Académique Documents

Professionnel Documents

Culture Documents

Job Safety Analysis For Rebar Fixing

Transféré par

Jayvee Baradas ValdezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Job Safety Analysis For Rebar Fixing

Transféré par

Jayvee Baradas ValdezDroits d'auteur :

Formats disponibles

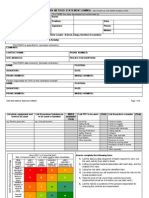

JOB SAFETY ANALYSIS

Project No.

SADARA-RTIP

Task Order/Contract No.:

Prepared By:

NARAYANAN KUTTY

Company Name:

OASIS PROJECT SUPPORT SERVICES

SME/BSNEI

RTIP-SC-002-1K

Date:

29-08-2012

Building:

N/A

Area: SNEI LAYDOWN YARD

Work Scope/Description: REBAR FIXING,BARRICATION,GRADING& LEVALING,COMPACTION,ERECTION OF TEMPERORY

SHELTER,PREPARARING FENCE,LOADING& UNLOADING MATERIALS(FENCE MATERIALS, SCAFFOLDING MATERIALS& ROAD

MARKING MATERIALS, BASE COURSE& MAREL) PREPARATION OF ROAD.

Emergency Contact Person(s):

Primary

SHAMEEM

Project HSE

NARAYAANAN KUTTY

Emergency Radio/Phone No.:

0544452852

Specific Work Location(s): SENI LAYDOWN AREA

Pre-Task Walkthrough Conducted:

Yes

0546108042

No

HSE Program Reference (***):

Corporate/000

Project-Specific

Before issuing a Permit to Work, the Issuer must review the job and consider the following:

1. Do you know EXACTLY what the intended job entails?

2. Do you need to personally visit the work area?

3. Does the employee about to do the job also know EXACTLY what the job entails?

4. Does the Permit to Work fall within your level

HAVE YOU CONSIDERED?

Accessibility

Area Classification

Cramped Work Area

Dust, Powders, Solids

Electric Power

Fumes, Odors

Gases, Flashing Liquids

Ignition of Surrounding Material

Motive Power

Noise

Obstructions, Falling Objects

Other People

Other Sections

Atmosphere Testing Frequency

Auxiliary Lighting

Breathing Protection

Emergency Exit Route

Environmental Safeguards

Footwear

Gloves

Goggles

Head Protection

Superintendent Appointed

Dress Standards/Protective Clothing

PPE Checked

Test Date of Equipment Checked

Contractor Insurance Checked

Plant Standards Communicated

Contractor Briefing Completed

Copyright 2010, Fluor Corporation. All Rights Reserved.

Form Date: 23Dec2010

Portable Electrical Equipment

Pressure

Process and Other Liquids

Radioactive Emissions

Residual Process Materials

Restricted Field of Vision

Services Steam, Water, Air

Temperatures

Traffic Ways

Vapor

Weather Conditions

Welding Flash

Working at Height

Hearing Protection

Ladder, Scaffolding

Safety Spectacles

Standby Person(s) How many?

Standby Persons Briefing

Standby Persons Protection

Ventilation

Written Procedure

Site Statutory Induction Completed

Names on Plant Access Board

ID Badging, where appropriate

Contractor Licenses Checked

HSE Training Completed

Skill Training and Accreditation

Checklist Completed

Page 2 of 3

Health, Safety, and Environmental

JOB SAFETY ANALYSIS

Project No.

SADARA-RTIP

Task Order/Contract No.:

SME/BSNEI

RTIP-SC-002-1K

Date:

29-08-2012

Walkdowns

Walkdowns are completed in advance of the work.

Ideally, this review includes walkdown by the employees who will actually perform the task.

During the walkdown, the work scope is validated and verified, including materials and special tools needed to complete the task.

The walkdown should consider environmental and workplace factors that may impact critical steps of the task.

The consistency and thoroughness of walkdowns are improved with the aid of a checklist.

Use the walkdown as an opportunity to observe physical limitations that may exacerbate performance, especially at the critical steps, or

hinder execution.

The results of the walkdowns are incorporated into work packages or documentation preparation.

Safety Task Assignment

Qualification for the task is first and foremost, but not the only, consideration.

Assigning the right employee to the task is an opportunity for the supervisor to evaluate the risk, complexity, and frequency of

performance of the task.

Experience, proficiency, personal readiness, and previous risk-taking behavior should be considered in light of the risk and complexity

of the task, as well as how often task has been performed.

Factors related to an employees mental, physical, and emotional readiness to work should be considered such as fatigue, illness,

emotional stress, and physical disabilities relevant to the task.

Pre-Task Briefings

Employees should be given the opportunity to talk about what is to be accomplished and what should be avoided.

Possible negative consequences should be discussed to identify additional controls or barriers needed.

The supervisor and the employee can develop contingencies for the most likely and worst-case outcomes.

Such thinking enhances situational awareness and improves application of error-prevention tools at critical points in a task.

Copyright 2010, Fluor Corporation. All Rights Reserved.

Form Date: 23Dec2010

Page 2 of 3

Health, Safety, and Environmental

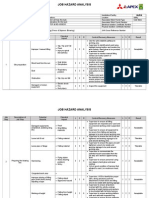

JOB SAFETY ANALYSIS

Project No.

SADARA-RTIP

Task Order/Contract No.:

Work Activity

1-REBAR FIXING.

SME/BSNEI

RTIP-SC-002-1K

Hazards Present

Date:

29-08-2012

Required Safety Measures/PPE

Personnel injury, Damage due to

falling tools,

Equipments& Slips, Trips, Falls

impalements.

Keep all small items and tools in a

box; Secure all the materials in safe

manner as per the safety

requirements, Clear all the walkway.

Barrication and signages, Wear

proper PPE, Maintain good

housekeeping.

Use impalements protection.

Plant movement and persons

working around plant,

Personnel injury. Noise & Dust

Slips, trips & falls

Wear proper PPE, ear plugs, Gloves

and dust mask. Secure all the

materials, Remove the unwanted

materials, Good housekeeping, Tools

box talk, Educate the work details to

the

Workers. Proper tools for the job.

Competent

Persons only handling the machine.

Provide

Fire preventing equipments, Inspect

& Tagged & colour coded all the tools

and equipments.

Flagmen at all times directing plant.

2-GRADING & LEVELLING

COMPACTION

Use proper PPE, Competent

persons, Tool

Box talk, Educate the work details,

Maintain

Good housekeeping, Secure all the

materials,

Removed unwanted materials.

Provide safety

Harness use softener.

3-ERECTION OF TEMPORARY

REST

SHELTER.

Personnel injury, Trips , Falls, Sharp

edge,

Pinch Points, Manual Handling,

4- LOADING AND UNLOADING

MATERIALS

Plant movement, Slips Trips and

Falls,

Manual handling

Barricade the area and use signs,

Provide trained flagmen , Remove

unwanted workers and materials,

Secure the materials, Transfer the

materials as per the safe manner.

Copyright 2010, Fluor Corporation. All Rights Reserved.

Form Date: 23Dec2010

Page 2 of 3

Health, Safety, and Environmental

JOB SAFETY ANALYSIS

Project No.

SADARA-RTIP

Task Order/Contract No.:

SME/BSNEI

RTIP-SC-002-1K

Date:

29-08-2012

Note: This form is referenced in numerous practices.

Copyright 2010, Fluor Corporation. All Rights Reserved.

Form Date: 23Dec2010

Page 2 of 3

Health, Safety, and Environmental

Vous aimerez peut-être aussi

- 07 - JSA Compaction and BackfillingDocument4 pages07 - JSA Compaction and Backfillingsatti100% (2)

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfPas encore d'évaluation

- Rebar PDFDocument1 pageRebar PDFjoker batmanPas encore d'évaluation

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4Pas encore d'évaluation

- Tool Box Talk - MK - Emergency Response ProceduresDocument2 pagesTool Box Talk - MK - Emergency Response ProceduresPaul McGahanPas encore d'évaluation

- Fencing, Installation and Repair.: Activity DescriptionDocument6 pagesFencing, Installation and Repair.: Activity DescriptionVictorPas encore d'évaluation

- 001 JSA Site CompoundDocument15 pages001 JSA Site CompoundRui Ribeiro100% (1)

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelPas encore d'évaluation

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDocument42 pagesBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanPas encore d'évaluation

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarPas encore d'évaluation

- Excavation of RoadDocument7 pagesExcavation of RoadCharles LambPas encore d'évaluation

- JOB SAFETY PLAN Replacement of CylinderDocument2 pagesJOB SAFETY PLAN Replacement of CylinderMaxi ProPas encore d'évaluation

- Casting ConcreteDocument9 pagesCasting ConcreteNontobeko MkhizePas encore d'évaluation

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinPas encore d'évaluation

- 01 JSA For Earthworks at Corridor ADocument32 pages01 JSA For Earthworks at Corridor AHilbrecht De Pedro100% (1)

- Man Machine InterfaceDocument22 pagesMan Machine Interfaceamdarrif3723100% (1)

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21Pas encore d'évaluation

- Excavation SWMS 1Document8 pagesExcavation SWMS 1azlinaz100% (2)

- Job Safety Analysis (JSA) - HVAC Ducting DateDocument1 pageJob Safety Analysis (JSA) - HVAC Ducting DatenabeelPas encore d'évaluation

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabPas encore d'évaluation

- JSA - Civil Compaction WorkDocument4 pagesJSA - Civil Compaction WorkRajuPas encore d'évaluation

- JSA-Site Survey and Downloading of Relay ConfigurationDocument4 pagesJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (1)

- Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Document2 pagesJob Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Jayvee Baradas Valdez25% (4)

- SWMS 001 Drilling Soil BoresDocument3 pagesSWMS 001 Drilling Soil BoresEngr Faheem AkhtarPas encore d'évaluation

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyPas encore d'évaluation

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- Concrete Surface Coating JSA-027Document5 pagesConcrete Surface Coating JSA-027shivgovind pal100% (1)

- JSA Concrete WorksDocument8 pagesJSA Concrete Worksfrancis_e_tan93% (27)

- Excavation PermitDocument2 pagesExcavation PermitRajesh Kumar SinghPas encore d'évaluation

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailPas encore d'évaluation

- 6.0 ISOLATION JSA CONCRETE WORK HanesDocument7 pages6.0 ISOLATION JSA CONCRETE WORK HanesMc Loki100% (3)

- Working at Height - JHA-1Document13 pagesWorking at Height - JHA-1Burhan KhanPas encore d'évaluation

- Job Safety Analysis (JSA) Worksheet Attachment III PTW No.: - Date IssuedDocument3 pagesJob Safety Analysis (JSA) Worksheet Attachment III PTW No.: - Date IssuedSawLaiBoyanPas encore d'évaluation

- SWMS 2 Fixing CarpenterDocument3 pagesSWMS 2 Fixing CarpenterJonasPas encore d'évaluation

- JHA Scaffolding - ApprovedDocument15 pagesJHA Scaffolding - ApprovedLuqman OsmanPas encore d'évaluation

- Exacavation Job Safety AnalysisDocument1 pageExacavation Job Safety AnalysisNeelakantamPas encore d'évaluation

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatPas encore d'évaluation

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanPas encore d'évaluation

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebPas encore d'évaluation

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Risk Assisment For Fence WorkDocument2 pagesRisk Assisment For Fence Workashishakare100% (1)

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDocument2 pagesRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaPas encore d'évaluation

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanPas encore d'évaluation

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATETamPas encore d'évaluation

- Hazard Control GuideDocument6 pagesHazard Control GuideImran KhanPas encore d'évaluation

- Job Safety Analysis For Scaffolding 1Document3 pagesJob Safety Analysis For Scaffolding 1Arshad Khan100% (5)

- 004 Piling JSADocument5 pages004 Piling JSAmidozotyPas encore d'évaluation

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiPas encore d'évaluation

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajPas encore d'évaluation

- DEMOLITION SAFETY Print PDFDocument16 pagesDEMOLITION SAFETY Print PDFTed Alden Magno ZamoraPas encore d'évaluation

- JSA-02-trench Excavation by EquipmentDocument1 pageJSA-02-trench Excavation by Equipmentabou bakarPas encore d'évaluation

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYAPas encore d'évaluation

- Bhate & Raje Construction Co. Pvt. LTD: Electrical Work PermitDocument1 pageBhate & Raje Construction Co. Pvt. LTD: Electrical Work Permitvinayak salve100% (1)

- Flagman/ Banksman TrainingDocument25 pagesFlagman/ Banksman TrainingAatif Patil100% (1)

- Sajan John CV Update CVDocument6 pagesSajan John CV Update CVKrishna TravelsPas encore d'évaluation

- SINOPEC - RTR SOC Attendance Sheet 24-08-2021Document3 pagesSINOPEC - RTR SOC Attendance Sheet 24-08-2021Jayvee Baradas ValdezPas encore d'évaluation

- 0002 Rev 00 Jsa TR Seg Piping ErectionDocument11 pages0002 Rev 00 Jsa TR Seg Piping ErectionJayvee Baradas ValdezPas encore d'évaluation

- SDM 023 Attendance SheetDocument1 pageSDM 023 Attendance SheetJayvee Baradas ValdezPas encore d'évaluation

- Sinopec-Tr-Safety Training Attendance SheetsDocument2 pagesSinopec-Tr-Safety Training Attendance SheetsJayvee Baradas ValdezPas encore d'évaluation

- 0001 Rev 00 Jsa TR Seg Structural ErectionDocument10 pages0001 Rev 00 Jsa TR Seg Structural ErectionJayvee Baradas ValdezPas encore d'évaluation

- Sinopec Status of Firstaid BoxDocument1 pageSinopec Status of Firstaid BoxJayvee Baradas ValdezPas encore d'évaluation

- Good Practices Guide To Dark Rooms OperationsDocument3 pagesGood Practices Guide To Dark Rooms OperationsJayvee Baradas Valdez0% (1)

- Application Form OSH PractitionerDocument3 pagesApplication Form OSH PractitionerJayvee Baradas Valdez100% (4)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument8 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJayvee Baradas ValdezPas encore d'évaluation

- Incident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerDocument14 pagesIncident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerJayvee Baradas ValdezPas encore d'évaluation

- Contractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedDocument3 pagesContractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedJayvee Baradas ValdezPas encore d'évaluation

- FGP SEG TR JSA 20 - Man Lift Operation Rev. 02Document15 pagesFGP SEG TR JSA 20 - Man Lift Operation Rev. 02Jayvee Baradas ValdezPas encore d'évaluation

- Saes T 555Document21 pagesSaes T 555Jayvee Baradas ValdezPas encore d'évaluation

- Powder Actuated ToolsDocument1 pagePowder Actuated ToolsJayvee Baradas ValdezPas encore d'évaluation

- Powerline Pre Board Ree Sept 2010 PDFDocument14 pagesPowerline Pre Board Ree Sept 2010 PDFJayvee Baradas ValdezPas encore d'évaluation

- Certficate of ExperienceDocument1 pageCertficate of ExperienceJayvee Baradas ValdezPas encore d'évaluation

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezPas encore d'évaluation

- RPB Astro Instruction ManualDocument20 pagesRPB Astro Instruction ManualJayvee Baradas ValdezPas encore d'évaluation

- JSA Template 2017-05-30 Powder Actuated ToolsDocument19 pagesJSA Template 2017-05-30 Powder Actuated ToolsJayvee Baradas Valdez100% (2)

- Certificate of Appreciation: Sayyed Amjad Ullah ShahDocument6 pagesCertificate of Appreciation: Sayyed Amjad Ullah ShahJayvee Baradas ValdezPas encore d'évaluation

- Traffic PlanDocument1 pageTraffic PlanJayvee Baradas ValdezPas encore d'évaluation

- Married: Real Estate MortgageDocument1 pageMarried: Real Estate MortgageJayvee Baradas ValdezPas encore d'évaluation

- Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Document1 pageJob Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Jayvee Baradas ValdezPas encore d'évaluation

- Duties and Responsibilities of HSE Supervisor (Oil and Gas Plant Construction)Document2 pagesDuties and Responsibilities of HSE Supervisor (Oil and Gas Plant Construction)Jayvee Baradas Valdez0% (1)

- Safety Training Attendence List: Umm Wu'Al Phosphate Project U&I Multidiscipline PackageDocument1 pageSafety Training Attendence List: Umm Wu'Al Phosphate Project U&I Multidiscipline PackageJayvee Baradas ValdezPas encore d'évaluation

- Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Document2 pagesJob Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Jayvee Baradas Valdez25% (4)

- R123 UpdateDocument2 pagesR123 Updateasayed_1@hotmail.comPas encore d'évaluation

- En Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARDocument4 pagesEn Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARZhenyuan LiPas encore d'évaluation

- Drive ConfigDocument136 pagesDrive ConfigGiangDoPas encore d'évaluation

- En 12604 (2000) (E)Document7 pagesEn 12604 (2000) (E)Carlos LanzillottoPas encore d'évaluation

- Process Control in SpinningDocument31 pagesProcess Control in Spinningapi-2649455553% (15)

- QBDC - Season 5-RulebookDocument50 pagesQBDC - Season 5-RulebookHggvgPas encore d'évaluation

- Mitsubishi Electric Product OverviewDocument116 pagesMitsubishi Electric Product OverviewPepes HiuuPas encore d'évaluation

- STOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary FacilitiesDocument25 pagesSTOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary Facilitiesjfl2096Pas encore d'évaluation

- Brochure FDP - EG 16.08.2021-1-2-2Document3 pagesBrochure FDP - EG 16.08.2021-1-2-2sri sivaPas encore d'évaluation

- 01-19 Diagnostic Trouble Code Table PDFDocument40 pages01-19 Diagnostic Trouble Code Table PDFmefisto06cPas encore d'évaluation

- Unistream-Installation Operation & MaintenanceDocument24 pagesUnistream-Installation Operation & MaintenanceJoanna Lauer-TrąbczyńskaPas encore d'évaluation

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalPas encore d'évaluation

- Ruckus Wired Accreditation ExamDocument15 pagesRuckus Wired Accreditation ExamDennis Dube25% (8)

- Parth Valves and Hoses LLP.: Test & Guarantee CertificateDocument1 pageParth Valves and Hoses LLP.: Test & Guarantee CertificateSURYAKANTPas encore d'évaluation

- Fasteners Lecture 11-20-03Document67 pagesFasteners Lecture 11-20-03laponggaPas encore d'évaluation

- Fm-II Quiz 1 19-20 - Section1 - Set1Document2 pagesFm-II Quiz 1 19-20 - Section1 - Set1nivedithashetty0123Pas encore d'évaluation

- Dnvgl-Ru-Ships (2015) Part 3 Ch-10 TrolleyDocument7 pagesDnvgl-Ru-Ships (2015) Part 3 Ch-10 TrolleyyogeshPas encore d'évaluation

- Jun SMSDocument43 pagesJun SMSgallardo0121Pas encore d'évaluation

- Logcat 1693362990178Document33 pagesLogcat 1693362990178MarsPas encore d'évaluation

- The Effects of Crankshaft Offset On The Engine FrictionDocument15 pagesThe Effects of Crankshaft Offset On The Engine Frictionqingcaohe100% (1)

- d9 VolvoDocument57 pagesd9 Volvofranklin972100% (2)

- Epson Eb-W22 ProjectorDocument2 pagesEpson Eb-W22 Projectorandresboy123Pas encore d'évaluation

- 01 Cone Winding Study (Calculation)Document4 pages01 Cone Winding Study (Calculation)Hasan Istiaque Ahmed60% (5)

- Rheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteDocument3 pagesRheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteFrancois-Pas encore d'évaluation

- Status Profile Creation and Assignment To An Order Type in SAP PPDocument7 pagesStatus Profile Creation and Assignment To An Order Type in SAP PPHemant UNICHEMLLPPas encore d'évaluation

- CS 162 Memory Consistency ModelsDocument22 pagesCS 162 Memory Consistency Modelsravikumarsid2990Pas encore d'évaluation

- Experiment SCDocument5 pagesExperiment SCnitinmgPas encore d'évaluation

- Photosynthesis LabDocument3 pagesPhotosynthesis Labapi-276121304Pas encore d'évaluation

- RT120 ManualDocument161 pagesRT120 ManualPawełPas encore d'évaluation

- Data Structure Algorithm Using C PresentationDocument245 pagesData Structure Algorithm Using C PresentationdhruvwPas encore d'évaluation