Académique Documents

Professionnel Documents

Culture Documents

0708 R RE 001 Design Basis

Transféré par

Himawan Sigit NugrohoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

0708 R RE 001 Design Basis

Transféré par

Himawan Sigit NugrohoDroits d'auteur :

Formats disponibles

PT.

MEDCO ENERGI

KERAMASAN GAS RECEIVING FACILITY

DESIGN BASIS

02-05-2008

Approved for Construction

RHM

DNU

SAS

11-04-2008

Issued for Approval

RHM

DNU

SAS

REV.

DATE

DESCRIPTION

BY

CHKD

CHKD

KELSRI

APPVD

MEDCO ENERGI

STATUS CODE :

A= Issued for Approval ; B= Approved For Construction ; C= As Built ; I= Issued for Information ;

X= Document Cancelled

Total Or Partial Reproduction And / Or Utilization of This Document Are Forbidden Without Prior Written

Authorization of The Owner

ENGINEERING PROCUREMENT

CONSTRUCTION COMMISSIONING

KRS-R-RE-001

PT. KELSRI

0708-R-RE-001

SUBCONTRACT NO. : BF 2691

STATUS

REVISION

Page 1 of 11

TABULATION OF REVISED PAGES

SHEETREVISIONSSHEET

ABCD

REVISI

ONS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Page 2 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

TABLE OF CONTENTS

INDEX

Pages

1. Introduction

2. Codes & Standard

3. Unit Measurement

4. Design Data

5. Facilities Description

5.1.

Process Facilities

5.2.

Utilities

6. Design Criteria

6.1.

Design Life

6.2.

Line Sizing

6.3.

Vessel

10

6.4.

Gas Filter

10

6.5.

Relief System

10

6.6.

Flare System

10

6.7.

Compressed Air System

10

6.8.

Utility Water

11

6.9.

Fire Safety System

11

7. Control & Shutdown System

11

8. Attachment

12

Page 3 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

1. INTRODUCTION

PT Medco E&P Indonesia is planning to supply gas to PLTG

Keramasan. The supplied gas will be tied in from existing 6 pipeline

from Simpang Keramasan to PLTG Keramasan. For future additional

gas supply, 8 pipeline will be installed parallel with the existing 6

pipeline by Pertamina. In order to achieve delivered gas minimum

specification, PT Medco E&P Indonesia is planning to install a receiving

facility in the downstream of the pipeline. This receiving facility will have

functions i.e. separate liquid (condensate and water) from the gas,

minimize liquid particle diameter and measure the supplied gas for

billing purpose. This receiving facility will be named as Keramasan Gas

Receiving Facilities.

This document provides information relevant to process design basis for

Keramasan Gas Receiving Facilities.

2. CODES & STANDARD

The following is a list of general recommended practices, codes and

standard shall be used in the detailed engineering design. In addition to

these codes and standards, all Indonesian governmental and regulatory

agency requirements and regulations shall be applied. The most current

version of these codes and standards shall be used.

MES

Medco Engineering Standard

ANSI

American National Standards Institute

ASME

American Society of Mechanical Engineers

SNI

Standard National Indonesia

NACE

National Association of Corrosion Engineers

API

American Petroleum Institute

NEC

National Electric Code

NFPA

National Fire Protection Association

3. UNIT MEASUREMENT

US Customary Unit shall be used for all design, drawing and

specification. Standard conditions for process calculation are 14.7 psia

Page 4 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

and 60F. In general, the following units and abbreviations shall be

used:

Application

Area

Density

Flow Rate (Mass)

Flow Rate (Volume)

Gas

Liquid

Unit

Square Feet

Pounds per Cubic Foot

Pounds per Hour

Abbreviations

ft2

lb/ft3

lb/hr

Million Standard Cubic Feet Per day

Standard Cubic Feet per Minutes

Barrels per Day

Barrels Fluid per Day (Well or Mixed

MMscfd

SCFM

BPD

Fluid)

Barrels Water per Day (water)

Gallon per Minute

Feet

British Thermal Unit

Feet

Inch

Feet

Pound

Kilowatt

Horse Power

Pound per Square Inch

Pound per Square Inch Absolute

Pound per Square Inch Gauge

British Thermal Unit per ft per hour

Degrees Fahrenheit

Seconds

Minute

Hour

Feet per second

Barrels (Petroleum)

Cubic Feet

Gallons (US)

CentiPoise

Head

Heat

Elevation

Length

Mass

Power

Pressure

Radiation

Temperature

Time

Velocity

Volume

Viscosity

BFPD

BWPD

GPM

Ft

Btu

Ft

In

Ft

Lb

kW

HP

Psi

Psia

Psig

Btu/fr2/hr

F

Sec

Min

Hr

Fps

Bbl

ft3

Gal.

cP

4. DESIGN DATA

4.1.1.

Site Location

Keramasan Gas Receiving Facilities site location is planned at PLTG

Keramasan Companys area, Palembang, South Sumatera, Indonesia.

4.1.2.

Ambient Data

a. ambient pressure

: 14.7 psi (1 atm)

Page 5 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

b. ambient temperature

4.1.3.

: 75 100 F

Inlet Gas Data

Data of inlet gas for Keramasan Gas Receiving Facilities is referred to

PFD for Looping Pipeline Simpang Y Keramasan, supplied by

Pertamina, dated February 23, 2007 (see attachment) and listed bellow:

a. Pressure

: 450 psig

b. Temperature

: 73 F

c. Composition

: (dry basis)

COMPONENT

METHANE

ETHANE

PROPHANE

I-BUTANE

N-BUTANE

I-PENTANE

N-PENTANE

N-HEXANE

N-HEPTANE

N-OCTANE

NITROGEN

CARBON DIOXIDE

4.1.4.

UNIT

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

VALUE

85.36

5.64

2.81

0.38

0.45

0.18

0.13

0.03

0.00

0.00

0.00

5.00

Design Capacity

Based on Notulen Rapat Pembahasan Draft Amandemen PJBG Pusat

Listrik Keramasan dated April 19, 2007, committed gas deliverability is

22.3 BBTUD (see attachment).

Design capacity of Keramasan Gas Receiving Facilities is MMscfd of

Gas and 250 BPD of liquid.

4.1.5.

Sales Gas Specification

Specifications of sales gas for Keramasan Gas Receiving Facilities is

referred to Specifikasi Gas Bumi untuk Pusat Listrik Keramasan sesuai

PJBG (see attachment) and listed bellow:

COMPONENT

METHANE

ETHANE

PROPHANE

BUTANE

C5+

N2

CO2

UNIT

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

% MOL

VALUE

MINIMUM MAXIMUM

74

100

5

5

5

2

1

10

Page 6 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

H2S

KADAR AIR

TEMPERATURE

NILAI KALOR KOTOR

TEKANAN DI TITIK

PENYERAHAN

ppm

lb/MMSCFD

C

BTU/SCF

psig

20

950

280

2

10

40

1200

350

5. FACILITIES DESCRIPTION

5.1. Process Facilities

Keramasan process facilities consist of Gas Scrubber, Gas Filter, Metering

System, Condensate System and Flare System.

a. Gas Scrubber

Keramasan Gas Receiving Facilities receives gas from the existing 6

diameter and 3.3 km length Simpang Keramasan Keramasan pipeline

with incoming pressure of 450, approximately. The pressure of gas will be

reduced to 300 370 psig using pressure control valve before enter to gas

scrubber. Gas enters gas scrubber for gas-liquid separation process. The

function of this gas scrubber is to remove entrained liquid from the gas

stream. The gas product will pass through the top this vertical separator

with mist extractor and the design pressure is 700 psig and 160F.

b. Gas Filter

Gas from the top of gas scrubber will enter gas filter. The function of this

filter is to achieve the diameter requirement. The filtration efficiency is 99%

removal droplet @ 0.5-micron maximum solid & liquid. The gas outlet gas

filter is sent to the metering system for further handling. Design pressure

of gas filter is 700 psig @ 160F.

c. Metering System

The gas outlet filter is then measured at a gas metering system before

transferred to PLTG Keramasan. The metering system used for this

measurement is custody metering system type complete with gas

chromatography and moisture analyzer. The metering installation shall

follow AGA-3 requirement and the gas chromatography shall follow AGA-8

requirement. Design pressure of Gas Metering is 700 psig @ 160F.

d. Condensate System

Page 7 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

This system consists of condensate drum and recovery pump. Liquid

product from gas scrubber, gas filters and others will be sent to KO Drum

before transferred and stored to condensate drum. After the liquid

maintain a specific level at condensate drum, the liquid is then pumped to

an unloading truck using recovery pump.

e. Drain System

Closed drain system shall be provided to collect the entire hydrocarbon

inventory for disposal. Low point drain connections are provided at Gas

Scrubber, Filter, and Condensate Tank. Closed drain system consist of

closed drain line, header and pond.

An open drain system is also provided to collect the wash water in the

facilities areas. These are routed to the rainwater collection that completed

with control box.

f.

Flare System

Flare system is provided for safe disposal of waste hydrocarbon vapour

which are generated during plant upset, emergency and shut down

condition. Flare system consist of a flare header, flare KO drum (horizontal

type, without mist extractor), flare KO drum pump, and multiple-jet

enclosed flare complete with a flare ignition system. Flare gas is released

to flare header through Pressure Control Valve (PCV), or blow down

during emergency.

Flare gas is then sent to flare K.O. drum for liquid-gas separation. Liquid

product, drain, is transferred to condensate system using flare KO drum

pump.

5.2. Utilities

Utilities for Keramasan Receving Facilities consist of compressed air system,

electricity power, fresh water and fire safety system.

a. Compressed Air System

Compressed air system is used to produce clean, oil free and dry air for

instrument air, utility air and diaphragm pump driven. This system consists

of air compressors, air dryers and air receiver. Ambient air is compressed

using air compressor to produce compressed air. The compressed air is

then dehydrated in the air dryer. The air dryer is used to separate

Page 8 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

condensed moisture from the compressed air. Dry air is then stored at air

receiver for instrument air, utility air and air pump driver purpose.

b. Electric Power

Main electric power will be provided by PT. PLN (Persero). Emergency

electric power will be provided by the power plant contractor, PT. Asta

Keramasan Energy. UPS shall be provided for temporary power supply to

the metering system in case of power loss.

c. Utility Water

Water is used for utility purpose. A deep well be used for fresh water

source and shall be provided with water tank and plumbing system.

d. Fire Safety System

Fire safety system shall be provided for both light and heavy fire fighting.

Fire safety system for light fire case is provided by portable gas fire

extinguishers. Fire safety system for heavy fire case is provided by fusible

loop. This loop is connected with ESD system. When heavy fire case

occurs in Keramasan Gas Receiving Facilities, fusible loop will trigger

ESD system to shut down the facility.

6. DESIGN CRITERIA

6.1. Design Life

The facility is designed for a 15-year design life.

6.2. Line Sizing

Process line sizing and criteria shall refer to International API Standards, RP

14E, Recommended Practice for Design and Installation of Offshore

Production Platform Piping Systems and PT. Medco E&P Indonesia

Engineering Standard MEP-P-ES-001, Standard Specification for Piping

Material Specification.

6.3. Vessel

Page 9 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

Vessel Sizing and design criteria shall refer to International API Standards, RP

12J, Specification for Oil and Gas Separator. Vessel sizing and criteria shall

also refer to PT. Medco E&P Indonesia Engineering Standard MEP-R-ES-001,

Standard Specification for Vapor Liquid Separator. For special case, K.O.

Drum sizing shall also refer to API 521, Guide for Pressure-Relieving and

Depressuring Systems.

6.4. Gas Filter

Gas filter sizing and criteria shall refer to PT. Medco E&P Indonesia

Engineering Standard MEP-R-ES-003, Standard Specification for Fuel Gas

Separator and Filter.

6.5. Relief System

Relief gas system including relief valve and blow down calculation and criteria

shall refer to International API Standards RP 520, Sizing, Selection, and

Installation of Pressure-Relieving Devices in Refineries; Part I Sizing and

RP 521, Guide for Pressure-Relieving and Depressuring Systems.

6.6. Flare System

Flare system criteria including the ignition system shall refer to international

API STD 521, Guide for Pressure-Relieving and Depressuring Systems. Flare

system and API STD 537, Flare Details for General Refunery and

Petrochemical Service.

6.7. Compressed Air System

Criteria of all equipments included in instrument air system such as air

compressor, air filter, air dryer and air receiver shall refer to standards as

follow:

a. API STD 618, Reciprocating Compressors for Petroleum, Chemical, and

Gas Industry Services.

b. API STD 619, Rotary Type Positive Displacement Compressors for

Petroleum, Chemical, and Gas Industry Services.

c. MEP-M-ES-004, Standard Specification for Instrument Air Compressor

Package.

d. MEP-I-ES-001, Standard Specification for Engineering and Design of

Instrument System.

Page 10 of 11

KELSRI

DESIGN BASIS

0708-R-RE-001

e. API 550 & Vendor Catalogue for Air Demand Calculation.

f.

ANSI/ISA 7.0.01 1996, Quality Standard for Instrument Air.

6.8. Utility Water

Utility water criteria shall refer to local standard, i.e. PDAM Standard.

6.9. Fire Safety System

Fire safety system and fire fighting equipment shall refer to PT. Medco E&P

Indonesia Engineering Standard MEP-F-ES-001, Standard Specification for

General Fire and safety and MEP-F-ES-003, Standard Specification for

Portable & Auxiliary Fire Fighting Equipment.

7. CONTROL & SHUTDOWN SYSTEM

Control, alarm and shutdown system will use pneumatic system. New pneumatic

panel will be provided for alarm and shutdown system.

Shutdown level shall developed with initial outline of the expected hierarchy:

Unit Shutdown

Process Shutdown (PSD), which will shut off process inflow and outflow of

the facility and initiate gas inventory depressurizing.

Emergency Shutdown (ESD), which will intake process shutdown and

blowdown gas from system to annunciate fire/emergency alarm.

PSD will be triggered by push/pull button. ESD will be triggered by ESD push/pull

Button and fusible loop.

8. ATTACHMENT

A.

PFD for Looping Pipeline Simpang Y Keramasan

B.

Notulen Rapat Pembahasan Draft Amandemen PJBG Pusat Listrik

Keramasan dated April 19, 2007.

C.

Spesifikasi Gas Bumi untuk Pusat Listrik Keramasan sesuai PJBG.

Page 11 of 11

Vous aimerez peut-être aussi

- A Dictionary of Oil Gas Industry Terms, 2nd Edition (2023)Document553 pagesA Dictionary of Oil Gas Industry Terms, 2nd Edition (2023)Ali Hosseini100% (1)

- Commissioning Manual Unit 21Document35 pagesCommissioning Manual Unit 21Arjun Shantaram Zope100% (1)

- Electrical Cable SizingDocument21 pagesElectrical Cable SizingKuwat Riyanto100% (7)

- DatasheetDocument17 pagesDatasheetHimawan Sigit NugrohoPas encore d'évaluation

- ResEng Flame Ch6Document48 pagesResEng Flame Ch6Caleb Jonatan Montes VelardePas encore d'évaluation

- Standard Refinery Fuel TonsDocument2 pagesStandard Refinery Fuel TonsPinjala Anoop100% (4)

- Amec SpecDocument32 pagesAmec Specshinojbaby4148Pas encore d'évaluation

- Indra: SonatrachDocument9 pagesIndra: SonatrachhichamPas encore d'évaluation

- DMI-BD-10-001-A4 Process Operating and Control PhilosophyDocument14 pagesDMI-BD-10-001-A4 Process Operating and Control Philosophykemas100% (2)

- PP10CC 00 Lab MR Abc 001Document7 pagesPP10CC 00 Lab MR Abc 001anbesivam87Pas encore d'évaluation

- Proc Eng P&I DDocument60 pagesProc Eng P&I DGiang T LePas encore d'évaluation

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoPas encore d'évaluation

- Design BasisDocument85 pagesDesign BasisBabji Munagala100% (2)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument56 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar Perdawood100% (1)

- 135355-01-REP-06-012 - Update 19.5Document28 pages135355-01-REP-06-012 - Update 19.5Bui Khoi NguyenPas encore d'évaluation

- DMI-DB-10-013-A4 CONTROL SAFEGUARD PHILOSOPHY Rev.0Document12 pagesDMI-DB-10-013-A4 CONTROL SAFEGUARD PHILOSOPHY Rev.0Kemas Muhandis M.100% (2)

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Document11 pagesDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanPas encore d'évaluation

- Technical FF PRT C 20181016 1715231Document99 pagesTechnical FF PRT C 20181016 1715231AayeshaPas encore d'évaluation

- 4.3 Vol II Sec.3.2 - Process Design CriteriaDocument34 pages4.3 Vol II Sec.3.2 - Process Design CriteriaPrasath Palanichamy0% (1)

- PreComm-Comm & RR Execution Plan Rev 0 PDFDocument22 pagesPreComm-Comm & RR Execution Plan Rev 0 PDFMaulana HaniefPas encore d'évaluation

- (D-103) Fractionating Trays - Rev1 PDFDocument10 pages(D-103) Fractionating Trays - Rev1 PDFmihir_jha2Pas encore d'évaluation

- Volume IIA Technical SpecificationDocument83 pagesVolume IIA Technical SpecificationSanjeev Kumar DasPas encore d'évaluation

- NGP-001-PCS-15.03-0001!00!00 - Specification For Gas Engine Driven Reciprocating CompressorDocument39 pagesNGP-001-PCS-15.03-0001!00!00 - Specification For Gas Engine Driven Reciprocating Compressorm.shehreyar.khanPas encore d'évaluation

- Utilities Consumption List - PreliminaryDocument1 pageUtilities Consumption List - PreliminarykokocdfPas encore d'évaluation

- Process Design CriteriaDocument23 pagesProcess Design CriteriaDoctorOberman100% (1)

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomPas encore d'évaluation

- PP Aaa PP1 149Document14 pagesPP Aaa PP1 149Rabah AmidiPas encore d'évaluation

- Urhoud: DATE 11-Sep-'00 SHEET 1 OF 33 M. Kawase K. Akimoto K. AkimotoDocument33 pagesUrhoud: DATE 11-Sep-'00 SHEET 1 OF 33 M. Kawase K. Akimoto K. AkimotoBassem BalghouthiPas encore d'évaluation

- Ammonia Plant Revamp: SPIC, Tuticorin, TamilnaduDocument9 pagesAmmonia Plant Revamp: SPIC, Tuticorin, TamilnaduAl Musabbir LeeonPas encore d'évaluation

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDPas encore d'évaluation

- 811612471216UEWAYPFRDocument92 pages811612471216UEWAYPFRVenkatesh RamanPas encore d'évaluation

- 05 FS GduDocument18 pages05 FS GduAnonymous O0lyGOShYGPas encore d'évaluation

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument6 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PShanjiPas encore d'évaluation

- Process Control and Shutdown PhilosophyDocument14 pagesProcess Control and Shutdown PhilosophyJoanrenis SaranyaPas encore d'évaluation

- Operating & Control PhilosophyDocument16 pagesOperating & Control PhilosophyPrasadPas encore d'évaluation

- Basket Strainer HD 003 1Document9 pagesBasket Strainer HD 003 1Natalie Ordoñez KandiaPas encore d'évaluation

- 1 PipelineStudio Gas Simulator Module Tuning - English - Rev421Document28 pages1 PipelineStudio Gas Simulator Module Tuning - English - Rev421sushilPas encore d'évaluation

- Bài Tập Kỹ Thuật Điện TửDocument13 pagesBài Tập Kỹ Thuật Điện TửNguyenCanhBaoPas encore d'évaluation

- Annexure-I Instrument Datasheet For Self Actuating Pressure Control ValveDocument5 pagesAnnexure-I Instrument Datasheet For Self Actuating Pressure Control ValveAmit BansalPas encore d'évaluation

- Drain Philosophy Rev BDocument26 pagesDrain Philosophy Rev BAnonymous nxWj29Pas encore d'évaluation

- Elm Pul PR XXX 034 Agc FinalDocument16 pagesElm Pul PR XXX 034 Agc Finaljagiprem123Pas encore d'évaluation

- CLP-PSP-020-003-Rev 1 Specification For Pumps (Review HH)Document37 pagesCLP-PSP-020-003-Rev 1 Specification For Pumps (Review HH)henry hutabarat100% (2)

- 7856-Me-Spc-198-025 Rev - ADocument17 pages7856-Me-Spc-198-025 Rev - Ashameer_febi100% (1)

- Vol - V of V - Gspl-DrawingsDocument102 pagesVol - V of V - Gspl-Drawingsapi-36989960% (1)

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaisePas encore d'évaluation

- BOWER-CRESTECH-IBDCG-PX-5507-00001 - Process Design Philosophy DA CommentsDocument31 pagesBOWER-CRESTECH-IBDCG-PX-5507-00001 - Process Design Philosophy DA CommentsPaul OhiorPas encore d'évaluation

- IPS Standard PDFDocument44 pagesIPS Standard PDFFathy MostafaPas encore d'évaluation

- List Prioritas DokumenDocument6 pagesList Prioritas Dokumenmochamad iwanPas encore d'évaluation

- NGP 006 PCS 15.03 0012-10-00 Specification For Loading ArmsDocument9 pagesNGP 006 PCS 15.03 0012-10-00 Specification For Loading Armsm.shehreyar.khanPas encore d'évaluation

- Pid Btorf - Rev 0 HighlightDocument20 pagesPid Btorf - Rev 0 HighlightBayuPawitraBrodjonegoroPas encore d'évaluation

- P&ID 335 Comment Marking 220606Document50 pagesP&ID 335 Comment Marking 220606Azhar BudimanPas encore d'évaluation

- Attachment 2 - Technical Bid Evaluation - Rev00 - 2018.04.27Document46 pagesAttachment 2 - Technical Bid Evaluation - Rev00 - 2018.04.27nhutbang21891Pas encore d'évaluation

- 1230 OperationDocument346 pages1230 OperationYasin Elaswad100% (1)

- JACOBS Flow Instrument SpecDocument9 pagesJACOBS Flow Instrument Specshantanubiswas1Pas encore d'évaluation

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083Pas encore d'évaluation

- NKGSB PRS CL 008 A4 D Foam Solution Demand CalculationDocument8 pagesNKGSB PRS CL 008 A4 D Foam Solution Demand Calculationahmad santoso100% (2)

- Ras Markaz Crude Oil Park Project (Phase1)Document16 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILPas encore d'évaluation

- Volume 1 - General - V1-CH05-Process Design Basis Rev1Document13 pagesVolume 1 - General - V1-CH05-Process Design Basis Rev1MohamedPas encore d'évaluation

- 12-MGDP-I-1024-1 (Spec For General Instrumentation) PDFDocument23 pages12-MGDP-I-1024-1 (Spec For General Instrumentation) PDFJairo WilchesPas encore d'évaluation

- PSV D-103Document24 pagesPSV D-103DIANTOROPas encore d'évaluation

- Om-Tk-5.4.4-16-1 P&idDocument1 pageOm-Tk-5.4.4-16-1 P&idLu CianusPas encore d'évaluation

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigDocument2 pagesAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigJhonny Rincones100% (1)

- Sov - 1Document1 pageSov - 1biswasdipankar05Pas encore d'évaluation

- Q1 SUMMIT US 2020 Web RezDocument40 pagesQ1 SUMMIT US 2020 Web RezHimawan Sigit NugrohoPas encore d'évaluation

- Install and Setup X4iDocument8 pagesInstall and Setup X4iHimawan Sigit NugrohoPas encore d'évaluation

- Kabel Katalog Airfield LightingDocument10 pagesKabel Katalog Airfield LightingHimawan Sigit NugrohoPas encore d'évaluation

- 4life Transfer Factor CardioDocument1 page4life Transfer Factor CardioHimawan Sigit NugrohoPas encore d'évaluation

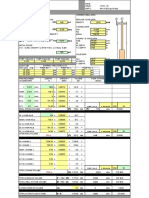

- Cable Sizing and Voltage Drop Calculation: Emp Bentu LimitedDocument1 pageCable Sizing and Voltage Drop Calculation: Emp Bentu LimitedHimawan Sigit NugrohoPas encore d'évaluation

- ESP Cables: Exploration & ProductionDocument2 pagesESP Cables: Exploration & ProductionHimawan Sigit NugrohoPas encore d'évaluation

- 1.dresser Rand Surge ControlDocument4 pages1.dresser Rand Surge ControlHimawan Sigit NugrohoPas encore d'évaluation

- SMC All El3 001 A4.rev.1Document24 pagesSMC All El3 001 A4.rev.1Himawan Sigit NugrohoPas encore d'évaluation

- Controls: Telephone (985) - 876-4117 ISO 9001 CertifiedDocument2 pagesControls: Telephone (985) - 876-4117 ISO 9001 CertifiedHimawan Sigit NugrohoPas encore d'évaluation

- Controls: Telephone (985) - 876-4117 ISO 9001 CertifiedDocument1 pageControls: Telephone (985) - 876-4117 ISO 9001 CertifiedHimawan Sigit NugrohoPas encore d'évaluation

- Data SheetDocument12 pagesData SheetHimawan Sigit NugrohoPas encore d'évaluation

- Datasheet Pressure Indicating Controller PDFDocument5 pagesDatasheet Pressure Indicating Controller PDFHimawan Sigit NugrohoPas encore d'évaluation

- Derivation of 1-D Flow Equation in Cartesian Coordinates-2Document9 pagesDerivation of 1-D Flow Equation in Cartesian Coordinates-2Chukwuma LystanPas encore d'évaluation

- Describing Graphs and Charts Handout2Document10 pagesDescribing Graphs and Charts Handout2MoaazDardeerPas encore d'évaluation

- Close Window Print This Page: Units of MeasureDocument2 pagesClose Window Print This Page: Units of MeasureGeorge John AmegashiePas encore d'évaluation

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandharePas encore d'évaluation

- Petrosil Base Oil Report - March 15, 2010 - 0Document20 pagesPetrosil Base Oil Report - March 15, 2010 - 0Divik TanwarPas encore d'évaluation

- Refinery Planning PresentationDocument142 pagesRefinery Planning Presentationalagurm67% (6)

- Economic 1st Lecture. Third Stage 2020Document16 pagesEconomic 1st Lecture. Third Stage 2020Homam MohammadPas encore d'évaluation

- Minister's Statement Kingfisher Oil Field LicenceDocument6 pagesMinister's Statement Kingfisher Oil Field LicenceAfrican Centre for Media ExcellencePas encore d'évaluation

- 2007 - Handbook of Formula and Physical ConstantsDocument56 pages2007 - Handbook of Formula and Physical Constantsapi-385925889% (9)

- Kpi Examples: Example Kpis For The Mining IndustryDocument4 pagesKpi Examples: Example Kpis For The Mining IndustryRyan Dave AlutayaPas encore d'évaluation

- Di Ds PracticeDocument22 pagesDi Ds Practicenits_wazzupPas encore d'évaluation

- SPE 163117 High Rate ESP Application in Onshore Rajasthan Fields: A Case StudyDocument26 pagesSPE 163117 High Rate ESP Application in Onshore Rajasthan Fields: A Case Studymoh kadPas encore d'évaluation

- Americas Refined Oil Products MethodologyDocument46 pagesAmericas Refined Oil Products Methodologycarlos vielmaPas encore d'évaluation

- Pharaonic Petroleum Company (PHPC) : PHPC Operations Unit SummaryDocument21 pagesPharaonic Petroleum Company (PHPC) : PHPC Operations Unit SummaryramyPas encore d'évaluation

- The Drawworks and The CompoundDocument135 pagesThe Drawworks and The CompoundIbrahim MohamedPas encore d'évaluation

- China Loans Chinese PerspectiveDocument6 pagesChina Loans Chinese Perspective520462755Pas encore d'évaluation

- Reliance IndustriesDocument9 pagesReliance IndustriesNaveenkumar YerawarPas encore d'évaluation

- SPE 127827 Combining Stimulation and Water Control in High-Water-Cut WellsDocument10 pagesSPE 127827 Combining Stimulation and Water Control in High-Water-Cut WellsNavneet SinghPas encore d'évaluation

- Technical Notes On The 2019 Proposed National BudgetDocument113 pagesTechnical Notes On The 2019 Proposed National BudgetMarvin CabantacPas encore d'évaluation

- Abbrevation and AcronymDocument22 pagesAbbrevation and AcronymWanto SupriyoPas encore d'évaluation

- Tiger Offshore Catalog LowresDocument64 pagesTiger Offshore Catalog LowresRafaelPas encore d'évaluation

- 19720ipcc CA Vol1 Cp1Document28 pages19720ipcc CA Vol1 Cp1manoPas encore d'évaluation

- Method Computes PVT Properties For Gas CondensateDocument5 pagesMethod Computes PVT Properties For Gas CondensateSergio FloresPas encore d'évaluation

- SPE 150760 Efficient Methodology For Stimulation Candidate Selection and Well Workover OptimizationDocument14 pagesSPE 150760 Efficient Methodology For Stimulation Candidate Selection and Well Workover OptimizationVlassis SarantinosPas encore d'évaluation

- Usp 5Document43 pagesUsp 5Kanha NayakPas encore d'évaluation

- Assignment Energy CrisisDocument5 pagesAssignment Energy Crisisahsan azizPas encore d'évaluation

- Tankers at The Westridge Terminal - R3Document36 pagesTankers at The Westridge Terminal - R3The ProvincePas encore d'évaluation