Académique Documents

Professionnel Documents

Culture Documents

50 KW

Transféré par

SpectrumRaijinTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

50 KW

Transféré par

SpectrumRaijinDroits d'auteur :

Formats disponibles

CUMMINS SERIE 4B

Definicines

Potencia Prime

Estos valores son aplicables para el suministro de energa elctrica continua

(a carga variable) en lugar de la red comercial + 10% sobrecarga

Potencia Stand by

Estos valores son aplicables para el suministro de energa elctrica continua

(con carga variable) en caso de falla de la red comercial. No se permite sobrecarga sobre estos valores.

Ratings at 0.8pf

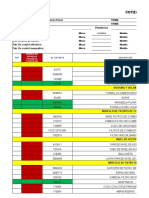

Tabla de Potencias

Modelo

Voltaje

CNY50

CNY60

CNY80

220-440V

220-440V

220-440V

kVA Prime kWe Prime kVA Stand-by

57

69

91

45

55

73

63

75

100

kWe Stand-by

50

60

80

0.8 Factor de potencia

Informacin Tcnica

Datos Tcnicos

Frecuencia:

Marca / Modelo

Generador Modelo:

Nmero de Cilindros:

Diametro por Carrera :in (mm)

Relacin de Compresin:

Aspiracin:

Velocidad:

Potencia: BHP(kWm)

Presion Efectiva: psi (kPA)

Velocidad dePiston: ft/min (m/s)

Consumo a plena carga: lt / hr - 100%

Calor Expulsado en el Sistema de

Escape: BTU/min (kWm)

Calor Expulsado en el Sistema de

Enfriamiento: BTU/min (kWm)

Temperatura de Escape: F (C)

Flujo de Enfriamiento en el Radiador

m/seg - FPM

Flujo de Escape: cfm (litros/s)

CNY50

CNY60

CNY80

60 Hz

4BT3.3G3

Stamford UCI224D

4 en linea

3.74X4.53 (95X115)

18.0:1

Turbocargado

1800 RPM

80 (60)

177 (1220)

1359 (6.9)

15

60 Hz

4BT3.9G4

Stamford UCI224E

4 en linea

4.02X4.72 (102X120)

16.5:1

Turbocargado

1800 RPM

102 (76)

190 (1312)

1416 (7.2)

19

60 Hz

4BTA3.9G3

Stamford UCI224G

4 en linea

4.02X4.72 (102X120)

16.5:1

Turbo y Postenfriado

1800 RPM

125 (93)

233 (1604)

1416 (7.2)

24

2858 (50.3)

3390 (59.5)

4500 (79.2)

2181 (38.3)

2240 (39.3)

2860 (50.3)

1090 (588)

919 (493)

815 (435)

llame a fabrica

llame a fabrica

llame a fabrica

420 (198)

516 (244)

366 (173)

Nota: Imagen de carcter ilustrativa ya que los equipos

en foto pudieran incluir accesorios opcionales

Ottomotores, S.A de C.V.

Como leer nuestro codigo: Ejem: CNY50

C=Motor Cummins

N=Generador Newage Stamford

Y=60Hz-1800 RPM

50= Potencia del Equipo.

LAPEM

Calz. San Lorenzo No.1150

Col. Cerro de la estrella, C.P. 09860

Delg. Iztapalapa Mxico, D.F.

Tels:52-55-5624-5600

Fax: 52-55-5426-5521 / 52-55-5426-5581

email: ventas@ottomotores.com.mx

sitio web: www.ottomotores.com.mx

Dimensiones

Cz

A

x

B

y

E

CNY50

Equipo con

Base Estructural

A

B

175,00 70,00

Peso: 624,00 kgs

CNY60

Equipo con

Base Estructural

A

B

175,00 70,00

Peso: 650,00 kgs

CNY80

C

108,50

C

108,50

Equipo con

Base Estructural

A

B

202,00 77,00

Peso: 841,00 kgs

C

123,00

Equipo con

Base Tanque

x

y

218,00 109,00

Peso: 945,00 kgs

z

134,50

Equipo con

Base Tanque

Equipo con

Caseta Acstica*

D

E

F

260,00 109,00 165,00

Peso: 1392,00kgs

Equipo con

Caseta Acstica*

x

y

z

D

E

F

218,00 109,00 134,50 260,00 109,00 165,00

Peso: 1069,00 kgs

Peso: 1489,00kgs

Equipo con

Base Tanque

Equipo con

Caseta Acstica*

x

y

z

D

E

F

218,00 109,00 137,50 260,00 109,00 165,00

Peso: 1129,00 kgs

Peso: 1575,00kgs

[*] Equipo opcional

Informacin Tcnica

Nota: las condiciones de referencia estndar son de 25 C (77 F) temperatura de entrada de aire. Todos los datos de desempeo de motores son basados en la potencia mencionada arriba.

Datos de consumo de combustible a plena carga con combustible diesel tienen una gravedad especfica de 0,85.

Comercializado por:

Ottomotores se reserva el derecho de hacer cambios sin previo aviso con el fin de

mejorar nuestros productos 2010

DESCRIPTION

In. 3

Out. 7.5

MODELS

CNE55

CNE65

CNY50

CNY60

Air filter

RADIATOR:

68.02

Radiator

OT 5

ENGINE:

Turbocharger

4BT 3.9 G3/G4

AIR FILTER:

AH1107

BASE FRAME:

Box

Connections

BMT-4B3-STF

SPRING AVMSS 4 PZS

Start

Motor

103.46

118.50

Generator

22.00

131.00

175.00

2.50

22.00

2.50

61.00

66.00

SIDE VIEW

19.54

FRONT VIEW

NOTES:

TOP VIEW

In. 3

Out. 7.5

-THE GENSET DIMENSIONS ARE THE SAME BY FAMILY MODEL, THERE COULD BE ONLY DIFFERENCES ON THE ALTERNATOR

LENGHT SEE SPECIFIC GENERAL ARRAGEMENT DRAWING OF CERTEIN MODEL

-TOTAL WEIGHT COULD VARY CHECK RATING CHART FOR EACH MODEL

Customer:

Title:

S/O:

CUMMINS ENGINE 4BT3.9G-/G4 - STAMFORD ALTERNATOR

Draw:

Date:

R.G.C.

JAN 05th 2005

Revised: F.H.M.

Certificated:

Date:

Date:

JAN 05th 2005

F.H.M.

JAN 05th 2005

Code:

CNE/Y-02

Dept.: Engineering

Marks: cms

Scale:

Draw:

s/e

Of:

Rev.

Description

Reviews

Date

Certificated

Ottomotores keeps the right to change the information with out prior notice

FO 023-0

Basic Engine Model:

Curve Number:

4BT3.3-G3

FR-30233

Columbus, Indiana 47202-3005

Engine Critical Parts List:

Date:

Engine Data Sheet

CPL: N/A

13May08

Cummins Inc.

Displacement : 3.3 litre (199 in3 )

Bore : 95 mm (3.74 in)

No. of Cylinders : 4

Aspiration : Turbocharged

Engine Speed

B3.3

1

Stroke : 115 mm (4.53 in)

Standby Power

Prime Power

Continuous Power

rpm

kWm

hp

kWm

hp

kWm

hp

1500

51

68

46

62

N/A

N/A

1800

60

80

54

72

N/A

N/A

Engine Performance Data @ 1500 rpm

OUTPUT POWER

%

G-DRIVE

kWm

FUEL CONSUMPTION

20.0

kg/

kWmh

lb/

hph

litre/

hour

US gal/

hour

68

0.217

0.358

13

3.4

hp

litre/hour

1500 rpm

15.0

STANDBY POWER

100

51

10.0

PRIME POWER

100

46

62

0.212

0.349

11

3.0

75

35

47

N.A

N.A.

N.A.

N.A.

50

23

31

N.A

N.A.

N.A.

N.A.

25

12

16

N.A

N.A.

N.A.

N.A.

5.0

0.0

0

10

15

20

25

30

35

40

45

50

55

Gross Engine Output - kWm

Engine Performance Data @ 1800 rpm

OUTPUT POWER

%

kWm

FUEL CONSUMPTION

kg/

kWmh

lb/

hph

litre/

hour

US gal/

hour

80

0.216

0.355

15

4.0

hp

STANDBY POWER

100

60

US gallons/hour

6.0

1800 rpm

4.0

PRIME POWER

100

54

72

0.212

0.349

13

3.5

75

41

54

N.A

N.A.

N.A.

N.A.

50

27

36

N.A

N.A.

N.A.

N.A.

25

14

18

N.A

N.A.

N.A.

N.A.

2.0

0.0

0

10

20

30

40

50

60

70

80

90

Gross Engine Output - hp

CONVERSIONS:(litres = US Gal x 3.785) (US Gal = litres x 0.2642)

These guidelines have been formulated to ensure proper application of generator drive engines in A.C. generator set installations. STANDBY POWER RATING: Applicable for supplying emergency power for the duration of the utility power

outage. No overload capability is available for this rating. Under no condition is an engine allowed to operate in parallel

with the public utility at the Standby Power rating. This rating should be applied where reliable utility power is available. A

Standby rated engine should be sized for a maximum of an 80% average load factor and 200 hours of operation per year.

This includes less than 25 hours per year at the Standby Power rating. Standby ratings should never be applied except in

true emergency power outages. Negotiated power outages contracted with a utility company are not considered an emergency. PRIME POWER RATING: Applicable for supplying electric power in lieu of commercially purchased power. Prime

Power applications must be in the form of one of the following two categories:UNLIMITED TIME RUNNING PRIME POWER: Prime Power is available for an unlimited number of hours per year in a variable load application. Variable load should

not exceed a 70% average of the Prime Power rating during any operating period of 250 hours. The total operating time

at 100% Prime Power shall not exceed 500 hours per year. A 10% overload capability is available for a period of 1 hour

within a 12-hour period of operation. Total operating time at the 10% overload power shall not exceed 25 hours per year.

LIMITED TIME RUNNING PRIME POWER: Limited Time Prime Power is available for a limited number of hours in a nonvariable load application. It is intended for use in situations where power outages are contracted, such as in utility power

curtailment. Engines may be operated in parallel to the public utility up to 750 hours per year at power levels never to exceed the Prime Power rating. The customer should be aware, however, that the life of any engine will be reduced by this

constant high load operation. Any operation exceeding 750 hours per year at the Prime Power rating should use the Continuous Power rating.CONTINUOUS POWER RATING: Applicable for supplying utility power at a constant 100% load for

an unlimited number of hours per year. No overload capability is available for this rating.

Data Subject to Change Without Notice

Reference AEB 10.47 for determining Electrical Output.

Data shown above represent gross engine performance capabilities obtained and corrected in accordance with ISO3046 conditions of 100 kPa (29.53 in Hg) barometric pressure [110 m (361 ft) altitude], 25 C (77 F) air inlet temperature, and relative humidity of 30% with No. 2 diesel or a fuel corresponding to ASTM D2.

Derates shown are based on 15 in H2O air intake restriction and 2 in Hg exhaust back pressure.

The fuel consumption data is based on No. 2 diesel fuel weight at 0.85 kg/litre (7.1 lbs/US gal). Power output curves are

based on the engine operating with fuel system, water pump and lubricating oil pump; not included are battery charging

alternator, fan, optional equipment and driven components.

Data Status: --Limited Production-Data Tolerance: 5%

Chief Engineer:

G-DRIVE

4BT3.3-G3

Operation At Elevated Temperature And Altitude:

The engine may be operated at:

1800 RPM up to 3280ft. (1000 m) and 104oF (40oC) without

power deration.

1500 RPM up to 3280ft. (1000 m) and 104oF (40oC) without

power deration.

For sustained operation above these conditions, derate by TBD% per

328ft. (100 m), and TBD% per 18oF (TBD% per 10oC).

B3.3

2

G-DRIVE

B3.3

3

Cummins Inc.

Engine Data Sheet

ENGINE MODEL: 4BT3.3-G3

INSTALLATION DIAGRAM

Fan to Flywheel: 4953779

CONFIGURATION NUMBER : D782002GX03

DATA SHEET : DS-30233

DATE : 13May08

PERFORMANCE CURVE : FR-302033

CPL NUMBER

Engine Critical Parts List: N/A

GENERAL ENGINE DATA

Type ...............................................................................................................................................................

Aspiration .......................................................................................................................................................

Bore x Stroke.............................................................................................................. in x in (mm x mm)

Displacement.............................................................................................................................. in3 (litre)

Compression Ratio........................................................................................................................................

Dry Weight (Approximate),

Fan to Flywheel Engine.......................................................................................................... lb (kg)

Wet Weight (Approximate),

Fan to Flywheel Engine.......................................................................................................... lb (kg)

Moment of Inertia of Rotating Components

with FW 30001 Flywheel ........................................................................................ lbm ft2 (kg m2)

Center of Gravity from Rear Face of Block............................................................................... in (mm)

Center of Gravity Above Crankshaft Centerline ....................................................................... in (mm)

Maximum Static Loading at Rear Main Bearing.......................................................................... lb (kg)

4-Cycle; In-line; 4-Cylinder Diesel

Turbocharged

3.74 x 4.53 (95 x 115)

199 (3.3)

18 : 1

584

(265)

599

(272)

29.8

10.07

4.33

275

(1.25)

(256)

(110)

(125)

918

(1245)

(75)

30

12

(102)

(41)

1.2

26

180-203

7

221/212

4/5

(4.5)

(8)

(82-95)

(50)

(105/100)

(28/35)

34

67

248

1.45-1.9

2.1

(235)

(461)

(120)

(5.5-7.0)

(8.0)

ENGINE MOUNTING

Maximum Bending Moment at Rear Face of Block ......................................................... lb ft (N m)

EXHAUST SYSTEM

Maximum Back Pressure..................................................................................................... in Hg (kPa)

AIR INDUCTION SYSTEM

Maximum Intake Air Restriction

with Dirty Filter Element.................................................................................................. in H2O (kPa)

with Clean Filter Element................................................................................................ in H2O (kPa)

COOLING SYSTEM

Jacket Water Circuit Requirements

Coolant Capacity Engine Only ...................................................................................... US gal (litre)

Maximum Static Head of Coolant Above Engine Crank Centerline .............................................. ft (m)

Standard Thermostat (Modulating) Range ................................................................................. F (C)

Minimum Pressure Cap............................................................................................................ psi (kPa)

Maximum Top Tank Temperature for Standby / Prime Power ................................................. F (C)

Maximum Coolant Friction Head External to Engine ............................................................. psi (kPa)

LUBRICATION SYSTEM

Oil Pressure @ Idle Speed .................................................................................................... psi (kPa)

@ Governed Speed ......................................................................................... psi (kPa)

Maximum Oil Temperature.......................................................................................................... F (C)

Oil Capacity with OP 30002 Oil Pan : Low - High............................................................ US gal (litre)

Total System Capacity (Including Filter) ........................................................................... US gal (litre)

G-DRIVE

FUEL SYSTEM

Type Injection System......................................................................................................................................................................

Maximum Inlet Restriction at Injection Pump ................................................................................................... in Hg (mm Hg)

Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head) ............. in Hg (mm Hg)

Maximum Fuel Flow to Injection Pump........................................................................................................... US gph (litre/hr)

Fuel Flow to Lift Pump @ 43 psi (3 kg/cm2) .................................................................................................... US gph (litre/hr)

B3.3

4

Zexel A Direct Injection

2.9

(73)

15

(381)

4.5

(17.2)

10.5

(40)

ELECTRICAL SYSTEM

Cranking Motor (Heavy Duty, Positive Engagement) ................................................................................................ volt

Battery Charging System, Negative Ground ........................................................................................................ ampere

Maximum Allowable Resistance of Cranking Circuit ............................................................................................... ohm

Minimum Recommended Battery Capacity

Cold Soak @ 0 F to 32 F (-18 C to 0 C) ............................................................................................ 0F CCA

12

35

0.00075

725

COLD START CAPABILITY

Minimum Ambient Temperature for NFPA 110 Cold Start (90 degree F Coolant Temperature) ..................... F (C)

Minimum Ambient Temperature for Unaided Cold Start ........................................................................................ F (C)

-9

12.2

(-23)

(-11)

PERFORMANCE DATA

All data is based on:

Engine operating with fuel system, water pump, lubricating oil pump, air cleaner and exhaust

silencer; not included are battery charging alternator, fan, and optional driven components.

Engine operating with fuel corresponding to grade No. 2-D per ASTM D975.

ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure : 100 kPa (29.53 in Hg) Air Temperature

: 25 C (77 F)

Altitude

: 110 m (361 ft)

Relative Humidity : 30%

Steady State Stability Band at Any Constant Load ....................................................................................................... %

Estimated Free Field Sound Pressure Level of a Typical Generator Set;

Excludes Exhaust Noise; at Rated Load and 7.5 m (24.6 ft); @1800 rpm ............................................................... dBA

Exhaust Noise at 1 m Horizontal from Centerline of Exhaust Pipe Outlet Upwards at 45 ..................................... dBA

STANDBY POWER

60 hz

Governed Engine Speed ............................................................. rpm

Engine Idle Speed........................................................................ rpm

Gross Engine Power Output................................................. hp (kW)

Brake Mean Effective Pressure........................................... psi (kPa)

Piston Speed .................................................................... ft/min (m/s)

Friction Horsepower............................................................ HP (kW)

Engine Water Flow at Stated Friction Head External to Engine:

1 psi Friction Head............................................. US gpm (litre/s)

Maximum Friction Head .................................... US gpm (litre/s)

1800

700 - 900

80

(60)

177 (1220)

1359

(6.9)

8.8

(6.6)

22

14

N.A.

N.A.

60 hz

1500

700 - 900

68

(51)

180 (1241)

1133

(5.8)

6.0

(4.5)

19

12

0.25

PRIME POWER

50 hz

(1.4)

(0.9)

+/-

(1.2)

(0.8)

1800

700 - 900

72

(54)

159 (1096)

1359

(6.9)

8.8

(6.6)

22

14

(1.4)

(0.9)

50 hz

1500

700 - 900

62

(46)

165 (1137)

1133

(5.8)

6.0

(4.5)

19

12

(1.2)

(0.8)

Engine Data

Intake Air Flow.................................................................. cfm (litre/s)

Exhaust Gas Temperature ..................................................... F (C)

Exhaust Gas Flow............................................................ cfm (litre/s)

Air to Fuel Ratio..................................................................... air : fuel

Radiated Heat to Ambient .......................................... BTU/min (kW)

Heat Rejection to Coolant........................................... BTU/min (kW)

Heat Rejection to Exhaust .......................................... BTU/min (kW)

139

1090

420

(65)

(588)

(198)

20 : 1

841

(14.8)

2181

(38.3)

2858

(50.3)

107

(51)

1111

(599)

330 (156.)

19 : 1

851

(15)

1717 (30.2)

2270 (39.9)

131

(62)

1014

(546)

375

(177)

22 : 1

733

(12.9)

1858

(32.7)

2472

(43.5)

102

(48)

1034

(557)

298

(141)

21 : 1

684 (12.0)

1534 (27.0)

1983 (34.9)

N.A. - Not Available

N/A - Not Applicable to this Engine

TBD - To Be Determined

Cummins Inc.

Columbus, Indiana 47202-3005

ENGINE MODEL :

DATA SHEET :

DATE :

CURVE NO. :

4BT3.3-G3

DS-30233

13May08

FR-30233

NEWAGE INTERNATIONAL LIMITED

PO BOX 17, Barnack Road, Stamford, Lincolnshire PE9 2NB, England.

Telephone 44 (0) 1780 484000

Telex 32268 Cables Newage Stamford Fax 44 (0) 1780 484100

Vous aimerez peut-être aussi

- 600 KWDocument13 pages600 KWmoussaPas encore d'évaluation

- Curvas de Potencia DetroitDocument2 pagesCurvas de Potencia Detroitdetroitpnt83% (6)

- fr6672 QSK78-G7Document4 pagesfr6672 QSK78-G7acere18Pas encore d'évaluation

- C9Document5 pagesC9Juan Carlos Latorre BozaPas encore d'évaluation

- 30kw PDFDocument19 pages30kw PDFAlex TrinidadPas encore d'évaluation

- Motor DetroitDocument2 pagesMotor DetroitDanny Wilson Quiza Paye95% (19)

- Geh275-4 LSHF0172-01Document4 pagesGeh275-4 LSHF0172-01Tomas Leon Julia100% (1)

- Grupo Electrogeno GEP200Document4 pagesGrupo Electrogeno GEP200Freddy GodinoPas encore d'évaluation

- Geh220-2 - Cat Olympian PDFDocument4 pagesGeh220-2 - Cat Olympian PDFWillian MazaPas encore d'évaluation

- Planta Electrica Olympian GEP65-9Document4 pagesPlanta Electrica Olympian GEP65-9rei100% (1)

- NTA855 G3 EspañolDocument4 pagesNTA855 G3 EspañolRichard De La Peña100% (1)

- Serie 60 DatasheetDocument2 pagesSerie 60 DatasheetOscar Lomas80% (10)

- Curvas de Motor Caterpillar C15Document5 pagesCurvas de Motor Caterpillar C15Tomas Escalera100% (1)

- DS2 C1000D6Document3 pagesDS2 C1000D6Elvis Martinez CantaroPas encore d'évaluation

- MP 135Document1 pageMP 135Marco EcheverríaPas encore d'évaluation

- TR1, 2 y 3 de La SerieDocument4 pagesTR1, 2 y 3 de La SerieLuis Miguel PérezPas encore d'évaluation

- Maquinaria municipalDocument8 pagesMaquinaria municipalalfredo minayaPas encore d'évaluation

- Ficha TecnicaDocument4 pagesFicha TecnicaMarcos CnPas encore d'évaluation

- C350D6 SP Rev01 PDFDocument2 pagesC350D6 SP Rev01 PDFElvisor VisorPas encore d'évaluation

- 185 KWDocument12 pages185 KWEthan KhorPas encore d'évaluation

- Hoja Especificacion 3412 750 Hp271Document4 pagesHoja Especificacion 3412 750 Hp271Miguel Samaniego GPas encore d'évaluation

- C50 D6 - SP - Rev04Document2 pagesC50 D6 - SP - Rev04asuhuane100% (1)

- DS640 Catalogo GeneradorDocument6 pagesDS640 Catalogo GeneradorabenitechPas encore d'évaluation

- Volvo TAD734Document10 pagesVolvo TAD734bassouadPas encore d'évaluation

- Ficha TecnicaDocument6 pagesFicha Tecnicalcsandovalr989Pas encore d'évaluation

- Motores ElectricosDocument29 pagesMotores ElectricosEli Parra50% (4)

- Ficha Tecnicca Grupo Electrogeno P165e1 PDFDocument4 pagesFicha Tecnicca Grupo Electrogeno P165e1 PDFemiliojelvesPas encore d'évaluation

- Caterpillar c7 AcertDocument5 pagesCaterpillar c7 Acertanon_993776485100% (1)

- MOTOR D20 Ciclo ElectromecanicoDocument124 pagesMOTOR D20 Ciclo ElectromecanicoOvidio Rios100% (4)

- Generador P22-4Document4 pagesGenerador P22-4Rojo ArrebolPas encore d'évaluation

- Gep 110-2 PDFDocument4 pagesGep 110-2 PDFLEO100% (1)

- Manual CarretillaDocument4 pagesManual CarretillaStreeTSpoiLPas encore d'évaluation

- 6081af001 - Ind - 250hp Motor Jhon DeereDocument2 pages6081af001 - Ind - 250hp Motor Jhon DeereJorge Reyes Aguilar50% (2)

- 450 KWDocument12 pages450 KWErick VenegasPas encore d'évaluation

- Motor Intraborda en Base Mitsubishi SM-105Document2 pagesMotor Intraborda en Base Mitsubishi SM-105Mike Alex Herrera DomínguezPas encore d'évaluation

- Geh220 2Document4 pagesGeh220 2yadiramperaltamPas encore d'évaluation

- Cat c15 AcertDocument5 pagesCat c15 AcertRuben Marin67% (3)

- MOTORES ELÉCTRICOS (Autoguardado)Document38 pagesMOTORES ELÉCTRICOS (Autoguardado)Miguel Villanueva MarquezPas encore d'évaluation

- Ac 750Document8 pagesAc 750DarmerPas encore d'évaluation

- Programa Tractor Massey FergusonDocument102 pagesPrograma Tractor Massey FergusonEnrique Vasquez GzPas encore d'évaluation

- Mge-500a 500kw AutomaticaDocument5 pagesMge-500a 500kw AutomaticaJohn MartinezPas encore d'évaluation

- MTU 1200 KW Serie 18V2000: Tabla de PotenciasDocument2 pagesMTU 1200 KW Serie 18V2000: Tabla de PotenciasPablo NuñezPas encore d'évaluation

- 100 KWDocument12 pages100 KWElsad HuseynovPas encore d'évaluation

- Calculo de Protecciones de MotoresDocument22 pagesCalculo de Protecciones de Motoresalfredo_1313Pas encore d'évaluation

- QSC8 3 Hoja EspecDocument2 pagesQSC8 3 Hoja EspecDelvis QuesadaPas encore d'évaluation

- Tractor Komatsu D155ax-6 Japan Spanish PDFDocument6 pagesTractor Komatsu D155ax-6 Japan Spanish PDFAlvaro RamirezPas encore d'évaluation

- Ficha Técnica WPG1100L7Document3 pagesFicha Técnica WPG1100L7freddyguzman3471Pas encore d'évaluation

- Grupo GE - 700 KWDocument1 pageGrupo GE - 700 KWjgiraolewisPas encore d'évaluation

- Especificaciones Tecnicas Generador OLYMPIAN GEH220-2Document4 pagesEspecificaciones Tecnicas Generador OLYMPIAN GEH220-2Alex Alfonso25% (4)

- C400D6 SP PDFDocument2 pagesC400D6 SP PDFJose Alberto IzquielPas encore d'évaluation

- Catalogo Motor Isx400st2 Cummins Desempeno Especificaciones Tecnicas Tecnologia Aplicaciones Cambios PDFDocument1 pageCatalogo Motor Isx400st2 Cummins Desempeno Especificaciones Tecnicas Tecnologia Aplicaciones Cambios PDFWalter A Gómez de la CruzPas encore d'évaluation

- QSB5 9 Hoja EspecDocument2 pagesQSB5 9 Hoja EspecJoséPas encore d'évaluation

- LP Surrey 002-2014Document31 pagesLP Surrey 002-2014Jonathan NathanojPas encore d'évaluation

- Gegroup Cummins Cud66Document3 pagesGegroup Cummins Cud66Kape LuzPas encore d'évaluation

- UF1217 - Mantenimiento de sistemas auxiliares del motor de ciclo dieselD'EverandUF1217 - Mantenimiento de sistemas auxiliares del motor de ciclo dieselÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Mantenimiento de sistemas auxiliares del motor de ciclo diésel. TMVG0409D'EverandMantenimiento de sistemas auxiliares del motor de ciclo diésel. TMVG0409Évaluation : 5 sur 5 étoiles5/5 (7)

- Ingeniería de la energía eólicaD'EverandIngeniería de la energía eólicaÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Mantenimiento del sistema de arranque del motor del vehículo. TMVG0209D'EverandMantenimiento del sistema de arranque del motor del vehículo. TMVG0209Évaluation : 5 sur 5 étoiles5/5 (2)

- Mantenimiento, preparación y manejo de tractores. AGAC0108D'EverandMantenimiento, preparación y manejo de tractores. AGAC0108Pas encore d'évaluation

- UF1214 - Mantenimiento de motores térmicos de dos y cuatro tiemposD'EverandUF1214 - Mantenimiento de motores térmicos de dos y cuatro tiemposÉvaluation : 5 sur 5 étoiles5/5 (1)

- Bomba AdecomDocument3 pagesBomba AdecomSpectrumRaijinPas encore d'évaluation

- Procedimiento para El Correcto Manejo de Los Residuos PeligrososDocument12 pagesProcedimiento para El Correcto Manejo de Los Residuos PeligrososEnrique SepulvedaPas encore d'évaluation

- 4BTA3.9G: Poshsemco de Mexico Atención: Ing. Víctor ReyesDocument3 pages4BTA3.9G: Poshsemco de Mexico Atención: Ing. Víctor ReyesSpectrumRaijinPas encore d'évaluation

- Manual Aceite Motor Maquinaria Pesada KomatsuDocument24 pagesManual Aceite Motor Maquinaria Pesada Komatsuvivac9100% (1)

- 10 - TMM-PH-009 Procedimiento para Realizar Prueba Hidrostatica A Valvulas de RetencionDocument17 pages10 - TMM-PH-009 Procedimiento para Realizar Prueba Hidrostatica A Valvulas de RetencionSpectrumRaijinPas encore d'évaluation

- Logistica Olmeca Unidad 10Document10 pagesLogistica Olmeca Unidad 10SpectrumRaijinPas encore d'évaluation

- Bomba de Aceite ISBDocument38 pagesBomba de Aceite ISBSpectrumRaijin100% (1)

- Cortadora NB30Document6 pagesCortadora NB30SpectrumRaijinPas encore d'évaluation

- Plantilla de Excel para Mantenimiento de VehiculosDocument4 pagesPlantilla de Excel para Mantenimiento de VehiculosRodolfo BaccagliniPas encore d'évaluation

- Inyector ISBDocument57 pagesInyector ISBSpectrumRaijinPas encore d'évaluation

- Terceras Vueltas 4 y 6Document4 pagesTerceras Vueltas 4 y 6SpectrumRaijinPas encore d'évaluation

- Explosion de Material 855Document18 pagesExplosion de Material 855SpectrumRaijinPas encore d'évaluation

- Cat electrónicos controlDocument166 pagesCat electrónicos controlSpectrumRaijinPas encore d'évaluation

- Garantias ExtendidasDocument10 pagesGarantias ExtendidasSpectrumRaijinPas encore d'évaluation

- Lucha ContraincendiosDocument55 pagesLucha Contraincendiosalaska234Pas encore d'évaluation

- Dse5220 ManualDocument58 pagesDse5220 Manualolmcorpinsa86% (7)

- P.A. AvanzadoDocument79 pagesP.A. AvanzadoSpectrumRaijinPas encore d'évaluation

- Manual Generación BásicaDocument149 pagesManual Generación BásicaSpectrumRaijinPas encore d'évaluation

- Manual Del Participante Basico de Seguridad en Plataformas y BarcazasDocument68 pagesManual Del Participante Basico de Seguridad en Plataformas y BarcazasSpectrumRaijin50% (2)

- H2S Vior P.ADocument12 pagesH2S Vior P.ASpectrumRaijinPas encore d'évaluation

- Excitación Del Campo Del AlternadorDocument3 pagesExcitación Del Campo Del AlternadorSpectrumRaijinPas encore d'évaluation

- Reparacion de ArnesesDocument26 pagesReparacion de ArnesesSpectrumRaijin67% (3)

- Orden de Encendido Motores Kta 38 Kta 50Document1 pageOrden de Encendido Motores Kta 38 Kta 50SpectrumRaijinPas encore d'évaluation

- Prueba alternador 40VDocument5 pagesPrueba alternador 40VSpectrumRaijinPas encore d'évaluation

- Combustión BásicaDocument64 pagesCombustión BásicaSpectrumRaijin100% (1)

- Sistema de Avance de Tiempo STCDocument16 pagesSistema de Avance de Tiempo STCSpectrumRaijin100% (14)

- Alter NadorDocument10 pagesAlter NadorSpectrumRaijinPas encore d'évaluation

- Tiempo de InjecciónDocument1 pageTiempo de InjecciónSpectrumRaijinPas encore d'évaluation

- Teoria y Operación Del Sistema de Combustible PTDocument22 pagesTeoria y Operación Del Sistema de Combustible PTSpectrumRaijinPas encore d'évaluation

- COSTUMBRES CAÑARISDocument1 pageCOSTUMBRES CAÑARISSara JimenezPas encore d'évaluation

- Pa MV 2019 08 001 1 PDFDocument780 pagesPa MV 2019 08 001 1 PDFsirpitorcasPas encore d'évaluation

- Diplomado de Energia SolarDocument67 pagesDiplomado de Energia SolarCrissPas encore d'évaluation

- Monografia para Optar Al Titulo De: Cirujano DentistaDocument69 pagesMonografia para Optar Al Titulo De: Cirujano DentistaLlanos A. AlexisPas encore d'évaluation

- Naomi Lucas - Serie Cyborg Shifters 01 - Wild BloodDocument192 pagesNaomi Lucas - Serie Cyborg Shifters 01 - Wild BloodCristina Tamayo RuizPas encore d'évaluation

- La Misoginia A Través de La Narrativa Feminista de Fernanda Melchor en Temporada de HuracanesDocument7 pagesLa Misoginia A Través de La Narrativa Feminista de Fernanda Melchor en Temporada de HuracanesDaniela Otero OteroPas encore d'évaluation

- Clase #8 - Transfusiones en Cirugia (Dr. Burgos)Document35 pagesClase #8 - Transfusiones en Cirugia (Dr. Burgos)Ana Luisa Tacanga RodriguezPas encore d'évaluation

- ETS y sus causasDocument5 pagesETS y sus causasAnonymous etW8Yv3S1Pas encore d'évaluation

- Hospitales de Guatemala ListadoDocument2 pagesHospitales de Guatemala Listadoluli76Pas encore d'évaluation

- 1315 Retardador Funcionamiento Retardador FuncionamientoDocument1 page1315 Retardador Funcionamiento Retardador FuncionamientoLuis Arturo Castro San MartinPas encore d'évaluation

- Proyecto de InvestigaciónDocument60 pagesProyecto de InvestigaciónSara GacharnáPas encore d'évaluation

- Módulo 8. Discapacidad Intelectual. Taller Elaboración de Material Didáctico Inclusivo. Tallerista Gpe. Mendoza Ortiz Folio EAE202-15838.Document8 pagesMódulo 8. Discapacidad Intelectual. Taller Elaboración de Material Didáctico Inclusivo. Tallerista Gpe. Mendoza Ortiz Folio EAE202-15838.CECILIA ESTRADA TORRESPas encore d'évaluation

- Rol de Ingreso Oficial Xxxi Entrada Folklorica Universitaria 2018 PDFDocument5 pagesRol de Ingreso Oficial Xxxi Entrada Folklorica Universitaria 2018 PDFdanieljuanPas encore d'évaluation

- Examen Final de Procesamiento Digital de SeñalesDocument25 pagesExamen Final de Procesamiento Digital de SeñalesAndreeGarciaRuaPas encore d'évaluation

- Auditoria Comedor Segun NOM 251Document3 pagesAuditoria Comedor Segun NOM 251Adrián 63100% (1)

- Programa de Prevención y Promoción de La Desnutrición InfantilDocument30 pagesPrograma de Prevención y Promoción de La Desnutrición InfantilAlexia Coronado Cabrera100% (1)

- Migración Dental Fisiológica y Su Importancia para El Desarrollo de La OculusiónDocument9 pagesMigración Dental Fisiológica y Su Importancia para El Desarrollo de La OculusiónLiceth Herrera MartinezPas encore d'évaluation

- 1 Evaluar Condiciones de Operación Minera de Acuerdo Con Normativa de Seguridad en Labores SubterráneasDocument4 pages1 Evaluar Condiciones de Operación Minera de Acuerdo Con Normativa de Seguridad en Labores SubterráneasDidier AlejandroPas encore d'évaluation

- Identificacion de Riesgos en La Mineria....Document14 pagesIdentificacion de Riesgos en La Mineria....SEGUNDO SENENCIO GARCIA DOMINGUEZPas encore d'évaluation

- Nutricion Clinica InfoDocument13 pagesNutricion Clinica InfoBeto NayaPas encore d'évaluation

- Complicaciones y Tratamiento HTADocument12 pagesComplicaciones y Tratamiento HTAGregory Leon100% (1)

- Ciclo Del AzufreDocument3 pagesCiclo Del AzufreMiry Liz Lectong Anchundia67% (3)

- Química II Manual Del AlumnoDocument93 pagesQuímica II Manual Del AlumnoJose Lopez PerezPas encore d'évaluation

- Marco Teorico VacunasDocument75 pagesMarco Teorico VacunasESTELA ARIAS NAYELI MERIAN100% (1)

- Propagacion Por Yema AxilarDocument2 pagesPropagacion Por Yema AxilarJavier RamirezPas encore d'évaluation

- Manual Prevencion de Riesgos LaboralesDocument10 pagesManual Prevencion de Riesgos LaboralesOlga Lucía Gallego LoaizaPas encore d'évaluation

- Tartalimon6raciones69euroDocument3 pagesTartalimon6raciones69euroMarta Velasco Lozano0% (1)

- Img 20230117 0005Document2 pagesImg 20230117 0005rodolfo riosPas encore d'évaluation

- Actividad de Aprendizaje II EJERCICIO TECNICAS DE CONTABILIDADDocument3 pagesActividad de Aprendizaje II EJERCICIO TECNICAS DE CONTABILIDADYAMIL RODRIGUEZPas encore d'évaluation

- ¿Por Qué Dios Permite El Sufrimiento?Document27 pages¿Por Qué Dios Permite El Sufrimiento?United Church of God88% (8)