Académique Documents

Professionnel Documents

Culture Documents

Hydrogenation of Vegetable Oil To Margarine

Transféré par

Chengsi WuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hydrogenation of Vegetable Oil To Margarine

Transféré par

Chengsi WuDroits d'auteur :

Formats disponibles

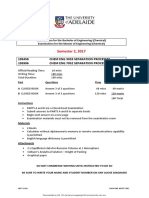

Hydrogenation of Vegetable oil to Margarine

The raw materials for the manufacture of margarine are vegetable oils such as palm,

sunflower, rape seed and soya bean oils. The main method used to modify natural

vegetable oils into the fatty base for margarine is by the selective catalytic hydrogenation

of the triglycerides of the unsaturated acids in vegetable oils. This produces hydrogenated

fat and trans-isomers.

i.

Hydrogen + Vegetable oil

Margarine

raw materials: vegetable oils such as palm, sunflower, rape seed and soya bean oils

temperature: 430 K

catalyst: nickel and palladium (finely divided and supported on kieselguhr which is a

form of silica)

Vegetables oils is extracted by high temperature and pressure then the remaining fraction

of oil removed with hexane and other solvents. Oils are now rancid, steam cleaned to

remove all vitamins and antioxidants. After that, oils mixed with a nickel catalyst. Oil

with catalyst subjected to hydrogen gas in high-pressure, high-temperature reactor. Soaplike emulsifiers mixed in. Oil steam cleaned again to remove horrible odor. Gray color

removed by bleaching. Artificial flavors, synthetic vitamins and natural color added.

Hydrogenation to treat with hydrogen is a chemical reaction between molecular

hydrogen (H2) and another compound or element, usually in the presence of a catalyst such

as nickel, palladium or platinum. The process is commonly employed

to reduce or saturate organic compounds. Hydrogenation typically constitutes the addition of

pairs of hydrogen atoms to a molecule, generally an alkene. Catalysts are required for the

reaction to be usable; non-catalytic hydrogenation takes place only at very high

temperatures. Hydrogenation reduces double and triplebonds in hydrocarbons.[1]

Because of the importance of hydrogen, many related reactions have been developed for its

use. Most hydrogenations use gaseous hydrogen (H2), but some involve the alternative

sources of hydrogen, not H2: these processes are called transfer hydrogenations

Hydrogenation of unsaturated fats produces saturated fats. In

hydrogenation, trans fats may be generated as well.

the

case

of

partial

Industrial reactors[edit]

Catalytic hydrogenation is done in a tubular plug-flow reactor (PFR) packed with a supported

catalyst. The pressures and temperatures are typically high, although this depends on the

catalyst. Catalyst loading is typically much lower than in laboratory batch hydrogenation, and

various promoters are added to the metal, or mixed metals are used, to improve activity,

selectivity and catalyst stability. The use of nickel is common despite its low activity, due to its

low cost compared to precious metals.

Gas Liquid Induction Reactors (Hydrogenator) are also used for carrying out catalytic

hydrogenation.[

Vous aimerez peut-être aussi

- 1996 - Walford - Composition of Cane JuiceDocument2 pages1996 - Walford - Composition of Cane JuiceMartha GamalPas encore d'évaluation

- Wiegand 1990Document9 pagesWiegand 1990ftmPas encore d'évaluation

- Industrial Catalytic Processes-Phenol Production: Robert J. SchmidtDocument15 pagesIndustrial Catalytic Processes-Phenol Production: Robert J. SchmidtUzair WahidPas encore d'évaluation

- Distillation Technology and Need of Simultaneous Design and Control A ReviewDocument24 pagesDistillation Technology and Need of Simultaneous Design and Control A ReviewHesam AhmadianPas encore d'évaluation

- Distillation TypesDocument34 pagesDistillation TypesJoshua Johnson100% (1)

- Full Report Exp 1Document8 pagesFull Report Exp 1Wan IrsyaduddinPas encore d'évaluation

- Catalytic Hydrogenation of Organic Polymers by Mixed Transition Metal OxidesDocument8 pagesCatalytic Hydrogenation of Organic Polymers by Mixed Transition Metal OxidesInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- 5.2. Classification of FuelsDocument16 pages5.2. Classification of FuelsadiPas encore d'évaluation

- Cyclohexane PDFDocument14 pagesCyclohexane PDFsushant kadamPas encore d'évaluation

- NaphthaleneDocument7 pagesNaphthalenesudivgulla1100% (1)

- Design Principles For Liquid-Liquid Extraction PDFDocument9 pagesDesign Principles For Liquid-Liquid Extraction PDFRajendraPas encore d'évaluation

- Separation Processes 2019-2020 (Part 1) StudPortDocument34 pagesSeparation Processes 2019-2020 (Part 1) StudPortunnatPas encore d'évaluation

- CSTRDocument11 pagesCSTRfarahanisiliasPas encore d'évaluation

- Membrane Reactor TechnologyDocument140 pagesMembrane Reactor TechnologyMohamed Laíd SakhriPas encore d'évaluation

- General Guidelines For Distillation ColumnDocument23 pagesGeneral Guidelines For Distillation ColumnCristinaPas encore d'évaluation

- Advanced Chemical Reaction Engineering CBE9450 ProjectDocument21 pagesAdvanced Chemical Reaction Engineering CBE9450 Projectdaoud saleemPas encore d'évaluation

- Adaptive Generic Model Control: Dual Composition Control of DistillationDocument11 pagesAdaptive Generic Model Control: Dual Composition Control of DistillationYlm PtanaPas encore d'évaluation

- Assignment 2 With SolutionsDocument4 pagesAssignment 2 With SolutionsVenkat MacharlaPas encore d'évaluation

- REPORT CorrectedDocument143 pagesREPORT CorrectedLifted CornPas encore d'évaluation

- PDFDocument74 pagesPDFHARISHKOTHARU48Pas encore d'évaluation

- Chapter One 1.1. BackgroundDocument16 pagesChapter One 1.1. Backgroundchisom100% (1)

- Process Flow Diagram New PDFDocument5 pagesProcess Flow Diagram New PDFdinurj100% (1)

- CHE F422 - Compre - PRT PDFDocument4 pagesCHE F422 - Compre - PRT PDFTarun MandalamPas encore d'évaluation

- 12 - Algal Oil Production - Super Pro DesignerDocument26 pages12 - Algal Oil Production - Super Pro DesignerLucilaFernandez100% (1)

- Selection of Reboilers For DistillationDocument25 pagesSelection of Reboilers For DistillationYris RosarioPas encore d'évaluation

- Syllabus (New) Gujarat University B E Chemical Engineering All SemesterDocument57 pagesSyllabus (New) Gujarat University B E Chemical Engineering All Semestertarunbnsl100% (1)

- Chemical Engineering GATE 1999Document13 pagesChemical Engineering GATE 1999Anonymous 8pCXXsPas encore d'évaluation

- Chemical Enginineering Fourth YearDocument68 pagesChemical Enginineering Fourth YearHabib NuredinPas encore d'évaluation

- Exam 2017 Questions SeparationsDocument12 pagesExam 2017 Questions SeparationsJules ArsenePas encore d'évaluation

- MEE NumericalsDocument9 pagesMEE NumericalsenzoPas encore d'évaluation

- The General Structure of A Chemical ProcessDocument16 pagesThe General Structure of A Chemical Processagrocel_bhv5591Pas encore d'évaluation

- VRL Logistics & Navkar Corporation: Financial, Valuation, Business & Management AnalysisDocument5 pagesVRL Logistics & Navkar Corporation: Financial, Valuation, Business & Management AnalysisKaran VasheePas encore d'évaluation

- Process Development For Metal SoapsDocument98 pagesProcess Development For Metal SoapsAlex RichardPas encore d'évaluation

- Separation ProcessDocument7 pagesSeparation ProcessJaramillo MarioPas encore d'évaluation

- Physical Refining of Coconut OilDocument6 pagesPhysical Refining of Coconut OilHiếu LêPas encore d'évaluation

- Chapter 12Document91 pagesChapter 12Carmen de LeonPas encore d'évaluation

- BT 0413 BioseparationTechnologyLaboratoryDocument21 pagesBT 0413 BioseparationTechnologyLaboratoryvijaygovindarajPas encore d'évaluation

- The System Formaldehyde-Water-Methanol ThermodynamicsDocument7 pagesThe System Formaldehyde-Water-Methanol Thermodynamicssatishchemeng100% (1)

- Convergence Hints (Aspen)Document13 pagesConvergence Hints (Aspen)Saurabh GuptaPas encore d'évaluation

- Production of MTBE Using Reactive DistilDocument4 pagesProduction of MTBE Using Reactive DistilIndraPas encore d'évaluation

- AbsorptionDocument41 pagesAbsorptionmahmoudPas encore d'évaluation

- CH3-CH-OH CoohDocument105 pagesCH3-CH-OH CoohAniket GawdePas encore d'évaluation

- Study On A New Wet Flue Gas Desulfurization Method Based On The Buns 2017 FuDocument5 pagesStudy On A New Wet Flue Gas Desulfurization Method Based On The Buns 2017 FuDiana ReyesPas encore d'évaluation

- Formic Acid TechnologyDocument3 pagesFormic Acid Technologyatharnadim_osPas encore d'évaluation

- Separation Processss Lecture NotesDocument17 pagesSeparation Processss Lecture NoteskeatyPas encore d'évaluation

- Production of Naphthalene.Document101 pagesProduction of Naphthalene.زهراء عادل عبد الزهرة إسماعيلPas encore d'évaluation

- Continuous Process Technology A Tool ForDocument8 pagesContinuous Process Technology A Tool ForAmjadRiazPas encore d'évaluation

- BITS Pilani: Module 2: Flowsheet Synthesis Lecture-6Document63 pagesBITS Pilani: Module 2: Flowsheet Synthesis Lecture-6sukhmaniPas encore d'évaluation

- Process Description DmeDocument3 pagesProcess Description DmeFirdaus YahyaPas encore d'évaluation

- HAZOP Studies On Distillation ColumnDocument3 pagesHAZOP Studies On Distillation ColumnHaneen HamamPas encore d'évaluation

- Design of Packed Tower PDFDocument4 pagesDesign of Packed Tower PDFAnonymous FWlt8Y100% (1)

- Aofw Chg802 Part Ia Intro Aug2018Document273 pagesAofw Chg802 Part Ia Intro Aug2018Yinka OlatunjiPas encore d'évaluation

- Production of Styrene Via Dehydrogenation of EthylbenzeneDocument21 pagesProduction of Styrene Via Dehydrogenation of EthylbenzeneSeanne CruzPas encore d'évaluation

- Hydrogenation of Fatty Acid Methyl Esters To FattyDocument9 pagesHydrogenation of Fatty Acid Methyl Esters To FattyYulius Harmawan Setya PratamaPas encore d'évaluation

- MT 304 - Gas Liquid Absorption: CL 333 Chemical Engineering Lab-III (2021)Document13 pagesMT 304 - Gas Liquid Absorption: CL 333 Chemical Engineering Lab-III (2021)Shivansh SinghPas encore d'évaluation

- Chlorine: International Thermodynamic Tables of the Fluid StateD'EverandChlorine: International Thermodynamic Tables of the Fluid StatePas encore d'évaluation

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentD'EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentPas encore d'évaluation

- Reactive Distillation Design and ControlD'EverandReactive Distillation Design and ControlÉvaluation : 1 sur 5 étoiles1/5 (1)

- Disposal of GasesDocument82 pagesDisposal of GasesChengsi WuPas encore d'évaluation

- AnthraceneDocument142 pagesAnthraceneChengsi WuPas encore d'évaluation

- Assignment EKC 474 Effluent Engineering Answer All Questions 1.0 Physical TreamentDocument1 pageAssignment EKC 474 Effluent Engineering Answer All Questions 1.0 Physical TreamentChengsi WuPas encore d'évaluation

- Reactor Design and Analysis (MHU)Document164 pagesReactor Design and Analysis (MHU)Chengsi WuPas encore d'évaluation

- PCG2014 Annual ReportDocument278 pagesPCG2014 Annual ReportChengsi WuPas encore d'évaluation

- Rubric For Assessing Lab ReportsDocument2 pagesRubric For Assessing Lab ReportsChengsi WuPas encore d'évaluation

- Chapter 1Document6 pagesChapter 1Chengsi WuPas encore d'évaluation

- CHP 24Document4 pagesCHP 24Chengsi WuPas encore d'évaluation

- Valarie KuDocument3 pagesValarie KuDonna BellePas encore d'évaluation

- Nuclear Energy.: 6.1 Radioactive SubstancesDocument7 pagesNuclear Energy.: 6.1 Radioactive SubstancesElly EllynaPas encore d'évaluation

- Defender - 07my - RHD New Type ElectricsDocument83 pagesDefender - 07my - RHD New Type ElectricsAnthony JonesPas encore d'évaluation

- Sach NivomatDocument18 pagesSach NivomatjbouzaPas encore d'évaluation

- Breaker-HB Series 6904104 EnUS Om 10-15Document212 pagesBreaker-HB Series 6904104 EnUS Om 10-15Henry Huayhua100% (1)

- Gen Chem Revision 2013 PDFDocument2 pagesGen Chem Revision 2013 PDFPSCPas encore d'évaluation

- Partes Xavs 400 JD 1310 3129 32 - Xa (TV) S 400 JD7 T4i HopDocument92 pagesPartes Xavs 400 JD 1310 3129 32 - Xa (TV) S 400 JD7 T4i Hopedizon vargas67% (3)

- Manual Atlas Copco Xa90Document29 pagesManual Atlas Copco Xa90bvhdareldalmassoPas encore d'évaluation

- Eni Ghana2017Document20 pagesEni Ghana2017Gyimah SamuelPas encore d'évaluation

- Analyzis by Simulation of In-Cylinder Tumble MotionDocument8 pagesAnalyzis by Simulation of In-Cylinder Tumble MotionLorant BordasPas encore d'évaluation

- Yamaha xvs650 97 Supplementary Service ManualDocument16 pagesYamaha xvs650 97 Supplementary Service ManualWilliam JohnstonPas encore d'évaluation

- Elemax General2014Document8 pagesElemax General2014Nguyễn Đức LợiPas encore d'évaluation

- Valvoline All Fleet Plus E900Document1 pageValvoline All Fleet Plus E900Denis HernandezPas encore d'évaluation

- Natural Building 2011-2Document3 pagesNatural Building 2011-2Peter Paleon PatagonicoPas encore d'évaluation

- More User Manuals On: Ford - CaDocument32 pagesMore User Manuals On: Ford - CaJORFREPas encore d'évaluation

- Workshop Manual Engine ComponentsDocument384 pagesWorkshop Manual Engine Componentsfreeze595988% (34)

- KSB B: Deep Well Turbine Pump BDocument36 pagesKSB B: Deep Well Turbine Pump BKishore Krishna0% (1)

- Smart Car (Green Cars)Document50 pagesSmart Car (Green Cars)Radu_ISPas encore d'évaluation

- NMR Shifts of Common ImpuritiesDocument2 pagesNMR Shifts of Common ImpuritiespolypeptidePas encore d'évaluation

- VWvortex Forums - Diagnostic Trouble Codes Part 1Document94 pagesVWvortex Forums - Diagnostic Trouble Codes Part 1api-3739501100% (1)

- Combined Marine Propulsion PDFDocument10 pagesCombined Marine Propulsion PDFSea Man Mkt100% (1)

- Fuel Test Method(s)Document6 pagesFuel Test Method(s)Sarbast KhoshnawPas encore d'évaluation

- P-sr-005r1 Methanol Injection Skid SpecDocument6 pagesP-sr-005r1 Methanol Injection Skid SpecHedi Ben MohamedPas encore d'évaluation

- 2013 Mom Hse 036 PDFDocument22 pages2013 Mom Hse 036 PDFebsmsartPas encore d'évaluation

- High Cost of Quick Turnarounds and Erroneous Procedures: Petr LenfeldDocument11 pagesHigh Cost of Quick Turnarounds and Erroneous Procedures: Petr Lenfeldkirandevi1981Pas encore d'évaluation

- Uk Product CatalogueDocument94 pagesUk Product CataloguePersefoniaPas encore d'évaluation

- Application Note: Oil & Gas - Midstream: Commercial Operations in MidstreamDocument2 pagesApplication Note: Oil & Gas - Midstream: Commercial Operations in Midstreamjhon berez223344Pas encore d'évaluation

- D4G XLDocument24 pagesD4G XLgychcontratistasPas encore d'évaluation

- Isomer Is at Ion of Light Naphtha - FinalDocument58 pagesIsomer Is at Ion of Light Naphtha - FinalSohaib Ahmed Khan100% (1)

- Gas Miscibility and PVT ProDocument30 pagesGas Miscibility and PVT ProBesmir Buranaj HoxhaPas encore d'évaluation