Model

Fig. 3a is a contour map for a slightly dipping reservoin Fig. 3b is a cross-section view along Line A-A. Cook

stated that even in reservoirs having low vertical perme.

ability (less than 10 md ), gas liberated from solution can

segregate to the top of the sand and then flow through a

secondary gas cap along the top of the sand into the mail;

gas cap at the crest of the structure. He stated that this

type of performance

was recognized as an important

mechanism active in massive sand reservoirs in western

Venezuela. Cook also concluded that gravity-segregation

performance

could be influenced greatly by a downdip

concentration of withdrawal in this type of reservoir. Fig.

~~#-

4 shows the gas-oil contacts that could result. Gas saturation that can build up subsequently in downdip areas

will lead to early GOR problems, Other authoma have

investigated the tilting of a gas-oil contact for crestal

gas-injection operations.

The general flow patterns that would exist under conditionsshown in Fig. 4precludethe

use of a one-dimensional

model for predicting reservoir performance.

If there are

no regional lateral variations in reservoir properties (dip,

permeability and porosity) and well concentration

is laterally unform, then this type of performance

could be

predicted with a two-dimensional model.

Fig. 5a depicts how the reservoir would be modeled by

breaking it up into areal segments that are further divided

into vertical blocks, The reservoir model is shown in perspective in Fig. 5b, with dashed lines showing the direction

in which oil and gas are assumed to flow.

Conditions Requiring a

Three-Din~eosiooal

Model

Theasymmetrical

anticline shown in Fig. 1 is used again

for illustrating reservoir and production ~~.ditions requiring a three-dimensional

model. Instead of having equal

well spacing, it is specified that a certain production rate

is to be maintained from the reservoir with a limited num.

ber of wells. The main question is whether there will be

sufficient lateral migration of oil to achieve a condition

similar to that shown in Fig. 6a where the gas-oil contact

A-

-A

GAS-OIL CONTACT

GAS-OIL

CONTACT

3-a

STRUCTURAL

CONTOUR

2-a

CROSS SECTION

3-b

SECTION A-A

Fig. 3Typical

reservoir, mwdimensionai

model.

PRODUCTION

(

GAS-OIL CONTACT

2-b

PERSPECTIVE

Fig. 2Physical

model

of reservoir for one-ditnerrsional

model.

Fig. 4-Gas-oil

contact profi!e, segregated flow

cross-section oj reservoir.

moves down uniformly. or whether there would be a

pronounced lowering of the gas-oil contact in the vicinity

of the production wells as shown in Fig, 6b, If movement

of the gas-oil contact is not uniform, it will be necessary

to consider the actual location of producing wells and

regional changes in porosity, thickness and permeability

to calculate this type of performance. Actual well production rates obviously cannot be estimated on average conditions; the true pressure in the vicinity of the well and

location of the gas-oil contact at the well also must be

considered.

Fig. 7 shows how a reservoir similar 10 that shown in

Fig. 1 worrId be modeled to make three-dimensional

reservoir predictions. The reservoir is separated into a large

number of areal segments. each subdivided into vertical

blocks. Each block is assigned a value of area, porosity,

permeability and fluid content corresponding to that ac.

[ually occurring in the reservoir. The three-dimensional

mathematical model constructed using this physical model

would account for oil and gas fiow in two lateral direc.

tions, and for the vertical direction. These are denoted in

Fig. 7 by arrows.

Three-Dimensional

process was described to solve these equations, and thus

predict gravity-drainage

performance for one-dimensional

systems,

Fig. 8 shows saturations obtained throughout a onedimensional gravity-drainage

model produced under primary.type depletion (i.e., no gas injection). The production

rate was a low percentage of the gravity reference rate,

and pressure was allowed to decline with time. Gas coming

out of solution in the oil column migrated updip into the

gas cap as oil flowed downward. The dynamic conditions

encountered were such that a near-constant

average gas

saturation was maintained in the oil column. Note that

S-OIL CONTACT

VARIOUS TIMES

Model

The one-dimensional

method previously referred to

is applicable for conditions of either complete or partial

pressure maintenance. or for normal pressure depletion.

Provisions were made to account for vertical variation in

permeability and fluid composition. The method was based

on representing the reservoir by a series of vertically

stacked blocks, similar to that shown in Fig. 2b, The

mathematical model that was developed accounts for the

flow of oil and gas at all points ~hroughout the section

while simultaneously satisfying material balance considerations. The numerical expressions developed consisted of

gas and oil material balance equations for each block in

the reservoir in conjunction with expressions describing the

flow of oil and gas between blocks. These equations are

implicit; i.e.. they involve unknown values of pressure and

fluid saturation at the end of a time step. An iterative

1

6-a

EQUAL MOVEMENT

L CONTACT

IOUS TIMES

6-b

UNEQUAL MOVEMENT

CROSS SECTION

--+-DIRECTION

5-b

PERSPECTIVE

Fig, 5Physical

M jy

OF OIL

R GAS MOVEMENT

11

${

model of resert,[)ir

calcltladons.

I PRODUCTION

Fig. 7Physicrd model oj reservoir f,,r three-dimemionrd

crrlculrrtimz.s,

behind the front, especially near the top of the structure.

most of the change in saturation occurs as a result of oil

shrinkage rather than from flow.

A three-dimensional

calculation method was developed,

based on the one-dimensional method previously described.

by considering a large number of one-dimensional

(vertical) areal segments linked together by specifying the

migration of oil and gas between adjacent blocks in the

segments. Fig. 9 shows a typical block in an areal segment

with four surrounding blocks in adjacent areal segments.

All these blocks are considered to be at the same eleva.

tion. At the start of a time step, pressures and saturations

are known for each block, Actual migration that will

occur during a time step cannot be specified because

the values of pressure and saturation in the surrounding

blocks at the end of a particular time step will not bc

known. Therefore, it was decided to specify the migration

during any time step by explicit methods. In other words.

for calculating horizontal migration of oil and gas, pressure

and saturations for the five horizontal blocks in Fig. 9

were estimated at the mid-point of the next time step by

extrapolating

from previously calculated

values at the

previous two time levels. For the first time step, pressure

it time I 1 is assumed to be equal to pressure at time I.

[n starting from static conditions, very little error is made

by this assumption since the system is in equilibrium and

the first time step is short. Subscripts a, j and i in Fig. 9

correspond to vertical, x and y indicators, respectively.

for designating blocks, Eq. 1 is an expression for pressure

at any general point (designated as the point at space

location a, i, j) at a time midway between time I and

timet +1.

(P)l+i = W)f +

Y2

[(i), (P)f.1l

.,.

(l]

Eq. 2 expresses the rate of oil migration at 14.7 psi and

60F between blocks <t, i, j, and a, i 1, j.

(E,.-),+,

[(P

),+,

A similar expression

is given as Eq. 3.

= (M-)

_ (p%!.,.,

)t+il

for giis migration

(2)

at 14.7 psi and 60T

1.0

-.

5

F .8

u

2 ,7

\t

w

z

g ,5

\,

&

~ .6

Z

F .4

~

g .3

a

w

WI,2

w

ORIGINAL

GAS-OIL

CONTACT

$.,.!,l.l,,

).

(Was.,.,

.!.,)

In Eqs. 2 and 3, # and Q are evaluated on the basis of

saturation existing at the start of each time step.

Writing expressions for flow between the a, i, j block

and the three adjacent blocks, the totaI horizontal migration of oil and gas into the a, i, j block is given by Eqs. 4

and 5. This is designated as the a block to be consistent

with terminology in the previous paper (i.e., it is the ath

vertical block of an areal segment).

(E,,+),., (1:,,,

(fib.,),.:

-, (f;,,,,

(E,,;),,,

T

)..

(E*.)!,)

)! :

(E,,;),,j

(~h,,,..,

(4)

Ll)t>

J. ,

(5)

), , (.E*.),,,

(E,,,,

~hmc migration terms then are used as a pseudoproduction term in the one.dimensional

gravity-drainage

prediction method, For example. Eq. 6 gives a materiaI balance

on the gas content of a block in the oil column (this

equation is the same as Eq. 13, in the Appendix of Ref. 7).

1

(.s;),.,

(P)

1.1(~)l+1

[

(R,),

-(K),

[

- R:-]

(B.,),.,

(R,),., (

1

(eC),

~ ($[p)~

-r (e.,),,,

~

.

1[

(1

.s ,)

(B:.,

$-

At j (e.,), -t (e. ),.,

~

( v+) ~[

1[

::::~:1

(R,-), -t (R, I,.,

(n,), i- (B, ),., 1

(!<,)! + (ft. ),.,

(B2), + (B,),., 1

)(p ) (8) Y) (): (J

([

(eu), (), (8<), + (t,.)(., (p

(aa)fl

(&f.!

(R,*),+,

[(P),+* (p ),+~]. ~E=

+ (w..)

-./) .

0+

(n:)

. [( P)(.) (P) t+tltl ( P*)fsi (~*)1.:

. . . . . . . . . . . . (3)

-[-

. (#;{-)

1

o (~~-j,.:

),,*

(1%,

2)-

q) [K4)~(]{)

1

), r

1:)

e.,,+,,.

@

OIL

GAS

\l

.I

.2

.4

.6

.8

1.0

LIQUIDSATURATION(FRACTION)

Fig. S-Satwation

distribution determined

one-ditnensional lnodel,

by

6)

Fig. 9Blctck configuration for three-ditwtssionai

calculations.

This equation is modified by Eqs. 4 and 5 to include

horizontal migration of oil and gas, and becomes Eq. 7.

1

(s,,), , - -

(P<)t,l(~)l.l -

(R:) , ;,-

@~,

.

.

(R:),

(B7-),

[-

-S)

-$:+::1S;)r[(p)()

f-%%l+(;a)

,,. l), ~ (r,, .-,),.,

_

-_

(R.-),

+ (l?,),+,

(e,

(Boo-),+, 1

2

1

[ -(B.-),+

{1

_ ~,,,.: ),+- (e,,),:, (R.), + (R.),., .

.

2

(B.,), + (B,,),; 1

1[

[

(ej ), (P

)i(8)t

-: (~.; a)(+!

(Po-)

t.l(~aO])t.l

.

Esmnplc of Predicted Reservoir

Performance Using a Three-Dimensional

Gravity-Drainage

Model

~-

[--

([

(1,,

~,(p?,.

fl.,

),

~*J

),

(e,),., (p),.

.,.

. .

(7)

131. 16 In th~ previous paper is a material balance cm the

oil con[cvst of a block in the oil column, and becomes Eq

8 on modification

by including horizontal oil and ga.

migrali(~n

(B,:),

(M )(+)

+ (B.,),.l

p)=(Rr)(+))-{[

(P) (p.,)

(p),

144

[

(E>,.),.,

[1

-1-

(q;),

(B,,j,-~

_:,

1

1

(v+)

A-i

(l-.s,,

) (.s,,), [

.$,.) (s,) !.!

,(

(B,,),

(N),l

-

Fig. IO is a contour map of a hypothetical reservoir.

Origin~l oil in place was 650 million bbl, and original

reservoir pressure was 4,100 psia at a datum of 7,200 ft

subsea, Fig 11 represents values of permeability

times

thickness, and Fig. 12 shows porosity times thickness

values used. Connate water saturation used was 18 percrmt.

A gas-oil contact existed at 7,070 ft subsea cm discovery.

Production wells are located as indicated. Total oil production was maintained constant at 20,000 STB/D with wells

being produced al equal rates. All oil production came

from blocks below the gas-oil contacl. ~-he section open in

tiny well was at least 10 ft below the location of the gas-oil

contac!. No coning was assumed in this example during a

time step.

Fluid properties were selected in such a way that they

varied with structure in the reservoir. Fluid at the gas-oil

1(l?.,)=

((.),

1[ (BO);+-(-B7),.;

(e,,),+ (e,,-),.,

(bV*j7+@}*jT

A similar procedure is used for modifying all other oil

and gas material balance equations listed in the Appendix

of the paper describing the one-dimensional

method for

predicting gravity-drainage performance.

By using this technique to specify horizontal migration

for gas and oil flow, the reservoir can be divided into a

large number of areal segments and the implicit approach

for a single segment can be utilized for each segment to

predict three-dimensicmal performance.

(8;

B

#

AL

IL

CT

Fig. 10SlrucVurol cotllwr~,

Fig. 1 lPermeabifi/y

.wnple problew.

fhickness cm~lwws, sclmpk

reservoir (darcy-feef).

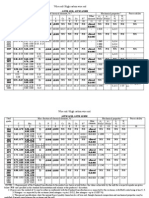

TABLE 1 FLUID

PROPERTIESSAMPLE

PROBLEM

Bottom of

Reservoir

Top of

Reservoir

.

..

Saturation pressure (psig)

Oil viscosity (cp)

Oil reservoir volume factor

Gas in solution (scf/STB of oil)

2,150

0.7

4,300

0.26

1.26

1,84

1,720

700

..-

contact had a saturation pressure of 4.300 psi and decreased downdip to a value of 2,150 psi. Fluid properties

are given in Table 1. Variations in saturation pressure and

msociated fluid properties were not linear,

The reservoir was represented by the type of physical

model shown in Fig. 7, and 22 rectangular, areal segments

were used. In the j direction (along the major axis of the

reservoir).

blocks were five times the length in the i

direction. Each block was25 ft high.

Fig. 13 shows pressures and GORs calculated for 25

years of production from this reservoir. The solid line in

the pressure. vs-time curve in Fig. 13 represents the calculated, volumetrically

weighted average reservoir pressure

at a datum of 7,200 ft subsea. The circles represent an

average of reservoir pressuie in the vicinity of producing

wells at various times, Note that the average of the pressures in the vicinity of the wells is lower than the average

reservoir pressure. This is emphasized further by Fig. 14.

which represents pressure contours throughout the reservoir after 20 ytars of production history. The shape of

the reservoir pressure-vs-tirne

curve is characteristic

of

undersaturated

conditions existing in the reservoir at the

start of production. Pressure declines rapidly to the saturation pressure, and then declines at a slower rate due to

evolution of gas in the oil column. The fact that saturation pressure changes with structure makes this a very

gradual change as compared with predicted performance

using standard material balance calculations where an oil

with a single saturation pressure is considered.

The produced GOR shown in Fig. 13 increased slightly

from an initial value of 970 scflbbl during the first 5

years of production. This reflects the fact that all wells

were producing from the oil column only, and due to

permeability variation the largest amount of oil came from

4000

3000

u

:

m

w

~

2000

1000

10

YEARS

15

OF PRODUCTION

20

25

2000

2500

Ffg. 14Presswe

PRODUCING

WELLS

conrours, sample problem

ptductirm).

(20 ye[m

,Ij

low in [he structilrc. MOSI of the produccri oil was still

undcrsaturatwi duc to the variation in saturation pressure

with elevation. The decline in GOR with time indicates

that cmmtcrcurren[

flow existed in the oil column below

the gas.l. il contact, As rcwrvoir prcssuiw declined, produced

GORs were only slightly higher than solution GOR, since

most of the gas evolved in the reservoir migrated updip

into the gas cap. The liquid saturation at wrrious times

changcxi in a manner similar to that shown in Fig. 8 where

u iow gas saturation is observed heiow the gas.oii contac[

at all times.

Figs. 15a and 15b represent the location of the gas-oil

contact aiong Lines A-A and B-B of Fig. 10 after 20

years of production. It is obvious that horizontal migration

has been ineffective in maintaining a uniform rate of advance of the gas-oil contact throughout the reser joir. Oil

has migrateci from the edges of the reservoir; however,

most of the produced oii has come from movement of

the gas-oii contact in the vicinity of the producing wells.

Aiong the iine A-A only the section at the extreme edges

is underwturated,

whiie along B-B, a large portion of the

southern end of the field was under.saturated.

A I(hough constant

production rates for each wcii were

considered in the sampie problem, actuai ikid practices

may be such !hat individual weli.producing rates wouhi he

aiiocated on tnc basis of equal drawdown, equal wellheati

llowing pressures or some other criteria. The uneven movement of gas-oil contact with time, and regional variations

in pressure throughout the reservoir, indicate that individual weli productivity wili not rermin constant throughout

the iife of a reservoir, anti that it cannot he cstimate[i

accurately by considering average reservoir conditions.

ro obtain the best estimate possibie regarding future performance of a reservoir of this type, it is essential to

consider actual Ioctition of wells and regional changes in

porosity, thickness anti structure.

B,, = oil formation volume factor (bbl at reservoir temperature and pressure) /(bbl at

60F and 14.7 psi)

e. = oii influx rate in verticaI dirwtion, cu ft/

day at reservoir temperature and pressure

Cfl= gas influx rate in verticai direction, cu ft/

day at reservoir temperature and pressure

E,. = horizontal oii migration rate between acijacent blocks at the same elevation, cu

ft/day at 14.7 psi and 60F

E,, = horizontal gas migration rate between adjacent blocks at the same elevation, cu

ft/day at 14,7 psi and 60F

F = eievation difference between points in the

reservoir (used to determine gravity gradient between blocks ), ft

k = absolute permeability, darcies

k , = relative permeability to oii

k,, = relative permeability to gas

L = distance from mid-point of block to edge

of other block, ft

M = 6,33 X absolute permeability X cross-sectional area, da rcics X sq ft

P = pressure, psi

q = oii producing rate, cu ft/{iay (measured al

60F and 14.7 psi)

SECTION B-B

R=

producing GOR, cu ft/cu ft (measured a

60F and 14.7 psi)

R. = soiutiors GOR (gas soIubiihy in oii). cu ft/

cu ft (measured at 60F anti i4.7 psi)

connate water saturation

gas saturation

total pore spacc$ cu ft

lempcrature, F

time intcrvai, days

gtis compressibility fachw

#/a, i.t. <#.

l

1,1 ~

ctlcctive oii pcrmcabiiit y

(iength X ofi viscosity)

=

(k,:{ ),(k,o-),

. ..

.- - -.. _

[(k,: (),(U-J~+

(k,o-)J)]J)]

l/(ft x Cp)

1

(/I.,,*),

p,, = ciensity of oii, lb/cu ft

S = conversmr factor = (ii i 4.7). 1520/(460

T)] < (l/z)

t% = oii viscosity, cp

l% = gas viscosity, cp

# = porosity

Superscripts

a = number

of vertical blocks in areal segment

i = areal segment in ith row of areal array o

segments

j = areai segment in jth column of areal array

of segments

The following superscripts

blocks rr, i-l, j and a, i, j,

arc dcscrihed

in terms

of

(I,i, j;a, i 1,j = conditions between hi~cks (I, i, j and G

i1, j

* = Value existing between blocks referred to

for p,,, N,,, 8, p.. h,, and p, this superscript indicates the average value at the

boundary of Mocks r?,i 1. i and 6,i, j

t = vaiue at time I

t+l = value at time (t+l)

r-l-% = value at mid-point of time interval

References

1, Stewart, F. M., ffarthwaite, D. L. and Krebil, F, K.: Pressure Maintenance by Inert Gas Injection in the High Relief

Elk Basin Field, Trans., AIME ( 195S) Vol. 204, 49-55.

2. SI_sreve,D. R, and Welch, L. W., Jr.: Gas Drive and Gravity

Drainage Analysis for Pressure Maintenance Operations,

Trans., AIME (1956) Vol. 207, 136-143.

3. Kirby, J. E., Jr., Stamm, H. E. IIJ and Schnitz, L. Il.: Calculation of the Depletion History and Future Performance of

a Gas-Cap-Drive Reservoir, Tram., AIME (1957) Vol. 210,

218.226.

4. Martin, John C.: Reservoir Analysis for Pressure Maintenance Operations Based on Complete Segregation of Mobile

Fluids, Trans., AlME (1958) Vol. 213, 220-227.

5, Cook, Robert E.: Analysis of Gravity Segregation Perform-

S24

During Natural Depletion, SOC. Pet, Eng. J, (Sept,,

1962) 261-274.

6, Sheldon, J, W. and Fayer~, F. J,: The Motion of an Interface Between Two Fluids m a Slightly Dippi~lg Porous Medium, SOc, Pel. .Errg.J. (Sept., 1962) 275-282.

7, Hall, H, N,: Analysis of Gravity Drainage, J. Pet, Tech.

**

(Sept., 1961) 927-936,

anee

Ii. N, Hall is u .sfafl reseurch en~inrw

working in ihe Prrxlwtion

Research

Peir,>leuttt C[>rp,,v

Div. cjf P(IIIA tnericu)t

Re.wircil Cm ter, IuI.Yu. HiIll received

a

BS

}ro)u

drgrw

Tul.wl.

JfJURNA1.

degree

in

okkihot)u:

chcinical

Stuie

itl tmi IIwt }I(ifirs

OF

PRTROI.F.VM

tw.gineerittg

U. atrd UN MS

frf utl Tk,

V. 0/

TECHNOLOGY

Vous aimerez peut-être aussi

- Production Performance of Gas Condensate Reservoirs - Compositional Numerical ModelDocument13 pagesProduction Performance of Gas Condensate Reservoirs - Compositional Numerical ModelJamalPas encore d'évaluation

- Horizontal Barriers For Controlling Water ConingDocument8 pagesHorizontal Barriers For Controlling Water ConingBahman MatouriPas encore d'évaluation

- The Development, Testing, and Application of A Numerical Simulator For Predicting Miscible Flood PerformanceDocument9 pagesThe Development, Testing, and Application of A Numerical Simulator For Predicting Miscible Flood PerformancechazingPas encore d'évaluation

- Water Coning For V H WellDocument12 pagesWater Coning For V H WellBrayanCastañoPas encore d'évaluation

- Frontal AdvancementDocument4 pagesFrontal Advancementshashwatsharma8Pas encore d'évaluation

- Material Balance Calculations for Solution-Gas-Drive ReservoirsDocument12 pagesMaterial Balance Calculations for Solution-Gas-Drive ReservoirsMuhammed Al-BajriPas encore d'évaluation

- Critical Rate For Water ConingDocument8 pagesCritical Rate For Water ConingHari HaranPas encore d'évaluation

- SPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoirDocument5 pagesSPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoircmkohPas encore d'évaluation

- Spe 131787Document15 pagesSpe 131787downloader1983Pas encore d'évaluation

- Modeling Three-Phase Flow in EOR ReservoirsDocument15 pagesModeling Three-Phase Flow in EOR ReservoirsGabo Merejildo QuimiPas encore d'évaluation

- Articulos Yacimientos de GasDocument27 pagesArticulos Yacimientos de GasChristian Narváez BarajasPas encore d'évaluation

- SPE 153022 A Workflow For Modeling and Simulation of Hydraulic Fractures in Unconventional Gas ReservoirsDocument11 pagesSPE 153022 A Workflow For Modeling and Simulation of Hydraulic Fractures in Unconventional Gas Reservoirstomk2220Pas encore d'évaluation

- Three Phase CalculationDocument11 pagesThree Phase CalculationKhalid Al-RawiPas encore d'évaluation

- Evaluation of Multiple Geostatistical Models Using Coarse GridsDocument16 pagesEvaluation of Multiple Geostatistical Models Using Coarse Gridspande_100Pas encore d'évaluation

- Res Eng CH 18Document76 pagesRes Eng CH 18mohammed yasharPas encore d'évaluation

- Sca2013 028 PDFDocument14 pagesSca2013 028 PDFDeGees Efosa AiguiPas encore d'évaluation

- Multiphase Pressure Buildup AnalysisDocument13 pagesMultiphase Pressure Buildup Analysismiguel_jose123Pas encore d'évaluation

- Introduction To Applied Reservoir Engineering: Es V Yb AsDocument18 pagesIntroduction To Applied Reservoir Engineering: Es V Yb AsjhalendrafbPas encore d'évaluation

- IPTC16669Document14 pagesIPTC16669jangolovaPas encore d'évaluation

- AIAA-2000-0858 PaperDocument12 pagesAIAA-2000-0858 PaperksvvijPas encore d'évaluation

- MSDocument17 pagesMSIndra Bangsawan100% (1)

- Efficiency of Gas Injection Scenarios For Intermediate Wettability: Pore-Network ModellingDocument6 pagesEfficiency of Gas Injection Scenarios For Intermediate Wettability: Pore-Network ModellingRosa K Chang HPas encore d'évaluation

- Material Balance Calculations For Solution-Gas-Drive ReservoirsDocument15 pagesMaterial Balance Calculations For Solution-Gas-Drive ReservoirsRashaq AL-HeetyPas encore d'évaluation

- SPE 118173 Using A Dynamic Coupled Well-Reservoir Simulator To Optimize Production of A Horizontal Well in A Thin Oil RimDocument8 pagesSPE 118173 Using A Dynamic Coupled Well-Reservoir Simulator To Optimize Production of A Horizontal Well in A Thin Oil RimDavide BoreanezePas encore d'évaluation

- SPE-199074-MS Solving The Challenges of A Complex Integrated Production System in Camisea Field Using Novel Modeling TechniquesDocument16 pagesSPE-199074-MS Solving The Challenges of A Complex Integrated Production System in Camisea Field Using Novel Modeling TechniquesEfrain Alex Morales CaballeroPas encore d'évaluation

- SPE 68666 Analysis of A Non-Volumetric Gas-Condensate ReservoirDocument9 pagesSPE 68666 Analysis of A Non-Volumetric Gas-Condensate ReservoirSergio A L'pez CPas encore d'évaluation

- Understanding pressure buildup tests affected by phase redistributionDocument17 pagesUnderstanding pressure buildup tests affected by phase redistributionhari6622100% (1)

- Article HolidayDocument10 pagesArticle HolidaygregPas encore d'évaluation

- High Relief Pool Performance EvaluationDocument9 pagesHigh Relief Pool Performance EvaluationcarolinatabajaraPas encore d'évaluation

- Spe 189279 StuDocument26 pagesSpe 189279 StujuansebosornobPas encore d'évaluation

- SPE 63158 Inflow Performance Relationships For Gas CondensatesDocument14 pagesSPE 63158 Inflow Performance Relationships For Gas Condensatesabnou_223943920Pas encore d'évaluation

- Dual completion configuration for controlling water coning in gas wellsDocument133 pagesDual completion configuration for controlling water coning in gas wellsTeresa Espada PadillaPas encore d'évaluation

- Dual completion configuration for controlling water coning in gas wellsDocument30 pagesDual completion configuration for controlling water coning in gas wellsTeresa Espada PadillaPas encore d'évaluation

- Instrucciones de Acceso A PlataformaDocument12 pagesInstrucciones de Acceso A PlataformafelixPas encore d'évaluation

- Evaluating Vertical Lift Performance in Oil WellsDocument9 pagesEvaluating Vertical Lift Performance in Oil Wellsmiguel_jose123Pas encore d'évaluation

- Dokumen - Tips Brian F Towler Fundamental Principles of Reservoir Engineering Spe TextbookDocument2 pagesDokumen - Tips Brian F Towler Fundamental Principles of Reservoir Engineering Spe TextbookHéctor GallardoPas encore d'évaluation

- A New Analytical Model To Predict Oil Production For Cyclic Steam Stimulation of Horizontal WellsDocument19 pagesA New Analytical Model To Predict Oil Production For Cyclic Steam Stimulation of Horizontal WellsjhonPas encore d'évaluation

- Correlations For Predicting Oil Recovery by Steamflood: SPE-AIME, Standard Oil Co. of CaliforniaDocument8 pagesCorrelations For Predicting Oil Recovery by Steamflood: SPE-AIME, Standard Oil Co. of CaliforniaVasundhara SinghPas encore d'évaluation

- Reservoir Geomechanics With ABAQUSDocument15 pagesReservoir Geomechanics With ABAQUSDaani Olora100% (1)

- Paper 2 Word FixDocument16 pagesPaper 2 Word FixICHSAN AL SABAH LPas encore d'évaluation

- Rod Loading of Reciprocating CompressorsDocument18 pagesRod Loading of Reciprocating Compressors최승원Pas encore d'évaluation

- Shuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development ChallengesDocument12 pagesShuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development Challengesari_siPas encore d'évaluation

- Gas FloodingDocument6 pagesGas FloodingJan David InocPas encore d'évaluation

- Capillary Pressure and Relative Permeability Corre PDFDocument18 pagesCapillary Pressure and Relative Permeability Corre PDFcristinaPas encore d'évaluation

- Well Test Analysis in Gas-Condensate Reservoirs: Impact of Wellbore DynamicsDocument4 pagesWell Test Analysis in Gas-Condensate Reservoirs: Impact of Wellbore DynamicsKaouachi Ahmed LouayPas encore d'évaluation

- Una Metodología para Determinar La Altura de La Columna de Líquido de Los Pozos de Elevación de Gas IntermitenteDocument10 pagesUna Metodología para Determinar La Altura de La Columna de Líquido de Los Pozos de Elevación de Gas IntermitenteCeleste ZapataPas encore d'évaluation

- An Evaluation of Recent Mechanistic Models of Multiphase Flow For Predicting Pressure Drops in Oil and Gas WellsDocument11 pagesAn Evaluation of Recent Mechanistic Models of Multiphase Flow For Predicting Pressure Drops in Oil and Gas WellsfanziskusPas encore d'évaluation

- KPIM of GasCondensate Productivity - Prediction of Condensate Gas Ratio (CGR) Using Reservoir Volumetric BalanceDocument10 pagesKPIM of GasCondensate Productivity - Prediction of Condensate Gas Ratio (CGR) Using Reservoir Volumetric BalanceIrwan JanuarPas encore d'évaluation

- SPE 27343 Sand Production As A Viscoplastic Granular FlowDocument10 pagesSPE 27343 Sand Production As A Viscoplastic Granular FlowMuhammad SyarifudinPas encore d'évaluation

- 10 The Material Balance Equation: InitialDocument46 pages10 The Material Balance Equation: InitialAyesha AzizPas encore d'évaluation

- 43 - Gas-Injection Pressure Maintenance in Oil ReservoirsDocument19 pages43 - Gas-Injection Pressure Maintenance in Oil Reservoirsrizal tri susiloPas encore d'évaluation

- Ep Petrochina MangroveDocument3 pagesEp Petrochina MangroveStiveGrajalesPas encore d'évaluation

- OTC-26450-MS Application of Artificial Intelligence For Water Coning Problem in Hydraulically Fractured Tight Oil ReservoirsDocument22 pagesOTC-26450-MS Application of Artificial Intelligence For Water Coning Problem in Hydraulically Fractured Tight Oil ReservoirsAbbas AlkhudafiPas encore d'évaluation

- Spe 21221 MSDocument30 pagesSpe 21221 MSkapereshemPas encore d'évaluation

- Gas ConingDocument10 pagesGas ConingMarcelo Ayllón RiberaPas encore d'évaluation

- Advanced Chemical Reaction Engineering CBE9450 ProjectDocument21 pagesAdvanced Chemical Reaction Engineering CBE9450 Projectdaoud saleemPas encore d'évaluation

- Mathematical Geoenergy: Discovery, Depletion, and RenewalD'EverandMathematical Geoenergy: Discovery, Depletion, and RenewalPas encore d'évaluation

- Well Production Performance Analysis for Shale Gas ReservoirsD'EverandWell Production Performance Analysis for Shale Gas ReservoirsPas encore d'évaluation

- Working Guide to Reservoir Rock Properties and Fluid FlowD'EverandWorking Guide to Reservoir Rock Properties and Fluid FlowÉvaluation : 3 sur 5 étoiles3/5 (1)

- 00018428Document13 pages00018428Hamidreza AnjidaniPas encore d'évaluation

- Review On Gravity Drainage PerformanceDocument10 pagesReview On Gravity Drainage PerformanceHamidreza AnjidaniPas encore d'évaluation

- Numerical Simulation of Naturally Fractured Reservoirs: F. Sonier, Souillard, BlaskovichDocument9 pagesNumerical Simulation of Naturally Fractured Reservoirs: F. Sonier, Souillard, BlaskovichHamidreza AnjidaniPas encore d'évaluation

- 00028641Document10 pages00028641Hamidreza Anjidani100% (1)

- Effects of Fracture Boundary Conditions On Matrix-Fracture Transfer Shape FactorDocument21 pagesEffects of Fracture Boundary Conditions On Matrix-Fracture Transfer Shape FactorHamidreza AnjidaniPas encore d'évaluation

- Spe 84184-Prediction of Oil Production by Gravity DrainageDocument8 pagesSpe 84184-Prediction of Oil Production by Gravity DrainageHamidreza AnjidaniPas encore d'évaluation

- 31-j Por MediaDocument14 pages31-j Por MediaHamidreza AnjidaniPas encore d'évaluation

- Analytical Modeling of Oil Production From A Matrix Block by FreeDocument24 pagesAnalytical Modeling of Oil Production From A Matrix Block by FreeHamidreza AnjidaniPas encore d'évaluation

- Experimental Studyand Modeling of Gravity DrainageDocument11 pagesExperimental Studyand Modeling of Gravity DrainageHamidreza AnjidaniPas encore d'évaluation

- Fields AbrivationDocument1 pageFields AbrivationHamidreza AnjidaniPas encore d'évaluation

- Spe 84184-Prediction of Oil Production by Gravity DrainageDocument8 pagesSpe 84184-Prediction of Oil Production by Gravity DrainageHamidreza AnjidaniPas encore d'évaluation

- Analytical Modeling of Oil Production From A Matrix Block by FreeDocument24 pagesAnalytical Modeling of Oil Production From A Matrix Block by FreeHamidreza AnjidaniPas encore d'évaluation

- Comparing Core Analysis Data To Field Observations For Gravity Drainage Gas InjectionDocument12 pagesComparing Core Analysis Data To Field Observations For Gravity Drainage Gas InjectionHamidreza AnjidaniPas encore d'évaluation

- XU - Modeling Unsteady State Gravity Driven Flow in Porous MediaDocument7 pagesXU - Modeling Unsteady State Gravity Driven Flow in Porous MediaHamidreza AnjidaniPas encore d'évaluation

- SPE 114164 (Rushing) Rock Typing Keys Productivity Tight Gas SandsDocument31 pagesSPE 114164 (Rushing) Rock Typing Keys Productivity Tight Gas SandsFord EtisalatPas encore d'évaluation

- Chapter 5 Amyx Reservoir Fluid PropertiesDocument89 pagesChapter 5 Amyx Reservoir Fluid PropertiesHamidreza AnjidaniPas encore d'évaluation

- Chapter 6 Amyx Water PropertiesDocument25 pagesChapter 6 Amyx Water PropertiesHamidreza AnjidaniPas encore d'évaluation

- Amines PDFDocument1 pageAmines PDF최승원Pas encore d'évaluation

- CARB in Industrial FansDocument8 pagesCARB in Industrial FansJurun_Bidanshi100% (1)

- Ethanol Production by Fermentation and DistillationDocument3 pagesEthanol Production by Fermentation and DistillationChris WarnerPas encore d'évaluation

- Equilibrium Calculation For DMEDocument8 pagesEquilibrium Calculation For DMEAbhishek KumarPas encore d'évaluation

- Sensibilidad y Especificidad Del Gammagrama Ciprofloxacino-Tc99M Sensibilidad y Especificidad en Osteomielitis Infantil (AOM 2010)Document4 pagesSensibilidad y Especificidad Del Gammagrama Ciprofloxacino-Tc99M Sensibilidad y Especificidad en Osteomielitis Infantil (AOM 2010)Simon ChangPas encore d'évaluation

- Mahatma Jyotirao Govindrao PhuleDocument12 pagesMahatma Jyotirao Govindrao PhuleSagar V. ThakkarPas encore d'évaluation

- DentinDocument133 pagesDentindentistry24100% (1)

- Bio Molecules 9Document3 pagesBio Molecules 9SilVI MARDELPas encore d'évaluation

- Scotch Tape Method: Producing Graphene FlakesDocument3 pagesScotch Tape Method: Producing Graphene Flakestaniya balochPas encore d'évaluation

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan RamasamyPas encore d'évaluation

- Lecture 18 & 19 - Abrasives and Temporary Crowns Material (Slides)Document57 pagesLecture 18 & 19 - Abrasives and Temporary Crowns Material (Slides)JustDen09Pas encore d'évaluation

- Recovery and Purification of Lactic Acid From Fermentation BrothDocument185 pagesRecovery and Purification of Lactic Acid From Fermentation BrothBilli CostanPas encore d'évaluation

- Noller, Et Al (2000) Introduction To Quaternary GeochronologyDocument11 pagesNoller, Et Al (2000) Introduction To Quaternary GeochronologyAbellPas encore d'évaluation

- Aucet 2014 BrochureDocument43 pagesAucet 2014 BrochurebtvlnarayanaPas encore d'évaluation

- CentralTexas What Is Theta JA-CTEADocument38 pagesCentralTexas What Is Theta JA-CTEASai Santhosh ManepallyPas encore d'évaluation

- EOR Screening-TaberDocument14 pagesEOR Screening-TaberAjeng AyuPas encore d'évaluation

- Ground Slab CourseDocument36 pagesGround Slab CoursezainalharrisPas encore d'évaluation

- 1 02 Coco PDFDocument13 pages1 02 Coco PDFsandeep lalPas encore d'évaluation

- Patrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossDocument9 pagesPatrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossBrahian Alexander RinconPas encore d'évaluation

- Test II. Multiple Choice. Encircle The Letter of The Correct AnswerDocument1 pageTest II. Multiple Choice. Encircle The Letter of The Correct AnswerjoylynPas encore d'évaluation

- High Carbon Wire RodDocument9 pagesHigh Carbon Wire Rodninganray6316100% (1)

- Sodium Alginate TestingDocument2 pagesSodium Alginate TestingImran Anwar0% (1)

- Sulfur and Nirogen IndustriesDocument58 pagesSulfur and Nirogen IndustriesSarah SanchezPas encore d'évaluation

- Fundamentals of Natural Gas Liquid MeasurementsDocument9 pagesFundamentals of Natural Gas Liquid Measurementsmakasad26Pas encore d'évaluation

- Electricity PowerPoint-0Document34 pagesElectricity PowerPoint-0Ryan P. YapPas encore d'évaluation

- Alternative-Refrigerants R22 GBDocument12 pagesAlternative-Refrigerants R22 GBMon PerezPas encore d'évaluation

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiPas encore d'évaluation

- Reforming 2Document15 pagesReforming 2HAFIZ IMRAN AKHTERPas encore d'évaluation

- An114 Hand Soldering Tutorial For The Fine Pitch QFP DevicesDocument22 pagesAn114 Hand Soldering Tutorial For The Fine Pitch QFP DevicesPat Jojo SadavongvivadPas encore d'évaluation