Académique Documents

Professionnel Documents

Culture Documents

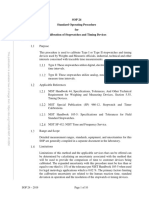

08 Hydrostatic Test Procedure Section I OK

Transféré par

Eduardo GarciaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

08 Hydrostatic Test Procedure Section I OK

Transféré par

Eduardo GarciaDroits d'auteur :

Formats disponibles

CROMANZA S.A. DE C.V.

Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

1 of 9

INDEX

CONTENS

SHEET

1. Purpose.

2. Scope

3. Applicable Documents.

4. Responsibilities

5. Definitions..

6. Procedures

6.1. Hydrostatic Test

6.2. Test Gages.

6.3. Hydrostatic Deformation Test.

6.4. Acceptance Standard..

7. Records

7.1.

Forms: Annex AP-TEST-01.....

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

2 of 9

1. PURPOSE

The purpose of this document is to establish the activities that will be carried out for

the performance of the hydrostatic tests in shop or field site that are required in

Boilers and its components.

2. SCOPE

This procedure applies to all the hydrostatic tests to be performed by Cromanza,

S.A de C.V., at shop and field in Boilers and its components after all fabrication has

been completed, under the Section I of ASME Code.

3. APPLICABLE DOCUMENTS

- Chapter 4, 9, and 10, of the Quality Control System Manual

- Section I of the ASME Code, for Boiler and Pressure Vessels, 2013 Edition.

4.

RESPONSIBILITIES

Quality Control Manager shall be responsible for the approval, implementation

and updating of this procedure and approval of test certificates. Witness the test

by himself or his designee.

Coordinate all activities related to the verification and record of hydrostatics tests,

preparation and preservation of calibrated gages and thermometers in

accordance with this procedure. Also, review of test certificates their filling and

preservation.

Engineering Manager shall be responsible for the establish fabrication

drawings, the test pressure rate and special instructions when applicable, to

which the equipment or component will be tested, in accordance to applicable

Customer and Code requirements.

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

3 of 9

Construction Manager (Shop and Field) shall be responsible for the preparation

and filling with water of vessels to be tested, installation of all test gages and

recorders and assistance during test perform. Drained, and cleanness of vessels

after successful tests.

5. DEFINITIONS

The following definitions are applicable to this document:

LEAK: Is the evidence that a fluid is passing from on side to another in a closed

vessel, independent the amount of fluid.

COMBINATION UNITS: Is a pressure vessel, which consists of two or more

independently pressurized chambers that operate at the same or different pressure.

6. PROCEDURE

6.1. HYDROSTATIC TEST

Hydrostatic testing of the completed boiler unit shall be conducted in accordance

with the following requirements:

After a boiler has been completed [includes all piping and piping components], it

shall be subjected to pressure tests using water at not less than ambient

temperature, but in no case less than 70 F [20 C ]. Where required test pressure

is specified in this paragraph, whether minimum or maximum pressures, they apply

to the highest point of the boiler system. When the boiler is completed in the

Cromanza, S.A. de C.V., shop without boiler external piping, subsequent

hydrostatic testing of the boiler external piping shall be the responsibility of any

holder of a valid S, A, or PP stamp. The pressure relief valves need not be

included in the hydrostatic test. The tests shall be made in two stages in the

following sequence:

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

4 of 9

(1) Hydrostatic pressure tests shall be applied by raising the pressure gradually to

not less than 1 times the maximum allowable working pressure as shown

on the Data Report to be stamped on the boiler. No part of the boiler shall be

subjected to a general membrane stress greater than 90% of its yield strength

[0.2% offset] at test temperature. The primary membrane stress to which boiler

components are subjected during hydrostatic test shall be taken into account

when designing the components. Close visual inspection for leakage is not

required during this stage.

(2) The hydrostatic test pressure may then be reduced to the maximum allowable

working pressure, as shown on the Data Report, to be stamped on the boiler

and maintained at this pressure while the boiler is carefully examined. The

metal temperature shall not exceed 120 F [50 C] during the close

examination.

(3)

A completed forced-flow steam generator with no fixed steam and waterline,

having pressure parts designed for different pressure levels along the path of

water-steam flow, shall be subjected to a hydrostatic pressure test by the

above procedure [(1) and (2)] based upon:

a. For the first stage test a hydrostatic test pressure of not less than 1 times

the maximum allowable working pressure at the superheater outlet as

shown in the master stamping but no less than 1 times the maximum

allowable working pressure of any part of the boiler external piping,

excluding the boiler external piping.

b. For the second stage test [(2) above] the hydrostatic test pressure may be

reduced to not less than the maximum allowable working pressure at the

superheater outlet.

6.2. TEST GAGES

(1) An indicating gage, visible to the operator controlling the pressure applied,

shall be connected to the pressure parts. Hydrostatic head on the gage shall

be considered such that the required test pressure is achieved at the top of the

boiler.

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

5 of 9

(2) Dial pressure gages used in testing shall preferably have dials graduated over

their entire range of about the intended maximum test pressure, but in no case

shall the range be less than 1 that pressure. The spacing between

graduations shall be such that the inspector and the operator controlling the

test shall be able to determine when the required test pressure has been

applied. Digital pressure gages having a wider range of pressure readings may

be used provided the readings give the same or greater degree of accuracy as

obtained with dial pressure gages.

6.3. HYDROSTATIC DEFORMATION TEST

Where no rules are given and it is impossible to calculate with a reasonable

degree of accuracy the strength of a boiler structure or any part thereof, a fullsized sample shall be built by Cromanza, S.A de C.V., and tested in accordance

with the Standard Practice for Making a Hydrostatic test on a Boiler Pressure Part

to determine the Maximum Allowable Pressure, given in A-22 of Section I of the

ASME Code or in such other manner as the Committee may prescribe.

6.4. ACCEPTANCE STANDARD

The Boiler and its components shall not show any leak. In case of leaks it must

be examined to determine the magnitude of the discontinuity and to repair in

accordance with requirements of Section I of the ASME Code (as apply), after

which the vessel shall be re-tested in accordance with paragraph 6.1 to 6.3

above. When repairs are made, the part shall again be tested in the regular way,

and if it passes the test the Inspector shall accept it. If does not pass the test the

Inspector may permit supplementary repairs, or if in his judgment the pressure

part is not suitable for service, he may permanently reject it.

7. RECORDS.

All the records and other documents originated by the activities described in this

procedure shall be maintained by the Quality Control Manager on Job File and

shall be properly filled.

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

7.1.

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

6 of 9

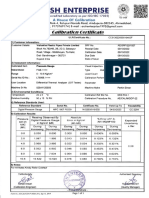

FORMS

The Hydrostatic Test results shall be recorder in the Traveler Sheet; acceptance

of the test is obtained by signature and dated in the document: Annex Exhibit No. 21

Annex: Exhibit No. 21

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Procedure

Rev.

Date

Page

08

0

06/12/2015

7 of 9

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

Field of Boilers and Its

Components. (SECTION I)

Approved By

Quality Control Manager

Authorized Inspector

Sign

Date

Procedure

Rev.

Date

Page

08

0

06/12/2015

8 of 9

CROMANZA S.A. DE C.V.Hydrostatic Test For Shop and

Industrial Service and

Maintenance

06/12/2015

Rev.

Date

Field of Boilers and Its

Components. (SECTION I)

S.G.P.

S.G.P.

Revisions

By

Approved

S.A.R.M.

Q.C.M.

Reviewed

Area

Procedure

Rev.

Date

Page

08

0

06/12/2015

9 of 9

S.G.P.

Initial issue

Involved Areas

Responsible

Modification

Vous aimerez peut-être aussi

- Chestionar 2Document5 pagesChestionar 2Alex AndruPas encore d'évaluation

- Anthony Robbins - Time of Your Life - Summary CardsDocument23 pagesAnthony Robbins - Time of Your Life - Summary CardsWineZen97% (58)

- Hydrostatic Pressure Tests ASME Pressure VesselsDocument3 pagesHydrostatic Pressure Tests ASME Pressure VesselsAsad KhanPas encore d'évaluation

- Ip Gauge Calibration ChecklistDocument1 pageIp Gauge Calibration ChecklistKumarPas encore d'évaluation

- Procedure For Magnetic Particle Examination 1.0 SCOPEDocument3 pagesProcedure For Magnetic Particle Examination 1.0 SCOPEpmkar100% (1)

- Roland Fantom s88Document51 pagesRoland Fantom s88harryoliff2672100% (1)

- ITP FORMAT - PSV Modified FormateDocument1 pageITP FORMAT - PSV Modified Formatemurthy challapalliPas encore d'évaluation

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument24 pagesThermoplastic Flanges: Technical Information Weights & DimensionsAngs TazPas encore d'évaluation

- W14-661 (0 To 40 Bar) PDFDocument3 pagesW14-661 (0 To 40 Bar) PDFBalaji BobadePas encore d'évaluation

- PTDocument7 pagesPTMohdHuzairiRusliPas encore d'évaluation

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarPas encore d'évaluation

- Work Instruction FOR: Charpy Impact TestDocument4 pagesWork Instruction FOR: Charpy Impact TestmahendraPas encore d'évaluation

- SOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesDocument10 pagesSOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesAli RizviPas encore d'évaluation

- Nuflo Mc-III Exp DatasheetDocument4 pagesNuflo Mc-III Exp DatasheetJerrydawangPas encore d'évaluation

- Pipe Schedule Chart: 160 XXS 80S 80 100 120 40S 60 XS 40 30 140 10S 10 20 STD 5S 5Document1 pagePipe Schedule Chart: 160 XXS 80S 80 100 120 40S 60 XS 40 30 140 10S 10 20 STD 5S 5vijayachiduPas encore d'évaluation

- Qcf301 Tp05 Pressure Test ChecklistDocument1 pageQcf301 Tp05 Pressure Test ChecklistminhnnPas encore d'évaluation

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 pagesStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomPas encore d'évaluation

- Equal-Friction-Method (From Engineering Toolbox)Document2 pagesEqual-Friction-Method (From Engineering Toolbox)Naw AzPas encore d'évaluation

- MP 2585Document5 pagesMP 2585Juan Sebastián Martinez NunciPas encore d'évaluation

- Pressure Form Test RecordDocument1 pagePressure Form Test Recordphyo7799Pas encore d'évaluation

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- Kit 138 New Bresle Salt PDFDocument2 pagesKit 138 New Bresle Salt PDFDian FaraPas encore d'évaluation

- Is 9902 2004Document11 pagesIs 9902 2004cbbasakPas encore d'évaluation

- Mil STD 271Document103 pagesMil STD 271Byungsuk ShimPas encore d'évaluation

- Bellingham Stanley Refractometer Adp 440 Plus Manual PDFDocument87 pagesBellingham Stanley Refractometer Adp 440 Plus Manual PDFĐăng LưuPas encore d'évaluation

- Pressure Gauge Technical InformationsDocument4 pagesPressure Gauge Technical Informationssahayaraaj100% (1)

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- B31.1 Weld Insp.Document3 pagesB31.1 Weld Insp.Ivan AlanizPas encore d'évaluation

- RNS - NDT - MT - 001 Rev.0Document10 pagesRNS - NDT - MT - 001 Rev.0Goutam Kumar DebPas encore d'évaluation

- NDE-Penetrant TestDocument2 pagesNDE-Penetrant TestCandy KendeePas encore d'évaluation

- (509869149) Leak DetectionDocument12 pages(509869149) Leak Detectionsathish_iyengarPas encore d'évaluation

- INS T 004, Tol - OvalityDocument4 pagesINS T 004, Tol - OvalityDeepakPas encore d'évaluation

- Qam 3Document35 pagesQam 3Arunachalam AvanashiPas encore d'évaluation

- Calibration of ChronometersDocument13 pagesCalibration of ChronometersGustavo SánchezPas encore d'évaluation

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalPas encore d'évaluation

- Tightness Control SystemDocument4 pagesTightness Control SystemYetkin Erdoğan100% (1)

- General Repair Procedure For Welds R1 PDFDocument4 pagesGeneral Repair Procedure For Welds R1 PDFsutrimoPas encore d'évaluation

- RT ProcedureDocument51 pagesRT ProcedureAwale UdinPas encore d'évaluation

- UT Procedure PDFDocument14 pagesUT Procedure PDFAbhayPas encore d'évaluation

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazPas encore d'évaluation

- Ddaily Drift Calibration Procedure: 1. ScopeDocument1 pageDdaily Drift Calibration Procedure: 1. ScopeJohn DolanPas encore d'évaluation

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefPas encore d'évaluation

- Hydrotest ProcedureDocument3 pagesHydrotest ProcedureAprilia dwita sariPas encore d'évaluation

- A Traceability System For Outgrower SchemesDocument157 pagesA Traceability System For Outgrower SchemessebichondoPas encore d'évaluation

- Chemical Cleaning ProcedureDocument2 pagesChemical Cleaning ProcedureEscobar ValderramaPas encore d'évaluation

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoPas encore d'évaluation

- Special Process Procedure Details From Schedule QDocument1 pageSpecial Process Procedure Details From Schedule QAnonymous VohpMtUSNPas encore d'évaluation

- Asme VDocument1 pageAsme VMohd AnsariPas encore d'évaluation

- Two-Wire Radar Level Transmitter: Rosemount 5400 SeriesDocument36 pagesTwo-Wire Radar Level Transmitter: Rosemount 5400 SeriesthotalnPas encore d'évaluation

- Radiation Safety ProcedureDocument57 pagesRadiation Safety ProcedureibrahimPas encore d'évaluation

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- Coca-Cola Femsa Philippines, Inc.: Report On The Result of Inspection of Pressure VesselDocument30 pagesCoca-Cola Femsa Philippines, Inc.: Report On The Result of Inspection of Pressure VesselEphraim John Tangelon AquinoPas encore d'évaluation

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosPas encore d'évaluation

- 3600 - Hi-Lo Pilot SwitchDocument10 pages3600 - Hi-Lo Pilot Switchsumesh19778933Pas encore d'évaluation

- SLB Check List-1Document2 pagesSLB Check List-1Jitendra BhosalePas encore d'évaluation

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraPas encore d'évaluation

- Quality Control Manual: Rev. DateDocument1 pageQuality Control Manual: Rev. DatealokbdasPas encore d'évaluation

- Price List Principal - 01 Feb 21Document393 pagesPrice List Principal - 01 Feb 21novitaPas encore d'évaluation

- API Repair ProcedureDocument1 pageAPI Repair ProcedurejacquesmayolPas encore d'évaluation

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbPas encore d'évaluation

- Client Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved byDocument7 pagesClient Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved bySARSAN NDTPas encore d'évaluation

- Penumatic TestDocument10 pagesPenumatic TestahmadPas encore d'évaluation

- FAT ProcedureDocument7 pagesFAT ProcedureOlek TybińskiPas encore d'évaluation

- Report-Smaw Group 12,13,14Document115 pagesReport-Smaw Group 12,13,14Yingying MimayPas encore d'évaluation

- What Are Some of The Best Books On Computer ScienceDocument9 pagesWhat Are Some of The Best Books On Computer ScienceSarthak ShahPas encore d'évaluation

- Marieb ch3dDocument20 pagesMarieb ch3dapi-229554503Pas encore d'évaluation

- Cpar ReviewerDocument6 pagesCpar ReviewerHana YeppeodaPas encore d'évaluation

- Risha Hannah I. NazarethDocument4 pagesRisha Hannah I. NazarethAlpaccino IslesPas encore d'évaluation

- ProjectDocument33 pagesProjectPiyush PatelPas encore d'évaluation

- Nyamango Site Meeting 9 ReportDocument18 pagesNyamango Site Meeting 9 ReportMbayo David GodfreyPas encore d'évaluation

- English For General SciencesDocument47 pagesEnglish For General Sciencesfauzan ramadhanPas encore d'évaluation

- Datos Adjuntos Sin Título 00013Document3 pagesDatos Adjuntos Sin Título 00013coyana9652Pas encore d'évaluation

- ATAL Selected FDPs AY 2023 24Document15 pagesATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- Grasa LO 915Document2 pagesGrasa LO 915Angelo Carrillo VelozoPas encore d'évaluation

- Guidelines For Plenipotentiary - 1Document6 pagesGuidelines For Plenipotentiary - 1Oladimeji Ibukun IjaodolaPas encore d'évaluation

- Participatory EvaluationDocument4 pagesParticipatory EvaluationEvaluación Participativa100% (1)

- Mindray PM 9000 User ID10240 PDFDocument378 pagesMindray PM 9000 User ID10240 PDFJuan FernandoPas encore d'évaluation

- Smart Plug Installation GuideDocument9 pagesSmart Plug Installation GuideFrancisco GuerreroPas encore d'évaluation

- RevlonDocument13 pagesRevlonSarosh AtaPas encore d'évaluation

- Caso Estudio: Reliability Analysis of Power Distribution System. A Case StudyDocument6 pagesCaso Estudio: Reliability Analysis of Power Distribution System. A Case StudyCarlos HernandezPas encore d'évaluation

- Thermodynamic c106Document120 pagesThermodynamic c106Драгослав БјелицаPas encore d'évaluation

- Beautiful SpotsDocument2 pagesBeautiful SpotsLouise Yongco100% (1)

- SahanaDocument1 pageSahanamurthyarun1993Pas encore d'évaluation

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Document82 pagesGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbPas encore d'évaluation

- Nyambe African Adventures An Introduction To African AdventuresDocument5 pagesNyambe African Adventures An Introduction To African AdventuresKaren LeongPas encore d'évaluation

- Forces L2 Measuring Forces WSDocument4 pagesForces L2 Measuring Forces WSAarav KapoorPas encore d'évaluation

- Thesis On Retail Management of The Brand 'Sleepwell'Document62 pagesThesis On Retail Management of The Brand 'Sleepwell'Sajid Lodha100% (1)

- Friday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDocument3 pagesFriday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDONI ARTAPas encore d'évaluation

- KiSoft Sort & Pack Work Station (User Manual)Document41 pagesKiSoft Sort & Pack Work Station (User Manual)Matthew RookePas encore d'évaluation

- Strategic Audit of VodafoneDocument35 pagesStrategic Audit of VodafoneArun Guleria89% (9)