Académique Documents

Professionnel Documents

Culture Documents

Assessing Cox

Transféré par

Jia IdrisCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assessing Cox

Transféré par

Jia IdrisDroits d'auteur :

Formats disponibles

Safety Science 34 (2000) 111129

www.elsevier.com/locate/ssci

Assessing safety culture in oshore environments

S.J. Cox, A.J.T. Cheyne *

Centre for Hazard and Risk Management, The Business School, Loughborough University, Leicestershire

LE11 3TU, UK

Abstract

This paper discusses a joint industry and UK Health and Safety Executive research project

on the assessment of safety culture in oshore environments. It particularly describes the

development of a safety culture assessment methodology which is based on a systems

approach to organisational culture. This approach combines a number of assessment methods, such as: questionnaires, focus groups, behavioural observations and situational audits, to

describe and explore the ecacy of health and safety management systems. The evidence

produced by these methods are complementary rather than alternatives and provide dierent

views of organisational health and safety culture by tapping many aspects of the organisation's structure, function and behaviour. The assessment techniques have been piloted within

collaborating organisations, both within the UK and the Gulf of Mexico. The culmination of

the work is the ``Safety Climate Assessment Toolkit'' which is now published and available

for use by managers and safety professionals within the oshore oil extraction industry.

# 2000 Elsevier Science Ltd. All rights reserved.

Keywords: Organisational culture; Safety culture; Health and safety management; Cultural assessment;

Safety Climate Assessment Toolkit

1. Introduction

In the decade following the 1988 Piper Alpha disaster many of the oshore oil and

gas processing organisations within the UK have made changes in the manner in

which they manage health and safety (Alexander et al., 1994; Flin et al., 1996; Cox

and Cheyne, 1999). The majority of these changes were precipitated by developments

in the oshore health and safety regulatory regime following on from the recommendations of the Cullen Report (Cullen, 1990), including, for example, the establishment of the Oshore Safety Division of the Health and Safety Executive (HSE)

and the application of the Oshore Installations (Safety Case) Regulations (1992).

* Corresponding author. Tel.: +44-1509-222162; fax: +44-1509-223961.

E-mail address: a.j.t.cheyne@iboro.ac.uk (A.J.T. Cheyne).

0925-7535/00/$ - see front matter # 2000 Elsevier Science Ltd. All rights reserved.

PII: S0925-7535(00)00009-6

112

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

In the wake of such changes, a Cross Industry Safety Leadership Forum has been

established to facilitate the sharing of safe working practices. The members of this

forum recently highlighted a number of indicators of improved safety performance

(Cross Industry Safety Leadership Forum, 1997), including an overall decrease in

reported injury frequency rates and an estimated $5 billion in investments in health

and safety-related improvements. However, despite these overall eorts, there is

some evidence to suggest that the rate of improvement, as measured by accident/

injury frequency, has slowed down over the past 2 years (HSE, 1997; Cox and

Cheyne, 1999). Furthermore the Cross Industry Safety Leadership Forum (1997)

have also conrmed that much of the existing eorts in support of these improvements have been focused upon technology and management systems rather than

human factors. They also suggest that potential for future improvements may best

be realised through enhanced eorts in the areas of human factors and through the

associated developments in health and safety culture. In light of this initiative this

paper considers how oshore installation managers can gauge their safety culture.

Discussion here focuses on the development of a generic safety culture assessment

methodology which was designed to support improvements in safety performance

across the sector.

This paper describes a series of studies that are focused on the practical needs of

oshore managers and workers for the monitoring of safety culture through the

development of a self-assessment tool. It aims to give a broad overview of the

development of this methodology (Cox and Cheyne, 1999) and draws heavily upon

recent work carried out in the UK sector of the North Sea. It also explores the

practical utility of the concept in oshore environments. The methods described

here are concerned with both the development and piloting of this tool. Whereas the

methodology is based on sound safety science, the overall aim of the assessment

process is to chart a path through, what is increasingly becoming, a conceptual

mineeld (Cox and Flin, 1998), and one in which researchers have been challenged

by industry to address practical issues (Cox and Lacey, 1998). Although much has

been done in other sectors (e.g. Hale and Hovden, 1998; Hofmann and Stetzer,

1998) in these studies the cultural context for investigation is set within the oshore

industry.

1.1. Previous studies

A number of previous studies in oshore environments have, either directly or

indirectly, considered employee perceptions and elements of health and safety culture. In an early study, Marek et al. (1985) examined risk perceptions, stress and

accidents among dierent work groups on an oshore installation. They identied

the main inuences on safety as the implementation of a safety policy, `correct'

safety management and safety promoting activities, and incorporation of employees'

views in designing safety programmes. Similarly Rundmo (1993) implemented a

questionnaire survey of personnel on eight oshore installations in the Norwegian

sector of the North Sea; rstly to determine the personnel evaluations of risk

resources and, secondly, to identify dierences in risk perceptions among dierent

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

113

work groups. These studies indicated that those personnel who were most prone to

injuries and near misses were also those who experienced the greatest physical strain

and who perceived the highest risks in relation to their work situation (Rundmo,

1993). Flin and Mearns (1994) carried this work forward into the UK sector of the

North Sea. They identied three important areas which could contribute to accidents and near misses: (1) individual characteristics (including experience, knowledge, attitudes to safety, etc); (2) job characteristics (work tasks, environment, job

stress, etc.); and (3) platform characteristics (safety culture, social support and safety

management systems). This study (Flin and Mearns, 1994) also indicated that management commitment to safety, job satisfaction, attitudes to safety versus production and job situation had the greatest eect on workers' perception of risk and their

satisfaction with safety measures.

In a study focussing specically on safety culture, Alexander et al. (1994) used selfadministered questionnaires and supporting interviews in an attempt to measure

aspects of safety culture in the oshore environment within one operating company

in the UK sector of the North Sea. The study also focussed on dierences in perceptions of the prevailing culture between company employees and contractors and

those working in onshore and oshore environments. The culture for safety within

the operating company was described, in terms of employees' attitudes and perceptions, by six factors, labelled as management commitment, personal need for safety,

appreciation of risk, attribution of blame, conict and control and supportive

environment. Contractor employees were found to have a higher appreciation of

risk and a higher personal need for safety compared with the operating company

employees. Similarly, oshore workers in general had a higher appreciation of risk,

greater personal need for safety and were more convinced of management's commitment to safety than those working onshore. Mearns et al. (1998) have continued

this focus on human and organisational issues in their study of safety climate in the

UK sector of the North Sea. Their study, based on a questionnaire survey of

employee attitudes, provided evidence that sub-cultures, centred around, for example, work teams or parent organisations, are important for workers' perceptions of

their overall safety.

There are, thus, a number of dominant themes in relation to human factors and,

in particular, safety culture emerging from these oshore studies and other reported

studies in the literature (Cox and Flin, 1998). For example, the importance of management commitment and, in particular, the perceived priority accorded to safety

matters, has been repeatedly highlighted. Equally a number of studies (e.g. Flin et

al., 1996) have conrmed the need to consider not only key organisational factors,

but also to take account of individual factors, such as personal appreciation of risks

and involvement in safety-related decisions, as key inuences on safety performance,

and the related safety culture, within oshore environments. Similarly, potential

sub-cultures, characteristic of dierent occupational groups, and the concomitant

inuences on overall installation, or organisational, culture have been identied. As

a consequence of these studies, and recent discussions and conferences within the

oshore environment (Cross Industry Safety Leadership Forum, 1997; Cox and

Lacey, 1998), the awareness and development of an `appropriate' safety culture is

114

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

now seen to be an important area of concern with managers, regulators and

researchers. It has also been argued by researchers into oshore health and safety

management practices that the safety culture concept has the potential to provide an

umbrella for both individual and organisational safety issues (Cox and Flin, 1998)

and can be used as a vehicle for framing further improvements. However, although

there is indeed some evidence to suggest that assessing the prevailing organisational

culture can assist in the identication and management of health and safety issues

(Cox and Flin, 1998), the practical utility of the safety culture concept in securing

safety-related improvements in oshore environments has not yet been established

(Lee, 1995).

1.2. The current studies

The present studies are concerned with the development and testing of an assessment technique which provides both a practical tool for the assessment of safety

climate and simultaneously aids the promotion of a `positive' safety culture. The

studies described here are published in the ``Safety Climate Assessment Toolkit''

(Cox and Cheyne, 1999) together with a guide for those using the toolkit. In view of

the practical intentions of the studies and the nature of the output, potential toolkit

users in participating organisations were widely consulted in the development of the

conceptual framework. This framework has been described in a number of previous

publications (e.g. Cheyne et al., 1988; Cox et al., 1998; Cox and Cheyne, 1999) and

involves a holistic view of safety climate assessment. Assessments of safety climate

are used here as an indicator of overall safety culture. Culture in general, and safety

culture in particular, is often characterised as an enduring aspect of the organisation

with trait-like properties and not easily changed. Climate, on the other hand, can be

conceived of as a manifestation of organisational culture (Schein, 1985) exhibiting

more state-like properties. The nature of culture and climate and their relationship

has also been related to the concepts of personality and mood (Cox and Flin, 1998),

where culture represents the more trait-like properties of personality and climate the

more state-like properties of mood. For the purposes of this discussion climate is

viewed as a temporal manifestation of culture, which is reected in the shared perceptions of the organisation at a discrete point in time (Cox and Cheyne, 1999).

A multiple perspective, or holistic, model of the safety climate assessment process

was proposed and, as such, dominated the project design. Similar approaches are

discussed within the literature in relation to the assessment of organisational climate

(James and Jones, 1974; Cox and Cox, 1996; Denison, 1996). It has been suggested

(Jick, 1979) that organisational researchers and practitioners can improve the accuracy of their judgements by both utilising multiple methods and collecting dierent

kinds of data bearing on the same phenomenon, in this case safety climate. `Between

(or across) methods' triangulation (Denzin, 1978) oers such an approach. Jick

(1979) cites the example of reviewing the eectiveness of an organisational `leader',

where eectiveness may be studied by: (1) interviewing the leader; (2) observing their

leadership behaviours; and (3) evaluating performance records. The focus remains

with the organisational issue (in Jick's, 1979 example `leadership') but the mode of

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

115

data collection varies. Multiple and independent measures, if they provide supportive evidence, can thus provide a more certain picture (or prole) of the issue under

review (Denzin, 1978; Cox and Cheyne, 1999).

In the same vein James and Jones (1974) describe three dierent approaches to the

assessment of organisational culture (and climate) and, in doing so, oer commentary on its dierent (conceptual) loci. First, is the `multiple measurement-organisational attribute approach' which regards organisational climate exclusively as a set

of organisational attributes (or main eects), measurable by a variety of methods;

e.g. organisational structure or organisational systems measured by propriety audit

systems. Second, there is the `perceptual-organisational attribute approach', which

views organisational climate as a set of perceptual variables which are still seen as

organisational eects, e.g. views of the organisation's commitment, etc. Finally,

there is the `perceptual measurement-individual attribute approach' which captures

organisational climate through perceptions of individual attributes, e.g. individuals'

feelings and attitudes towards organisational issues, their related behaviour, etc.

Given the importance of both organisational and individual factors in inuencing

safety culture (James and Jones, 1974; Denison, 1996) it is suggested that in an

attempt to measure culture these dierent approaches should be treated as complementary and not as alternatives. Thus a multiple perspective was taken which

also combined dierent approaches to assessment, as recommended by Jick (1979).

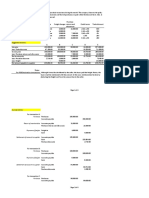

This is illustrated in the framework model shown in Fig. 1.

In such a model, the representation of organisational safety culture is consistent

with one sponsor's preferred (HSE, 1997) denition. For example, the Advisory

Fig. 1. Multiple perspective model of safety culture assessment.

116

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

Committee on the Safety of Nuclear Installations' (ACSNI) (Booth, 1996; ASCNI,

1993) denition, that safety culture is ``the product of individual and group values,

attitudes, perceptions, competencies, and patterns of behaviour that determine the

commitment to, and the style and prociency of, an organisation's health and safety

management'' (ASCNI, 1993, p. 23), is consistent with the representation in the

model. A similar approach has been taken in the assessment of safety culture in the

nuclear industry (Carroll, 1998) where aspects of the organisation derived through

peer observations and audit were considered alongside questionnaires. The data

were then used in ongoing discussions to further organisational learning.

1.3. Safety Climate Assessment Toolkit

The three methods proposed for use in a safety climate assessment exercise, and

illustrated in Fig. 1, form the basis of the assessment methods included in the Safety

Climate Assessment Toolkit. The toolkit is a practical instrument for in-house use

and it contains a selection of tools that can be used as part of the measurement

process. These tools include questionnaires, interview and focus discussion group

schedules and behavioural indicators. A full text and electronic version of the toolkit

can be found at http://www.lboro.ac.uk/departments/bs/safety

The remainder of this paper discusses some of the studies that contributed to the

development of these assessment methods. Two representative studies and a case

illustration, which collectively cover the issues of exploration, instrument development and practical use, are outlined here:

. Study 1 included a series of focus discussions which formed the basis of some

of the tools and measures which are developed in Study 2;

. Study 2 describes the development of a safety climate questionnaire; and

. the case illustration briey outlines a case study application of the questionnaire tools developed in Study 2 in a pilot organisation.

The accounts of the development of the behavioural indicators and the semistructured interview schedule, also included in the assessment process, are outside

the scope of the paper and are described within the ``Safety Climate Assessment

Toolkit'' (Cox and Cheyne, 1999). The nal discussions are focussed on the mutual

experiences of implementing the practical assessment process together with the perceived benets; e.g. the practical utility of the output of the assessment and the

potential for action planning.

2. Focus discussion groups (Study 1)

The rst study was concerned with exploring employees' understanding and perception of `safety culture'. These shared understandings and underpinning constructs were utilised in the design of subsequent studies and formed the bases of the

development of the assessment methodology. Focus discussion groups were

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

117

employed here for two reasons: (1) to elicit constructs based on individuals' notions

of `safety culture'; and (2) to provide initial indications of any dierences in overall

perceptions between dierent work groups in the study organisations. The focus

group studies were deemed to be particularly appropriate at this stage of the investigations since the data collected would be utilised as the basis for the toolkit development and, in particular, the development of the questionnaire tool. Focus groups

as a method are well accepted (Krueger, 1994) but they can be biased by a number

of factors, e.g. domination of the group by one member or too much direction by

the facilitator. These biases were controlled for by the use of a small number of

group facilitators who followed a structured discussion format.

2.1. Method

A series of focus group discussions (n=40) were conducted using both oshore

and onshore personnel in three separate organisations, at a total of six dierent

locations. These 40 discussion groups involved 375 employees in groups ranging

between three and 12 individuals. One hundred and eighty-one participants worked

in onshore locations and 194 were based on oshore installations. Eighty-three

managers and supervisors took part in the study. Wherever possible the groups were

homogenous and comprised either: (1) managers and supervisors; or (2) members of

the workforce. This promoted an atmosphere of open enquiry and, wherever possible, avoided inhibiting the group members (Carroll, 1998).

Each of the discussions involved four questions being put to the group participants, namely what they understood by the term safety, what they understood by

the term company culture, how safety ts into their picture of company culture and

what they understood by the term safety culture. The rst three questions were

designed to put participants at their ease and help focus their discussion of the

concept of safety culture. All members of the group were encouraged by the facilitator to make a response to the nal question.

Each of the focus group discussions were recorded on audiotape and then transcribed verbatim. These transcriptions were then subjected to a preliminary content

analysis (Holsti, 1969; Dane, 1990) involving two independent raters, and the

resulting keywords (based on the most commonly occurring constructs in the discussions of the concept of safety culture) were tabulated. There was 96% agreement

between raters on the classication of concepts. Where the raters did not agree on

the categorisation of a concept (in 13 cases), a third rater arbitrated. In addition to

the extraction of individual key constructs, general group feelings and perceptions of

safety were recorded as appropriate.

2.2. Results

All groups actively participated with a good degree of co-operation. The number

of occasions each concept was mentioned during the focus discussion groups is

shown in Table 1, together with a breakdown by organisation. The numbers shown

in brackets indicate the number of times each issue was raised in a negative sense.

118

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

Table 1

Focus group keywords

Keyword

Organisation 1

Organisation 2

Organisation 3

Total

Involvement in safety issues

Physical work environment

Priority of safety over other issues

Management actions for safety

Management commitment

Apportioning of blame

Safe systems/procedures

Accidents

Attitudes to personal safety

Safety training and instruction

Safety legislation

6(3)

2(2)

11(10)

3(2)

9(3)

5(4)

2(1)

67(20)

52(34)

44(37)

20(15)

21(6)

29(20)

5(1)

2(1)

27(21)

7(2)

23(17)

11(10)

10(2)

6(4)

73

56

55

50

37

34

23

11

10

7

6

Total number of discussion groups

19

15

40

For example, in the case of involvement, the number of time individuals felt that

they were not involved in safety issues.

Many of the non-managerial participants, especially within Organisation 2,

recounted experiences of not feeling that they were adding value to safety-related

processes and perceived that they were not involved in any safety decision-making

processes aecting anything other than routine day-to-day operations. Responses

from oshore workers suggest that they have a greater appreciation of risk than

onshore workers which, in turn, aects their perception of safety issues and may go

some way to explaining the many emotive comments made about the importance of

safety oshore. The responses from the onshore groups represented a more sanitised

viewpoint, given with much less emotion than those received from the oshore

groups. Several groups expressed the view that, although attitudes to safety had

improved, they perceived that the principles of risk management were providing the

main impetus for improvements in all three organisations. Combined responses

suggest that management were quite committed to safety although improvements

could still be made. Although some non-managerial participants, particularly in

oshore environments, related feelings that a blame culture existed.

2.3. Discussion

Of the constructs identied, management commitment, management actions for

safety and the physical work environment were the more common across all three

organisations, although involvement in safety issues and the priority given to safety

issues were also highlighted as important. These results give some indication of how

safety culture is perceived by those working in the oshore environment and are

consistent with earlier ndings both on and oshore (Zohar, 1980; Flin et al., 1996).

The constructs uncovered provided the basis, together with the review of current

literature on safety culture assessment (Cox and Flin, 1998) and climate identication, for the construction of a set of climate assessment tools. It should be noted

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

119

that, although the results of the studies described here were used primarily as an

important and essential starting point for the project, focus groups had further

potential for safety climate assessment in this environment.1 Furthermore the data

collected from the focus group studies supported the holistic view illustrated in Fig.

1, with reference being made to a range of organisational systems and artefacts and

to both organisational and individual factors.

3. Developing assessment methods (Study 2)

The second study is focussed on the development of one of the safety climate

assessment tools that are included in the toolkit (see earlier) and also builds upon the

constructs developed in Study 1. In particular this study describes the process

involved in developing the attitude questionnaire.

3.1. Development of the question bank

Over the last 5 years, a variety of safety attitude questionnaire surveys have been

carried out in the organisations participating in the project (e.g. Alexander et al.,

1994; Fitzpatrick, 1996). The common items and themes from the three survey

instruments were identied (and highlighted in Table 2). In addition to these studies,

Table 2

Oshore attitude survey dimensions and their origin

Oshore

questionnaires

Nuclear

(Lee, 1995)

Energy supply

(Donald, 1995)

Chemical/process

(Byrom and

Corbridge, 1997)

Management

commitment

Priority of safety

Management/supervisor support

Management

commitment

Communication

Safety information

Organisational

commitment and

communication

Reporting accidents Arrangements for

safety

and near

misses

Workmate's

inuence

Personal role

Personal scepticism,

personal immunity

Risk-taking

behaviour

Responsibility

Safety rules

Safety procedures,

safety rules

Supportive

environment

Personal priorities

and need for safety

Personal appreciation

of risk

Involvementa

Work environment

a

Safe working procedures

Work group support

Risk

Participation/

ownership

Design

Work environment:

hardware

Manufacturing

(Cox and Cox, 1991)

Safeness of the work

environment

Safeness of the work

environment

Indicates a dimension not previously covered by the surveys in participating organisations.

1

The results not only provided this basis for future development, but also gave the facilitators valuable

insights into the organisations under study.

120

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

safety attitude measures have also been developed and utilised in other industrial

sectors (e.g. Zohar, 1980; Brown and Holmes, 1986; Cox, 1988; Dedobbeleer and

Beland, 1991; Cooper and Philips, 1994; Mearns et al., 1998). An initial question

bank, derived from the initial in-house studies, was rened in the light of other

published studies. Consideration was given to developments within: (1) the nuclear

industry (Lee, 1995); (2) the energy supply industry (see Donald, 1995, for details);

(3) a variety of manufacturing settings (Cox and Cox, 1991; Cheyne and Cox, 1994;

Cox et al., 1998); and (4) the HSE attitudinal indicator of safety climate (Byrom and

Corbridge, 1997). Extra dimensions, not included in the common threads from previous studies in participating organisations, were included if common to two or

more of the external studies and if highlighted by the focus group discussions (Study

1). The full set of dimensions and their origin is shown in Table 2.

In summary, the initial question bank for the questionnaire instrument was,

therefore, based on:

1. an initial review of oshore surveys within the study organisations and the

establishment of common themes;

2. comparisons between these and instruments in other industrial sectors (in particular the nuclear and chemical/process industries); and

3. a review of the constructs identied in the focus discussion groups (Study 1 above).

These reviews and comparisons allowed a pilot questionnaire to be developed to

include 47 items covering the areas of Management Commitment, Communication,

Priority of Safety, Safety Rules and Procedures, Supportive Environment, Involvement, Personal Priorities and Need for Safety, Personal Appreciation of Risk and

Work Environment. This attitude questionnaire was piloted using a population of

oshore personnel in two locations. These personnel were asked not only to complete the questionnaire but also to comment on the general content and any specic

items they felt to be unclear. Sixty completed questionnaires were returned. The

main objective of this pilot study was to test the face validity of the items in the

questionnaire with an appropriate group. Comments were restricted to individual

items and resulted in two items being reworded and four items being deleted. The

new, 43-item questionnaire was tested on a larger pilot population.

3.2. Analysis

The questionnaire was distributed to 350 employees on three oshore installations. Two-hundred and twenty-one questionnaires were returned, representing a

63% response rate. There was no evidence that this sample was unrepresentative of

the total population. These data were subjected to a series of statistical tests including conrmatory factor analysis (CFA), internal-scale consistency and alternate

forms reliability tests.

3.2.1. Factor analysis

The data were subjected to CFA using version 5.1 of the EQS (structural equation)

program (Bentler and Wu, 1995). In CFA the researcher postulates a model (a

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

121

Table 3

Standardised factor loadings

Item

Loading

Management commitment

In my workplace management acts quickly to correct safety problems

Management acts decisively when a safety concern is raised

In my workplace management turn a blind eye to safety issues

Corrective action is always taken when management is told about unsafe practices

In my workplace managers/supervisors show interest in my safety

Management acts only after accidents have occurred

Managers and supervisors express concern if safety procedures are not adhered to

0.811

0.792

0.737

0.690

0.520

0.500

0.440

Priority of safety

Management clearly considers the safety of employees of great importance

I believe that safety issues are not assigned a high priority

Safety procedures are carefully followed

Management considers safety to be equally as important as production

0.665

0.585

0.585

0.534

Communication

There is good communication here about safety issues which aect me

Safety information is always brought to my attention by my line manager/supervisor

My line manager/supervisor does not always inform me of current concerns and issues

Management operates an open door policy on safety issues

I do not receive praise for working safely

0.721

0.633

0.594

0.541

0.481

Safety rules

Some safety rules and procedures do not need to be followed to get the job done safely

Some health and safety rules and procedures are not really practical

Sometimes it is necessary to depart from safety requirements for production's sake

0.724

0.685

0.583

Supportive environment

I am strongly encouraged to report unsafe conditions

I can inuence health and safety performance here

When people ignore safety procedures here, I feel it is none of my business

Employees are not encouraged to raise safety concerns

A no-blame approach is used to persuade people acting unsafely that their behaviour is inappropriate

Co-workers often give tips to each other on how to work safely

0.639

0.543

0.480

0.421

0.367

0.323

Involvement

I am involved in informing management of important safety issues

I am involved with safety issues at work

I am never involved in the ongoing review of safety

0.724

0.687

0.524

Personal priorities and need for safety

It is important that there is a continuing emphasis on safety

I understand the safety rules for my job

Safety is the number one priority in my mind when completing a job

A safe place to work has a lot of personal meaning to me

Personally I feel that safety issues are not the most important aspect of my job

0.655

0.642

0.623

0.571

0.500

Personal appreciation of risk

I am sure it is only a matter of time before I am involved in an accident

In my workplace the chances of being involved in an accident are quite large

I am rarely worried about being injured on the job

I am clear about what my responsibilities are for health and safety

0.782

0.464

0.286

0.273

Work environment

Operational targets often conict with safety measures

Sometimes I am not given enough time to get the job done safely

Sometimes conditions here hinder my ability to work safely

There are always enough people available to get the job done safely

I cannot always get the equipment I need to do the job safely

This is a safer place to work than other companies I have worked for

0.795

0.668

0.666

0.596

0.448

0.256

122

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

particular set of linkages between the observed variables and their underlying factors)

and then tests this model statistically, examining the degree to which it ts with the

available data. In its conrmatory approach, factor analysis is concerned with

implementing a theorist's hypothesis about how a domain of variables may be structured. The nine factors included in the questionnaire were already well-established

dimensions derived from the literature and so in this case, the hypothesis that is being

tested is whether the variables actually relate to each factor, or latent variable. An

exploratory approach would have been more appropriate if there had been no theoretical structure to the questionnaire and it was necessary to explore the factors it covered.

Incremental t indices measure the proportionate improvement in t by comparing a target model with a restricted baseline model, usually a null model in which all

the observed variables are independent. The comparative t index (CFI) was used as

it is one of the best t indices (Marsh et al., 1996). A value of around 0.9 is accepted

as indicating good model t.

A nine factor model was proposed and tested. This model indicated a relatively

poor t for the data (CFI=0.78) and so six constraints identied in the model

modication statistics were released. This involved six of the items being associated

with dierent factors. This improved the model t (CFI=0.85) and resulted in the

structure shown in Table 3. Each item is shown in this table with its standardised

loading, all of which were statistically signicant at the 0.05 level. It should be noted

that those items with relatively low factor loadings may not be wholly indicative of

the factor, but such items could be usefully consulted individually. Furthermore, in

any summation of factor scores these loading might be used to weight individual

items.

3.2.2. Reliability

Two forms of reliability were examined, internal-scale reliability and alternateforms reliability. Internal-scale reliability (or consistency) is applied to groups of

items that are thought to measure dierent aspects of the same concept (Litwin,

1995). This is important because a group of items that purports to measure one

variable should be clearly focused on that variable and the accepted level for this

statistic (Cronbach's alpha) is around 0.7. Measures of internal reliability for each of

Table 4

Factor internal reliability

1

2

3

4

5

6

7

8

9

Factor

Cronbach's a

Management commitment

Priority of safety

Communication

Safety rules

Supportive environment

Involvement

Personal priorities and need for safety

Personal appreciation of risk

Work environment

0.845

0.722

0.734

0.715

0.606

0.705

0.607

0.531

0.779

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

123

Table 5

Alternate-forms reliability coecients

Item

Inter-item correlation

Management acts decisively when a safety concern is raised

Managers and supervisors express concern if safety procedures are not adhered to

Management considers safety to be equally as important as production

There is good communication here about safety issues which aect me

Safety information is always brought to my attention by my line

manager/supervisor

Some health and safety rules and procedures are not really practical

Employees are not encouraged to raise safety concerns

When people ignore safety procedures here, I feel it is none of my business

I can inuence health and safety performance here

I am never involved in the ongoing review of safety

Safety is the number one priority in my mind when completing a job

I understand the safety rules for my job

It is important that there is a continuing emphasis on safety

I am rarely worried about being injured on the job

I cannot always get the equipment I need to do the job safely

Operational targets often conict with safety measures

Sometimes I am not given enough time to get the job done safely

0.622*

0.353*

0.583*

0.036

0.089

0.589*

0.561*

0.361*

0.555*

0.292

0.564*

1*

1*

0.664*

0.361*

0.363*

0.728*

*Signicance at the 0.05 level.

the factors in Table 3 are presented in Table 4. It can be seen that all the alphas

reported are in the range 0.53 through 0.84, the lower ones being consistent with

those factors where some original factor loadings were low.

Alternate-forms reliability involves comparing two dierent versions of the same

measure (Dane, 1990). In the case of the questionnaire, 30 subjects were asked to

complete the survey and then later, after an interval of at least 18 h, were asked 17 of

those items orally as part of an interview format. These items were chosen randomly

from the larger questionnaire. The inter-item correlations are shown in Table 5.

Only three of the inter-item correlations are non-signicant, indicating overall good

alternate-forms reliability. The low inter-item correlation in these cases may have

been due to the relatively small sample size involved and the eect of a few outlying

scores on such a sample.

3.3. Discussion

This study has dealt with one of the tools for use in a safety climate assessment, as

well as detailing its development, the instrument's reliability and consistency has

also been discussed. This tool has been based, wherever possible on the concepts

highlighted by the focus group discussions (Study 1) and a review of relevant literature pertaining to the measurement and assessment of safety culture and climate.

The organisations involved also requested that any questionnaire tool developed be

consistent with what had been used in the past. The nal section of this paper briey

describes the use of the toolkit and discusses some of the issues raised, the proling

124

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

of the results of the assessment process, and subsequent actions that may be considered by those assessing safety climate. The condential nature of the assessment

process makes it dicult to report this study in great detail.

4. Illustration of the toolkit in practice

The developed ``Safety Climate Assessment Toolkit'' process was initially tested

in one organisation involved in hydrocarbon production. The pilot organisation is

involved in the extraction of hydrocarbons, operating on various sites world-wide.

This organisation had a strong commitment to safety, health and environmental

excellence and also has a tradition of `quality'. The initial management characterisation of their culture for safety was one of `total commitment and safety excellence'. The organisation hoped to appreciate a broader perspective of shared

attitudes and communicate these goals through the use of the assessment toolkit, as

well as examining dierences between occupational groups. The toolkit procedures

were implemented by an in-house team, who only made use of back-up from the

research team in analysing the dierences between occupational groups.

The full assessment toolkit (Cox and Cheyne, 1999) consists of three sets of tools,

as described earlier: climate questionnaire, semi-structured interview schedule and a

set of behavioural indicators. It also provides guidance on their application and

interpretation. The organisation using the toolkit in this case considered the following sources of evidence:

Fig. 2. Radar plot for pilot organisation.

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

125

Table 6

Means for the three work groups involved in the studya

Dependent variable

Managers

Production

Drilling

Communication

Supportive environment

Involvement

Personal priorities

Personal appreciation of risk

Work environment

6.4

6.64

5.75

9.2

8.75

9.1

6.24

6.02

4.75

8.86

7.75

7.95

5.56

5.92

4.45

7.89

7.71

6.62

Emboldened groups dier signicantly from the others (Tukey tests, P<0.05).

1. organisational documentation and team observations;

2. data collected from sta interviews and focus groups; and

3. data collected via an employee attitude questionnaire (described in Study 2).

Much of the data were condential to the organisation in question; however, it

was prepared to share certain data as part of the development process. Discussion

here, therefore, focuses primarily on the use of the safety climate questionnaire in

the assessment of attitudes to safety within the organisation and its ability to differentiate between occupational groups.

4.1. Results

Two-hundred workers took part in the proling exercise and the results of climate

assessment surveys were represented on a radar plot graph (Fig. 2). These plots were

included at the request of the participants and provided a visual representation of

climate proles in dierent parts of the organisation (i.e. on dierent installations).

Each of the dimensions represented on the radar plot was scored on a standardised

scale (out of 10) and included not only questionnaire dimensions but also the data

collected from interviews and document audits.

Overall, the assessment process conrmed the organisation's strengths in the areas

of Management Commitment and Management Style and the implementation of

Safety Systems. The questionnaire survey, however, highlighted Communication

issues (with a standardised mean of 6.1), the Supportive Environment (with a standardised mean of 5.6) and Employee Involvement (with a mean of 4.9) as the three

areas most in need of improvement. The interviews and focus groups supported

these ndings in highlighting Co-operation and Safety Training as being relatively

poor, and the direct and indirect observations also found problems with Communication, e.g. unclear and/or ambiguous brieng documents. These preliminary

ndings illustrate some of the relationships between separate measures, particularly

those related to the work and supportive environments and involvement, which in

this case provided the initial focus for action in this organisation.

An examination of the dierences between certain occupational groups was also

made. The organisation involved in this study was particularly interested in dier-

126

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

ences between managers, production teams and drilling teams. A series of one-way

analyses of variance were performed for each factor in the attitude questionnaire.

Dierences in mean scores (standardised to a 10-point scale for each factor) for each

of the three groups are shown in Table 6.

Dierences were found in six of the questionnaire dimensions with drilling teams

showing signicantly lower evaluations than managers in terms of Supportive

environment, Involvement, Personal appreciation of risk and Work environment

and lower evaluations of Communication and Personal priorities than both managers and production teams. Production teams, however, only diered signicantly

from managers in terms of Involvement, Personal appreciation of risk and work

environment. These nding are consistent with those of Mearns et al. (1998) suggesting that drilling teams, who often belong to another `parent organisation' may

have their own sub-culture and may, consequently, nd themselves outside various

communication channels.

4.2. Discussion

Users found the process straightforward and found little diculty in constructing

their safety climate prole. Users then examined the initial questionnaire items and

interview responses in order to get some notion of the exact nature of any problems

highlighted by poor scores. This investigation revealed that a large number of

employees felt that they were not involved, in, or informed of, safety initiatives,

indeed it was perceived that a small group of `select' people were the only individuals

involved in any safety activities, and these individuals gave little, or no, support to

others on safety issues. These feelings were also reected with regard to safety

training. Once again, the majority of those questioned felt that they were not

informed of relevant training or encouraged to attend courses, other than those

legally required.

Several initiatives are planned as a result of these ndings. Firstly, the users have

decided to actively promote, with the help of the training manager, the range of

safety training courses on oer. This involves listings of appropriate courses

appearing in the company newsletter, as well as announcements at all team meetings

in an attempt to reach the various `sub-cultures'. Team meetings are also to be used,

in the rst instance, to encourage individuals to get involved in, and indeed to propose, new safety initiatives. The user will reassess the safety climate prole when

these measures have been in place for at least 1 year.

5. Discussion

This paper has described the development of an innovative approach to assessing

culture, and specically safety culture and climate. The development of the ``Safety

Climate Assessment Toolkit'' has exploited the notions of multiple organisational

perspectives and data triangulation (Jick, 1979). It utilises approaches which can be

combined to provide an in-depth picture of an organisation's current safety climate.

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

127

During this process reliance is not placed on any single form of assessment, e.g.

questionnaires, nor is it placed on any single part of the overall system, e.g. only

organisational systems and compliance. It builds upon a holistic approach and provides

a `rich-picture' of the overall safety climate as recommended by Cox and Flin (1998).

The immediate benets of using the toolkit are the proling of safety climate and

the action planning that this prole allows. In theory, achieving and maintaining a

positive safety climate will provide an environment where improvements in safety

performance can be made (ASCNI, 1993). Specic benets of using the toolkit can

be summarised as: (1) providing a focus for raising the prole of health and safety;

(2) allowing active monitoring in support of other processes; (3) providing an

opportunity for sensitive issues to be discussed, which in other circumstances may be

seen as disruptive; (4) providing a focus for working together on safety issues; and

(5) facilitating benchmarking, both internally and externally.

The particular assessment tool described in Study 2, the employee attitude questionnaire, has been extensively piloted. The initial analysis has shown the instrument

to be reliable in terms of what it measures, and sensitive enough to uncover dierences between occupational groups. The initial feedback also suggests that the

questionnaire is easy to administer and prole. Similarly users found the toolkit's

interview schedule and behavioural observations practical and straightforward. The

prole, once completed in the pilot organisation, allowed the various relationships

between its measures to be examined in detail. The results of the initial climate

assessment exercise have provided the organisation in Study 3 with several useful

prompts for future action, as well as highlighting the level at which these actions

should be aimed.

5.1. Future development

The employee attitude questionnaire, and the ``Safety Climate Assessment

Toolkit'' in general, will be the subject of further rigorous evaluation through their

use in the oshore oil extraction industry. In particular the utility of the instruments

in planning improvements and their ability to detect changes will be investigated.

The toolkit is freely available to interested managers and safety practitioners in

either written or electronic formats.

A subsidiary aim of the assessment process is to stimulate discussion and

improvement through the assessment process. Organisations using the toolkit may

nd that, through time, it will be appropriate to customise the tools presented here

and/or develop in-house instruments to chart the full range of indicators they feel

are important. User groups may also be established and thus allow for benchmarking and discussion across oshore installations and organisations.

Acknowledgements

The studies described in this paper have been funded and supported by the Oshore Safety Division of HSE, Chevron UK, Chevron Gulf of Mexico (Ship Shoal/

128

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

Eugene Island), Mobil North Sea and Oryx UK. The authors would like to

acknowledge the assistance of Martin Alexander and Bill Cockburn in the gathering

of data. The views expressed here are those of the authors and are not necessarily

representative of any other individual or organisation.

References

ACSNI, 1993. Organising for Safety Third Report of the Human Factors Study Group of ACSNI.

HMSO, London.

Alexander, M., Cox, S., Cheyne, A., 1994. The concept of safety culture within a UK based organisation

engaged in oshore hydrocarbon processing. Proceedings of the Fourth Annual Conference on Safety

and Well-being at Work, Loughborough University of Technology, UK, November 12.

Bentler, P.M., Wu, E.J.C., 1995. EQS for Windows User's Guide. Multivariate Software, Inc, Encino,

CA.

Booth, R.T., 1996. The promotion and measurement of a positive safety culture. In: Stanton, N. (Ed.),

Human Factors in Nuclear Safety. Taylor and Francis, London, pp. 313332.

Brown, R.L., Holmes, H., 1986. The use of a factor-analytic procedure for assessing the validity of an

employee safety climate model. Accident Analysis and Prevention 18, 455470.

Byrom, N., Corbridge, J., 1997. The Assessment of an Organisation's Health and Safety Climate. OECD

Workshop on Human Performance in Chemical Process Safety, Munich.

Carroll, J., 1998. Safety culture as an ongoing process: cultural surveys as opportunities for enquiry and

change. Work and Stress 12, 272284.

Cheyne, A., Cox, S., 1994. A comparison of employee attitudes to safety. Proceedings of the Fourth

Conference on Safety and Well-being at Work, Loughborough University of Technology, UK,

November 12.

Cheyne, A., Cox, S., Oliver, A., Tomas, J.M., 1988. Modelling safety climate in the prediction of levels of

safety activity. Work and Stress 12, 255271.

Cooper, M.D., Philips, R.A., 1994. Validation of a safety climate measure. Proceedings of the British

Psychological Society: Annual Occupational Psychology Conference, Birmingham, 35 January.

Cox, S., 1988. Employee Attitudes to Safety, M.Phil. thesis, University of Nottingham, UK.

Cox, S., Cox, T., 1991. The structure of employee attitudes to safety: a European example. Work and

Stress 5, 93106.

Cox, S., Cox, T., 1996. Safety, Systems and People. Butterworth-Heinemann, Oxford.

Cox, S., Flin, R., 1998. Safety culture: philosopher's stone or man of straw? Work and Stress 12, 189201.

Cox, S., Lacey, K., 1998. Measuring Safety Culture in Oshore Environments: Developing the Safety

Climate Assessment Toolkit. Paper presented at Changing Health and Safety Oshore, The Agenda for

the next 10 years, Aberdeen, 2224 July.

Cox, S., Cheyne, A., 1999. Assessing Safety Culture in Oshore Environments. HSE Oshore Research

Report, Loughborough University, UK.

Cox, S., Tomas, J.M., Cheyne, A., Oliver, A., 1998. Safety culture: the prediction of commitment to safety

in the manufacturing industry. British Journal of Management 9, S3S11.

Cross Industry Safety Leadership Forum, 1997. Step Change in Safety. Safety Leadership Forum.

Cullen, Hon Lord, 1990. The Public Inquiry into the Piper Alpha Disaster. HMSO, London.

Dane, F.C., 1990. Research Methods. Brooks/Cole, Pacic Grove, CA.

Dedobbeleer, N., Beland, F., 1991. A safety climate measure for construction sites. Journal of Safety

Research 22, 97103.

Denison, D.R., 1996. What is the dierence between organizational culture and organizational climate A

native's point of view on a decade of paradigm wars? Academy of Management Review 21, 619654.

Denzin, N.K., 1978. The Research Act, 2nd Edition. McGraw-Hill, New York.

Donald, I., 1995. Safety attitudes as a basis for promoting safety culture: an example of an intervention.

Work and Well-being: An Agenda for Europe Conference, Nottingham, December 1995.

S.J. Cox, A.J.T. Cheyne / Safety Science 34 (2000) 111129

129

Fitzpatrick, D., 1996. Employee Attitudes Oshore. Unpublished M.Sc. dissertation, Loughborough

University, UK.

Flin, R.H., Mearns, K.J., 1994. Risk Perception and Safety in the Oshore Oil Industry. Second International Conference on Health, Safety, and the Environment in Oil and Gas Exploration, Jakarta.

Flin, R., Mearns, K., Fleming, M., Gordon, R., 1996. Risk Perception and Safety in the Oshore Oil and

Gas Industry, (Oshore Technology Report OTH 94 454). HSE Books, Sudbury.

Hale, A.R., Hovden, J., 1998. Management and culture: the third age for safety. A review of approaches

to organizational aspects of health, safety and environment. In: Feyer, A.-M., Williamson, A. (Eds.),

Occupational Injury: Risk, Prevention and Intervention. Taylor and Francis, London, pp. 129165.

Hofmann, D.A., Stetzer, A., 1998. The role of safety climate and communication in accident interpretation: implications for learning from negative events. Academy of Management Journal 41, 644657.

Holsti, O.R., 1969. Content Analysis for the Social Sciences and Humanities. Addison-Wesley, Reading,

MA.

HSE, 1997. Health and Safety Climate Tool Process Guidelines. Health and Safety Exectutive Books,

Sudbury.

James, L.R., Jones, A.P., 1974. Organisational climate: a review of theory and research. Psychological

Bulletin 81 (12), 10961112.

Jick, T.D., 1979. Mixing qualitative and quantitative methods: triangulation in action. Administrative

Science Quarterly 24, 602611.

Krueger, R.A., 1994. Focus Groups, 2nd Edition. Sage, Thousand Oaks.

Lee, T.R., 1995. The role of attitudes in the safety culture and how to change them. Conference on

`Understanding Risk Perception', Oshore Management Centre, Robert Gordon University, 2 February, Aberdeen.

Litwin, M.S., 1995. How to Measure Survey Reliability and Validity. Sage, Thousand Oaks.

Marek, J., Tangenes, B., Hellesouy, O., 1985. Experience of Risk and Safety. Work Environment Statfjord Field. Oslo University.

Marsh, H.W., Balla, J.R., Hau, K., 1996. An evaluation of incremental t indices: a clarication of

mathematical and empirical properties. In: Marcoulides, G.A., Schumacker, R.E. (Eds.), Advanced

Structural Equation Modeling: Issues and Techniques. LEA, Mahwah, NJ, pp. 315354.

Mearns, K., Flin, R., Gordon, R., Flemming, M., 1998. Measuring safety climate on oshore installations. Work and Stress 12, 238254.

Rundmo, T., 1993. Risk perception and occupational accidents on oshore petroleum platforms. Paper

presented at the 2nd Oshore Installation Management Conference, The Robert Gordon University,

Aberdeen, April.

Schein, E.H., 1985. Organisational Culture and Leadership. Jossey-Bass, San Francisco, CA.

Zohar, D., 1980. Safety climate in industrial organisations: theoretical and applied implications. Journal

of Applied Psychology 65 (1), 96102.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- hsk1 A3 PDFDocument1 pagehsk1 A3 PDFJia IdrisPas encore d'évaluation

- 13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledDocument5 pages13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledRomany AllamPas encore d'évaluation

- CIDB - Construction Industries ReviewDocument32 pagesCIDB - Construction Industries ReviewJia IdrisPas encore d'évaluation

- Price and Wage Rates: Prices of Major Construction Materials 34 Wage Rates For Construction Personnel 57Document35 pagesPrice and Wage Rates: Prices of Major Construction Materials 34 Wage Rates For Construction Personnel 57Jia IdrisPas encore d'évaluation

- 29% of Malaysians Have Mental Problems Due To Stress, Says Lam ThyeDocument2 pages29% of Malaysians Have Mental Problems Due To Stress, Says Lam ThyeJia IdrisPas encore d'évaluation

- Measurement For Civil Engineering Works: - Retaining WallDocument22 pagesMeasurement For Civil Engineering Works: - Retaining WallJia IdrisPas encore d'évaluation

- 57 151202 1229142914 Architects Certification by Ar Joseph TanDocument35 pages57 151202 1229142914 Architects Certification by Ar Joseph TanNg JialinPas encore d'évaluation

- Annex: Road Maintenance Definitions and Practices: Common DefinitionDocument3 pagesAnnex: Road Maintenance Definitions and Practices: Common DefinitionJia IdrisPas encore d'évaluation

- Ibs 2Document98 pagesIbs 2Jia IdrisPas encore d'évaluation

- Handbook Safety PDFDocument219 pagesHandbook Safety PDFJia IdrisPas encore d'évaluation

- ThesisDocument53 pagesThesisJia IdrisPas encore d'évaluation

- F Master Project Submission ChecklistDocument10 pagesF Master Project Submission ChecklistJia IdrisPas encore d'évaluation

- Ground Floor: Project: Taman Rinting Subject: GFA Date: 28 JAN 2009 L W Area Item XDocument2 pagesGround Floor: Project: Taman Rinting Subject: GFA Date: 28 JAN 2009 L W Area Item XJia IdrisPas encore d'évaluation

- Future Scope and ConclusionDocument13 pagesFuture Scope and ConclusionGourab PalPas encore d'évaluation

- Tuan Nor Akmal Imanina Binti Tuan MasorDocument2 pagesTuan Nor Akmal Imanina Binti Tuan MasorIzza RosliPas encore d'évaluation

- Baltrushes2006 PDFDocument46 pagesBaltrushes2006 PDFsilikondioksidaPas encore d'évaluation

- ErtlDocument64 pagesErtlManpreet SinghPas encore d'évaluation

- Sector San Juan Guidance For RepoweringDocument12 pagesSector San Juan Guidance For RepoweringTroy IveyPas encore d'évaluation

- Buzan, Barry - Security, The State, The 'New World Order' & BeyondDocument15 pagesBuzan, Barry - Security, The State, The 'New World Order' & Beyondyossara26100% (3)

- Egalitarianism As UK: Source: Hofstede Insights, 2021Document4 pagesEgalitarianism As UK: Source: Hofstede Insights, 2021kamalpreet kaurPas encore d'évaluation

- Historic Trial of Ali Brothers and Shankaracharya-1921Document276 pagesHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- Theoretical & Conceptual Framework (RESEARCH)Document3 pagesTheoretical & Conceptual Framework (RESEARCH)Rizza Manabat PacheoPas encore d'évaluation

- 1.4 BG00381946 - ADocument1 page1.4 BG00381946 - AAnand KesarkarPas encore d'évaluation

- Preliminary Exam (Primark)Document4 pagesPreliminary Exam (Primark)Zybel RosalesPas encore d'évaluation

- MCQ With AnsDocument8 pagesMCQ With AnsAman KumarPas encore d'évaluation

- Free Vibration of SDOFDocument2 pagesFree Vibration of SDOFjajajajPas encore d'évaluation

- Heating Curve Lab Report - Ava MonizDocument7 pagesHeating Curve Lab Report - Ava Monizapi-533828039Pas encore d'évaluation

- 1 Kane Equations - Example 1Document8 pages1 Kane Equations - Example 1Khisbullah HudhaPas encore d'évaluation

- AP1 Q4 Ip9 v.02Document4 pagesAP1 Q4 Ip9 v.02Fayenah Pacasum Mindalano100% (1)

- Commissioning 1. Commissioning: ES200 EasyDocument4 pagesCommissioning 1. Commissioning: ES200 EasyMamdoh EshahatPas encore d'évaluation

- E650E650M-17 Guía Estándar para El Montaje de Sensores Piezoeléctricos de Emisión Acústica1Document4 pagesE650E650M-17 Guía Estándar para El Montaje de Sensores Piezoeléctricos de Emisión Acústica1fredy lopezPas encore d'évaluation

- Nur Syamimi - Noor Nasruddin - Presentation - 1002 - 1010 - 1024Document14 pagesNur Syamimi - Noor Nasruddin - Presentation - 1002 - 1010 - 1024abdulhasnalPas encore d'évaluation

- The Mystery of Putins DissertationDocument16 pagesThe Mystery of Putins DissertationDoinaCebanuPas encore d'évaluation

- TSM 101 Course Outline (2022)Document2 pagesTSM 101 Course Outline (2022)ChryseanjPas encore d'évaluation

- Blackrock Methods of Delay AnalysisDocument36 pagesBlackrock Methods of Delay AnalysisAhmed MoubarkPas encore d'évaluation

- Graphs in ChemDocument10 pagesGraphs in Chemzhaney0625Pas encore d'évaluation

- Hatchery Practice: InternationalDocument40 pagesHatchery Practice: Internationalabhe prasetyaPas encore d'évaluation

- RULE 130 Rules of CourtDocument141 pagesRULE 130 Rules of CourtalotcepilloPas encore d'évaluation

- G-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Document7 pagesG-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Prince Ali50% (2)

- Akira 007Document70 pagesAkira 007Ocre OcrePas encore d'évaluation

- Format Mini Lesson Plan: What Is Narrative Text?Document3 pagesFormat Mini Lesson Plan: What Is Narrative Text?Muhammad FahrurajiPas encore d'évaluation

- Handout No. 03 - Purchase TransactionsDocument4 pagesHandout No. 03 - Purchase TransactionsApril SasamPas encore d'évaluation