Académique Documents

Professionnel Documents

Culture Documents

Casing Design Calculation

Transféré par

Nurul AishahCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Casing Design Calculation

Transféré par

Nurul AishahDroits d'auteur :

Formats disponibles

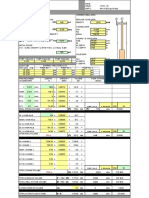

Casing Design Example

The table below is a data set from a real land well. As a drilling engineer you are required to

calculate the burst and collapse loads that would be used to select an appropriate weight and

grade of casing for the Surface, Intermediate and Production strings in this land well:

Driven

100

26" 3000

17" 6000

12" 10000

8" 9500

- 120000

30"

20"

13"

9"

7" L

8.6

8.6/9.5

9.5/11.0

11.0/14.0

13.0@3000

16.0@6000

16.5@10000

9.0

11.00

14.00

15.00

TOC

seabed

4300

7500

9500

Lead slurry

(PPG)

13.5

13.5

13.5

15.88

Cementing

Tail slurry

data

(PPG)

15.88

500ft

15.88

500ft

15.88

500ft

15.88

500ft

Mix-Water

(PPG)

8.5

8.5

8.5

8.5

Unconsolidated

Caving

Sloughing

Possible

lost circ.

Unstable

shales

Overpressured

shales

Hole size depth(ft)

Casing size (in.)

Expected min/max. pore

pressure grad. (PPG)

Expected LOT pressure

grad. (PPG)

Mud-weight (PPG)

Potential hole problems

Assumptions:

Production test data:

Gas density

above 10000ft

: 0.1 psi/ft

Well test completion

fluid density

8.60 ppg.

Design factor

(Burst)

: 1.1

Test packer depth

11000 ft

TVD RKB

Design factor

(Collapse)

: 1.0

Test perforation depth

11250 ft

TVD RKB

Pressure at top of

perforation

14.0 ppg.

Well test shut-in fluid

gradient

10.15 psi/ft

Gas lift may be

required

Surface Casing (20" @ 3000 ft)

From the Drilling Program it can be seen that the following data is to be used for the design:

Casing size

Setting depth

Pore pressure above 3000

Mud Weight in which the casing is to be run

:

:

:

:

20"

3000

8.6

9.0

ppg.

ppg.

Depth of next 17" hole

Max. pore pressure at bottom of 17" hole

:

:

6000

9.5

ppg.

Frac. pressure gradient at the 20" shoe

Expected gas gradient

13

0.1

Burst

1.1

Collapse

1.0

ppg.

psi/

Design Factors:

Burst Design - Drilling

Internal Load: Assuming that an influx of gas has occurred and the well is full of gas to surface.

Pore pressure at bottom of 17" hole

=

=

Pressure at surface = Pressure at bottom of 17"

=

hole - pressure due to column of gas

=

9.5 x 6000

2964 psi

2964 - (0.1 x 6000)

2364

psi

Pressure at 20" casing shoe

=

=

2961 - (0.1 x 3000)

2664 psi

LOT pressure at 20" casing shoe

=

=

13 x 0.052 x 3000

2028 psi

The formation at the casing shoe will breakdown at 2028 psi and therefore it will breakdown if

the pressure of 2664 psi is applied to it. The maximum pressure inside the surface casing at the

shoe will therefore be 2028 psi.

The maximum pressure at surface will be equal to the pressure at the shoe minus a column of

gas to surface:

=

=

2028 - (0.1 x 3000)

1728 psi

External Load: Assuming that the pore pressure is acting at the casing shoe and zero pressure at

surface.

Pore pressure at the casing shoe

=

=

External pressure at surface

8.6 x 0.052 x 3000

1342 psi

0

psi

Line up against equals

Summary of burst loads

Depth

External

load

Internal load

Net Load

Design load

(Load x 1.1)

Surface

1728

1728

1901

1342

2028

686

755

Casing shoe(3000 ft)

Collapse Design - Drilling

Internal Load: Assuming that the casing is totally evacuated due to losses of drilling fluid.

Internal pressure at surface

psi

Internal pressure at shoe

psi

External Load: Assuming that the pore pressure is acting at the casing shoe and zero pressure at

surface.

Summary of collapse loads

Depth

External

load

Internal load

Net Load

Design load

(Load x 1.0)

Surface

1342

1342

1342

Casing shoe(3000 ft)

Intermediate Casing (13" @ 6000 ft)

From the Drilling Program it can be seen that the following data is to be used for the design:

Casing size

Setting depth

Minimum pore pressure above 6000

Maximum pore pressure above 6000

Mud Weight in which the casing is to be run

:

:

:

:

:

13"

6000

8.6

9.5

11.0

ppg.

ppg.

ppg.

Depth of next 12" hole

Max. pore pressure at bottom of 12" hole

:

:

10000

11.0

ppg.

Frac. pressure gradient at the 13" shoe

Expected gas gradient

16

0.1

Burst

1.1

Collapse

1.0

ppg.

psi/

Design Factors:

Burst Design - Drilling

Internal Load: Assuming that an influx of gas has occurred and the well is full of gas to surface.

Pore pressure at bottom of 12" hole

=

=

Pressure at surface = Pressure at bottom of 12"

=

hole - pressure due to column of gas

=

11 x 0.052 x 10000

5720 psi

5720 - (0.1 x 10000)

4720

psi

Pressure at 13" casing shoe

=

=

5720 - (0.1 x 4000)

5320 psi

LOT pressure at 13" casing shoe

=

=

16 x 0.052 x 6000

4992 psi

The formation at the casing shoe will therefore breakdown when the well is closed in after the

gas has flowed to surface. The maximum pressure inside the casing at the shoe will be 4992 psi.

The maximum pressure at surface will be equal to the pressure at the shoe minus a column of

gas to surface:

=

=

4992 - (0.1 x 6000)

4392 psi

External Load: Assuming that the minimum pore pressure is acting at the casing shoe and zero

pressure at surface.

Pore pressure at the casing shoe

=

=

External pressure at surface

8.6 x 0.052 x 6000

2684 psi

0

psi

Summary of burst load

Depth

External

load

Internal load

Net Load

Design load

(Load x 1.1)

Surface

4392

4392

4831

2684

4992

2308

2539

Casing shoe(6000 ft)

Collapse Design - Drilling

Internal Load: Assuming that the casing is totally evacuated due to losses of drilling fluid.

Internal pressure at surface

psi

Internal pressure at shoe

psi

External Load: Assuming that the maximum pore pressure is acting at the casing shoe and zero

pressure at surface.

Pore pressure at the casing shoe

=

=

External pressure at surface

9.5 x 0.052 x 6000

2964 psi

0

psi

Summary of collapse loads

Depth

External

load

Internal load

Net Load

Design load

(Load x 1.0)

Surface

2684

2694

2964

Casing shoe(6000 ft)

Production Casing (9" @ 10000 ft)

From the Drilling Program it can be seen that the following data is to be used for the design:

Casing size

Setting depth

Top of 7" liner

Test perforation depth

Pressure at top of perforation

:

:

:

:

:

9"

10000

9500

11250

14.0

ppg.

Minimum pore pressure above 10000

Maximum pore pressure above 10000

Mud Weight in which the casing is to be run

:

:

:

9.5

11.0

14.0

ppg.

ppg.

ppg.

Density of completion/packer fluid

Packer depth

:

:

8.6

11000

ppg.

Expected gas gradient

0.15

psi/

Design Factors:

Burst

1.1

Collapse

1.0

Burst Design - Production

Internal Load: Assuming that a leak occurs in the tubing at surface and that the Closed In

Tubing Head Pressure (CITHP) is acting on the inside of the top of the casing. This pressure

will then act on the column of packer fluid. The 9" casing is only exposed to these pressure

down to the Top Of Liner (TOL). The 7" liner protects the remainder of the casing.

Max. pore pressure at the top of the production

zone

CITHP (at surface) - Pressure at top of prefs pressure due to column of gas (0.15 psi/)

14 x 0.052 x 11250

8190

psi

8190 - 0.15 x 11250

6503

psi

External Load: Assuming that the minimum pore pressure is acting at the liner depth and zero

pressure at surface.

Pore pressure at the top of liner

=

=

External pressure at surface

9.5 x 0.052 x 9500

4693 psi

0

psi

Summary of burst loads

Depth

External load

Internal load

Net Load

Design load (Load x 1.1)

Surface

6503

6503

7153

4693

10751

6058

6664

TOL (9500 ft)

Collapse Design - Drilling

Internal Load: Assuming that the casing is totally evacuated due to gaslifting operations.

Internal pressure at surface

psi

Internal pressure at top of liner (TOL)

psi

External Load: Assuming that the maximum pore pressure is acting on the outside of the casing

at the TOL.

Pore pressure at the TOL

=

11 x 0.52 x 9500

=

5434 psi

Summary of collapse loads

Depth

External load

Internal load

Net Load

Design load (Load x 1.0)

Surface

5343

5434

5434

TOL (9500 ft)

Vous aimerez peut-être aussi

- Casing and Casing Design 1Document60 pagesCasing and Casing Design 1Albert Wilson DavidPas encore d'évaluation

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziPas encore d'évaluation

- Casing Design PDFDocument41 pagesCasing Design PDFfabianandres23100% (2)

- Horizontal Well Drill String DesignDocument23 pagesHorizontal Well Drill String DesignTarek HassanPas encore d'évaluation

- Leak Off TestDocument80 pagesLeak Off Testb4rfPas encore d'évaluation

- Guidelines For Volumetric Stripping Rev.1 Feb.2004Document27 pagesGuidelines For Volumetric Stripping Rev.1 Feb.2004Yuri KostPas encore d'évaluation

- Well ControlDocument43 pagesWell ControlIsmail Mohammed100% (1)

- Casing Setting Depth DesignDocument26 pagesCasing Setting Depth Designehsan100% (1)

- Abnormal Pore Pressure PredictionDocument41 pagesAbnormal Pore Pressure PredictionSandesh Chavan100% (2)

- Top Squeeze or Top FillDocument5 pagesTop Squeeze or Top Filldrilling moneytreePas encore d'évaluation

- SPE-105068-MS-How Good Is The Torque-Drag ModelDocument9 pagesSPE-105068-MS-How Good Is The Torque-Drag ModelHassaanAhmedPas encore d'évaluation

- Swab & Surge Pressure EstimationDocument1 pageSwab & Surge Pressure Estimationfrancisryan4519Pas encore d'évaluation

- Bit Hydraulics Optimization for Maximum Drilling PerformanceDocument23 pagesBit Hydraulics Optimization for Maximum Drilling PerformanceShakerMahmood100% (1)

- Wellbore Hydraulics, Pressure Drop CalculationsDocument85 pagesWellbore Hydraulics, Pressure Drop CalculationsDan Morrell100% (1)

- Rahimov, MPDDocument102 pagesRahimov, MPDYassir HindiPas encore d'évaluation

- WELLCAT Data SheetDocument8 pagesWELLCAT Data SheetErik Rodriguez100% (1)

- Remedial Cementing TechniquesDocument4 pagesRemedial Cementing TechniquesColor RougePas encore d'évaluation

- 9B. Fracture Gradient DeterminationDocument61 pages9B. Fracture Gradient Determinationdriller2280% (5)

- Hydraulic Fracture Treatment Design & ExecutionDocument23 pagesHydraulic Fracture Treatment Design & ExecutionAndre YudhistiraPas encore d'évaluation

- Casing Seat SelectionDocument20 pagesCasing Seat SelectionEzekiel Agberen100% (1)

- Casing DesignDocument10 pagesCasing DesignAry Rachman0% (1)

- 6.mud Hydraulics Fundamentals PDFDocument11 pages6.mud Hydraulics Fundamentals PDFمعلومات ممتعه mohammedPas encore d'évaluation

- Casing Setting Depth Optimisation Based On Well Control Considerations by Lek Chun HouDocument6 pagesCasing Setting Depth Optimisation Based On Well Control Considerations by Lek Chun HouLek Chun Hou100% (1)

- Overpressure Mod-2Document72 pagesOverpressure Mod-2Antonio Jose da CostaPas encore d'évaluation

- Drilling Formulas Calculation SheetDocument213 pagesDrilling Formulas Calculation SheetSyed Shaiq100% (1)

- Drilling Problems N Drilling OptimizationDocument68 pagesDrilling Problems N Drilling Optimizationngecus50% (2)

- Surge Pressure Prediction For Running LinersDocument13 pagesSurge Pressure Prediction For Running LinersPegasus Vertex, Inc.100% (1)

- Well Engineering Guidlines For Hole CleaningDocument13 pagesWell Engineering Guidlines For Hole CleaningWilliam100% (1)

- Formation PressureDocument30 pagesFormation PressureTarek HassanPas encore d'évaluation

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignAnonymous H9n5g3aaCEPas encore d'évaluation

- Spe 30364 Seebty Ofpotrebum Endnws: Platform Concept OutlineDocument12 pagesSpe 30364 Seebty Ofpotrebum Endnws: Platform Concept Outlinebr_fdm1604100% (1)

- Casing Design PDFDocument19 pagesCasing Design PDFJorge Flores BarzolaPas encore d'évaluation

- IDPT - 12 - Casing Design PrinciplesDocument12 pagesIDPT - 12 - Casing Design PrinciplesDaymas Arangga RadiandraPas encore d'évaluation

- TAMU - Pemex: Well ControlDocument60 pagesTAMU - Pemex: Well Controldriller22Pas encore d'évaluation

- NP GP30 MP Drilling Program Rev.4Document177 pagesNP GP30 MP Drilling Program Rev.4Syed Tauseef HaiderPas encore d'évaluation

- Searchable Text2Document547 pagesSearchable Text2ChrisPas encore d'évaluation

- Technical Reference Self Study Material: Wellbore StabilityDocument11 pagesTechnical Reference Self Study Material: Wellbore StabilityArijit RayPas encore d'évaluation

- Drilling Programme TemplateDocument15 pagesDrilling Programme TemplateaMRHAGGAHPas encore d'évaluation

- Geothermal Drilling Problems and SolutionsDocument38 pagesGeothermal Drilling Problems and Solutionskrishnsgk100% (1)

- 31 - Well Design WorkflowDocument45 pages31 - Well Design WorkflowEmekaVictorOnyekwere100% (2)

- Enerplus Resources Inc - Drilling Diagram OurwellDocument4 pagesEnerplus Resources Inc - Drilling Diagram OurwellHeris SitompulPas encore d'évaluation

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandharePas encore d'évaluation

- Drilling Formulae - 9th Edition PDFDocument87 pagesDrilling Formulae - 9th Edition PDFEng Mohamed SaberPas encore d'évaluation

- Expandable Liner Hangers reduce pressure drop in Ecuador wellsDocument22 pagesExpandable Liner Hangers reduce pressure drop in Ecuador wellsHosam Ali100% (1)

- Guía para Tapones de CementoDocument15 pagesGuía para Tapones de CementoJunnior López PintadoPas encore d'évaluation

- TAMU - Pemex Offshore DrillingDocument42 pagesTAMU - Pemex Offshore Drillingdriller22100% (1)

- Cementing Presentation 1Document48 pagesCementing Presentation 1asrafosmanPas encore d'évaluation

- PETE 355 Pore Pressure PDFDocument89 pagesPETE 355 Pore Pressure PDFNural MuradliPas encore d'évaluation

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocument13 pagesA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadPas encore d'évaluation

- TAMU - Pemex: Well ControlDocument54 pagesTAMU - Pemex: Well Controldriller22100% (2)

- Formation DamageDocument36 pagesFormation Damagestaph23100% (1)

- Effective Hole Cleaning at High - Angle and Horizontal WellsDocument14 pagesEffective Hole Cleaning at High - Angle and Horizontal WellsColin100% (3)

- Balanced Cement Plug CalculationDocument7 pagesBalanced Cement Plug CalculationAlejandro ViscarraPas encore d'évaluation

- Deepwater Landing String DesignDocument6 pagesDeepwater Landing String Designrdos14Pas encore d'évaluation

- Measurement While Drilling: Signal Analysis, Optimization and DesignD'EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignPas encore d'évaluation

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceD'EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssurancePas encore d'évaluation

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsD'EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsÉvaluation : 4 sur 5 étoiles4/5 (9)

- Drilling Supervisor: Passbooks Study GuideD'EverandDrilling Supervisor: Passbooks Study GuidePas encore d'évaluation

- Dynamics Test 2 SolutionsDocument2 pagesDynamics Test 2 SolutionsNurul AishahPas encore d'évaluation

- A Comparison of Semester Systems and Students' Perception of Its Effectiveness Towards Their Performance in StudyDocument13 pagesA Comparison of Semester Systems and Students' Perception of Its Effectiveness Towards Their Performance in StudyNurul AishahPas encore d'évaluation

- INTRODUCTION TO MANAGEMENT - Managing Across The Globe ChallengesDocument25 pagesINTRODUCTION TO MANAGEMENT - Managing Across The Globe ChallengesNurul AishahPas encore d'évaluation

- Week 3-APA ReferencingDocument11 pagesWeek 3-APA ReferencingNik Hakim Mohammad IzaniPas encore d'évaluation

- UTP CM Matlab Assignment and Test Questions - May 2015 SemDocument4 pagesUTP CM Matlab Assignment and Test Questions - May 2015 SemNurul AishahPas encore d'évaluation

- Midterm Utp Malaysian StudiesDocument8 pagesMidterm Utp Malaysian StudiesNurul AishahPas encore d'évaluation

- Softversion PDFDocument129 pagesSoftversion PDFWilliam Anthony100% (4)

- FINAL EXAM Mpw2133 Malaysian Studies Jan 15 UTPDocument2 pagesFINAL EXAM Mpw2133 Malaysian Studies Jan 15 UTPNurul AishahPas encore d'évaluation

- FINAL EXAM Mpw2133 Malaysian Studies Jan 15 UTPDocument2 pagesFINAL EXAM Mpw2133 Malaysian Studies Jan 15 UTPNurul AishahPas encore d'évaluation

- Quiz - 1 - CM Jan 2015 Sem - SolutionsDocument4 pagesQuiz - 1 - CM Jan 2015 Sem - SolutionsNurul AishahPas encore d'évaluation

- Quiz - 1 Solutions - Sept. 2012 Sem CMDocument4 pagesQuiz - 1 Solutions - Sept. 2012 Sem CMNurul AishahPas encore d'évaluation

- Universiti Teknologi Petronas Test-1 Solution - CM - May 2015 SemesterDocument4 pagesUniversiti Teknologi Petronas Test-1 Solution - CM - May 2015 SemesterNurul AishahPas encore d'évaluation

- City Planning and Neighbourhood Design Case Studies1Document132 pagesCity Planning and Neighbourhood Design Case Studies1shinmiPas encore d'évaluation

- Krishna District Map PDFDocument1 pageKrishna District Map PDFCVS RAJUPas encore d'évaluation

- National Energy Policy Final April 2021Document47 pagesNational Energy Policy Final April 2021Edward ChikuniPas encore d'évaluation

- Mining Haul Roads - Theory andDocument2 pagesMining Haul Roads - Theory andJose Navarro QuilodranPas encore d'évaluation

- 2018-2022 West Pokot County CIDPDocument249 pages2018-2022 West Pokot County CIDPBrian KytePas encore d'évaluation

- Beng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichDocument16 pagesBeng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichshanecarlPas encore d'évaluation

- Sectoral Aspects of Indian. Chapter20Document29 pagesSectoral Aspects of Indian. Chapter20Gomathi VenkateshPas encore d'évaluation

- Structure: Project Name: Client Authority Engineer: EPC Contractor: 02/dec/2021Document6 pagesStructure: Project Name: Client Authority Engineer: EPC Contractor: 02/dec/2021TPF Getinsa Gorakhpur RE1Pas encore d'évaluation

- PATSC Memo (CT) - PKG IVDocument24 pagesPATSC Memo (CT) - PKG IVArun ChauhanPas encore d'évaluation

- Industrial District ManagementDocument45 pagesIndustrial District ManagementBaburam Subedi67% (3)

- Underpinning and StrengtheningDocument40 pagesUnderpinning and StrengtheningvatsalewbPas encore d'évaluation

- Promotional Role of Government of IndiaDocument10 pagesPromotional Role of Government of IndiaDeepak Bajpai100% (3)

- Feasibility Study For A Tramway Network in Khartoum (The Sudan)Document33 pagesFeasibility Study For A Tramway Network in Khartoum (The Sudan)임동우Pas encore d'évaluation

- HidrometerDocument9 pagesHidrometerMeliana NovaaPas encore d'évaluation

- Fabrication Order Cut Length and Reinforcement DetailsDocument2 pagesFabrication Order Cut Length and Reinforcement DetailsAngelinePas encore d'évaluation

- Earth AnchorsDocument17 pagesEarth AnchorsMelissaPas encore d'évaluation

- Ilesa Print FinalDocument122 pagesIlesa Print FinalOlabode DaviesPas encore d'évaluation

- Earth Dam: (Water Resources Engineering)Document54 pagesEarth Dam: (Water Resources Engineering)Neelakash HaloiPas encore d'évaluation

- Rural MarketingDocument125 pagesRural MarketingPratik SapraPas encore d'évaluation

- Characteristics of A Developing CountryDocument2 pagesCharacteristics of A Developing CountryGhalib Hussain100% (1)

- Borehole Log Project DetailsDocument5 pagesBorehole Log Project DetailsAnonymous ilWXWxgPas encore d'évaluation

- Utilities, Road Reinstatement and Traffic Management at Road WorksDocument12 pagesUtilities, Road Reinstatement and Traffic Management at Road WorksGILBERTO POZZIPas encore d'évaluation

- Guidance Document For PAS2080 PDFDocument82 pagesGuidance Document For PAS2080 PDFfatimaPas encore d'évaluation

- Revised Climate Marker Handbook - FINALDocument34 pagesRevised Climate Marker Handbook - FINALpooriya zamaniPas encore d'évaluation

- Competitive Smart Cities in RajasthanDocument52 pagesCompetitive Smart Cities in RajasthanSimran Radheshyam SoniPas encore d'évaluation

- Studi Numerik Terhadap Respon Struktur Pada Bantalan Beton Termodifikasi Untuk Non-Ballasted TrackDocument14 pagesStudi Numerik Terhadap Respon Struktur Pada Bantalan Beton Termodifikasi Untuk Non-Ballasted Trackdian perwitasariPas encore d'évaluation

- Embankment DamDocument54 pagesEmbankment DamMark Alvin PunzalanPas encore d'évaluation

- General Notes For RoadDocument2 pagesGeneral Notes For RoadEngr Sayyar Ahmad100% (1)

- Mining Communities and Social DevelopmentDocument37 pagesMining Communities and Social DevelopmentJefferson CuadraPas encore d'évaluation