Académique Documents

Professionnel Documents

Culture Documents

Mid exam-QP

Transféré par

aeronayakCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mid exam-QP

Transféré par

aeronayakDroits d'auteur :

Formats disponibles

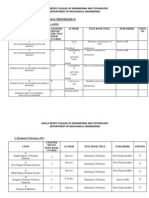

APPLIED TRIBOLOGY

1.How the contact surface topography and finish affect the friction and wear

characteristics of materials?.

2. How the lubricants reduce friction and wear characterisics of the parts in

contact?.

3.Describe the fields of applications of different oils, greases and solid

lubricants ,mentioning thrtr relative advantages.

4. Explain various metallic and nonmetallic seals used in practice.

5. Sketch and explain the applications of lip seals, packed gland seals and soft

piston seals.

6.How the soap and ferrography methods are employed in the wear analysis of

failure of sliding contact bearings?.

7. Explain various oil rings used for bearings?

8. (a) What are the laws of friction?

(b) Differentiate boundary friction with dry friction

9. What are the measurement systems of surface roughness.

10. a) Derive friction equation involving hard material.

b) Explain Pin-on-Disc method of friction measurement.

11. a) Enumerate different types of wear.

b) Derive wear equation for hard material over a soft material in sliding.

12. a) What are the sliding friction mechanisms ?.

b) Derive a modified Bowden and Tabor friction equation.

ADVANCED COMPOSITES MATERIALS

1. Write a note on types of Ceramic fibers?

2. How can the composite materials be classified according to the matrix and

rein-forcements?

3. Discuss how the properties of composite material are a function of the

following:

(a) Properties of the constituent phases.

(b) Their relative amounts.

4.

Discuss various composites used for structures.

5. a) Discuss characteristics of various composite laminates.

b) Derive relationships based on mixture when fibres are kept in parallel and

perpendicular to

load.

6. a) Discuss characteristic properties and applications of Reinforced

composites with illustrations.

b)

Distinguish metal matrix and

ceramic composites with illustrations highlighting characteristic properties.

7. a) Discuss manufacturing composites inform of tapes.

b) Discuss briefly pultrusion and RTM methods to fabricate composite systems.

8. a) Discuss characteristics of various composite laminates.

b) Derive relationships based on mixture when fibres are kept in parallel and

perpendicular to load.

ADVANCED MECHANICS OF SOLIDS

a) List out the assumptions on which a solution for contact stresses is based.

b) Explain the method of computing contact stresses

c. A shaft of hollow square section of outer side 60 mm and inner side 45 mm

is

subjected to twisting such that the maximum shear stress developed is

350

N/mm2. What is the torque acting on the shaft and angular twist if the

shaft is 1.2

m long. Take G = 8.1 x 10 N/mm2.

5

1. a) Derive an expression for torsion of bars with rectangular cross section

b) Explain in brief about the stresses developed when the two bodies in

line

contact

2. A long cylinder of diameter 60cm is rotating at 3000 rpm. Calculate the

maximum

stress in the cylinder. Draw the radial and hoop stresses along the radius.

3. A steel I-beam (E=200GPa) has a depth of 102 mm, width of 68mm,

Ix=2.53106mm4, and length of 4m. It is attached to a rubber foundation for which

Ko=0.350N/mm3. A concentrated load P=30kN is applied at one end of the beam.

Determine the maximum deflection, maximum flexural stress in the beam and the

location of each.

4. A flat steel turbine disk of 65 cm outside diameter and 10 cm inside diameter rotates at 3600

rpm, at which speed the blade and shrouding cause a tensile rim loading of 4300 kPa. The

maximum stress at this speed is to be 104026 kPa. Find the maximum shrink allowance on

the diameter when the disk and the shaft are rotating.

5. A T section with flange 10cm x 1cm and web 19cm x 0.8cm is subjected to a

torque of 200Nm. Find the maximum shear stress and angle of twist per metre

length. G = 82KN / mm2 .

Vous aimerez peut-être aussi

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RPas encore d'évaluation

- TUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignDocument8 pagesTUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignCharles OndiekiPas encore d'évaluation

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliPas encore d'évaluation

- 34412501-Design of MC ElementDocument8 pages34412501-Design of MC Elementsmg26thmayPas encore d'évaluation

- Agricultural Engineering Design PrinciplesDocument7 pagesAgricultural Engineering Design Principlesjaimin777Pas encore d'évaluation

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786Pas encore d'évaluation

- DRCS Important QuestionsxDocument26 pagesDRCS Important QuestionsxcsaPas encore d'évaluation

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuPas encore d'évaluation

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiPas encore d'évaluation

- Chapter 1:-Aesthetic and Ergonomic Consideration in DesignDocument14 pagesChapter 1:-Aesthetic and Ergonomic Consideration in Designkumbharashish37Pas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaPas encore d'évaluation

- Material Science Question BankDocument3 pagesMaterial Science Question BankSirish Chand PutlaPas encore d'évaluation

- QuestionsDocument11 pagesQuestionsSundara MoorthyPas encore d'évaluation

- WWW - Manaresults.Co - In: Set - 1 Code No: RT32033Document8 pagesWWW - Manaresults.Co - In: Set - 1 Code No: RT32033Sai RamPas encore d'évaluation

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTAPas encore d'évaluation

- Excersises For Essentials and Engineering of MaterialsDocument5 pagesExcersises For Essentials and Engineering of MaterialsBraulio BolañosPas encore d'évaluation

- rr312404 Design of Machine ElementsDocument8 pagesrr312404 Design of Machine ElementsSRINIVASA RAO GANTAPas encore d'évaluation

- Foundation Level Mechanical Engineering Challenge TestDocument10 pagesFoundation Level Mechanical Engineering Challenge TestMohamad Talhah Al HafizPas encore d'évaluation

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarPas encore d'évaluation

- Machine Design exam questionsDocument4 pagesMachine Design exam questionsjihardistPas encore d'évaluation

- VMKV Engineering College Question Bank on Machine Design ElementsDocument14 pagesVMKV Engineering College Question Bank on Machine Design ElementsSatwik PriyadarshiPas encore d'évaluation

- Tribology QP & Syllabus Vtu PRASHANTHDocument21 pagesTribology QP & Syllabus Vtu PRASHANTHpachieduPas encore d'évaluation

- B.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)Document5 pagesB.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)varunPas encore d'évaluation

- MCQ QuestionDocument9 pagesMCQ Questionmamaadam02Pas encore d'évaluation

- Mechatronics exam with questions on control systems and PLC applicationsDocument62 pagesMechatronics exam with questions on control systems and PLC applicationshaptooorPas encore d'évaluation

- WWW Manaresults Co inDocument2 pagesWWW Manaresults Co inmahendra babu mekalaPas encore d'évaluation

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GPas encore d'évaluation

- BRANCH: Machine Design: Advanced Mechanical Engg DesignDocument1 pageBRANCH: Machine Design: Advanced Mechanical Engg DesignyogeshwararaoPas encore d'évaluation

- DMM 1Document9 pagesDMM 1andhracollegesPas encore d'évaluation

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንPas encore d'évaluation

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDocument2 pagesB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyMilan MottaPas encore d'évaluation

- Mechanical Behaviour and Testing of MaterialsDocument5 pagesMechanical Behaviour and Testing of MaterialsSachi DhanandamPas encore d'évaluation

- 2Document4 pages2Shem YusoyaPas encore d'évaluation

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyPas encore d'évaluation

- Problems in Compos Mater Questions PG PDFDocument15 pagesProblems in Compos Mater Questions PG PDFJimmyFigueroaAPas encore d'évaluation

- ADGITM Machine Design Exam QuestionsDocument4 pagesADGITM Machine Design Exam QuestionsVishal JhaPas encore d'évaluation

- 07rr310305 Design of Machine Members IDocument8 pages07rr310305 Design of Machine Members IandhracollegesPas encore d'évaluation

- Scheme – E Sample Question PaperDocument4 pagesScheme – E Sample Question PaperBinyamin ChinikamwalaPas encore d'évaluation

- Rr310305 Design of Machine Members IDocument8 pagesRr310305 Design of Machine Members ISrinivasa Rao GPas encore d'évaluation

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadPas encore d'évaluation

- Simulation of Bolt Prestressing in Steel Shear Connections: Emistaki@Document10 pagesSimulation of Bolt Prestressing in Steel Shear Connections: Emistaki@Anis SuissiPas encore d'évaluation

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadPas encore d'évaluation

- Analisis de Falla Por Fatiga Eje de Hiladora de FiqueDocument15 pagesAnalisis de Falla Por Fatiga Eje de Hiladora de FiqueAMERIKARPas encore d'évaluation

- Civil Engineering Question Bank on Strength of MaterialsDocument19 pagesCivil Engineering Question Bank on Strength of MaterialsSanjay TiwariPas encore d'évaluation

- QBDocument18 pagesQBMudrikaPas encore d'évaluation

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechPas encore d'évaluation

- 07 r05310305 Design of Machine Members IDocument8 pages07 r05310305 Design of Machine Members IandhracollegesPas encore d'évaluation

- Mechanics of SolidsDocument15 pagesMechanics of Solidsselva1975Pas encore d'évaluation

- Mechanical Properties Question BankDocument20 pagesMechanical Properties Question Bankutsav_koshtiPas encore d'évaluation

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanPas encore d'évaluation

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadPas encore d'évaluation

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariPas encore d'évaluation

- Discrete Element Method to Model 3D Continuous MaterialsD'EverandDiscrete Element Method to Model 3D Continuous MaterialsPas encore d'évaluation

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainD'EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainPas encore d'évaluation

- Interface / Interphase in Polymer NanocompositesD'EverandInterface / Interphase in Polymer NanocompositesAnil N. NetravaliPas encore d'évaluation

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapD'EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancheriePas encore d'évaluation

- Friction and Wear of Polymer CompositesD'EverandFriction and Wear of Polymer CompositesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysD'EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysPas encore d'évaluation

- MD SylDocument40 pagesMD SylaeronayakPas encore d'évaluation

- FCFMDocument1 pageFCFMaeronayakPas encore d'évaluation

- Machine Design QPDocument4 pagesMachine Design QPaeronayakPas encore d'évaluation

- Software Development Life CycleDocument3 pagesSoftware Development Life CycleaeronayakPas encore d'évaluation

- FCFMDocument1 pageFCFMaeronayakPas encore d'évaluation

- FCFMDocument1 pageFCFMaeronayakPas encore d'évaluation

- MD SylDocument40 pagesMD SylaeronayakPas encore d'évaluation

- Design Synthasis: Experimental Stress AnalysisDocument7 pagesDesign Synthasis: Experimental Stress AnalysisaeronayakPas encore d'évaluation

- Chap3 Forward KinematicsDocument32 pagesChap3 Forward Kinematicsjoseph samuelPas encore d'évaluation

- MVDocument1 pageMVaeronayakPas encore d'évaluation

- 7 Tools for Continuous ImprovementDocument202 pages7 Tools for Continuous Improvementvivekanand bhartiPas encore d'évaluation

- Measures of CentralityDocument13 pagesMeasures of CentralityPRAGASM PROGPas encore d'évaluation

- Trishasti Shalaka Purusa Caritra 4 PDFDocument448 pagesTrishasti Shalaka Purusa Caritra 4 PDFPratik ChhedaPas encore d'évaluation

- The Daily Tar Heel For September 18, 2012Document8 pagesThe Daily Tar Heel For September 18, 2012The Daily Tar HeelPas encore d'évaluation

- Cloud Security Training and Awareness Programs For OrganizationsDocument2 pagesCloud Security Training and Awareness Programs For OrganizationsdeePas encore d'évaluation

- The German eID-Card by Jens BenderDocument42 pagesThe German eID-Card by Jens BenderPoomjit SirawongprasertPas encore d'évaluation

- Unitisation of Legal Methodsalsdkgh GHNJFKL A SDFG LKJH Asdfgf Lkjhasdfg LKKJ Asdfg LKJH A Slkjfs Aaaaaaaaaaaaslkdfj Asldkjf SLDKFJDocument3 pagesUnitisation of Legal Methodsalsdkgh GHNJFKL A SDFG LKJH Asdfgf Lkjhasdfg LKKJ Asdfg LKJH A Slkjfs Aaaaaaaaaaaaslkdfj Asldkjf SLDKFJKailashnath Reddy AjjuguttuPas encore d'évaluation

- Jeremy Hughes ReviewDocument5 pagesJeremy Hughes ReviewgracecavPas encore d'évaluation

- EMarketer Time Spent With Media SnapshotDocument13 pagesEMarketer Time Spent With Media SnapshotWei ShingPas encore d'évaluation

- 4D - Yulianti Viviana - Exercise 9Document7 pages4D - Yulianti Viviana - Exercise 9Uli JennerPas encore d'évaluation

- Manual EDocument12 pagesManual EKrum KashavarovPas encore d'évaluation

- Potato Peroxidase LabDocument2 pagesPotato Peroxidase LabKarla GutierrezPas encore d'évaluation

- APM200 Outdoor Power Supply System User Manual-20060628-B-1.0Document52 pagesAPM200 Outdoor Power Supply System User Manual-20060628-B-1.0Andrés MarroquínPas encore d'évaluation

- Nutritional support through feeding tubesDocument76 pagesNutritional support through feeding tubesKryzza LeizellPas encore d'évaluation

- Marketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Document20 pagesMarketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Miaow MiaowPas encore d'évaluation

- PPM To Percent Conversion Calculator Number ConversionDocument1 pagePPM To Percent Conversion Calculator Number ConversionSata ChaimongkolsupPas encore d'évaluation

- 2.7.3 Lab Use Steganography To Hide Data Answer KeyDocument3 pages2.7.3 Lab Use Steganography To Hide Data Answer KeyVivek GaonkarPas encore d'évaluation

- Digital MarketingDocument70 pagesDigital MarketingTarun N. O'Brain Gahlot0% (2)

- Lab Report AcetaminophenDocument5 pagesLab Report Acetaminophenapi-487596846Pas encore d'évaluation

- Delhi Mumbai Award Status Mar 23Document11 pagesDelhi Mumbai Award Status Mar 23Manoj DoshiPas encore d'évaluation

- Active Disturbance Rejection Control For Nonlinear SystemsDocument8 pagesActive Disturbance Rejection Control For Nonlinear SystemsTrần Việt CườngPas encore d'évaluation

- Fictional Narrative: The Case of Alan and His FamilyDocument4 pagesFictional Narrative: The Case of Alan and His Familydominique babisPas encore d'évaluation

- Socio-cultural influences on educationDocument4 pagesSocio-cultural influences on educationofelia acostaPas encore d'évaluation

- Transport in Plants: Test Yourself 9.1 (Page 178)Document3 pagesTransport in Plants: Test Yourself 9.1 (Page 178)lee100% (3)

- OS9000 AOS 6.1.5 R01 Network Configuration GuideDocument846 pagesOS9000 AOS 6.1.5 R01 Network Configuration GuideclaupasinaPas encore d'évaluation

- ProSteel Connect EditionDocument2 pagesProSteel Connect EditionInfrasys StructuralPas encore d'évaluation

- Reading in Philippine History (Chapter 3)Document14 pagesReading in Philippine History (Chapter 3)AKIO HIROKIPas encore d'évaluation

- Complimentary JournalDocument58 pagesComplimentary JournalMcKey ZoePas encore d'évaluation

- T Cells & Autoimmunity, s3Document21 pagesT Cells & Autoimmunity, s3LiaAriestaPas encore d'évaluation

- Mechanical EngineeringDocument14 pagesMechanical EngineeringSamuel WozabPas encore d'évaluation