Académique Documents

Professionnel Documents

Culture Documents

ARIMPIE 2015 (Vol 1)

Transféré par

whiteblood1Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ARIMPIE 2015 (Vol 1)

Transféré par

whiteblood1Droits d'auteur :

Formats disponibles

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Message from the Chairman

I am extremely delighted to note that Department of Mechanical Engineering , I.T.S Engineering

College, Greater Noida is set to organize the First International Conference on Advancements

and Recent Innovations in Mechanical, Production and Industrial Engineering (ARIMPIE-2015)

in association with the Indian Society for Technical Education, New Delhi during April 1011,2015. It is my conviction that this conference will provide quick snapshot of major

developments and innovations in the subject area with special emphasis on technological

breakthrough, competing technologies on the horizon and some key innovations. It will also

expose students to the latest developments in the area of expertise and help them correlate with

the knowledge garnered during class room teaching.

I am sure this conference will provide an opportunity to the academicians, industrialists,

scientists and research scholars to present their view and exchange ideas on the above mentioned

subjects.

Finally, I would like to congratulate all the members of the organizing team for their persistent

efforts and commitments to make this event a grand one.

Dr.R.P.Chaddha

Chairman

I.T.S Education Group

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Message from Organizing Chair

It is privilege and pleasure to welcome the conference speakers, presenters, delegates and

participants to the First International Conference on Advancements and Recent Innovations in

Mechanical. Production and Industrial Engineering ARIMPIE-2015. We would like to express

our personal gratitude to the sponsors and well wishers for their continued support as well as to

our students, faculty and staff who have worked with dedication for ensuring the success of the

Conference.

In the present day business environment technological edge and superiority is the major growth

engine for business. Academic institute provide the fertile ground for innovation and

technological breakthrough. Organizing conferences help in diffusion of knowledge and

exchange of ideas with the peer group.

We are fortunate to have received the support of the I.T.S Management, academic fraternity,

industry associates and sponsors. We thank one and all for the support and hope that we will

derive benefit from the deliberations in the conference.

We wish you all success in accomplishing the goals of the Conference.

Dr.Sanjay Yadav

Organizing Chair ARIMPIE2015

Dr.Vikas Dhawan

Organizing Chair ARIMPIE2015

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Message from Organizing Secretary

We are indeed privileged and delighted to host ARIMPIE-2015, the First International

Conference on Advancements and Recent Innovations in Mechanical, Production and Industrial

Engineering. This conference is aimed to provide a common platform for the interaction of the

academia and industry including personnel from research and development organizations.

The organizing committee, under the valuable guidance of our Director Dr.Vineet Kansal, has

been very active to ensure the successful organization of the conference. Special gratitude and

appreciation is due to the various track chairs as they are primarily responsible for the content

and conduct of the technical program. The Registrar, Dean Academics and faculty of I.T.S

Engineering College deserves special thanks for providing administrative and technical support

to ARIMPIE-2015. We wish to express a debt of gratitude to all the program committee

members and the outside reviewers. Thanks also to all those who submitted papers to the

Conference.

We heartily welcome all delegates, invitees, guests and participants to this conference.

Dr. Sanjay Mishra

Organizing Secretary

Mr. Manvendra Yadav

Organizing Secretary

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Preface

Welcome to the First International Conference on Mechanical, Production and Industrial

Engineering ARIMPIE-2015. In order to improve the quality of living, implication of innovative

solutions and best practices in Mechanical, Industrial and Production Engineering have critical

role. In the near future Mechanical Engineering will be at the forefront in developing new

technologies. The prime goal of the conference is to promote research and developmental

activities in Mechanical, Production and Industrial Engineering. The conference aimed to

provide a common platform for professionals, academicians, researchers and industrialists to

share their knowledge and ideas for achieving focused development and advancements in

emerging field of these areas. It will help the participants to redefine their horizons in recent

innovation in these fields through technical paper presentations and panel discussions leading to

networking of participant organizations for effective collaboration in R & D and recognizing the

areas which require future research. The organizing committee believes that the conference will

assist the participants to connect with the pace of innovation in the Mechanical, Production and

Industrial Engineering.

This Proceeding is a compilation of quality papers accepted for presentation in the conference.

The organizing committee of ARIMPIE-2015 extends their thanks to the authors for accepting to

share their knowledge in these Proceedings. All the experts who peer-reviewed the papers are

most thanked for ensuring that quality material was published. The guidance given by the

members of the International Advisory Committee is greatly acknowledged. The organizations

associated with us are most sincerely thanked for making it possible for the Conference and its

Proceedings to be realized. Our special thanks to the Director of the college Dr. Vineet Kansal,

for providing an environment that was conducive for the smooth accomplishment of the editorial

work.

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

ORGANIZING COMMITTEE

Chief Patron

International Advisory Committee

Dr. R. P. Chadha

(Chairman, I.T.S- The Education Group)

Prof. Raj Kumar Roy, Cranfield University, UK

Patrons

Dr.Rajesh Piplani, Nanyang

University, Singapore

Prof. Mohammed Arif, University of Salford,

UK

Mr. Sohil Chadha

Technological

Prof. Nikhil Ranjan Dhar, Bangladesh

University of Engineering and Technology,

Dhaka

(Vice Chairman, I.T.S- The Education Group)

Mr. Arpit Chadha

Dr. Nandita Hettiarachchi, Ruhuna University,

Srilanka

(Vice Chairman, I.T.S -The Education Group)

Mr. B. K. Arora

Prof. R.K. Khandal, Vice Chancellor, Uttar

Pradesh Technical University, India

(Secretary, I.T.S -The Education Group)

Prof. R.L.Sharma, Vice Chancellor, Himachal

Pradesh Technical University, India

Dr Vineet Kansal

(Director, I.T.S Engineering College, Greater

Prof. R.S. Agarwal, Senior Advisor & Expert,

Ozone Cell, India

Noida)

Dr.Sanjay Yadav, CSIR-National

Laboratory, New Delhi, India

Organizing Chairs

Physical

Prof. A.D. Bhatt, MNNIT Allahabad, India

Dr. Sanjay Yadav

Head, MED

Prof. Abid Haleem, Jamia Millia Islamia, New

Delhi, India

Dr. Vikas Dhawan

Professor, MED

Prof. Anuj Jain, MNNIT Allahabad, India

Prof. Ashitava Ghosal, IISc Banalore, India

Organizing Secretaries

Prof. B. Sahay, IIT Patna,India

Dr.Sanjay Mishra

Associate Professor, MED

Prof. H.K.Raval, SVNIT Surat, India

Prof. Mohd. Islam, Jamia Millia Islamia, New

Delhi, India

Mr. Manvendra Yadav

Assistant Professor, MED

Prof. M.D.Singh, MNNIT Allahabad, India

Joint Secretaries

Prof. Mohd. Muzaffarul Hasan, Jamia Millia

Islamia, New Delhi, India

Dr.B.P.Sharma

Associate Professor, MED

Prof. Puneet Tandon, IITDM Jabalpur, India

Prof. R.A.Khan, Jamia Millia Islamia, New

Delhi, India

Mr. Md. Kamal Asif Khan

Assistant Professor, MED

Prof. R.S. Jadoun, G. B. Pant University of

Agriculture & Technology Pantnagar, India

Prof. Ravi Kumar, IIT Roorkee, India

II

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Prof. S.K. Garg, Delhi Technological University,

India

Prof. Sanjay, NIT Jamsedhpur, India

Prof. Sanjay Sharma, NITIE Mumbai, India

Prof. Sehijpal

Ludhiana, India

Singh

Khangura,GNDDC

Prof. Sudhir Kumar, NIT Kurukshetra, India

Prof. Uday Shanker Dixit, IIT Guwhati, India

Prof. V.K. Jain, IIT Kanpur, India

Prof. Vinod Yadava, MNNIT Allahabad, India

Dr.Inderdeep Singh,IIT Roorkee, India

Dr.Narayan Agarwal,Delhi Institute of Tool

Engineering, New Delhi, India

Dr. P.M. Pathak, IIT Roorkee, India

Dr. Pulok M.Pandey, IIT Delhi, India

Dr. Vijay Pandey, BIT Mesra, Ranchi, India

Dr. Alok Kumar Das, ISM Dhanbad, India

Dr. Atul Thakur, IIT Patna, India

Dr. Akhilesh Barve, IIT Bhubaneswar, India

Dr. Rakesh Sehgal, NIT Hamirpur, India

Dr. Siddhartha, NIT Hamirpur, India

Dr. Varun, NIT Hamirpur, India

Mr. Arvind Sinha, SAS Motors, India

Mr. Deepak Maini, Cadgroup, Australia

Mr. R. K .Malhotra, SMC Pneumatics (India)

Pvt. Ltd, India

Mr. Raj Kumar Soni, Raj Soni & Co., India

Mr. Shraman Goswami, Honeywell Technology,

India

III

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

1. Preface

2. Organizing Committee

I

II

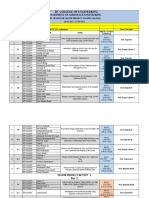

TABLE OF CONTENTS

MECHANICAL

Vol. 1

S. No.

Paper Title and Author(s)

Shape Oscillations of a Particle Coated Bubble During Rise in a Liquid Column

Prithvi R. Y., SabitaSarkar

Tensile Behaviour of 3-Ply Laminate Composite of Sheet Metals

Vijay Gautam, Bijender Prasad

Stress Analysis of Pelton Bucket using Mechanical APDL

Sonendra,NamanAgarwal, T.S.Deshmuk

Ships Steering Autopilot Design by Nomoto Model

Pradeep Mishra, S K Panigrah ,Swarup Das

Material Selection in Bearing Industry Using Multi Criteria based TOPSIS

Methodology

J. S. Karajagikar, R. R. Manekar

Data Acquisition and Monitoring of EMG (Electromyogram) Signals

MrinalJyotiSarma, RichaPandey

Sustainable Application of Compound Parabolic Solar Concentrator

D.K.Patel,P.K. Brahmbhatt

Effect of Radiative Heat Transfer Term in Weak NonLinear Waves in Fluid With

Internal State Variables

Nahid Fatima

Investigation to Compare Heat Augmentation from Plane, Dimpled and Perforated

Dimple Rectangular Fins using ANSYS

Sachin Kumar Gupta, Harishchandra Thakur

Dynamic Response of Selected Fruits using Laser Doppler Vibrometer

JitendraBhaskar, Anand Kumar, Bishakh Bhattacharya

Experimental Study of Comparison of Simple VCRS and VCRS with Phase Change

Material(PCM) as Potassium Chloride (KCL)

TalivHussain, SahilChadha, Gaurav Singh, Jaggi,Sourabh,Gourav Roy

Study of Fatigue Life Calculation of Steel under Various Loading Condition

Anil Kumar , AbhishekPandey

Experimental Investigation of ThermalPerformance of Liquid Flat Plate Collector by

Comparing Single Glass Sheet with the Double Glass Sheet

TalivHussain, Wasiur Rahman, Saddamul Haque, Rocky Singh Labana, Md.Sabbir

Ali

Effect of Phase Change Material (PCM) as Sodium Chloride (Nacl) in VCRS System

as Compare to Simple VCRS System.

TalivHussain, Sourabh, NeerajKatoch, SahilChadha, Rahul Wandra

2

3

4

5

6

7

8

10

11

12

13

14

IV

Page

No.

1

7

13

19

25

32

37

45

50

59

63

67

71

76

ELK Asia Pacific Journals Special Issue

15

16

17

18

19

Proc. Of the Int. Conf: ARIMPIE-2015

Experimental Analysis of A Waste-Heat-Utilization-Strategy using Thermoelectric

Device in C.I. Engine

R. Srivastava, S.K. Dhiman, J.V. Tirkey

Effect of Various Cut-Out on Buckling Analysis of Laminated Composite Plate using

FE Simulation

Rekha Shakya, Tushar Sharma, Rajendra Bahadur

To Evaluate the Performance of VCRS System by Comparing Lesser Superheated

Refrigerant(R-134a) to Higher Superheated Refrigerant (R143a)

Rahul Wandra, TalivHussain, JagannathVerma, Arjun Sharma,Gourav Roy

Kinematic Design Optimization of Planer-Link Mechanism Based Manipulator

Jagdish M Prajapati

In-Plane Free Vibrations of Symmetrically Laminated Rectangular Composite Plates

Kumar Pankaj ,UjjwalBhardwaj,Priyanka Singh

80

85

91

96

101

20

Experimental Investigation of Comparison of Air Cooled and Water Cooled Condenser

Attached with Cooling Tower

Gourav Roy, TalivHussain, Rahul Wandra

117

21

Computational Fluid Flow Analysis of High Speed Cryogenic Turbine using CFX

SushantUpadhyay, ShreyaSrivastava, SiddharthSagar, Surabhi Singh, Hitesh Dimri

Thermal Analysis of Various Perforated Tree Shaped Fin Array using ANSYS

Sachin Kumar Gupta, Rahul Singh, DivyankDubey, Harishchandra Thakur

A Review on the Analytical Analysis and Modeling of Earth Air Tunnel Heat

Exchanger

JagjitKaur, HarminderKaur

Ecoflush - Wastewater Recycling and Rainwater Harvesting Toilet Flush System

Mukesh Roy, AyushGoyal, Vivek Kumar

Experimental Investigation of Enhancing the COP of VCRS System by using Cooling

Tower

Gourav Roy,TalivHussain, Rahul Wandra

Improvement in Thermal Efficiency of a Compression Ignition Engine using A Waste

Heat Recovery Technique

Aashish Sharma, Ajay Chauhan, HimanshuNautiyal,Pushpendra Kumar Sharma,

Varun

Motion Control System of Dc Motor Drive Through PID Control

Pragya Singh, HemantChouhan

Effect of Subcooling in VCRS as Compared to Simple VCRS System

TalivHussain, Arjun Sharma ,Navin, Rahul Wandra, Gaurav Roy

Comparison of Different Failure Theories of Composite Material: A Review

SupriyaKabra, N.D. Mittal

Use of Polymer Matrix Composites for Conventional Steel Drive Shafts: A Study

Yusuf Abdulfatah Abdu

Experimental Investigation of Comparison of VCRS with Phase Change Material as

Sodium Sulphate (Na2SO4) and Simple VCRS System.

Rahul Wandra, Taliv Hussain, Gaurav Singh Jaggi, Sourabh,Gourav Roy

122

Behaviour of Polymer Matrix Composite under Different Environmental Conditions

Pathak, ShubendraNathShukla,VikasChaudhary, Kaushalendra Kr Dubey

Study of Flow Field of River for Hydro Kinetic Turbine Installation

A. Mishra, A.Kumar, M. Singhal,

191

22

23

24

25

26

27

28

29

30

31

32

33

129

137

143

147

152

161

167

174

179

187

195

ELK Asia Pacific Journals Special Issue

34

35

36

Proc. Of the Int. Conf: ARIMPIE-2015

A Review on the Performance of the Nano Fluid Based Solar Collectors - Solar Energy

Kapil Sharma, Satnam Singh, ManvendraYadav, Sanjay Yadav, Naveen Mani Tripathi

Study of Hardness & Microstructure of AISI 1050 Medium Carbon Steel after Heat

Treatment Processes

Sanjeev Kumar Jaiswal, Rajesh M, .T.Sharma, Vineet Kumar

Condition based Predictive Maintenance on board Naval Ships

S Jaison, KarajagikarJayant

PRODUCTION & INDUSTRIAL

Paper Title and Author(s)

37

Soft Computing Technique for Product Design Suggestion in Smart Manufacturing

Industry

Jitesh Kumar Khatri, Jyoti Kumar

Experimental Investigation of Electrical Discharge Face Grinding of Metal Matrix

Composite (Al/Sic)

Ram Singar Yadav, Gyan Singh, Vinod Yadava

Heuristic for Enabling Lean Characteristics in Cellular Manufacturing using

Reconfigurable Machines

Rajeev Kant, L N Pattanaik, Vijay Pandey

Finite Element Analysis of Laser Beam Percussion Drilling of TBC Superalloys

Km Afsana, VinodYadava

Dynamic Modelling and Machining Stability in A New Mill-Spindle Design for Drilling

Machine

JakeerHussain, Srinivas J

An Experimental Investigation of Travelling Wire Electrochemical Spark Machining

(TW-ECSM) of Epoxy Glass Using One-Parameter-At-A-Time (OPAT)

Vevek Kumar, VinodYadava

Experimental Study of Electrical Discharge Machining on Stainless Steel Workpiece

using One Parameter at A Time Approach

Param Singh,VinodYadava, Audhesh Narayan

Dry Sliding Wear Behaviour of Mg/Tip (Mg)-Based Composite Obtained Through P/M

Route

SanketPatro, M.Appoothiadigal, B.K.Raghunath

Effect of Magnetic Field on Electrode Wear Ratio in Electro-Discharge Machining

Govindaraju Anand, Komaraiah, S.Satyanarayana, Manzoor Hussain

A Quantitative Analysis of Modular Manufacturing in Garment Industry by using

Simulation

B.Sudarshan, D. NageswaraRao

Emerging Modelingand Simulation Techniques for Friction Stir Welding- A Review

PrashantPrakash, Shree PrakashLal, Sanjay Kumar Jha

Preparation and Mechanical Properties of Sintered Zrb2-Graphite Composites by Spark

Plasma Sintering (SPS) Method

NiteshKuma, Binay Kumar,Lokesh.C. Pathak

ANN Modelingand Multi Objective Optimization of Electrical Discharge Machining

Process

SanjeevKumarSinghYadav, DeepakAzad

39

40

41

42

43

44

45

46

47

48

49

213

220

Vol. 2

S. No.

38

201

VI

Page

No.

228

233

240

245

252

258

264

270

276

281

288

296

300

ELK Asia Pacific Journals Special Issue

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

Proc. Of the Int. Conf: ARIMPIE-2015

Optimization of Aluminium Die Casting Process using Artificial Neural Network

SanatanRatna, SwetNisha

A Review on Sisal, Jute and Bamboo Based Natural Fibers

Amrinder Singh Pannu, Sehijpal Singh, VikasDhawan

Multiobjective Optimization for Wire EDM of WC-Co Composite using GRA with

Entropy Measurement

Sachin Dev Barman, Ajay Suryavanshi

Optimization Of Electro Discharge Machining of Superalloys and Composites: A

Review

AmritShiwani, Amit Sharma

A Investigation of Machinability of Inconel 718 In EDM using Different Cryogenic

Treated Tools: A Review

Pradeep Joshi, Shiv DayalDhakad

Present &Future of Automation in Automotive Industries.

HemangSolanki, K.V.Parmar

Friction Stir Welding of AluminumAlloys 6xxx

Naveen Gadde, ShikharGoel, PiyushGulati

Development and Characterization of Green Composites: A Review

Jai InderPratap Singh, VikasDhawan, Sehijpal Singh

Study of Mechanical Properties of Rice Husk Composites

V K Joshi, V. Upreti, A., Chaudhary

An Overview of Turning Process

Monika Saini,Ravindra Nath Yadav, Sunil Kumar

Research and Developments in Laser Beam Machining A Review

Bhaskar Chandra Kandpal, Nilesh Ramdas, Rakesh Chaurasia, Abhishek singh,

Vishal Rawat, Saatvik Singh

Effect of Transverse Weld Feed Rate on Microstructure and Tensile Properties of FSW

Weld of AA6061

Ashwani Kumar, R S Jadoun

Modelling and Simulation of Temperature Distribution in Laser Cutting of Ti-Alloy

Sheet

ShivaniPandey, Arun Kumar Pandey

To Study the Effect of Various Parameters on Finishing of Inner Surfaces of Brass

Tubes using Magnetic Abrasive by RSM

Jai InderPratap Singh, VikasDhawan, Sehijpal Singh

Simulation of Hole-Taper And Material Removal Rate Due to Single Pulse Laser Beam

Drilling

Sanjay Mishra, VinodYadava

Analysis of Process Parameters of CNC Lathe Turner by Response Surface

Methodology

RichaSaxena, AbhishekPandey

Modelling of Electro-Discharge Machining of Difficult-to-Machine Materials: An

Overview

Achal Gupta,AdityaAgrawal, Amit Sharma

VII

310

315

321

331

340

349

356

366

374

377

387

393

399

405

416

422

429

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

INDUSTRIAL

S.No.

67

68

69

70

71

72

73

74

75

76

77

Vol. 2

Paper Title and Author(s) Name

Urban flooding and its risk associated with governance and management strategies: a

case study of Anand District, Western India

Pankaj Kumar, Srikantha, Herath, Ram Avtar, Kazuhiko Takeuchi

Ant colony optimization for scheduling of PCBs using single machine

Akshaye Malhotra, Vijay Pandey, S.K. Sahana, Somak Datta

Assessing the Success of Six Sigma: An Empirical Study

S. K. Tiwari, R. K. Singh, S. C. Srivastava

Product Development by Using Modular Design Structure Matrix

Puneet Saini, Ayush Dubey, Vijay Pandey

Design of a simple Vending Machine using Radio Frequency Identification

(RF-id)

Sunil Kumar, Richa Pandey

Imperatives of Green Manufacturing

Abhishek Kumar Singh, Sanjay Kumar Jha, Anand Prakash

Understanding Quality In Home Based Brassware Manufacturing Units in India

Kapil Deo Prasad, Sanjay Kumar Jha, Ritesh Kumar Singh

Application of Lean Manufacturing to Improve the Electronics Industry in Egypt: a

Case Study

Ali Abd El-Aty , Ahmad Farooq , Azza Barakat , Mohamed Etman

Solving Multi-Objective Problem on Supply Chain Performance Measure by multiObjective Evolutionary Algorithm

Susmita Bandyopadhyay, Indraneel Mandal

Multi-objective Goal Programming and its Applications: A review

Jyoti, Himani Mannan

Modeling the Individual/Group Knowledge Sharing Barriers: An Approach of

Similarity Coefficient

B P Sharma, Harsh Gupta

VIII

Page

No.

438

441

448

462

468

472

479

484

490

496

502

ELK Asia Pacific Journals Special Issue

1. SHAPE OSCILLATIONS OF A

PARTICLE

COATED

BUBBLE

DURING RISE IN A LIQUID

COLUMN

Prithvi R.Y

Department of Metallurgical and Materials

Engineering

Indian Institute of Technology Madras

Chennai, India

Sabita Sarkar

Department of Metallurgical and Materials

Engineering

Indian Institute of Technology Madras

Chennai, India

sabita.sarkar@iitm.ac.in

Abstract Particle coated bubble and its

stability plays a major role during particle

recovery in flotation process. A rising bubble

undergoes shape oscillations which are subjected

to change when particles are coated on the

surface of a bubble. Experiments were

performed to understand the effect of particle

coating on a rising bubble in a liquid column.

Hydrophobic Low density polyethylene particles

were used to coat the bubble surface and water

was used as liquid medium. Two images (one

direct and mirror image) were taken for all

position during rise of the bubble. Effect of

different fraction of particle coating on the

bubble surface oscillations was studied. It is

observed that the shape oscillations of bubbles

are arrested as coating fraction increased from

10% to 50% with the latter undergoing almost

no deformation in shape. The bubble in this case

behaves like a rigid body and exhibits pure

rotation as it moves up.

Keywordsshape

oscillations;

particle

coated bubble; single bubble rise ; coating

fraction.

Proc. Of the Int. Conf: ARIMPIE-2015

I.

INTRODUCTION

Bubble flotation in presence of particles is a

phenomena which has wide spread application

like waste water treatment, petrochemical plants,

froth flotation process, paper industry and in

refining operations like secondary steel making

process. Understanding the behaviour of bubble

motion and its characteristics in presence of

particles is a key step in evaluating preliminary

variables like air flow rate, bubble size, particle

size etc. with respect to its application in each

field. A significant amount of research has been

carried out in understanding the behaviour of a

single bare bubble rising in a fluid column [2,6].

The theory behind shape oscillations of a single

rising bubble has been given in detail by several

researchers [1,3 & 5]. However motion of

particle coated bubble in liquid medium is not so

evident in literature. In this work, motion of

particle coated single bubble was studied

experimentally. The effect of particle coating on

the bubble surface oscillation and the overall

bubbly motion was main focus of this study.

Strongly hydrophobic polymeric Low Density

Polyethylene (LDPE) particles were chosen with

interest to alumina inclusions present in molten

steel [4]. The shapes of bubbles were chosen in

the ellipsoidal regime which is commonly used

for removal of alumina inclusion in tundish [7].

EXPERIMENTAL METHODOLOGY

In order to study the shape oscillations of single

bubble during rise with particles coated on the

bubble surface, a bubble column made of plexiglass was fabricated. A schematic representation

of the experimental set-up is shown in Figure 1.

The tank comprised of two compartments

located one below the other. Initially the tank

was filled with distilled water up to a height of

0.55 m in the presence of polymeric LDPE

particles inside the lower compartment. The

particles which have specific gravity of 0.92

were prevented from floating to the upper

compartment by providing a slide door whose

opening was controlled manually. An air bubble

was held at the tip of a nozzle using an infusion

pump and the particle-water mixture was stirred

inside the compartment with the help of an

impeller arrangement powered by a universal

motor. The speed of rotation of the impeller and

II.

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

duration of rotation controlled the coating

fraction of particles on the bubble surface. In

this study the size of LDPE particles chosen

were from 150-210 microns and the bubble sizes

were 6.8 and 4.2 mm. After allowing sufficient

time for the particle-water mixture to reach a

quiescent state the slide door was opened and the

air pump was operated again. The particle laden

bubble was detached from the nozzle and moved

upwards due to buoyancy.

A test section between the heights 0.019 m to

0.028 m in the upper portion of the tank was

illuminated with white coloured diffuse back

lighting. This was the region where the particle

coated bubble behaviour was studied. A mirror

was placed inside the tank at an angle of 45 to

the camera axis. Light was projected on to the

mirror using a screen as a reflector and this

method provided back lighting for front view

where the bubble appeared white with dark

background and the side (reflected) lighting

illuminated the mirror image. In this way both

the front and side views of the bubble could be

obtained using a single camera placed in front of

the experimental setup.

Figure 1. Schematic of the Experimental Set-up

III.

The bubble rise and shape oscillations was

captured using a CMOS camera (Teledyne

Dalsa) having a frame rate of 300 frames per

second and a resolution of 640 480 pixels. The

images recorded were originally in greyscale

format.

The greyscale images were then converted

to binary format in subsequent steps by the

method of intensity thresholding, using Matlab14 software. At these stage properties like major

axes, minor axes, centroid, and bubble boundary

were measured using Matlab 14 - image

processing toolbox. In order to determine the

particle coating fraction on the bubble, the area

of particle coverage was determined by fitting a

closed spline around the periphery of the region

covered with particles using Image J-image

processing software.

RESULTS AND DISCUSSION

A. Behaviour of Particle coated Bubble

Bubbles with different extent of particle

coating and at different times were observed

during the experiments. In case of the bubble

with 10% particle coating at the surface,

oscillations were altered and reduced drastically

from the case of that of bare bubble. The

oscillations were accompanied by rotation of the

bubble as it moved upwards. The region where

the interface was coated with particles showed

no surface oscillation and behaved like solid

surface. The surface oscillations were prevalent

only at the regions where there were no

particles. This altered the overall oscillating

behaviour of the bubble.

When the extent of coating on the bubble surface

increased to almost half of the bubble surface

area, the oscillations were completely arrested.

The polymer particles completely retarded the

surface deformation and the bubble did not

undergo any shape oscillation during rise.

Instead the bubble exhibited only rotation about

its minor axis. The flow past the bubble at the

ELK Asia Pacific Journals Special Issue

boundary experienced no slip at regions where

the surface retardation had occurred. Visual

images of a bubble of 6.8 mm diameter with

different particle coatings and at different times

are compared and shown in Figure 2. The

particle coating on the bubble increases drag

force that it experiences and reduces the rise

velocity.

Experiments were done with a bubble having

diameter of 4.2 mm (Figure 3) and a similar

behaviour was observed. The only difference

was that the amplitude of oscillations undergone

by the 4.2mm bubble was comparatively lesser

than that of the 6.8mm bubble. The rise velocity

in this case is more when compared to that of

6.8mm diameter bubble, as coating fraction is

more and the bubble area is lesser. The force due

to buoyancy for the 4.2mm bubble exceeds the

drag force.

B. Effect

of particle coating on shape

oscillations

The shape oscillations of bubbles are

generally expressed in terms of spherical

harmonics with 2,0 and 2,2 as the dominant

modes [3]. These two modes are the dominant

modes of shape oscillation for an ellipsoidal

bubble. Mode 2,2 shape oscillations of the

bubble are axisymmetric in nature. In this mode,

t=1s

t=1s

Proc. Of the Int. Conf: ARIMPIE-2015

the capillary wave is assumed to travel around

the equator of the bubble and is characterized by

the ratio of major axes obtained from the direct

image (dd) to the major axis of that from the

mirror image (dm), R=dd/dm. The interpretation

of this mode of oscillation is that the bubble is

an ellipsoid rotating about its minor axis as it

travels vertically upwards and as it does a 2-D

projection of the 3-D bubble in either the front

or side plane will constitute major axes of

different lengths. Thus the ratio of major axes R

interprets change in the major axes length due to

rotation about its minor axes.

Figure 4 shows mode 2,2 oscillations for

bare bubble and 10% particle coated bubble. The

6.8 mm bubble shows a distinctive difference in

oscillation between the bare bubble and a

particle coated bubble, whose values of R are

varying from 0.5 to 1.5 for a bare bubble and

limited from 0.8 to 1.2 for the particle coated

bubble. This is an indication that the particle

coating has a decreasing effect on the extent of

elongation of the major axes. However for the

4.2 mm bubble size, particle coating seems to

have resulted in increased length of one of the

major axis (one seen from the direct image) as

the value of R remains always greater than unity.

t=1s

t = 1.012 s

t = 1.012 s

t = 1.012 s

t = 1.024 s

t = 1.024 s

t = 1.024 s

ELK Asia Pacific Journals Special Issue

t = 1.036 s

Proc. Of the Int. Conf: ARIMPIE-2015

t = 1.036 s

t = 1.036 s

Figure 2. Images of a 6.8 mm bubble for a time up to 0.036 s A) bare bubble undergoing shape deformation B)

10% coated bubble undergoing partial deformation C) 50 % coated bubble with no deformation

t=1s

t=1s

t=1s

t = 1.012 s

t = 1.012 s

t = 1.012 s

t = 1.024 s

t = 1.024 s

t = 1.024 s

t = 1.036 s

t = 1.036 s

t = 1.036 s

Figure 3. Images of a 4.2 mm bubble for time up to 0.036 s A) bare bubble undergoing shape deformation B)

10% coated bubble undergoing partial deformation C) 50 % coated bubble with no deformation

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Figure 4. Plot of R vs time for bare bubble and 10 % particle coated bubble. A) 4.2 mm bubble B) 6.8 mm bubble

Deq

Deq

Time (s)

Time (s)

Figure 5. Plot of Deq vs time for bare bubble and 10 % particle coated bubble. A) 4.2 mm bubble B) 6. 8 mm bubble

Mode 2,0 shape oscillation is represented by

equivalent major axis defined as deq = (dd

dm). This is an interpretation of the bubble

fluctuating from oblate spheroid to prolate

shape. In reality it does not transform

completely to prolate shape but as it tends to

oscillate in the 2,0 mode with alternating

elongation and contraction of the major axes.

This mode of oscillation is non-axisymmetric

in nature and the capillary waves are assumed

to be moving around the bubble from one end

of the bubble pole to another. Thus it is

elongation in major axis length gets reduced

since the particles inhibit wave action at the

bubble surface and behave as a rigid body.

For the 4.2mm bubble size the arrest in major

characterized by obtaining an equivalent

diameter of a circle whose surface area is the

same as that of the ellipse in the cross-section

plane containing the two major axes (Deq).

It can be seen from Figure 5 that in the case of

a bare bubble as well as partially coated

bubble the amplitude of 2, 0 mode of

oscillation is greater for the size

corresponding to 6.8mm bubble size since it

naturally has greater major axes lengths. For

this bubble size when particles are coated the

axes shrinkage is seen more predominantly as

there is a drastic decrease in amplitude of Deq

of particle coated bubble. The complete

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

prevention of surface deformation when

almost half of the bubble surface area was

coated can be evidently seen in the images in

Figure 2C and Figure 3C and it is

inappropriate to

use surface harmonics to describe such a body

which does not undergo shape oscillation. As

the bubble surface deformation is completely

arrested the restoring capillary force is

retarded preventing any further shape

oscillation.

Bubbles, Applied Scientific Research,

vol.58, pp.387-408,

1998

IV.

CONCLUSIONS

LDPE particles do not detach from

the bubbles for both sizes of 4.2mm

and 6.8mm due to shape oscillations

during rise in the static liquid column.

When the coating fraction on the

bubbles is as mild as 10 %, the bubble

surface deformation occurs only at

regions, where particles are absent.

Thus overall oscillation in amplitude

is reduced

The reduction in elongation of major

axes is more for a particle coated

smaller ellipsoidal (4.2mm size) than

the larger ellipsoidal bubbles (6.8 mm

size).

Heavily coated bubbles with coating

fraction as high as 50%, shows no

deformation behaviour, instead they

behaves like a rigid body undergoing

pure rotation during rise.

V.

[4] J.P. Rogler, Modeling of inclusion

removal in a tundish

by gas bubbling , M.S. Thesis, Ryerson

University,

2001.

[5] C. Veldhuis, A. Biesheuvel , L. van

Wijngaarden, Shape

oscillations on bubbles rising in clean and

in tap water,

Physics Of Fluids, vol.20, pp. 1-12, 2008.

[6] A.W.G de Vries, A. Biesheuvel, L. van

Wijngaarden,

Notes on the path and wake of a gas

bubble rising in pure

water, International Journal of Multiphase

Flow,

vol.28(11), pp.1823-1835, 2002.

[7] L.Zhang, S.Taniguchi, Fundamentals of

inclusion

removal from liquid steel by bubble

Flotation,

International Materials Reviews, vol.

45(2), pp.59-82,

2000.

REFERENCES

[1] C. Brucker, Structure and Dynamics of

the wake of the

bubbles and its relevance for bubble

interaction,

Physics of fluids, vol. 11(7), pp. 17811796, 1999.

[2] P.C. Duineveld, The rise velocity and

shape of bubbles

in pure water at high Reynolds number,

J.Fluid Mech, vol

292, pp. 325-332, 1995.

[3] K. Lunde, R.J. Perkins, Shape

Oscillations of Rising

ELK Asia Pacific Journals Special Issue

2. TENSILE BEHAVIOUR OF 3-PLY

LAMINATE

COMPOSITE

OF

SHEET METALS

Vijay Gautam1, Assistant Professor,

Department of Mechanical Engineering, Delhi

Technological University, Delhi-110042. Email:

vijay.dce@gmail.com

Bijender Prasad2, Research scholar,

Department of Mechanical Engineering, Delhi

Technological University, Delhi-110042. Email:

bijendra121@gmail.com

Abstract- Recently, clad metallic materials,

consisting of two or more layers, have been

preferred in various industrial applications

because of their unique corrosion resistance,

specific strength, and surface properties. The

present study has been carried out on three ply

composite laminate, containing AISI304L

austenitic stainless steel on one side and

AISI430 on the other side with AA1050 in the

core of the blank. Apart from excellent corrosion

and mechanical properties of stainless steel three

ply composite laminate possesses exceptional

thermal and electrical conductivities, which

makes it useful for utensils formed by deep

drawing process. Circular blanks of composite

laminate, produced by cold roll bonding, with a

combined thickness of 2.5mm, were procured in

the annealed condition from a leading

manufacturer. To ensure the bond strength of 3ply AISI304/AA1050/AISI430 sheets, peel tests

on various specimens were performed according

to ASTM-D1876-08 standard. Tensile samples

as per ASTM E8M standard, were laser cut in

three different directions i.e. parallel, inclined at

45 and transverse with respect to rolling

direction. Tensile specimens were tested to study

the deformational behaviour in uniaxial tension,

on a 50kN UTM.

Keywords- Clad metals; Three ply laminate

composite; cold roll bonding; peel test; tensile

behavior.

I.

INTRODUCTION

With the advancement in technology in

forming with sheet metals, new clad materials

Proc. Of the Int. Conf: ARIMPIE-2015

have been evolved and designed for various

industrial applications such as automobile,

aerospace and electrical industries. These

laminated sheets consist of different kind of

sheet metals with different mechanical, physical

properties and specifications to suit the various

applications. Various parameters such as

material type, thickness ratio, arrangement and

multiplicity of the metals, surface preparation,

bonding parameters and post heat treatment

results in unique deformational behavior [1-5].

Although, Clad sheets have been produced by

several solid state bonding methods such as

diffusion, explosive and roll bonding but cold

roll bonding (CRB) is the most efficient and cost

effective [6,7]. Many researchers have

contributed significantly on the various issues

related to formability of roll bonded clad sheets.

In the recent development of the clad sheets,

most widely used material combinations are Al

with Cu, Al-Fe, Al with stainless steel, Zn- Al

with stainless steel, Al-Cu with steel, Ti with

steel etc. [8,9]. Akramifard et al 2014 carried out

experimental studies on effect of reduction and

subsequent

annealing

temperatures

on

mechanical properties and bond strength of three

layered AA1050-304L-AA1050 clad sheets,

during roll bonding. An important contribution

of their work was the correlation of tensile and

peel test on the basis of principles of mechanics

of materials. The mechanical properties of some

laminated composite sheets, mainly of stainless

steel/aluminium sandwich sheets, have been the

subject of examination for many years. Choi et

al. 1997 experimentally investigated the

deformation behaviour of Al-STS430 bi-layer

clad sheets under uniaxial tension and concluded

that a difference in planar and normal anisotropy

results in the warping of edges of tensile

specimens. The material property of the

laminated sheet changes in the thickness

direction, their deformation behavior should be

affected by the blank placement position during

forming by deep drawing, i.e. which side of the

sheet would contact punch or die. Because of

such interesting formability issues, the behavior

of laminated sheets is the subject of much

research. However, only a few studies have

discussed the combination of 3-ply clad sheets

of AISI304/AA1050/AISI430. In view of the

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

above the present study deals with the tensile

behaviour of 3-ply laminate composite.

II.

A.

METHODOLOGY

Selection of material

Selection of material is based on the

increasing popularity of multi ply clad sheets in

deep drawn utensils, owing to the advantages of

excellent formability, good surface finish of

class of 2B, uniform heating and better heat

transfer. Circular blanks of 3-ply clad sheet of

AISI304/AA1050/AISI430 material of effective

thickness of 0.4, 1.5 and 0.6mm respectively,

that are joined by roll bonding and thermal

treatment, due to a metallurgical bond under

high pressure, was procured from a leading

supplier in India. The chemical composition of

individual

sheets

were

obtained

by

spectrometry- analysis and are given in Table 1.

B.

The peeling test

To investigate the bond strength due to CRB,

the peeling test was performed according to

ASTM-D1876-08

standard

(subsized).

Specimens for the peel test were laser cut in the

sub-size of 160X 25 mm due to limited

availability of the material. Since it is difficult to

detach the bonded sheets mechanically, one end

of the each specimen was immersed in the

solution of sodium hydroxide to dissolve

aluminium. The remaining length with intact

bond was used for the peel test as shown in the

Fig. 1. The specimens were prepared in such a

way that each bonded sheet of steel i.e. AISI304

and 430 be peeled from aluminium bond

respectively. The stainless steel sheet to be

peeled was held in the lower fixed jaw and the

rest with the upper movable jaw fixed with the

cross -head on the 50kN UTM. All the tests were

conducted at a cross head speed of 10mm/min.

Fig. 1. Peel test arrangement on 50kN UTM

C. The tensile test

Most common approach to characterize the

behaviour of a material is by conducting uniaxial

tensile tests. In this work, simple tension tests

were carried out on a universal testing machine

of maximum capacity 50 kN as shown in Fig. 2.

The tensile test specimens as per standard

ASTM-E8M, were prepared by laser cutting of

the blank as shown in Fig. 4. The anisotropy of

the 3-ply clad sheet metal was investigated by

performing tensile tests at specimen orientation

of 0, 45 and 90 to the rolling direction (RD)

and are shown in Fig. 5. The tests were carried

out include monotonic loadings in tension. Each

test is performed at least three times to ensure

good reproducibility of the experiments. The

tests were carried out at a cross head speed of

2.5mm/min. Typical engineering stress strain

curve is plotted on the basis of force and

displacement data acquired from the dedicated

software.

D.

Determination of tensile properties

The strain hardening exponent (n) and the

strength co efficient (K) values are calculated

from the stress strain data in uniform elongation

region of the stress strain curve.

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Fig. 3. Tensile tested specimens

Fig. 2. 50kN Universal testing machine

TABLE I CHEMICAL COMPOSITIONS OF SHEET MATERIALS USED IN THE LAMINATE

Steel Sheet

material

Si

Al

Ni

Cr

AISI304

0.05

1.450

0.820

0.044

9.620

18.03

0.009

0.023

AISI430

0.12

0.902

0.675

0.038

0.621

17.02

0.023

0.026

AA1050

0.18

0.018

0.156

Rest

0.032

0.012

0.015

0.034

The plot of ln(true stress) versus ln(true strain)

which is a straight line is plotted as discussed below :

The power law of strain hardening is given as :

= K n

(1)

where and are the true stress and the true

strain respectively.

Taking log on both sides

Log ( ) = log (K) + n log ()

(2)

Fig. 5. Tensile specimens at different orientations w.r.t. RD

This is an equation of straight line and the

slope of which gives the value of 'n' and 'K' can

be calculated taking the inverse natural log of

the y intercept of the line as shown in Fig. 8.

III.

Fig. 4. Laser cutting of tensile specimens

RESULTS AND DISCUSSION

To determine the bond strength of AA1050

with AISI304 and 430 respectively, the peel test

ELK Asia Pacific Journals Special Issue

specimens were prepared and tested on 50kN

UTM of Tenius Olsen make. The peeling force

and distance data were recorded using a

dedicated software Horizon and the plot between

them is shown in Fig. 6.

The average peel strength was determined as

the ratio of peeling force to the peeling width.

The range of the peeling strength of AISI 304

from AA 1050 was between 30 to 51N/mm,

whereas peeling strength of AISI430 from

AA1050 was found to be between 20 to

26N/mm. The experimental investigation

showed that the peeling strength of AISI304 is

higher than AISI430 by a factor of 1.5

approximately. In both the peeling tests, the

peeling strength remained stable for an

appreciable length of 80mm with a slight dip in

between at 40mm of peeling distance.

Fig. 6. Curve between Peeling force and

Peeling distance

Proc. Of the Int. Conf: ARIMPIE-2015

The peeling strength of aluminium from AISI

304 was 40N/mm on an average basis, whereas

the peeling strength of AISI430 was 25N/mm.

Peeling strength became maximum as the

peeling distance reaches near the end of the

specimens. Same trend was observed in all the

tests conducted.

To investigate the deformational behaviour,

tensile tests were performed on the specimens

cut at three different orientations i.e. parallel to,

inclined at 45 and perpendicular to the RD. The

various tensile properties are given in Table 2. In

all the tensile tested specimens, nucleation of

crack was observed to initiate from 0.6mm thick

AISI430 which may be contributed to the lower

ductility of this steel grade. Some waviness or

warping were seen at the edges of the tested

specimens due to the difference in anisotropy of

individual sheets. A typical true stress-strain

curve is shown in Fig. 7. Tensile specimens

oriented at 45 to the RD showed maximum

ductility on an average of 57% whereas least

ductility was found with the specimens oriented

at 0 to the RD. Highest tensile strength of order

of 260MPa was observed in the specimens

oriented at 90 to the RD and least strength was

seen in specimens oriented at 0 to the RD. The

strain hardening exponent (n) as shown in Fig.

8, which is an indicator of workability at room

temperature was found to be of order of 0.25 on

an average basis. High ductility coupled with

excellent strain hardening exponent and strength

is required in deep drawing of the utensils.

TABLE II

TENSILE PROPERTIES OF COMPOSITE LAMINATE AT DIFFERENT

ORIENTATIONS wrt RD

Orientation

Yield

w.r.t.

Rolling

(MPa)

Direction (RD)

Stress

Ultimate

Tensile

strength

(MPa)

Percentage

elongation

(%)

Strain

Hardening

Coefficient

(n)

Strength

Coefficient,

(K)

(MPa)

171

242

44.7

0.234

420

45

177

254

56.0

0.256

456

90

178

262

47.2

0.255

470

10

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Fig. 7. True stress vs True strain plot for composite laminate oriented at different directions

Fig. 8. ln(True stress) vs ln(True strain) plot for composite laminate

IV.

CONCLUSIONS

On the basis of the experimental

investigations conducted to study the

deformational behaviour in uniaxial tension test

of

3-ply

laminate

composite

of

AISI304/AA1050/AISI430,

following

conclusions can be drawn:

1. The peeling strength of the bond of AISI

304 with AA1050 is of order of 40N/mm

which is approximately 1.5 times higher

than that of AISI 430 with AA1050.

2. The peeling strength increases towards the

end of the peeling distance.

3. Tensile specimens oriented at 45 to the

RD showed maximum ductility on an

average of 57% whereas least ductility

was found with the specimens oriented at

0 to the RD.

4. In all the tensile tested specimens,

nucleation of crack was observed to

initiate from 0.6mm thick AISI430 which

may be contributed due to the lower

ductility of this steel.

References

[1]

J.Y. Jin and S.I. Hong , Effect of heat

treatment on tensile deformation

characteristics and properties of

11

ELK Asia Pacific Journals Special Issue

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Proc. Of the Int. Conf: ARIMPIE-2015

Al3003/STS439

clad

composite.

Mater.Sci.Eng., A 2014; 596:18.

L. Chen , Z. Yang , B. Jha , G. Xia and

J.W. Stevenson

Clad metals, roll

bonding and their applications for SOFC

interconnects, J Power Sources

2005;152:405.

E.Y. Kim ,J.H. Cho ,H.W. Kim and S.H.

Choi . Evolution of deformation texture

in Al/Al Mg/Al composite sheets

during

cold-roll

cladding,

Mater.Sci.Eng, A 2011;530:24452.

I.K. Kim and S.I. Hong . Effect of

component layer thickness on the

bending behaviors of roll-bonded trilayered Mg/Al/STS clad composites.

Mater.Des. 2013;49:93544.

H.G.Kang , J.K. Kim, M.Y. Huh and O.

Engler . A combined texture and FEM

study of strain states during rollcladding

of

five-ply

stainless

steel/aluminum

composites.

Mater.Sci.Eng, A 2007;452453:347

58.

I.K.

Kim

and

S.I.Hong.

Mater.Des.49(2013)935944.

H.R.Akramifard , H. Mirzadeh and

M.H.

Parsa,Estimating

interface

bonding strength in clad sheets based on

tensile test results , 2014, Mater.Des.

H.R.Akramifard , H.Mirzadeh and

M.H.Parsa Cladding of aluminum on

AISI 304L stainless steel by cold roll

bonding: Mechanism, microstructure,

and

mechanical

properties

Mater.Sci.Eng. A613 (2014)232239.

S.H. Choi ,K.H. Kim, K.H. Oh and D.N.

Lee .Tensile deformation behavior of

stainless steel clad aluminium bilayer

sheet, Mater.Sci.Eng. A222 (1997)

158-165.

12

ELK Asia Pacific Journals Special Issue

3. STRESS ANALYSIS OF PELTON

BUCKET USING MECHANICAL

APDL

Sonendra*1,N. Agarwal*2,

T.S.Deshmuk#3

*

Mechanical Department, ITS

Engineering College, Gr. Noida,Uttar Pradesh

(India)

#

Civil Department. MANIT Bhopal,

Madhya Pradesh (India)

1

sonendra.me@its.edu.in

namanaryan.agarwal@gmail.com

3

manit_tsd@yahoo.com

Abstract----In the present work an attempt has

been made to analyse the stress developed on the

surface of Pelton bucket using Mechanical

APDL. The geometric modeling of this bucket

has been done using CATIA software for a 50 m

head and stress analysis has been done in

Mechanical APDL. The stress analysis has been

done considering bucket as a cantilever element

fixed to the disc at one end with the force of jet

applied at the splitter. The stress analysis has

been done for flow rates ranging from 100 lit/sec

to 150 lit/sec and speed ranging from 700 rpm to

900 rpm. It is observed that 1st principle stress is

higher than 2nd principle stress and 3rd principle

stress. Von Mises stress as well as all three

principle stresses decreases as rotational speed

of pelton wheel increases.

Proc. Of the Int. Conf: ARIMPIE-2015

motion.Pelton turbine is tangential flow impulse

turbine.APelton turbine consists of a series of

buckets mounted around the periphery of a

circular disc.

II.GEOMETRIC MODELLING

The geometric modelling of the given pelton

bucket has been done using CATIA software. In

the present work, the runner of a Pelton turbine

model for 50 m head has been used for stress

analysis. The modelling of the runner blade

surface was done with the help of profile

coordinates at various sections.

The coordinates were available for 6 sections(AA, B-B, C-C, D-D, E-E, F-F) along the length of

the blade and 5 sections (U-U, W-W, S-S, K-K,

R-R) along the width of the blade. In addition to

this, the coordinates of the plan view as well as

lip surface were also available. Initially the

curves for all the 11 sections were plotted (in

different planes) with the distances between the

adjacent sections being determined on the basis

of plan view. Distance between splitter and E-E

curve, E-E curve and A-A curve, A-A curve and

F-F curve, F-F curve and B-B curve is 4.15 mm.

Distance between splitter and C-C curve is

28.07mm.

I.INTRODUCTION

The Pelton turbine is a hydraulic prime

mover which generates power by first converting

the pressure energy of water into kinetic energy

with the help of jet nozzle assembly and then

mechanical power is developed from this kinetic

energy with the use of runner. Runner of Pelton

turbine is made of buckets which are mounted

on the periphery of a disc.The bucket of Pelton

turbine has very complex geometry. The kinetic

energy of a jet of water is converted into angular

rotation of the bucket as the jet strikes. The highvelocity jet of water emerging from a nozzle

impinges on the bucket and sets the wheel into

Fig.1 Profile of Pelton Bucket

13

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Distance between splitter and DD curve is 37.49

mm.Section U-U passes through origin. Distance

between U-U curve and W-W curve is

20.87mm. Distance between UU curve and SS

curve is 23 mm. Distance between W-W and KK curve 11.45 mm. Distance between R-R and

S-S curve is 11.45 mm. The width of the bucket

is 104.5 mm. Using the given co-ordinates,

curves were created using point and spline

commands. The final assembly of all the bucket

curves for 11 sections is shown below

III.NUMERICAL SIMULATION

numerical simulation of this problem is done

using Mechanical APDL. This software is based

on the principle of Finite Element Analysis. The

basic steps involved in numerical analysis are as

follows:

Fig.2 Sections of bucket profile

B. Processing or Solution phase- In this phase,

all the details for solution are specified. The

analysis type used for stress calculations is static

structure analysis.Load and constraints are

considered as boundary conditions.

After this using inner curve of all sections (A-A,

B-B, C-C, D-D, E-E, F-F, U-U,W-W, S-S, K-K,

R-R ),a surface is generated. This surface forms

the inner surface of bucket. Similarily using the

outer curve of all sections the outer surface of

bucket is created. Both surfaces are converted

into a solid bath tub type shape. After this the lip

area is created. In this way we obtained the

profile of half-bucket. Mirror command is used

to obtain remaining half profile of bucket. The

complete solid model of the bucket is shown

below

A. Pre- Processing- In the pre-processor the

material definition and meshing of the imported

solid model was done. The element used in this

study is SOLID187. After selecting the element

type the material properties(Modulus of

Elasticity, Poissons Ratio, Tensile Strength,

Ultimate)are defined. Meshing is very important

part of pre-processing in any FEA software.

Mechanical APDL offers two options - area,

volume. Area is for 2D geometry and volume is

for 3D geometry. In the present work volume

was chosen. Free volume meshing is used for

this analysis. Meshing done by this method is

based on default setting.The obtained meshing

of peltonbucket,had 38982 number of nodes.

gr

Fig.4 Velocity diagram of Pelton Bucket

In this present work, a force according to

each operating condition (discharge and speed)

is applied on the splitter and the constraint is in

the form of fixed face of support of the bucket

Fig.3. Solid Model of Pelton

Bucket

14

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

The results of the simulation have been

presented in the form of contour plots obtained

through the APDL software for the three

principle as well as Von Mises stress.

Fig.5 Boundary Conditions

A Total number of 9 operating conditions

have been considered for the analysis.

TABLE.I

Forces on Pelton Bucket

rates

Speed

700

820

rpm

rpm

discharge

100 lit/sec 2947

2491

N

N

123 lit/sec 3624

3064

N

N

150 lit/sec 4420

3736

N

N

Fig.6 Ist Principal Stress distribution for

discharge Q = 123 lit/secand speed N= 820 rpm

at different flow

900 rpm

2185 N

2687 N

3277 N

Force on bucket is given by- F = Q ( Vu1-Vu2)

C.Post- Processing- results have been plotted in

the form of contour plots of following:

1st Principal Stress

2nd Principal Stress

3rd Principal Stress

Von Mises Equivalent Stress.

Fig.7 IInd Principal Stress distribution for

discharge Q = 123 lit/sec and speed N= 820 rpm

IV.RESULT

15

ELK Asia Pacific Journals Special Issue

Proc. Of the Int. Conf: ARIMPIE-2015

Fig.8 3rd Principal Stress distribution for

discharge Q = 123 lit/sec and speed N= 820 rpm

A study of contour plots for principle stress with

respect to blade surface (Fig 5.1) shows that the

value of 1stprinciple stress is more or less

constant throughout the blade surface except for

a triangular region near the joint of the blade

surface and the support. Thereafter from the

joint to the fixed edge of the support the stress

increases steadily reaching a maximum value at

the edge. This is probably because the jet of

fluid returns back after reaching the end of blade

surface hence creating large stresses at the joint

of the jet and support.

2nd Principle stress (Fig 5.2) is constant

throughout the blade surface as well as the

support except at the fixed edge of the support

where it shows higher stress. As the jet

bifurcates at the splitter in two opposite direction

hence the axial thrust gets nullified.

3rd Principle stress also shows (Fig 5.3) uniform

stress all along the blade surface as well as the

support except at the location where the jet

strikes and at the fixed edge of the support.

Fig 9 Von MisesStress distribution

for

discharge Q = 123 lit/sec and speed N= 700 rpm

. A study of contour plots of Von Mises stress

show that in general the Von mises stresses are

very low in the region between the lip section

and the point of application of jet. The stress

increases in a narrow zone from the point of

application of jet. This zone of high stress

widens gradually as we move towards the fixed

end of blade and simultaneously the magnitude

of stress also increases towards the fixed end.

This zone of high stress inside the bucket is

observed to follow the same pattern as that of

the jet flow. Initially it is a narrow band which

spreads out near the junction where the jet

returns from the blade surface. Within this wide

zone also the maximum stress is present in the

centre which happens to be the location of the

connection of the support. This increase in the

stress is probably due to the turning of the jet

which creates load on the blade surface.

When we consider the stress in the support then

it is seen that the stress increases continuously

from the connection with blade to the fixed end.

This is obvious due to the cantilever action.

Similarly if we consider the stress variation

across the depth of the support then maximum

stress are observed at the both bottom and top

surfaces with minimum stress at the center

region. This is also due to cantilever action.

It is observed that for a given discharge as the

rotational speed is increase there is

16

ELK Asia Pacific Journals Special Issue

corresponding decrease in the magnitudes of all

three principle stresses. The reduction of all

three principle stresses and Von-mises stress

with speed is shown in table below

Table II. Variation of Stress with speed

Speed

900

rpm

820

rpm

700

rpm

Discharge

Stress

(N/m2)

Von

mises

Stress

1st

Principle

Stress

2nd

Principle

Stress

3rd

Principle

Stress

Von

mises

Stress

1st

Principle

Stress

2nd

Principle

Stress

3rd

Principle

Stress

Von

mises

Stress

1st

Principle

Stress

2nd

Principle

Stress

3rd

Principle

Stress

Proc. Of the Int. Conf: ARIMPIE-2015

The reason behind this is already discussed

while explaining the contour plots. It is observed

that at higher speed (900 rpm), maximum stress

is nearly same for all discharges. The value of

this stress is- about 13000 N/m2 for 1st principle

stress, 6000 N/m2 for 2nd principle stress and

4500 N/m2 for 3rd principle stress. At lower

speed (700rpm), there is very less variation in

stress for 100 lit/sec and 123 lit/sec. This

variation is about 14000N/m2 to 16000 N/m2for

1st principle stress, 8500N/m2 to 10000N/m2 for

2nd principle stress and 6500N/m2 to 7500

N/m2for 3rd principle stress. The stress increases

abruptly for 150 lit/sec. However in all cases the

maximum principle stress is well below the yield

limit of the material (650 MPa).

100

lit/sec

8685

123

lit/sec

9628

150

lit/sec

11339

11022

12445

14408

5137

5798

6713

3928

4415

5118

10578

13522

17091

13501

17323

21857

6289

8072

10187

4784

6162

7793

Fig 10. Variation of von mises stress with speed

it is also observed that for a given discharge as

the rotational speed is increased, there is a

corresponding decrease in the magnitude of the

stress.

14259

16746

22823

18361

21359

29137

8556

9955

13580

6527

7617

10386

The principle stress vs speed graphs (fig 5.14 to

5.16) show that 1stprinciple stress is higher than

2nd and 3rd principle stresses.

V.CONCLUSION

The reason for this decrease in stress with

increase in rotational speed is probably due to

the fact that as the speed increases the contact

time of the jet on the blade decreases thus

reducing the stress.

REFERENCES

[1] Argyris J.H. (1954). Recent Advances in

Matrix Methods of

Structural Analysis, Pergamon Press,

Elmsgford, NY.

17

ELK Asia Pacific Journals Special Issue

[2] Binaya K.C., BholaThapa, 2009, Pressure

Distribution at Inner

Surface of Selected Pelton Bucket For

Micro Hydro,

Proc. Of the Int. Conf: ARIMPIE-2015

[9] R. Angehrn, Safety Engineering for the 423

MW-PeltonRunners at Bieudron, August 6 9, 2000

VATech ESCHER

WYSS, Zurich, Switzerland

[3] Clough R.W., September 8-9 1960, The

Finite Element

Method in Plane stresses Analysis

,Proceeding of 2nd ASCE

Conference on Electronic computation,

Pittsburg, P.A,.

[4] Hirt C.W., 1981, Nichols B.D, Volume of

fluid method for

dynamics of free boundaries, journal of

computational physics

[5]

I.U. Atthanayake, Department of

Mechanical Engineering,

October 2010, The Open University of Sri

Lanka Nawala, Sri

Lanka.Analytical Study On Flow Through

a Pelton Turbine

Bucket Using Boundary Layer Theory,

International Journal

of Engineering & Technology IJET-IJENS

Vol:09 No:09

[6]

Mr. Patel Dhaval, Mr.GajeraChintan,

Mr.ValaKuldip,

2010,Stress & Experimental Analysis Of

Simple And

Advanced Pelton Wheel.

[7] Nakanishi Y., Kubota and Shin T.,2002,

Numerical simulation

of flows on pelton bucket by partial method:

flow on a

stationary rotating flat plate, proceeding of

21th IAHR

symposium, Lausanne, Sept. 9-12

[8] Roache, P.J. (1972). Computational Fluid

Mechanics, Hermosa

Publishers Albquerque, NM

18

ELK Asia Pacific Journals Special Issue

4. SHIPS STEERING AUTOPILOT

DESIGN BY NOMOTO MODEL

Pradeep Mishra

M.Tech student

Mechanical Engg Dept

DIAT (DU),Pune

Dr. S K Panigrahi

Professor and HOD

Mechanical Engg Dept

DIAT (DU),Pune

Lt Cdr Swarup Das

Faculty & Project Guide

MILIT

ABSTRACT

Ships manoeuvring can be automated by using

the autopilot system. The marine autopilot

system design is based on the mathematical

model of steering dynamics. Here in the present

paper a study on Nomoto model has been

undertaken for its selection for the ships steering

dynamics. Choice of selection of the model with

respect to fundamental properties of first and

second order models has been considered.

Effectiveness of the models has been assessed

on the basis of main properties of Nomoto model

i.e. controllability, observability, identifiability.

Further, reasonability of selecting state space

model and the transfer function model for the

study of different properties has been explained.

It is proven that the first order model is

controllable and observable whereas the second

order model is conditionally controllable. Zero

appearing in the transfer function model is found

responsible for the overshot behaviour which

indicates that the selection of second order

model is suitable if the overshoot behaviour has

to be studied. First and second order model are

identifiable with the ill conditioning problem

associated with the latter. hence the first order

model is suitable for autopilot applications.

Model reductions from fourth order to second

and then first order model has been undertaken

describing sway-yaw-roll dynamics and bode

plots for these models are drawn to show the

changes in frequency response due to model

simplification.

Proc. Of the Int. Conf: ARIMPIE-2015

1. INTRODUCTON

This paper is concerned with fundamental

properties like controllability, observability,

identifiability of Nomoto first and second order

model. State space model for Nomoto first and

second order model has been derived and solved

to find controllability, obeservability because

state space model represent non controllable as

well as non observable modes along with the

observable and controllable modes whereas the

transfer function model represents only

controllable and observable modes, non

controllable and non observable modes are

cancelled in transfer function model.

Subsequently the system overshoot with respect

to Nomoto second order model is explained.

Overshoot is caused due to sway coupling effect

on yaw rate which is represented by zero and a

high frequency pole in Nomoto second order

model i.e.(1+T3S) and (1+T2S).However the ill

conditioning problem due to near cancellation of

zero and poles T3T2 makes second order

model less preferable for autopilot design.

In this paper an alternative approach is

suggested for adaptive autopilot system which

comprises of keeping the zero of second order

model which is important for the study of

overshoot phenomenon at the same time keeping

T3 fixed and varying K, T1,T2 to avoid the ill

conditioning problem .further with the help of

Bode plots for forth ,second, first order model it

is proven that why simplification of fourth order

model to second order model is not significant

because the plots are almost similar except

humps in the fourth order plot. That means

coupling effect of roll mode on yaw motion is

negligible but effect of sway couple on yaw

motion which is represented by second order

bode plot cannot be neglected. Step input

response to Nomoto models is also studied.

2. SHIP STEERING DYNAMICS MODEL

SIMPLIFICATION

Ship response in waves is considered as 6 degree

of freedom motion in space. For manoeuvring

study 3 dof motion namely surge ,sway, yaw is

considered but for heavy vessels effect of roll

19

ELK Asia Pacific Journals Special Issue

cannot be neglected hence our study will revolve

around 4 dof motion description namely surge,

sway, yaw and roll.

Here fourth order transfer function relating yaw

rate to rudder angle is derived. Further

simplification to second order and first order

model is also described

Proc. Of the Int. Conf: ARIMPIE-2015

a1V = a2+ a3r + a4

(4)

b1= b2V + b3r + b4

(5)

c1r = c2V + c3+ c4

(6)

where

a1 = (m YV)S YV

a2 = YPS + YPS + Y

(7)

a3 = YS + Yr + mu0

a4 = Y

Figure 1

coordinate system.

Sway-yaw-roll

(8)

(9)

(10)

b 1 = (IX KP)S KPS + mgGM

(11)

b 2 = KVS + KV

(12)

b 3 = KS + Kr

(13)

b4 = K

(14)

c1 = (IZ N)S Nr

(15)

c2 = NVS + NV

(16)

c3 = NPS + NPS + N

(17)

c4 = N

(18)

motion

m( + u0r) = Y+ YVV + Y+ Y + Y PP + Yrr +

Y + Y

(1)

IX = KPP + K mgGM+ KVV+ K + Krr + K

+ K(2)

IZ = Nrr + N + N + NPP+ N + NVV + N

+ N

(3)

where YV, Y , , indicate the hydrodynamic

coefficients; for instance, YV indicates the

derivative of the sway force Y to the sway speed

V evaluated at the reference condition; m is the

mass of the ship; IX is the moment of inertia

about the x-axis; IZ is the moment of inertia

about the z-axis; V is the sway speed; u is the

surge speed; r is the yaw rate; is the heading

angle defined by = r ; p is the roll rate; is the

roll angle defined by = p and GM is the

metacentric height, which indicates the restoring

capability of a ship in rolling motion.

Taking the Laplace transform of Eqs. (1)-(3) and

rearranging, we have

After eliminating the sway speed V and roll

angle from Eqs. (4)-(6), the following transfer

function relating the yaw rate r to the rudder

angle can be obtained:

r = a1(b1C4 + b4C3) + a2(b4C2 b2C4) + a4(b1C2 + b2C3)

a1(b1C1 b3C3) a2(b2C1 + b3C2) a3(b1C2 + b2C3)

(19)

It can be easily verified that the numerator of

Eq.19 is third order in S, while the denominator

is fourth order in S. Hence, Eq. (19) can be

expressed in the following form

r = K(1 + T3S)(S + 2S +

(1 + T1S)(1 + T2S)(S + 2nS +n

(20)

where the quadratic factors are due to the

coupling effect from the roll mode on the yaw

20

ELK Asia Pacific Journals Special Issue

rate. The zero (1+ T3S) and the pole (1 + T2S)

are due to the coupling effect from the sway

mode on the yaw dynamics. If the roll mode is

neglected, Eq. (20) can be further reduced to the

following form

r = K(1 + T3S)

(1 + T1S)(1 + T2S)

(21)

Eq. (6) is known as the second order Nomoto

model, where K is the static yaw rate gain, and

T1, T2 and T3 are time constants. In practice,

because the pole term (1 + T2S) and the zero

term (1 + T3S) in Eq. (21) nearly cancel each

other, a further simplification of Eq. (21) can be

done to give the first order Nomoto model

r = ___K____

(1 + TS)

(22)

Where

T = T1 + T2 - T3