Académique Documents

Professionnel Documents

Culture Documents

Critical Ship Equipment - Working On Critical Systems

Transféré par

Wisnu KertaningnagoroTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Critical Ship Equipment - Working On Critical Systems

Transféré par

Wisnu KertaningnagoroDroits d'auteur :

Formats disponibles

Critical Ship Equipment- Working on critical systems

1 of 3

http://www.machineryspaces.com/critical-items.html

Critical Ship Equipment- Working on critical systems

Machinery Spaces.com

What are Critical Ship Equipment ?

If a sudden operational failure of equipment or technical systems on board may result in a hazardous situation, that equipment or system is

considered critical. Master and Chief Engineer must draw up a list of Critical Ship Functions and Critical Equipment (Main and Standby). These

Critical Lists are to be formalised on board and sent to the office. The agreed list of Critical Equipment must be accurately reflected and identified

in the vessels PMS.This list will always include; Supply of electrical power to essential services, Propulsion, Steering ,Main Engine, Steering gear,

Generators

Critical Ship Functions

The list of critical ship functions may also include ship specific functions, for example the capability to recover from a semi-submerged condition

for a heavy-lift vessel.

Critical Stand-By Equipment

Working from the basis of the critical machinery list, a list of critical stand-by arrangements should be drawn up. The critical stand-by

arrangements list should be decided using the criteria of Will a single critical stand-by arrangement failure compromise one of the critical

machinery functions.

Home page

Marine diesel engines - Main

propulsion machinery

Steam generating plant -Boiler

arrangements

Feed systems for auxiliary boilers

and steam turbines

Steam turbines - Energy conversion

process

DW Simpson Actuarial

Recruitment CRO / Risk

Management Employment

Other marine auxiliary machinery

Fuel oil & lub oil treatment &

centrifugal process

steering gear arrangement, testing &

regulatory requirement

Pumps and pumping arrangement

Valves and pipelines for machinery

spaces

Refrigeration of cargo spaces and

storerooms

The critical stand-by arrangement list will generally include:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Electrical Generating Plant

Main Air Compressor Sets

Control Air Compressor Sets

Main and Auxiliary Engine circulating systems pump sets

Main Engine Electrical Blower

Main Switchboard and Components

Main and Auxiliary Engine system filters

HFO & LO pumps

Feed Water System Pump Sets

Boiler Circulating Pump Sets

Boiler Water Gauge Glass Sets

Boiler Safety Valve Sets

Steering Gear Pump Sets

Rudder, Shafting and Propeller systems

Control engineering items

Ships Side Valves

Windlass and Mooring Sets

High and Low Level Alarms

Stand-by Whistle, Siren Horn etc

Critical Idle Functions (Equipment which is safety critical but not in day-to-day use).

Quick closing valves, Remote stops and switches

Over-speed trip arrangements

First start arrangement

Emergency Electrical Generating Plan

Emergency Lighting

Emergency Compressor

Heating, ventilation & air conditioning

Propeller shaft arrangement

Power generation , supply &

distribution system

Deck machineries & cargo gears

Control and instrumentation

Fire protection

Engine room safety

Terms and conditions of use

Read our privacy policy

6/30/2015 10:01 AM

Critical Ship Equipment- Working on critical systems

2 of 3

27.

28.

29.

30.

31.

32.

http://www.machineryspaces.com/critical-items.html

Emergency Fire Pump

Fire Fighting and Detection Systems

Safety and Lifesaving Equipment

B.A. Compressor

Emergency Steering Arrangement

Main & Auxiliary Engine Shutdown arrangements.

Minimum Stock Level for Critical, Spare Parts, Consumables and Tools

It is the responsibility of the Chief Engineer to set the minimum level stock listing, customised for each vessel and to formally agree with the Fleet

Superintendent the contents of the list.

The Chief Engineer must then maintain the agreed minimum stock levels and to ensure, as appropriate, the necessary requisitions. Deficiencies

are to be brought to the attention of the Master and the technical Department of the relevant management Office as Critical Spares Inventory

Monthly Report . This report must be completed and returned to the Managing Officer. The under-mentioned listings are the recommended

Minimum Stock Levels for the items list.

Working on critical equipment and systems

Persons who are responsible for the operation, maintenance, repair of critical equipment and systems, as well as the calibration and adjustment

of alarms and other parameters of the equipment, must be properly qualified, trained or experienced in the use of these crucial items. Either the

Master or Chief Engineer is responsible for ensuring that the competency of the person involved in the maintenance is sufficient to carry out the

task or must personally supervise critical phases of overhaul. If there is any doubt as to the ability and competence of those onboard to carry out

a particular task successfully on critical equipment or systems, then the management office must be notified for further guidance and/or

instruction as to how to proceed.

Whenever routine planned maintenance of major critical equipment is to be carried out that involves shutting down the equipment, ships staff will

consult with the management cell. A risk assessment will be required before the equipment is shut down. The risk assessment will include, but not

be limited to, addressing the following topics:

1. Alternative back-up equipment / systems.

2. Any necessary modification in operational procedures as a result of the equipment being out of service.

3. Any additional safety procedures (emergency equipment etc).

If the agreed out of service period for critical equipment or systems maintenance cannot be achieved, any extension or alternative actions will

require review by the shore management. In additional, a further risk assessment may be required if circumstances (such as environmental

conditions, crew fatigue or operational parameters) change.

Trends and historical data recorded in PMS should be used to modify the maintenance interval or critical systems, in order to prevent incidents or

out of service periods that could be associated with a failure.

Ordering Critical Repairs or Spares

When any item from this list requires a spare or repair, the Requisition Form must be endorsed Spare for Critical Equipment marked

appropriately and followed up with a telephone call, as explained in the Purchasing Section of these procedures.

It is the responsibility of the Chief Engineer to set the minimum level stock listing, customised for each vessel and to formally agree with the Fleet

Superintendent the contents of the list. The Chief Engineer must then maintain the agreed minimum stock levels and to ensure, as appropriate,

the necessary requisitions. Deficiencies are to be brought to the attention fo the Master and the technical Department of the relevant

management Office as Critical Spares Inventory Monthly Report . This report must be completed and returned to the Managing Officer.

Quick Checklist (QCL)

For portable tools and equipment which are more likely to get lost or stolen, and which are costly and essential for work and running of the ship,

a Q.C.L. list must be established. Include some of the items listed in the inventory for the ship, and one copy of the Q.C.L. to be forwarded to the

Company.

For the Deck Department, the following similar items are included: binoculars, walkie-talkies, sextants and other mobile navigational aids,

professional books supplied by the owners (e.g. Handbook, IMO dangerous goods code etc.,) large ropes, power tools, valuable entertainment

equipment, typewriters, calculators etc. For the Engine Department, the following similar items are included: measuring tools, test instruments,

power tools.

Such Q.C.L. is not normally to contain more than 10 to 15 items. This list must also include items which are in custody of the senior officers, such

as the Chief Mate, 1st Assistant Engineer, Electrician, etc., and when there is a change of Master or Chief Engineer, the content of the list must be

confirmed. The Master and the Chief Engineer are to check these items against the Q.C.L. when there is a change of officer, and report any

discrepancies immediately to the Company.

Below is our guideline for working principles and operational guideline for machinery spaces:

Marine diesel engine operational procedures

6/30/2015 10:01 AM

Critical Ship Equipment- Working on critical systems

3 of 3

http://www.machineryspaces.com/critical-items.html

Marine machineries - Useful tags

Marine diesel engines //Steam generating plant //Air conditioning system //Compressed air //Marine batteries //Cargo refrigeration //Centrifugal

pump //Various coolers //Emergency power supply //Exhaust gas heat exchangers //Feed system //Feed extraction pump // Flow measurement

// Four stroke engines // Fuel injector // Fuel oil system // Fuel oil treatment // Gearboxes // Governor // Marine incinerator // Lub oil filters //

MAN B&W engine // Marine condensers // Oily water separator // Overspeed protection devices // Piston & piston rings // Crankshaft deflection

// Marine pumps // Various refrigerants // Sewage treatment plant // Starting air system // Steam turbines // Steering gear // Sulzer engine //

Turbine gearing // Turbochargers // Two stroke engines // UMS operations // Engine room safety // Drydocking & major repairs //

Machinery Spaces.com is about working principles, construction and operation of all the machinery items in a ship intended primarily for engineers

working on board and those who working ashore . For any remarks please Contact us

Copyright 2010 Machinery Spaces.com All rights reserved.

6/30/2015 10:01 AM

Vous aimerez peut-être aussi

- Shipboard High Voltage Application and Safeties - Hanif Dewan's BlogDocument26 pagesShipboard High Voltage Application and Safeties - Hanif Dewan's BlogWisnu KertaningnagoroPas encore d'évaluation

- 5.3.3 HIRADC For Lifting and Installation of Container and Chiller (04!06!14)Document3 pages5.3.3 HIRADC For Lifting and Installation of Container and Chiller (04!06!14)Wisnu KertaningnagoroPas encore d'évaluation

- MLC 2006 - Onboard Complaint PDFDocument2 pagesMLC 2006 - Onboard Complaint PDFWisnu KertaningnagoroPas encore d'évaluation

- Teardrops in The Rain (Chords) by CNBlueDocument2 pagesTeardrops in The Rain (Chords) by CNBlueWisnu KertaningnagoroPas encore d'évaluation

- ABS Training Incident InvestigationDocument5 pagesABS Training Incident InvestigationWisnu KertaningnagoroPas encore d'évaluation

- 5.3.2 MOC-Installing Portable Container and ChillerDocument1 page5.3.2 MOC-Installing Portable Container and ChillerWisnu KertaningnagoroPas encore d'évaluation

- Enclosed Space Drill ScenarioDocument1 pageEnclosed Space Drill ScenarioWisnu KertaningnagoroPas encore d'évaluation

- Volume Chain Locker GL ClassDocument1 pageVolume Chain Locker GL ClassWisnu KertaningnagoroPas encore d'évaluation

- SOLAS - Mandatory Drills For Entry Into Enclosed Spaces - SkuldDocument3 pagesSOLAS - Mandatory Drills For Entry Into Enclosed Spaces - SkuldWisnu KertaningnagoroPas encore d'évaluation

- Coshh Basics - CoshhDocument2 pagesCoshh Basics - CoshhWisnu Kertaningnagoro100% (1)

- Volume Chain Locker GL ClassDocument1 pageVolume Chain Locker GL ClassWisnu KertaningnagoroPas encore d'évaluation

- Dry Cargo Ship - General Cargo DWT 5910 at 6,35 M DFTDocument2 pagesDry Cargo Ship - General Cargo DWT 5910 at 6,35 M DFTWisnu KertaningnagoroPas encore d'évaluation

- Vegetable Oils and Fats on Chemical TankersDocument29 pagesVegetable Oils and Fats on Chemical TankersWisnu KertaningnagoroPas encore d'évaluation

- NIS Circular 07-2007Document5 pagesNIS Circular 07-2007Wisnu KertaningnagoroPas encore d'évaluation

- Winposh Rampart Towing - Vertical & Horizontal Transvere Force Stated On Stability ...Document1 pageWinposh Rampart Towing - Vertical & Horizontal Transvere Force Stated On Stability ...Wisnu KertaningnagoroPas encore d'évaluation

- Wins Sop Limbah b3Document5 pagesWins Sop Limbah b3Wisnu KertaningnagoroPas encore d'évaluation

- Home Products Minerals & Metallurgy Steel Steel SheetsDocument13 pagesHome Products Minerals & Metallurgy Steel Steel SheetsWisnu KertaningnagoroPas encore d'évaluation

- HSE DocumentsDocument3 pagesHSE DocumentsWisnu KertaningnagoroPas encore d'évaluation

- Example COSHH Risk Assessment - Warehouse - COSHHDocument2 pagesExample COSHH Risk Assessment - Warehouse - COSHHWisnu KertaningnagoroPas encore d'évaluation

- Example COSHH Risk Assessment - Electronics - COSHHDocument2 pagesExample COSHH Risk Assessment - Electronics - COSHHWisnu KertaningnagoroPas encore d'évaluation

- Make A Checklist in WordDocument3 pagesMake A Checklist in WordWisnu KertaningnagoroPas encore d'évaluation

- ASP ManningDocument15 pagesASP ManningWisnu KertaningnagoroPas encore d'évaluation

- Calculating energy performance of buildingsDocument3 pagesCalculating energy performance of buildingsWisnu Kertaningnagoro100% (1)

- Indonesia ISPS Contact June 2015Document3 pagesIndonesia ISPS Contact June 2015Wisnu KertaningnagoroPas encore d'évaluation

- Example COSHH Risk Assessment - Electronics - COSHHDocument2 pagesExample COSHH Risk Assessment - Electronics - COSHHWisnu KertaningnagoroPas encore d'évaluation

- Example COSHH Risk Assessment - Office - COSHHDocument2 pagesExample COSHH Risk Assessment - Office - COSHHWisnu Kertaningnagoro100% (1)

- COSHH Workshop Risk AssessmentDocument2 pagesCOSHH Workshop Risk AssessmentWisnu KertaningnagoroPas encore d'évaluation

- TDI SMM ContentDocument2 pagesTDI SMM ContentWisnu KertaningnagoroPas encore d'évaluation

- Example COSHH Risk Assessment - Office - COSHHDocument2 pagesExample COSHH Risk Assessment - Office - COSHHWisnu KertaningnagoroPas encore d'évaluation

- Principal Functions of An ERRVDocument2 pagesPrincipal Functions of An ERRVWisnu KertaningnagoroPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Wartsila Pci Hfo Mdo e PrecoDocument20 pagesWartsila Pci Hfo Mdo e PrecoCarlos SopasPas encore d'évaluation

- Costa BulbDocument10 pagesCosta BulbVictor MartinsPas encore d'évaluation

- Lloyds Register Lay Up Guide June 2020Document30 pagesLloyds Register Lay Up Guide June 2020SUNILPas encore d'évaluation

- ECE TRANS SC3 115 Rev.5e - WEBDocument214 pagesECE TRANS SC3 115 Rev.5e - WEBMilan KnezevicPas encore d'évaluation

- Introduction To Shipping: Lead Examiner Report: Leif Ollivierre General CommentsDocument4 pagesIntroduction To Shipping: Lead Examiner Report: Leif Ollivierre General CommentsdiablolcPas encore d'évaluation

- Battlefleet Gothic Tactics OrkDocument4 pagesBattlefleet Gothic Tactics Orkairfix1999100% (1)

- Waste Management Plan Malta-Ship Gerenated WasteDocument10 pagesWaste Management Plan Malta-Ship Gerenated WasteIlie RomeoPas encore d'évaluation

- Banning Asbestos On ShipsDocument4 pagesBanning Asbestos On ShipsEMRE GABLANPas encore d'évaluation

- Selecting, Selling, and Pricing CruisesDocument16 pagesSelecting, Selling, and Pricing CruisesTrisha Kaira RodriguezPas encore d'évaluation

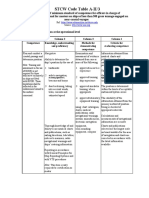

- STCW Table A II 3Document9 pagesSTCW Table A II 3Ernesto FariasPas encore d'évaluation

- Shell GTL N Paraffins c10 c13 Revision1Document4 pagesShell GTL N Paraffins c10 c13 Revision1Rohith KommuPas encore d'évaluation

- UNDERWATER SHIP PROPELLER MANUALSDocument129 pagesUNDERWATER SHIP PROPELLER MANUALSChristian Delgado RamosPas encore d'évaluation

- CLT SMM2014 PresentationDocument29 pagesCLT SMM2014 PresentationEmine DağPas encore d'évaluation

- Company Profile: Marine SurveyorsDocument8 pagesCompany Profile: Marine SurveyorsbeaconhoPas encore d'évaluation

- Preliminary Design of 25,000-Ton General Cargo VesselDocument32 pagesPreliminary Design of 25,000-Ton General Cargo VesselRama KrishnaPas encore d'évaluation

- Shahzad Tufail Master Thesis (Itu, Zut), June 2017 (Ok Final)Document120 pagesShahzad Tufail Master Thesis (Itu, Zut), June 2017 (Ok Final)Hakim Younes HAMDANIPas encore d'évaluation

- Who Are The VikingsDocument5 pagesWho Are The VikingsPiriya RajakumarPas encore d'évaluation

- Ag300 V22$$allDocument126 pagesAg300 V22$$alltesterPas encore d'évaluation

- Week 1 - What Is Oil Discharge Monitoring and Control System ODMCS On ShipDocument2 pagesWeek 1 - What Is Oil Discharge Monitoring and Control System ODMCS On ShipCriswin MalazartePas encore d'évaluation

- 5 Parsecs - Core SpaceDocument41 pages5 Parsecs - Core SpaceDavid GnéPas encore d'évaluation

- Accounting For Decision Making and Control 8th Edition Zimmerman Solutions ManualDocument26 pagesAccounting For Decision Making and Control 8th Edition Zimmerman Solutions ManualSandraHensonbtwd100% (48)

- Crude Oil Transport Risks and Impacts PDFDocument16 pagesCrude Oil Transport Risks and Impacts PDFBrenda Davis100% (1)

- FINAL MANUSCRIPT Group 5 NS1C2Document51 pagesFINAL MANUSCRIPT Group 5 NS1C2Princess P. GonzalesPas encore d'évaluation

- Twilight 2000 - Satellite DownDocument50 pagesTwilight 2000 - Satellite DownJohn Givens83% (6)

- IMO International Convention Calendar - ClassNKDocument37 pagesIMO International Convention Calendar - ClassNKVu Tung LinhPas encore d'évaluation

- Container Terminal Operational GuidelinesDocument30 pagesContainer Terminal Operational GuidelinesAbdelkader ChaouiPas encore d'évaluation

- 95 Teses de LuteroDocument236 pages95 Teses de LuteroRoney RondonPas encore d'évaluation

- Interviewing: Unstructured and Semistructured: The Big PictureDocument34 pagesInterviewing: Unstructured and Semistructured: The Big PictureChris KritikosPas encore d'évaluation

- SeakeepingDocument38 pagesSeakeepingSahil JawaPas encore d'évaluation

- 8 Common Mistakes While Operating Deck Machinery SystemsDocument15 pages8 Common Mistakes While Operating Deck Machinery SystemsmivanoPas encore d'évaluation