Académique Documents

Professionnel Documents

Culture Documents

SAIC-X-3102 Rev 3

Transféré par

mahdi_gCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SAIC-X-3102 Rev 3

Transféré par

mahdi_gDroits d'auteur :

Formats disponibles

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Galvanic CP Test Stations / Junction Boxes - Material

Receiving

PROJECT TITLE

SAIC-X-3102

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

30-Jun-08

DATE APPROVED

QR NUMBER

CPCONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

A.

ACCEPTANCE CRITERIA

REFERENCE

Document Review

A1

Review documents of Material Receiving for the Galvanic CP Test

Stations / Junction Boxes.

Schedule Q

Att. IV

Sec. 3.1

A2

Identification procedure reviewed and implemented for the Galvanic CP

Test Stations / Junction Boxes.

Schedule Q

Att. IV

Sec. 4.2

A3

Material identification shall be implemented for all materials, parts and

components, including partially fabricated assemblies. Galvanic CP Test

Stations / Junction Boxes shall be identified by using tags, stamps, color

coding, stencils or labels. The location and method of identification shall

not affect the function or quality of the material.

Schedule Q

Att. lV

Sec. 4.2

A4

The Supervisor of CSD/ME&CCD/Cathodic Protection and Coatings Unit

and the Supervisor of the proponent cathodic protection organization

shall indicate their review and approval of each Cathodic Protection

drawing by signature. The signatures shall be placed in the "Review of

Key Drawings" block of each Index X Drawing.

SAES-X-400

Sec. 5.1.2

B.

General Requirements

B1

Documentation for traceability reviewed and implemented. Galvanic CP

Test Stations / Junction Boxes shall be traceable from the manufacturer

and supplier through delivery, storage, fabrication, erection, installation,

repair, modification and use.

Schedule Q

Att. IV

Sec. 3.3

B2

Documented Control System shall be implemented for all Saudi Aramco

supplied material and equipment.

Schedule Q

Att. lV

Sec. 4

C.

Material Inspection

C1

QC Before Installation - Galvanic CP Test Stations / Junction Boxes shall

conform to all applicable requirements, standards, and specifications

prior to release to be used as part of work.

Schedule Q

Att. IV

Sec. 3.3

C2

Incoming Galvanic CP Test Stations / Junction Boxes shall be visually

inspected for damage / defects occurred during transportation.

Schedule Q

Att. IV

Sec. 3.3

C3

Galvanic CP Test Stations / Junction Boxes shall be new and unused.

Schedule G

Sec. 2.1

C4

Galvanic CP Test Stations / Junction Boxes shall be in accordance with

the Saudi Aramco-approved project-specific design drawings, diagrams,

schedules, lists, databases, and associated design documents.

Schedule G

Sec. 4.1

C5

Check that the Contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier

locations as required by the inspection level assigned for the materials

and equipment identified in SAER-1972 Inspection Requirements.

Schedule Q

Att. llI

Sec. 1.2

Page 1 of 5

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

C6

All boxes and conduit bodies, covers, extension rings, plaster rings and

the like shall be durably and legibly marked with manufacturer's name or

trademark.

NEC 314.44

Page 2 of 5

SAES-P-104

Sec. 3.2

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Galvanic CP Test Stations / Junction Boxes - Material

Receiving

PROJECT TITLE

SAIC-X-3102

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

C7

All boxes and conduit bodies, covers, extension rings, plaster rings and

the like shall be durably and legibly marked with manufacturer's name or

trademark.

NEC 314.44

SAES-P-104

Sec. 3.2

C8

Metal covers shall be of the same material as the box or conduit body

with which they are used, or they shall be lined firmly attached insulating

material that is not less than 0.79 mm thick, or they shall be listed for the

purpose.

NEC 314.41

SAES-P-104

Sec. 3.2

C9

Metal covers shall be of the same thickness as the boxes or conduit body

for which they are used, or they shall be listed for the purpose.

NEC 314.41

SAES-P-104

Sec. 3.2

Onshore cathodic protection junction box enclosures placed in nonclassified areas shall be NEMA 4 compliant and shall be constructed of:

type 5052 aluminum alloy, or

304 (or better) stainless steel, or

C10 UV stabilized polymeric material

The thickness of metal sheeting used for the enclosure construction shall

comply with Table 7-1 or Table 7-2 of NEMA ICS-6. Welding shall be

done by Gas Tungsten Arc Welding or Gas Metal Arc Welding. Aluminum

enclosures shall be welded with aluminum 5356 filler metal.

17-SAMSS-008

Sec. 6.1.1

Nearshore (within 1 km of a coastline) cathodic protection junction box

enclosures for non-classified areas shall be NEMA 4X compliant and

shall be constructed of:

type 5052 aluminum coated with baked polyester powder (70 to 100

microns with chromate pretreatment), or

304 (or better) stainless steel, or

UV stabilized polymeric material.

The thickness of metal sheeting used for the enclosure construction shall

comply with Table 7-1 or Table 7-2 of NEMA ICS-6. Welding shall be

done by Gas Tungsten Arc Welding or Gas Metal Arc Welding. Aluminum

enclosures shall be welded with aluminum 5356 filler metal.

17-SAMSS-008

Sec. 6.1.2

C11

30-Jun-08

DATE APPROVED

QR NUMBER

Offshore cathodic protection junction box enclosures for non-classified

areas shall be NEMA 4X compliant and shall be constructed of:

316L stainless steel, or

C12

UV stabilized polymeric material.

316L Stainless Steel breathers and drains shall be installed for all

offshore cathodic protection junction boxes.

17-SAMSS-008

Sec. 6.1.3

All cathodic protection junction box enclosures for non-classified areas

shall have:

a) a continuous full length hinge located on the left hand side when

facing the front of the enclosure

b) two quick release toggle latches located on the right hand side of the

enclosure

C13 c) hinges and latches fabricated from material that is galvanically

compatible with the enclosure metal and of equal or better corrosion

resistance. Non-metallic components may be used for hinges and

latches.

Exception:

Grade 304L stainless steel latches may be used on grade 316 or 316L

stainless enclosures.

17-SAMSS-008

Sec. 6.1

Page 3 of 5

CPCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Galvanic CP Test Stations / Junction Boxes - Material

Receiving

SAIC-X-3102

PROJECT TITLE

ITEM

No.

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

If explosion proof enclosures are required for classified areas, they shall

meet NEMA 7, 8 or 9 requirements in accordance with NEMA 250, based

C14 on the area specified. The enclosure shall be marked to show the

appropriate classified area location Class number and gas group letter

designation (i.e., Class/Zone/Group).

17-SAMSS-008

Sec. 6.2.1

The enclosure shall be provided with taper threaded openings to fit ANSI

C80.1 field conduit connections. Number and size of such openings shall

C15 be in accordance with the applicable Standard Drawing referenced in the

Purchase Order. Each conduit entry shall be capped with a plug to seal

the opening. Plugs with recessed heads are not acceptable.

17-SAMSS-008

Sec. 6.2.2

Enclosures shall be labeled or listed by an approved and recognized

C16 testing organization to indicate full compliance with NEMA ICS 6 and

NEMA 250 for NEMA Type 4, 4X, 7, 8 or 9 enclosures, as applicable.

17-SAMSS-008

Sec. 7

Enclosures manufactured in Saudi Arabia shall comply with Saudi

Aramco standard drawings and the NEMA standards above. However,

C17 they are exempt from the above labeling or listing provided the required

testing has been completed with documentation to confirm performance

and quality..

17-SAMSS-008

Sec. 7

C18

30-Jun-08

DATE APPROVED

QR NUMBER

The export packing, marking and shipping shall be as specified in the

Purchase Order.

CPCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

17-SAMSS-008

Sec. 8

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), March 2006

2. Schedule Q -- Quality Requirements (Pro Forma Contract), February 2008

3. SAES-X-400 Cathodic Protection of Buried Pipelines, 22 October 2007

4. 17-SAMSS-008 Junction Boxes for Cathodic Protection 31 March 2008

5. SAES-P-104 Wiring Methods and Materials, 13 January 2008

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party

Construction Representative*

Saudi Aramco

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

QC Inspector

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

T&I Witnessed

Name, Initials and Date:

Name, Organization,

Initials and Date:

Page 4 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - JUNE 2008)

REV 3

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Galvanic CP Test Stations / Junction Boxes - Material

Receiving

PROJECT TITLE

ITEM

No.

SAIC-X-3102

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

Quality Record Approved:

Name, Sign and Date:

30-Jun-08

DATE APPROVED

QR NUMBER

REFERENCE

CPCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

Y = YES

N = NO F = FAILED

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Page 5 of 5

Vous aimerez peut-être aussi

- 03 11 4297Document3 pages03 11 4297mahdi_gPas encore d'évaluation

- Satr-P-3101 Rev 3Document8 pagesSatr-P-3101 Rev 3mahdi_gPas encore d'évaluation

- Satr B 4001Document3 pagesSatr B 4001mahdi_gPas encore d'évaluation

- Saudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 PlumbDocument2 pagesSaudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 Plumbmahdi_gPas encore d'évaluation

- Monthly QA/QC Report SummaryDocument2 pagesMonthly QA/QC Report Summarymahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & DateDocument2 pagesSaudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & Datemahdi_gPas encore d'évaluation

- SATR-X-3201 Rev 3Document4 pagesSATR-X-3201 Rev 3mahdi_gPas encore d'évaluation

- EKL-QC-F-0106-C Post Weld Heat Treatment ReportDocument1 pageEKL-QC-F-0106-C Post Weld Heat Treatment Reportmahdi_gPas encore d'évaluation

- SATR-X-3101 Rev 3Document3 pagesSATR-X-3101 Rev 3mahdi_gPas encore d'évaluation

- Saic S 4006Document2 pagesSaic S 4006mahdi_gPas encore d'évaluation

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 15-Dec-09 PlumbDocument1 pageSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 15-Dec-09 Plumbmahdi_gPas encore d'évaluation

- Satr S 4001Document1 pageSatr S 4001mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: MeteringDocument1 pageSaudi Aramco Pre-Commissioning Form: Meteringmahdi_gPas encore d'évaluation

- Sa P 070Document3 pagesSa P 070mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: FORM # J-011 (5/19/15) SHT 1 of 2Document2 pagesSaudi Aramco Pre-Commissioning Form: FORM # J-011 (5/19/15) SHT 1 of 2mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning FormDocument2 pagesSaudi Aramco Pre-Commissioning Formmahdi_gPas encore d'évaluation

- Sa J 001Document2 pagesSa J 001mahdi_gPas encore d'évaluation

- Sa J 001Document2 pagesSa J 001mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning FormDocument1 pageSaudi Aramco Pre-Commissioning Formmahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning FormDocument1 pageSaudi Aramco Pre-Commissioning Formmahdi_gPas encore d'évaluation

- Sa F 001Document13 pagesSa F 001mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning FormDocument1 pageSaudi Aramco Pre-Commissioning Formmahdi_gPas encore d'évaluation

- Sa e 001aDocument7 pagesSa e 001amahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)Document1 pageSaudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning FormDocument2 pagesSaudi Aramco Pre-Commissioning Formmahdi_gPas encore d'évaluation

- Saer 5711Document161 pagesSaer 5711sethu1091100% (1)

- Sa G 005Document1 pageSa G 005mahdi_gPas encore d'évaluation

- Saudi Aramco Pre-Commissioning FormDocument2 pagesSaudi Aramco Pre-Commissioning Formmahdi_gPas encore d'évaluation

- Saer 5895Document18 pagesSaer 5895sethu1091Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Steel View Tower Quantity Estimatev1.0Document14 pagesSteel View Tower Quantity Estimatev1.0Prayush RajbhandariPas encore d'évaluation

- Corev Color BookDocument5 pagesCorev Color BookMariana CruzPas encore d'évaluation

- Pmi Louis Proserv 3Document6 pagesPmi Louis Proserv 3Ebit TrisnoPas encore d'évaluation

- Amphenol: Amphenol /pyle Industrial Connectors Star-Line, Star-Line EX, Star-LokDocument85 pagesAmphenol: Amphenol /pyle Industrial Connectors Star-Line, Star-Line EX, Star-Lokrolando laffontPas encore d'évaluation

- 110 Block Termination Instructions For Feeder Pair Cabling.Document4 pages110 Block Termination Instructions For Feeder Pair Cabling.Victor L. HartPas encore d'évaluation

- Aa CPS 000433Document3 pagesAa CPS 000433stignzPas encore d'évaluation

- 2124R 04Document13 pages2124R 04Cynti DZPas encore d'évaluation

- Burao Water Supply Expansion Sub-Project LOT - Install two 1000m3 Reservoirs on the GroundDocument19 pagesBurao Water Supply Expansion Sub-Project LOT - Install two 1000m3 Reservoirs on the Groundmustafe0% (1)

- 7861 2 PDFDocument26 pages7861 2 PDFUdit Kumar SarkarPas encore d'évaluation

- Joints in Poured Walls - tcm45-342541Document3 pagesJoints in Poured Walls - tcm45-342541Youssef RomanosPas encore d'évaluation

- Assignment 2, Flat Slab Flexural DesignDocument1 pageAssignment 2, Flat Slab Flexural DesignKelly Obrien0% (1)

- Alltek: An Internal Finish For Walls & Ceilings, Designed To Replace Gypsum Based PlasterDocument3 pagesAlltek: An Internal Finish For Walls & Ceilings, Designed To Replace Gypsum Based PlasterTinashePas encore d'évaluation

- Type of Thread PDFDocument13 pagesType of Thread PDFrefae0% (1)

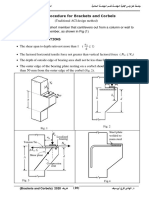

- Brackets and Corbels ACI 318 L # 1Document7 pagesBrackets and Corbels ACI 318 L # 1soran azizPas encore d'évaluation

- ACE Hammer CatalogueDocument8 pagesACE Hammer CatalogueAgung NgurahPas encore d'évaluation

- Data Sheet BISALLOY 500-STEELDocument1 pageData Sheet BISALLOY 500-STEELFery FebryantoPas encore d'évaluation

- LUBRICACIONDocument48 pagesLUBRICACIONdamian_k19Pas encore d'évaluation

- Pipe and Tube SizeDocument32 pagesPipe and Tube Sizehothanhdung2002Pas encore d'évaluation

- Engineering Materials - Mechanical Engineering Multiple Choice Questions and Answers For Competitive ExamsDocument37 pagesEngineering Materials - Mechanical Engineering Multiple Choice Questions and Answers For Competitive Examsahmish kabbaxePas encore d'évaluation

- Fastener Size Chart TitleDocument1 pageFastener Size Chart TitlejayendrapatilPas encore d'évaluation

- Architectural Fasteners & Fittings - Stainless Steel - AnzorDocument18 pagesArchitectural Fasteners & Fittings - Stainless Steel - AnzorBhaiJan59Pas encore d'évaluation

- Compounding Plants For The Cable Industry: 130301 FLD X-COMP - RZ - Indd 3Document12 pagesCompounding Plants For The Cable Industry: 130301 FLD X-COMP - RZ - Indd 3Shung Tak ChanPas encore d'évaluation

- Data Sheet Soundsoak Walls PDFDocument2 pagesData Sheet Soundsoak Walls PDFSameera LakmalPas encore d'évaluation

- IS Code of Cement & ConcreteDocument8 pagesIS Code of Cement & ConcreteKuldeep UpadhyayPas encore d'évaluation

- ROCK JACKET PIPELINE COATINGDocument2 pagesROCK JACKET PIPELINE COATINGInamPas encore d'évaluation

- Lecture 6 - BricksDocument28 pagesLecture 6 - BricksVanessa AlexanderPas encore d'évaluation

- Top Construction Companies in the PhilippinesDocument15 pagesTop Construction Companies in the PhilippinesJoms Jac AbajaPas encore d'évaluation

- MS 01 180Document88 pagesMS 01 180DucVikingPas encore d'évaluation

- Pohokura DeckDocument54 pagesPohokura DeckLynn BishopPas encore d'évaluation

- Workshop ManualDocument26 pagesWorkshop ManualHarender KumarPas encore d'évaluation