Académique Documents

Professionnel Documents

Culture Documents

Energy Audit in Industry Unit India

Transféré par

john sepentCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Energy Audit in Industry Unit India

Transféré par

john sepentDroits d'auteur :

Formats disponibles

International Journal of Emerging Science and Engineering (IJESE)

ISSN: 23196378, Volume-2, Issue-1, November 2013

Energy Audit of an Industrial Unit- A Case Study

S. U. Kulkarni, Kalpana Patil

These activities include shutting off unused equipment,

changingequipment consuming more energy, improving

electricity demand management, reducing winter

temperature settings, turning off the light, etc. [5] . An

Energy Management System can be developed with the

basic idea to store the cheaper electrical energy at night in

an energy buffer and to use this stored energy during the day

[6] .

Abstract - In any industry, the three top operating expenses

are often found to be on energy, labor and materials. If one were

to find out the potential cost savings in each of the components,

energy would invariably emerge at the top, and thus energy

management function constitutes a strategic area for cost

reduction. This paper discusses the common aspects of electrical

energy management in small- and medium-sized industries. It

contains the findings and the analysis of the results obtained

from the electrical energy audit program employed in an

industrial unit, Loknayak J.P.Narayan Shtekari Sahakari

Sootgirni, Untawad Hol, Shahada.Dist.-Nandurbar. The

electrical energy audit was carried out under three major heads:

(i) lighting audit, (ii) power load audit (motors, meters, etc.), and

(iii) harmonic analysis. Readings were taken under these heads

and analyzed to find the scope of energy conservation

opportunities in the selected test case industrial unit.

II. AUDITING PROCEDURE

Energy audit cannot be successfully carried out without the

commitment from the top management. Management must

be firstly convinced of the necessity of implementing energy

management and hence energy audit [7] . Energy audit

consists of several tasks, which can be carried out depending

on the type of the audit and the size and the function of the

audited facility [8] . Therefore, an energy audit is not a

linear process and is rather iterative. The audit described in

this paper has been carried out based on the following

functional activities:

Walk-through survey

Motor load survey used in various processes

Harmonics analysis

Keywords: Energy audit, energy conservation opportunities,

harmonic analysis, industrial unit

I.

INTRODUCTION

Electrical energy is the most expensive and the most

important form of purchased energy. For this reason, its use

must be confined to a minimum for efficient and economic

operation [1] . Because of its flexibility, electricity offers

advantages over the conventional fossil fuels, and efforts to

conserve electricity can result in significant cost savings [2]

. Industries use a large amount of electrical energy, and that

is why it is important to ensure a loss-free and energyefficient system in industries [3] . In developing countries

like India, where electrical energy resources are scarce and

production of electricity is very costly, energy conservation

studies are of great importance. Energy audit is the

translation of conservation ideas into realities by blending

technically feasible solutions with economic and other

organizational considerations within a specified time frame

[4] . An energy audit is a study of a plant or facility to

determine how and where energy is used and to identify

methods for energy savings. Energy audits can mean

different things to different individuals. The scope of an

energy audit, the complexity of calculations, and the level of

economic evaluation are all issues that may be handled

differently by each individual auditor and should be defined

prior to the beginning of any audit activities [5],[6] . If we

can reduce the energy usage or improve the energy

efficiency in mechanical and electrical installations in a

building, energy can be conserved and some of the resulting

environmental problems, such as greenhouse effect and

ozone depletion, can be alleviated. The energy audit of an

industrial unit has been explored in this work. Energy

conservation can be obtained by proper maintenance and

operation.

III. FIELD VISITS AND MEASUREMENT WORK

Loknayak J.P.Narayan Sahakari Sootgirni is one of the

competitive yarn manufacturing industry in India supplying

around

60%

production

of

yarn

in

Export

Marketi.einUSA,Germany,Itly,Grees,Belgium,Portugal,Spai

n,Brazil,China,Egypt,Bangladesh, Srilanka etc. and also

domestically in various industries. An exhaustive electrical

energy audit was carried out and various data were collected

related to the audit work, for further analysis.

A. PLANT ELECTRICAL ENERGY CONSUMPTION

The energy consumption of the factory was identified in

terms of the equipment and functional area wise. The results

were obtained after measurements during the factory visits.

Data loggers, power analyzers, clamp meters, etc. were used

to measure the electrical energy consumption of the factory.

The total load of the unit is approximately 4273.104 KW.

The following points can be observed from this survey:

There are four transformers of the rating11 kv/415

kV, 1000KVA and one transformer of the rating 33 kV /11

kV, 5000 KVA.

The major load in the plant is that of motor, which

constitutes approximately 80% of the total load.

Total number of units consumed per month after taking

average of 12 months is 16 to 17 lakhs.

B. LIGHTING SURVEY

A walk-through audit was conducted during visits to assess

the illumination requirement of the plant and scope of

improvement of illumination quality and illumination level,

with an objective of cutting down the electrical energy

consumption and cost of electricity.

After the survey, it is observed that a large no.of fluorescent

tubes are used with copper ballast. It was observed

Manuscript received November, 2013.

Prof.Mrs S.U.Kulkurni, M.E. Control system from collage of

engg.,Pune, India

Kalpana D.Patil, B.E Electrical Engg. From D.N.Patel Collage of

Engg.,Shahada., India.

22

Energy Audit of an Industrial Unit- A Case Study

thatpresently reflectors are removed resulting into wastage

of light towards ceiling. It is recommended

1) To use electronics ballast in place of copper ballast.

1) To use reflector in ring frame area which are removed.

Use of reflector will improve illumination level at

work plane.

2) Clean light fixtures and lamps periodically

IV. HARMONIC ANALYSIS

With the increased usage of non-linear electrical loads and

automation in industrial units, poor power quality due to

harmonic distortion has come up as a serious issue. To

tackle the problem of increasing harmonic distortion in

power distribution system, Maharashtra State Electricity

Distributionco. has recently issued guidelines to various

medium- and large-scale industrial units of the state to get

voltage and current harmonic contents evaluated at their

premises at the Point of Common Coupling (PCC) and

undertake remedial filtering solutions, if required, for

harmonic limits in excess of the limits stipulated by IEEE519-1992Standard.

The goal of harmonic studies is to quantify the distortion

in voltage and current waveforms in the power system of

industrial units. The results are useful for evaluating

corrective

measures

and

troubleshooting

harmonicrelatedproblems.

Energy saving by replacement of copper ballast by

electronics ballast assuming average 12 hrs in

operation:Energy consumed per year with copper ballast = No. of

tubes watts 12 365

= 1059 36 12 365/1000= 1, 66,983.12 kwh

Energy consumed per year with electronics ballast

=118558.02 KWh

Energy saved by electronics ballast= 48,425 KWh

Amount saved per year by replacement of copper ballast =

Energy saving Rate/KWh =48,425 5.50

=Rs. 2, 66,338

Thus 29% energy is saved by replacement of copper ballast

byelectronics ballast

A.EFFECTS OF HARMONICS ON NETWORKS

C.MOTOR SURVEY

Many motors used in plant and other sections have plastic

cooling fans. Still some of the motors are fitted with heavy

metal cooling fan. The metallic fans are heavy and over the

years develop pitting due to corrosion and allow material

build up and consume more power. Fiberglass Reinforced

Plastic cooling fans are lighter and also prevents materials

build up and hence consume less power. As the mechanical

power consumed by the rotor is constant irrespective of the

load on the motor, the energy savings resulting from this

modification will be around 2% of the rated KW of the

motor.

Thepowerconsumedbyfanmotorsisalsodefendantonthewei

ght

of

thefans.

FiberglassReinforced

Plasticbladesaremuchlighterin

weightcomparedto

aluminumbladesandconsume20to40%lesspower.

Overloading of neutral conductor

Reduced efficiency of motors

Malfunctioning of control equipment

Poor power factor of the total system due to

introduction of distortion power factor

Overloading of power factor capacitors

Increase in kVA demand of the plant due to

increase in rms current drawn

B.HARMONIC MEASUREMENTS AT THE CASE

UNIT:The harmonic spectrum of LT currents in three-phase

distribution system of the plant recorded with the help of

Power and Harmonic Analyzer is indicated in the following

fig. 1 to 8 and table no. 1to 6.

Term

V1-THD

V2-THD

V3-THD

U12-THD

U23-THD

U31-THD

I1-THD

I2-THD

I3-THD

IN-THD

RECOMMENDATIONS: For large motors metallic

cooling fans are used it is recommended to replace all such

metallic fans by Fiberglass Reinforced Plasticfans. Total

energy cost saving will be @ 2% of rated power of motor.

Also for the fan motors metal fans areused, it is

recommended to replace all these fans by FRP fans. Total

energy saving will be 25%.

Energy saving by replacement of metal fan by FRP fan =

Rating of motor no. of motors working

hrs/yearpercentage energy cost saving by replacement

Amount saved per year = Energy saved rate of energy

Unit

%

%

%

%

%

%

%

%

%

%

Max.

9.74

9.73

10.46

9.57

10.11

10.09

32.85

33.3

35.5

654.87

Min.

8.48

8.52

9.12

8.41

8.92

8.92

26.46

27.19

30.34

18.85

Avg.

9.129224299

9.227841121

9.82846729

9.079158879

9.561943925

9.507439252

30.2007757

30.75662617

33.1386729

426.9777903

Table no. 1 Transformeran electrical Trends

d) Replacement of metal cooling fan of fan motors by FRP

fan

11.0

10.5

Rated power of fan motors =7.5KW

Number of fan motors =7

Energy consumption with metal fans= =7.578760 =

459900 KWh

Energy consumption with FRP fans = 344925 KWh

Energy saving by replacement of metal cooling fans by FRP

fans per year = 114975 KWh

Amount Saved Per Year = 1149755.50

= Rs.6, 32,362.5

10.0

9.50

9.00

8.50

8.00

6/28/2013

3:23:00.000 PM

15:00.000 (min:s)

3 min/Div

6/28/2013

3:38:00.000 PM

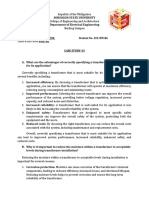

Fig.1 Total Harmonic Distortion (THD) Voltage

23

International Journal of Emerging Science and Engineering (IJESE)

ISSN: 23196378, Volume-2, Issue-1, November 2013

Ter

Unit

Max.

Min.

Avg.

34.0

V1-THD

V2-THD

%

%

7.17

6.74

6.28

5.81

6.75907

6.247384

32.0

V3-THD

6.89

5.95

6.467373

U12-THD

6.02

6.554324

U23-THD

6.61

5.88

6.255968

U31-THD

6.95

6.24

6.6312

I1-THD

15.85

13.15

14.62276

I2-THD

12.98

10.49

11.91174

I3-THD

15.17

12.08

13.9587

IN-THD

654.17

162.5

423.8821

36.0

%

30.0

28.0

26.0

6/28/2013

3:23:00.000 PM

15:00.000 (min:s)

3 min/Div

6/28/2013

3:38:00.000 PM

Fig.2 Total Harmonic Distortion (THD) Current

Term

Unit

Max.

Min.

Avg.

V1-THD

8.01

8.01

8.01

V2-THD

7.68

7.68

7.68

V3-THD

7.77

7.77

7.77

U12-THD

7.87

7.87

7.87

U23-THD

7.49

7.49

7.49

U31-THD

7.89

7.89

7.89

I1-THD

17.96

17.96

17.96

I2-THD

15.66

15.66

15.66

I3-THD

15.84

15.84

15.84

IN-THD

390.13

390.13

390.13

Table no. 3Transformer C electrical Trends

7.50

7.00

6.50

6.00

5.50

6/28/2013

2:41:00.000 PM

13:00.000 (min:s)

2 min/Div

6/28/2013

2:54:00.000 PM

Fig.5 Total Harmonic Distortion (THD) Voltage

Table no.2 Transformer B electrical Trends

16.5

8.50

16.0

15.5

15.0

8.00

14.5

14.0

7.50

13.5

13.0

12.5

7.00

12.0

11.5

11.0

6.50

10.5

10.0

6/28/2013

3:51:00.000 PM

15:00.000 (min:s)

3 min/Div

6/28/2013

2:41:00.000 PM

6/28/2013

4:06:00.000 PM

Term

V1-THD

V2-THD

V3-THD

U12-THD

U23-THD

U31-THD

I1-THD

I2-THD

I3-THD

IN-THD

18.5

18.0

17.5

17.0

16.5

16.0

15.5

15.0

14.5

14.0

13.5

13.0

6/28/2013

3:51:00.000 PM

15:00.000 (min:s)

3 min/Div

6/28/2013

2:54:00.000 PM

Fig.6 Total Harmonic Distortion (THD) Current

Fig.3 Total Harmonic Distortion (THD) Voltage

13:00.000 (min:s)

2 min/Div

Unit

%

%

%

%

%

%

%

%

%

%

Max.

6.56

6.09

6.18

6.32

5.94

6.26

13.67

11.83

13.1

652.91

Min.

5.7

5.4

5.35

5.61

5.32

5.61

10.48

8.72

10.01

21.61

Avg.

6.126647

5.741192

5.794848

5.993236

5.675479

5.9591

11.18354

9.455222

10.63162

389.5415

6/28/2013

4:06:00.000 PM

Table no. 4 Transformer D electrical Trends

Fig.4 Total Harmonic Distortion (THD) Current

24

Energy Audit of an Industrial Unit- A Case Study

measured THD value (voltage) is large as compared tothis

limit. Therefore, the consumer must install a harmonic filter

to improve the power quality and save the penalty on

harmonic emission.

6.50

6.00

V.FOLLOWING RECOMMENDATIONS HAVE BEEN

SUGGESTED TO THE CONSUMER:

5.50

5.00

6/28/2013

2:18:01.000 PM

13:00.000 (min:s)

2 min/Div

6/28/2013

2:31:01.000 PM

Fig.7 Total Harmonic Distortion (THD) Voltage

12.5

12.0

11.5

11.0

10.5

10.0

9.50

9.00

8.50

6/28/2013

2:18:01.000 PM

13:00.000 (min:s)

2 min/Div

6/28/2013

2:31:01.000 PM

Fig.8 Total Harmonic Distortion (THD) Current

3 Verification of IEEE Limit Compliance

From the data provided by the Electrical Section of the

Plant, The short-circuit current (Isc ) calculated at PCC is

20725.9 A and short-circuit ratio is 14.9

Table no. 5 Current distortion limit of IEEE-519-1992

standard

Table no. 6 Voltage Distortion Limit

It is recommended to replace Copper ballast by

Electronic ballast.

Whenever 40Watt/36 Watt conventional tube lights

will fail replace the same by 36 Watt tri-phosphor,

True light of Philips make .Lumen output of the same

is 3250 lumen as compared to conventional 40W /36

watt tube rod hasFOLLOWING FEATURES

Aspectrumalmostidenticaltonaturaldaylight

Stimulatingbiologicaleffect

Superbcontrastvision

Absolutelytrue-tolifecolourrenderingthroughcolourtemperature

inoptimumdaylightrange5,500

Optimumcolour renderingpropertiesRa96

Wider,morecontinuousspectrum

comparedwithotherfluorescent lamps

Steady,balancedlightquality

Servicelife

whenoperatedwithelectronicballast(Warmstart):13,000

hours

Lamps shall be switched OFF when not required.

Use reflector in ring frame area which are removed

.Use of reflector will improve illumination level at

work plane. Presently reflectors are removed resulting

into wastage of light towards ceiling.

Clean light fixtures and lamps periodically.

Electric energy cost could also be saved in the office

area where air conditioners are used, by using false

ceiling and double door system

Replace metal cooling fans by Fiberglass Reinforced

Plastic Fans to save energy.

Harmonic components at PCC are greater than the

permissible limits. Therefore, the consumer must

install harmonic filter to improve the power quality and

save the penalty on harmonic emission.

Harmonic component across individual loads is much

higher where variable frequency drives are used, which

reflects at the PCC, so a more in-depth analysis is

required and a harmonic filter can be designed.

NominalVoltagekV

%VTHD

0.415kV

5.0%

VI. CONCLUSION

11kVor3.3kV

4.0%

33kV

3.0%

By performing Energy Audit above recommendations have

been suggested due to which industry can save total amount

of Rs. 8,98,700/- per year.

132kV

1.0%

REFERENCES

[1]S. K. Aggarwal, M. Kumar, L. M. Saini, and A. Kumar, "Short-term load

forecasting in deregulated electricity markets using fuzzy approach",

Journal of Engineering and Technology, Vol. 1, no. 1, pp. 24-30, JanJun2011.

[2]H. K. Wong, and C. K. Lee, "Application of energy audit in buildings and

a case study", IEEE International Conference on Advances in Power

System

Control,

Operation

and

Management

1993,

HongKong,Dec1993.

[3]P. Z. Yaacoh, and A. A. Mohd. Zin, "Electrical energy management in

small and medium size industries", IEEE TENCON, Beijing, 1993.

The industrial consumer under study falls in the category of

short-circuit ratio lying in the range <20, for which the

maximum allowable THD value is 4% (up to 11 th

harmonics). It is clear that the measured THD value at the

PCC of Loknayak J.P.NarayanS.Sootgirni is large as

compared to its allowable limit of 4%.Also the allowable

percentage voltage THD limit is 5% for0.415 kV. The

25

International Journal of Emerging Science and Engineering (IJESE)

ISSN: 23196378, Volume-2, Issue-1, November 2013

[4]A. Thumann, and W. J. Yonger, "Hand Book of Energy Audits", 7 th ed,

Lilburn: Fairmont Press Inc.; 2007.

[5]W. J. Lee, "Energy Management for Motors, Systems, and Electrical

Equipment", Industrial and Commercial Power Systems Technical

Conference, IEEE, 2001.

[6]B. Huyck, and J. Cappelle, "Electrical energy management for lowvoltage clients", International Conference on Clean Electrical Power,

IEEE, 2007.

[7]X. W. Chen, "Energy Audit of Building: A Case Study of A Commercial

Building in Shanghai", Power and Energy Engineering Conference,

Asia-Pacific, 2010.

[8]A. Tyagi, "Hand Book of Energy Audit & Management" India: TERI

Press; 2000.

[9]"Catalouge Surelink Technologies" Shenzhen, China, 2008

[10] "IEEE recommended practice for electric power systems in commercial

buildings", Recognized as an American National Standard (ANSI) IEEE

Standard, pp. 241, 1990.

[11] "Hindustan Electric Motors Catalouge", Arranged from Admin Off. Mumbai,

India: Hindustan Electric MotorCompany;2008.p.1-2.

[12] Havells Catalouge: Energy Efficient Three phase Induction Motors" arranged

from Branch office. Chandigarh, India: Havells lafert Motors; 2009. p. 3-4.

[13] Havells Catalouge: Energy Efficient Three phase Induction Motors" arranged

from Branch office. Chandigarh: 2008.

[14] C. T. Andrade, and S. T. Ricardo, "Three-phase induction motors- Energy

Efficiency Standards-A Case Study", Pontes Electrical Engineering

Department, Cear Federal University, 2008.

[15] "IEEE Recommended Practice for Energy Management in Industrial and

Commercial Facilities", Recognized as an American National Standard

(ANSI)

IEEE

Standard,

pp.

739,

1995.

Prof.Mrs S.U.Kulkurni,M.E. Control system from collage of engg.,Pune.

Associate Professor in Dept. Of Electrical Engg.,Bharti Vidyapeeth

Deemed University Collage of Engg.,Pune

Kalpana D.Patil B.E Electrical Engg. From D.N.Patel Collage of

Engg.,Shahada. North Maharastra University,Jalgaon Pursuing M.tech

Electrical Power System From Bharti Vidyapeeth Deemed University

Collage of Engg.,Pune

26

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- IEC 60601-1 Medical Design Standards - 3rd EditionDocument7 pagesIEC 60601-1 Medical Design Standards - 3rd Editionacm573100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Failure of Transformer InsulationDocument9 pagesFailure of Transformer InsulationSachin RaiPas encore d'évaluation

- Earthing & Lightning Protection System TrainingDocument25 pagesEarthing & Lightning Protection System TrainingNaushad Haider100% (1)

- General Requirement - RAN Site Infrastructure v.01 - FINALDocument80 pagesGeneral Requirement - RAN Site Infrastructure v.01 - FINALSoepar Nova Syam100% (1)

- Sanyu SY2000 English ManualDocument37 pagesSanyu SY2000 English Manualhv1793 VPas encore d'évaluation

- En - Steval-Idb011v1 Schematic PDFDocument6 pagesEn - Steval-Idb011v1 Schematic PDFJemPas encore d'évaluation

- Sentron Harmonic Mitigating Transformers (HM1 & HM2)Document2 pagesSentron Harmonic Mitigating Transformers (HM1 & HM2)Alfredorodriguez GutierrezPas encore d'évaluation

- Om On280Document38 pagesOm On280yonasPas encore d'évaluation

- Aiwa - 4ZG - 1A, 1B e 1Z-MecanicaDocument70 pagesAiwa - 4ZG - 1A, 1B e 1Z-MecanicaSergioPas encore d'évaluation

- BarronDocument21 pagesBarronMltm DrmPas encore d'évaluation

- EMI Important Questions-1Document13 pagesEMI Important Questions-1SBU eduPas encore d'évaluation

- Planing PM Centrale GPEG 2021Document4 pagesPlaning PM Centrale GPEG 2021Salim82 LKPas encore d'évaluation

- wt6000 rs6000 Accessories GuideDocument14 pageswt6000 rs6000 Accessories GuideToma HrgPas encore d'évaluation

- Breaking Code Read Protection on NXP LPC MicrocontrollersDocument57 pagesBreaking Code Read Protection on NXP LPC MicrocontrollerspaulPas encore d'évaluation

- Piyali MoulickDocument2 pagesPiyali MoulickparthaPas encore d'évaluation

- LG+47ln5700 47ln570t 47ln570y 47ln5710 Chassis lb33bDocument119 pagesLG+47ln5700 47ln570t 47ln570y 47ln5710 Chassis lb33bmidominguez0% (1)

- AN10496 Vacuum Cleaner With Philips P89LPC901Document32 pagesAN10496 Vacuum Cleaner With Philips P89LPC901zdravkorrPas encore d'évaluation

- An 931 Appnote Ad7689Document4 pagesAn 931 Appnote Ad7689Gunta AkhiriPas encore d'évaluation

- Electrical Engineer Resume - 3+ Years ExperienceDocument5 pagesElectrical Engineer Resume - 3+ Years ExperienceAri MachaPas encore d'évaluation

- Goldstar 26lx1r-ZeDocument36 pagesGoldstar 26lx1r-Zef17439Pas encore d'évaluation

- Cerberr31 Manual EngDocument8 pagesCerberr31 Manual EngAdlenPas encore d'évaluation

- ADM2 Fault Codes Diagnosis, Version 203: DTC Description Remedial ActionDocument5 pagesADM2 Fault Codes Diagnosis, Version 203: DTC Description Remedial ActionJulioRamirezPas encore d'évaluation

- Edb RF51418 Eng UsDocument2 pagesEdb RF51418 Eng UsLuis DeibisPas encore d'évaluation

- iSTAR Ultra LT QSG 8200 1335 01 D0 enDocument27 pagesiSTAR Ultra LT QSG 8200 1335 01 D0 enJan Andre RøePas encore d'évaluation

- NPN Silicon Planar Transistors BC107/A/B/C BC108/A/B/C BC109/A/B/C TO-18 Metal Can PackageDocument4 pagesNPN Silicon Planar Transistors BC107/A/B/C BC108/A/B/C BC109/A/B/C TO-18 Metal Can PackageFilip BonacicPas encore d'évaluation

- Connectors: Installation InstructionsDocument4 pagesConnectors: Installation InstructionsRenzzo Gomez ReatigaPas encore d'évaluation

- Technical Data Aurora Fire Pump (ULFM) Project Kerry KIIC - Karawang - Rev.1Document84 pagesTechnical Data Aurora Fire Pump (ULFM) Project Kerry KIIC - Karawang - Rev.1Back To SumateraPas encore d'évaluation

- Case Study #3 - Gigantone, JustineDocument2 pagesCase Study #3 - Gigantone, JustineJustine LinesPas encore d'évaluation

- 6ES72315PF320XB0 Datasheet en PDFDocument4 pages6ES72315PF320XB0 Datasheet en PDFahmad 58parsPas encore d'évaluation

- II BTECH - I SEM - ECE - EDC - THEORY & QUIZ QUESTIONS - MID 2 - Students PDFDocument19 pagesII BTECH - I SEM - ECE - EDC - THEORY & QUIZ QUESTIONS - MID 2 - Students PDFK SrinuPas encore d'évaluation