Académique Documents

Professionnel Documents

Culture Documents

OSHA Checklist

Transféré par

César Augusto Quiroga MontenegroDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

OSHA Checklist

Transféré par

César Augusto Quiroga MontenegroDroits d'auteur :

Formats disponibles

HOW TO AVOID:

OSHA FINES | OPERATOR INJURIES | PRODUCT DAMAGE

AN 8 POINT GUIDE PROVIDED BY TRI-LIFT NJ

2 DAILY INSPECTIONS

TRAINING

1 OPERATOR

OSHA Sections 1910.178(I)(1)(i) - (I)(4)(iii)

OSHA Section 1910.178(q)(7)

The employer must ensure that each operator has successfully

completed the required training to operate the type of truck

he/she will be using. Re-certification is required every 3 years.

Industrial trucks must be examined before being placed in service.

If the examination shows any condition adversely affecting the safety

of the vehicle, it cannot be used. Such examination must be made daily.

When used in multiple shifts, they must be re-examined at the beginning

of each shift. Defects must be reported and corrected before use.

3 CHAINS

LIGHTS & ALARMS

Chains should be inspected,

cleaned and lubricated after

every 100 hours of service and

more frequently in abusive

or cold environments. Chains

should be replaced when it has

elongated by 3%. Chains can

never be repaired by

replacing a section.

OSHA Section 1910.178(i)(1)

When general lighting is less than 2 lumens

per square foot, auxiliary lighting shall be provided on

the truck. Back up alarms, amber strobes, and a horn

can significantly reduce operator accidents and

prevent product damage and operator injury.

YOUR COMPANY IS AT RISK!

Lift Truck accidents are very costly to

5

companies. The costs associated are:

FORKS 5

ANSI/ITSDF B56.1-2009, 6.2.8

Product and equipment damage

Lost time

Increased insurance costs

Litigation

Forks should be inspected at least once a year

(single shift operation, and more frequently in

severe applications) for wear and distortion. ANSI

ITSDF states, if the thickness is reduced by 10% of

the original thickness, the fork cannot be used.

It is not uncommon for accidents to cost a company

over 1 million dollars. Some companies cannot survive

the aftermath of such an accident, and permanently

close their doors.

6 TIRES

Tires are often overlooked on lift trucks. Forklifts have no suspension or

shocks, therefore all of the impact is transferred directly to the operator.

Plus, worn or chunked tires reduce load capacity and can seriously hinder

a standard operation.

Pneumatic-shaped solid tires should be replaced when the thickness of the

tire has worn to about three quarters of the original section height. Presson tires should be replaced when 30% of the tires tread has worn off.

7 FALL PROTECTION

ANSI/ITSDF B56.1-2009, 4.17.1

Now, the weight of the operator determines the type of safety restraint used

on low lift and high lift operator-up trucks. Also, fixed length, non-energy

absorbing lanyards are no longer permitted for these applications.

An operator may use the corresponding device based on their weight:

body belt + self-retracting lanyard

full-body harness + energy-absorbing lanyard

full-body harness + self-retracting lanyard

X

X

X

> 220 lbs.

AERIAL INSPECTIONS

The owner of an aerial platform has to ensure that an annual inspec-

X

X

220 - 310 lbs.

tion is performed on the aerial platform no later than 13 months

from the date of the prior annual inspection. The inspection shall be

X

311 - 400 lbs.

performed by a person(s) qualified as a mechanic on the specific

make and model of the aerial platform. The inspection shall include

all items specified by the manufacturer for an annual inspection.

EQUIPMENT WATCH LIST

POTENTIAL MACHINE ISSUES | SAFETY VIOLATIONS

Make:

Model:

Serial:

CHAINS

FORKS

TIRES

Make:

Model:

Serial:

Unit #:

SIGNALS

OTHER

NEEDS IMMEDIATE ATTENTION

Make:

Model:

Serial:

CHAINS

FORKS

TIRES

CHAINS

FORKS

TIRES

OTHER

EQUIPMENT

AERIAL

OTHER

FORKS

TIRES

Unit #:

SIGNALS

OTHER

OTHER

CHAINS

FORKS

TIRES

Unit #:

SIGNALS

NEEDS IMMEDIATE ATTENTION

ADDITIONAL SAFETY CONCERNS:

Make:

Model:

Serial:

SIGNALS

CHAINS

Make:

Model:

Serial:

NEEDS IMMEDIATE ATTENTION

TIRES

SIGNALS

NEEDS IMMEDIATE ATTENTION

Unit #:

SIGNALS

TIRES

Make:

Model:

Serial:

NEEDS IMMEDIATE ATTENTION

Make:

Model:

Serial:

FORKS

NEEDS IMMEDIATE ATTENTION

Unit #:

SIGNALS

CHAINS

Unit #:

OPERATOR TRAINING

Unit #:

OTHER

NEEDS IMMEDIATE ATTENTION

Need Training?

Go to www.tlnj.co/training

to setup a training class at your facility.

DAILY INSPECTIONS

EMISSIONS

SAFETY RESTRAINTS

OTHER

Need SERVICE?

Go to www.tlnj.co/service

Call 732.220.0444 ext.109

Email service@tlnj.co

www.tlnj.co

OTHER

Vous aimerez peut-être aussi

- Genie Train The Trainer CatalogDocument9 pagesGenie Train The Trainer CatalogClaudio FreitasPas encore d'évaluation

- ITI Bull Rigging-Webinar Markup 081618Document51 pagesITI Bull Rigging-Webinar Markup 081618Rezende JulioPas encore d'évaluation

- AWS D1.1 - Arjan Roza PDFDocument35 pagesAWS D1.1 - Arjan Roza PDFCésar Augusto Quiroga MontenegroPas encore d'évaluation

- 3576 Erbil MergedDocument4 pages3576 Erbil MergedAli AlahmaPas encore d'évaluation

- Forklift Pre UseDocument1 pageForklift Pre Usesandeep palPas encore d'évaluation

- 03-Slope Stability Analysis of Cut Slopes Using Rock and Slope MassDocument17 pages03-Slope Stability Analysis of Cut Slopes Using Rock and Slope MassArif KesumaningtyasPas encore d'évaluation

- CMCO Training BrochureDocument16 pagesCMCO Training BrochuresugiyantoPas encore d'évaluation

- Mobile Crane Logbook Permanent Record: (OHS) ActDocument20 pagesMobile Crane Logbook Permanent Record: (OHS) ActAltayeb YassinPas encore d'évaluation

- Grove Rt640 LCDocument17 pagesGrove Rt640 LCCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Winch System-Mechanical-Electrical-Clutch-HydraulicDocument2 pagesWinch System-Mechanical-Electrical-Clutch-HydraulicMamta Raybage100% (1)

- Mobile Crane Operator Candidate Handbook - 120122aDocument33 pagesMobile Crane Operator Candidate Handbook - 120122a전우영Pas encore d'évaluation

- 2009 UTILITY Trailer Manual V3.0Document92 pages2009 UTILITY Trailer Manual V3.0CR CPas encore d'évaluation

- Cranes and DerricksDocument15 pagesCranes and DerricksAl Hamra AyashofiyaPas encore d'évaluation

- Certificate For Examination of Overhead CraneDocument2 pagesCertificate For Examination of Overhead CraneAnisha MayaPas encore d'évaluation

- LEI - 3 Day Course-Thorough ExaminationDocument3 pagesLEI - 3 Day Course-Thorough ExaminationmossamorrisPas encore d'évaluation

- SFPSG-Safe Use DumpersDocument90 pagesSFPSG-Safe Use DumpersLyle KorytarPas encore d'évaluation

- Hoi Xe MyDocument81 pagesHoi Xe MyĐứcNhậtPas encore d'évaluation

- Lifting Categorisation Flow Chart OnshoreDocument3 pagesLifting Categorisation Flow Chart OnshoreEhab SaadPas encore d'évaluation

- Job MixDocument62 pagesJob MixShaim RehanPas encore d'évaluation

- Ecil Model Paper: Expected Model Pattern For The Entrance Exam of ECIL GET Is As BelowcDocument9 pagesEcil Model Paper: Expected Model Pattern For The Entrance Exam of ECIL GET Is As BelowcSumit KumarPas encore d'évaluation

- Kamag SPMTDocument3 pagesKamag SPMTJhun AquinoPas encore d'évaluation

- IMIA WGP 09115 CCPP Combined Cycle Power PlantsFinal 1 PDFDocument44 pagesIMIA WGP 09115 CCPP Combined Cycle Power PlantsFinal 1 PDFBikash Kr. Agarwal100% (1)

- Technical Test Theory: Compact Crane A66Document6 pagesTechnical Test Theory: Compact Crane A66memoPas encore d'évaluation

- Master Thesis The Development of Autonomous VehiclesDocument116 pagesMaster Thesis The Development of Autonomous Vehiclescristi_pet4742Pas encore d'évaluation

- Crawler Crane ChecklistDocument2 pagesCrawler Crane ChecklistAnuraj100% (1)

- Multiple Crane LiftingDocument11 pagesMultiple Crane LiftingAbdul Majid ZulkarnainPas encore d'évaluation

- Dumarent-manUSM Manitou MSI25 - MSI 30 - enDocument124 pagesDumarent-manUSM Manitou MSI25 - MSI 30 - enSerban AlexandruPas encore d'évaluation

- Especificaciones20108368 RevisionG ENGR LATESTDocument59 pagesEspecificaciones20108368 RevisionG ENGR LATESTRafael Dutil LucianaPas encore d'évaluation

- NPORS Training Category ListDocument56 pagesNPORS Training Category ListKevin MorrisPas encore d'évaluation

- Jennonoverlinecrane 35286 Smoe - 12x30t Eotc 2x10ton GC Span 30m Hol 12mDocument6 pagesJennonoverlinecrane 35286 Smoe - 12x30t Eotc 2x10ton GC Span 30m Hol 12mjurieskPas encore d'évaluation

- RM 1ehsapprovedcosforliftingequippressvessels250914Document9 pagesRM 1ehsapprovedcosforliftingequippressvessels250914wholenumberPas encore d'évaluation

- BT Lifter HPT Brochure 0614Document12 pagesBT Lifter HPT Brochure 0614Ram ReddyPas encore d'évaluation

- Overhead CraneDocument18 pagesOverhead Craneemail2yogeshshindePas encore d'évaluation

- DOE Std.1090 07 Forklift TrucksDocument35 pagesDOE Std.1090 07 Forklift TrucksjoseritoPas encore d'évaluation

- Montacarga Electrico 3 Ton PDFDocument12 pagesMontacarga Electrico 3 Ton PDFJEANR77Pas encore d'évaluation

- Cranes Hoisting and RiggingDocument25 pagesCranes Hoisting and Riggingkanakarao1Pas encore d'évaluation

- CIA-Brochure Crane Institute of AmericaDocument8 pagesCIA-Brochure Crane Institute of AmericaJonathan Soto OlayaPas encore d'évaluation

- Al Tasnim SOP For Periodic Maintenance and Repair FDocument90 pagesAl Tasnim SOP For Periodic Maintenance and Repair Franvijay dubeyPas encore d'évaluation

- Curriculum For The Trade Of: RiggerDocument34 pagesCurriculum For The Trade Of: Riggermd nasimPas encore d'évaluation

- Method Statement For Lifting Operations: 1 - IntroductionDocument3 pagesMethod Statement For Lifting Operations: 1 - Introductiontravman1Pas encore d'évaluation

- Tower Crane-Inspections-ListDocument3 pagesTower Crane-Inspections-ListLuffy11Pas encore d'évaluation

- 1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceDocument11 pages1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceIstiQamahh MuhamadPas encore d'évaluation

- Compliance Assistance Checklist For PrecastDocument6 pagesCompliance Assistance Checklist For PrecasttatonyPas encore d'évaluation

- LEEA Correspondence Courses: Assignment 1.2Document3 pagesLEEA Correspondence Courses: Assignment 1.2Primelift Safety Resources Limited0% (1)

- Products - Monthly Checklist MCDocument2 pagesProducts - Monthly Checklist MCDiegoCaicedo1982Pas encore d'évaluation

- Safety Alert: (E.g. Damage To Environment, Reputation, Equipment Schedule and Cost)Document5 pagesSafety Alert: (E.g. Damage To Environment, Reputation, Equipment Schedule and Cost)zaheerPas encore d'évaluation

- 64-Crane Operator Program NcmscurrentDocument5 pages64-Crane Operator Program NcmscurrentJojo Betanio AkajoknoPas encore d'évaluation

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanPas encore d'évaluation

- Superlift Advantage: Serial Number RangeDocument46 pagesSuperlift Advantage: Serial Number RangeEastermMetalWorksPas encore d'évaluation

- Strong Dual Hawk Tandem Rev H 2008Document70 pagesStrong Dual Hawk Tandem Rev H 2008FaderPas encore d'évaluation

- Liebherr LR1350 1 PDFDocument54 pagesLiebherr LR1350 1 PDFRazat RanaPas encore d'évaluation

- API RP 8B Hoisting EquipmentDocument8 pagesAPI RP 8B Hoisting EquipmentANSARAKUPas encore d'évaluation

- Fall Arrest: Product CatalogueDocument60 pagesFall Arrest: Product CatalogueBorislav VulićPas encore d'évaluation

- Offshore Crane OperationsDocument1 pageOffshore Crane OperationsAnonymous cekPJylABoPas encore d'évaluation

- Tomar - Industrial Signalling CatalogDocument82 pagesTomar - Industrial Signalling CatalogPrejit RadhakrishnaPas encore d'évaluation

- Pre Lift PlanDocument1 pagePre Lift PlanPhilippe-Alexandre BérubéPas encore d'évaluation

- Gunnebo 2000Document36 pagesGunnebo 2000Ed CalhePas encore d'évaluation

- IP-HMT V07 - Hydraulic Car Lift: Car Parking Solutions: Tel: +61 (03) 9763 5899Document4 pagesIP-HMT V07 - Hydraulic Car Lift: Car Parking Solutions: Tel: +61 (03) 9763 5899Ishan RanganathPas encore d'évaluation

- Solar Operated Crane SystemDocument3 pagesSolar Operated Crane Systemankush belkar100% (1)

- Owner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEDocument10 pagesOwner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEmanafPas encore d'évaluation

- Specifications & Load Charts: 40 Ton Tele-Boom Crawler CraneDocument16 pagesSpecifications & Load Charts: 40 Ton Tele-Boom Crawler CraneLauren'sclub EnglishBimbel Sd-smaPas encore d'évaluation

- Rigger III PDFDocument1 pageRigger III PDFMohamed Hameem DeenPas encore d'évaluation

- Guia de Usuario GPS Spectra SP80 PDFDocument118 pagesGuia de Usuario GPS Spectra SP80 PDFAlbrichs BennettPas encore d'évaluation

- Morris Manual Hoists Winches BrochureDocument5 pagesMorris Manual Hoists Winches BrochurefirlimustariPas encore d'évaluation

- Despiece Polipasto Manual CycloneDocument40 pagesDespiece Polipasto Manual CyclonearmandoPas encore d'évaluation

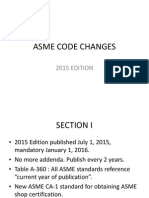

- Asme Code Changes: 2015 EDITIONDocument19 pagesAsme Code Changes: 2015 EDITIONInnocent RabiosaPas encore d'évaluation

- Tabla Caracteristicas Hiab Xs 322 Ep5 HiduoDocument1 pageTabla Caracteristicas Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Aws Bookstore. Whb-5.9 Welding Handbook..Document2 pagesAws Bookstore. Whb-5.9 Welding Handbook..César Augusto Quiroga Montenegro0% (1)

- Caracteristicas Hiab Xs 322 Ep5 HiduoDocument1 pageCaracteristicas Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Tabla Carga Hiab Xs 322 Ep5 HiduoDocument1 pageTabla Carga Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroPas encore d'évaluation

- D1 Committee On Structural Welding - Te..Document1 pageD1 Committee On Structural Welding - Te..César Augusto Quiroga MontenegroPas encore d'évaluation

- Caracteristicas Hiab Xs 322 Ep5 HiduoDocument1 pageCaracteristicas Hiab Xs 322 Ep5 HiduoCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Manta para SoldaduraDocument1 pageManta para SoldaduraCésar Augusto Quiroga MontenegroPas encore d'évaluation

- 500e Product GuideDocument8 pages500e Product GuideCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Law.resource.orgDocument3 pagesLaw.resource.orgCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Smart Inspection Form 2Document1 pageSmart Inspection Form 2César Augusto Quiroga MontenegroPas encore d'évaluation

- DOE Technical Standards Program - ArchiveDocument8 pagesDOE Technical Standards Program - ArchiveCésar Augusto Quiroga MontenegroPas encore d'évaluation

- ESP SketchBook 7 11 MASDocument85 pagesESP SketchBook 7 11 MASCésar Augusto Quiroga MontenegroPas encore d'évaluation

- Longest BridgeDocument2 pagesLongest BridgelenionliewPas encore d'évaluation

- 1929 Matchless V2 Instruction Book and Spares ListDocument50 pages1929 Matchless V2 Instruction Book and Spares ListThunderbird3Pas encore d'évaluation

- 9-11use of EnglishDocument5 pages9-11use of EnglishLô Vỹ Vy VyPas encore d'évaluation

- TRL 228 Movements Trigger Limits - Embedded Retaining WallsDocument28 pagesTRL 228 Movements Trigger Limits - Embedded Retaining WallsDoug WeirPas encore d'évaluation

- Albany AMP CH 8 ALP Draft Final W ALPDocument16 pagesAlbany AMP CH 8 ALP Draft Final W ALPAhmed Subhi AbdaljabbarPas encore d'évaluation

- Battle For The Beetle by Karl Ludvigsen - Table of ContentsDocument3 pagesBattle For The Beetle by Karl Ludvigsen - Table of ContentsBentley PublishersPas encore d'évaluation

- 3203T Accesorii Hunter EchilibratDocument16 pages3203T Accesorii Hunter EchilibratCiprian TarataPas encore d'évaluation

- Compact CityDocument12 pagesCompact CityVarna R anandPas encore d'évaluation

- Method Statement Open TrenchDocument4 pagesMethod Statement Open TrenchShafiq MustapaPas encore d'évaluation

- Vol3-Chapter6 Bridge DesignDocument13 pagesVol3-Chapter6 Bridge DesignRaditya AzkaLaodePas encore d'évaluation

- Composite Bridge AllDocument1 pageComposite Bridge AllNavanitha PPas encore d'évaluation

- What Is New in PTV Vissim/Viswalk 11Document20 pagesWhat Is New in PTV Vissim/Viswalk 11Billy BrosPas encore d'évaluation

- EZGO 5 PersonDocument100 pagesEZGO 5 PersonErnPas encore d'évaluation

- Pavement Distress Survey Manual: Pavement Services Unit Revised June 2010Document58 pagesPavement Distress Survey Manual: Pavement Services Unit Revised June 2010oh my godPas encore d'évaluation

- Thesis For Taxi DriverDocument6 pagesThesis For Taxi Driversoniasancheznewyork100% (2)

- Turfgrid: Versatile Permeable PavementDocument2 pagesTurfgrid: Versatile Permeable PavementBenPas encore d'évaluation

- Dotcdirectory 29 Ja 16 ADocument12 pagesDotcdirectory 29 Ja 16 ACarlos ValdesPas encore d'évaluation

- Project ManagementDocument99 pagesProject ManagementVIJAY BHILWADEPas encore d'évaluation

- RoadsDocument23 pagesRoadsNikhil SharmaPas encore d'évaluation

- BicycleDocument4 pagesBicycleFaqih AbdussalamPas encore d'évaluation

- Public Transportation: Greater Kota KinabaluDocument1 pagePublic Transportation: Greater Kota KinabaluSiti MasliahPas encore d'évaluation

- 5 - 15 - 2008 - 12 - 12 - 20 - PM38 Ais-039 PDFDocument10 pages5 - 15 - 2008 - 12 - 12 - 20 - PM38 Ais-039 PDF9096664279Pas encore d'évaluation

- Checklists For Interurban Highways - Detailed DesignDocument20 pagesChecklists For Interurban Highways - Detailed DesignKocic GradnjaPas encore d'évaluation

- Pemilihan Metode Penanganan Yang Efektif Pada Struktur Jalan Pekerasan Kaku (Rigid Pavement) Berdasarkan Surat Edaran No. 09/Se/Db/2021Document9 pagesPemilihan Metode Penanganan Yang Efektif Pada Struktur Jalan Pekerasan Kaku (Rigid Pavement) Berdasarkan Surat Edaran No. 09/Se/Db/2021Indra PermanaPas encore d'évaluation

- TH I Gian Làm Bài: 60 PhútDocument6 pagesTH I Gian Làm Bài: 60 PhútTú QuyênPas encore d'évaluation

- SP1208Document71 pagesSP1208Ajay KumarPas encore d'évaluation