Académique Documents

Professionnel Documents

Culture Documents

2-New Completion Technology4

Transféré par

klibiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2-New Completion Technology4

Transféré par

klibiDroits d'auteur :

Formats disponibles

1

SPE 113563

SPE 113563

New Completion Technology As A Catalyst to Improve Oil Recovery

Salem El-Abd, SPE, Abdel Hameed Amiri, SPE, Ashraf Keshka, SPE, Salem Al-Bakr, SPE, Saif Al Arfi, SPE (ADCO),

Magdi El-Asmar, SPE (Baker Oil Tools)

Copyright 2008, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the 2008 SPE Indian Oil & Gas Technical

Conference and Exhibition scheduled 4-6 March 2008 in Mumbai, India

This paper was selected for presentation by an SPE Program Committee following review of

information contained in a proposal submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300

words; illustrations may not be copied. The proposal must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

This paper presents the reservoir considerations,

implementation and results of a new completion technology

with the aim to improve ultimate recovery. The non-uniform

production profile across the horizontal hole especially in the

highly heterogeneous and fractured reservoirs can result in

premature water production and lower ultimate recovery. PLT

surveys were carried out in some horizontal wells which

indicated non-uniform production profile across the horizontal

holes. Therefore the need for production system as part of the

completion was raised to control water production and to

improve ultimate recovery. This completion technique will the

low and high permeability intervals to contribute to flow was

found to be the optimum option for this highly heterogeneous

and fractured reservoir.

Horizontal hole segmentation using ICD (Inflow Control

Device) completion was found to be the optimum option to be

tested as pilot in a new and an existing wells. The new well

was expected to penetrate highly fractured area and the

existing well is also located in highly fractured area.

The ICD Equalizer system was installed in both wells to

evaluate the technique. The surface testing results of the recompleted well indicated a drop in the well water cut from 7%

to traces. PLT survey was carried out in both wells and

indicated uniform production profile across the horizontal

section. Therefore the reliability of the technique was proved

and these jobs were considered as the first application in

United Arab Emirates. With field scale implementation, the

reservoir simulation and economic analysis revealed an

improved oil recovery of 1% and higher NPV.

Introduction

This paper presents the reservoir considerations,

implementation and results of the new completion technology

to improve ultimate recovery of an oil field in the United Arab

Emirates.

Horizontal well technology has become an established method

of drilling conventional wells due to their improved recovery

efficiency, reservoir drainage and delayed undesirable fluids

(water & gas). However non-uniform production profile across

the horizontal hole especially in the highly heterogeneous and

fractured reservoirs can result in premature water production.

This may cause bypassed oil, lower ultimate recovery and

therefore decrease in profitability.

The main characteristic of this reservoir is the presence of a

complex fracture network within the highly heterogeneous

matrix system. Both matrix and fracture systems play an

important role in the production mechanism of the reservoir.

Additionally, the reservoir is characterized by the presence of

Sucrosic Dolomite rock (mainly in the South part of the

middle reservoir unit) that significantly enhances matrix

permeability further. Matrix permeability ranges from 0.01

mD to 12 Darcy with the average in excess of 100 mD. The

fractures are described as fracture corridor system (or fracture

swarms) that show two major trends, namely N40E and

N70E. Fracture swarms/sub-seismic faults are structural

features extending laterally over several hundreds meters and

sometimes over several kilometers (Figure 1).

With water movement towards well-bore, sweep efficiency is

affected and recoverable oil is impacted. This progress in well

water cut and consequently fields water production increase

will cause loss of production and reserves.

The shortening of well life cycle is directly linked to the wells

water production and its source. In this field, once the well

water cut reaches 50%, the constrained well production rate of

2,000 stb/d will no longer be maintained and the well has to be

workedover or new wells to be drilled to be able to sustain the

field production capacity. Therefore the need for a production

system as part of completion strategy was raised with the aim

to improve production efficiency.

SPE 113563

Business Case

A multidisciplinary team was formed to investigate possible

techno-economical solution to the described problem of nonuniform production profile and water progress across the

horizontal sections. The following elements comprise the

business case and findings:

Reservoir Consideration & Business Need

The formation, which is the pay zone in this Field, is a

complex fractured carbonate reservoir exhibiting considerable

lateral and vertical lithological changes and consequently

variations of reservoir characteristics. Both matrix and fracture

systems play an important role in the production mechanism

of the reservoir. The reservoir is subdivided into three

reservoir units namely Unit Unit1, Unit2 and Unit3

(Figure 2).

At the early stage of the development of the field, the

significance of fractures in this reservoir was not recognized.

However, the latest fracture study which was carried out by

integrating all available data FMS/ FMI, Cores, Seismic and

production data revealed that this reservoir is moderately to

highly fractured reservoir. The fracture network is composed

of fracture-swarm zones. The width of such zones ranges

between 50 to 100m. The fracture swarms are oriented in two

main directions: N40E and N70E. No diffuse fracturing can

be characterized. This means that this reservoir is weekly

fractured between the fracture-swarms zones.

PLT surveys were carried out in some horizontal wells and all

of them indicated non-uniform production profile across the

horizontal holes. The following are the results of the

horizontal PLT surveys in some wells:

production rates from this short interval, the sharp

increase in temperature and the increase in Gamma ray

are due to the presence of large fracture as supported by

the fracture study (Figure 6).

A PLT survey was carried out in Well C, to determine

the production profile across the horizontal hole and to

measure the base sigma log for saturation monitoring.

Although this well is located in an area which considered

homogeneous, the PLT results (Figure 7) indicated that

the first half of the horizontal section is contributing all

production and the second half of the hole is contributing

nothing.

Based on the above PLT results, the need for a completion

technique to achieve uniform production profiles across the

horizontal holes was raised with the aim to improve the

reservoir sweep efficiency, achieve longer production plateau

of the wells by controlling the rate of water cut development

and consequently increasing the overall field ultimate

recovery.

Technical Options & Alternatives

Water shutoff techniques such as mechanical and chemical

were investigated and it was found that both techniques were

considered to be inefficient in the highly fractured reservoirs.

The technique of controlling the flow and establishing uniform

production profile across the horizontal hole will allow the

low and high permeability (fractures) intervals to contribute to

flow. Using ICD (Inflow Control Device) was found to be the

optimum option to be tested as a pilot in a new well (Well D).

Based on the latest fracture study, this new well is expected to

be drilled in a highly fractured area especially the second half

of the horizontal section (Figure 8).

A PLT survey was carried out in Well A to determine

the oil and water production profiles of the horizontal

open hole section, to define the produced water entry

points and to measure the base sigma log for saturation

monitoring. The well is located in a highly fractured area

as presented in Figure 3. The results of the survey

(Figure 4) indicated non-uniform production profile

across the horizontal section and most of the oil and

water producing intervals are in line with the fracture

study. The water cut reaches some 50% in this well and

it was planned to be horizontalized into another direction

but after the completion was retrieved, the casing

corrosion log indicated that the casing is severely

corroded. Therefore the well was plugged and

abandoned and a replacement well was drilled.

Market survey & Technique Evaluation

Through market survey different vendors were invited to

introduce their technologies and it was found that three

technologies have similar functionality and can provide in

theory the required effect on well-bore uniform production

profile. The technique of controlling the flow and establish

uniform production profile across the horizontal hole which

allow the low and high permeability (fractures) intervals to

contribute to flow was found to be the optimum option for this

highly fractured reservoir. The following were considered in

the technique evaluation:

Features, Benefits & Applications

Technical Specifications & Testing

Risk Assessment & Mitigation

Case Histories, Success Ratio & Experience Sharing

A PLT survey was carried out in Well B, to determine

the oil and water production profiles of the horizontal

open hole section, to define the produced water entry

points and to measure the base sigma log for saturation

monitoring. The results of the survey (Figure 5)

indicated that a short interval of some 40 ft is

contributing 70% of the total oil production and some

80% of the water production. The high oil and water

Techno - Economic Assessment

Reservoir simulation runs (using the existing Eclipse model)

were carried out to evaluate the benefits of installing the

Equalizer system in the new well (Well D) which was planned

to be drilled in November 2006. The results indicated an

incremental oil of 1.4 MMstb over the well life can be

achieved by running the Equalizer system compared with

barefoot completion. Moreover, to evaluate the impact of

SPE 113563

installing the Equalizer system on field scale implementation,

it was assumed that the Equalizer system will be installed in

70% of the planned future wells which are expected to

penetrate fractures. The results indicated an incremental oil

recovery of some 36 MMstb, which represent 1% of the

original oil in-place, can be achieved by running the Equalizer

system compared with barefoot completion. Moreover,

NetTool simulation runs were carried out to determine the

required number of ICDs to achieve uniform production

profile.

In February 2007, well D was drilled and completed as a

Unit 2 single lateral horizontal oil producer with 2,000

horizontal hole. Inflow Control Devices (ICD) with Mpas

packers were installed (11 ICDs and 11 MPas Packers) in

the horizontal section with the aim to achieve uniform

production profile along the horizontal section and reduce

water production. The well was completed with 3

single completion string equipped with ESP and Y-tool.

The final down hole completion string is presented in

Figure 9. The well was tied-in to the production station

and started production in March 2007. The initial testing

results indicated that the well produced some 2,100 stb/d

of dry oil. A PLT survey was carried out to confirm the

reliability of the technique in achieving uniform

production profile across the horizontal hole. The PLT

interpretation indicated uniform production profile across

the horizontal section (Figure 10).

In April 2007, the ESP failed in well B due to short circuit

in the downhole string after 9 years since commissioning.

In May 2007, the well was worked over to replace the

ESP. NetTool simulation runs (Figure 11) were carried

out to determine the optimum number of ICDs and MPas

packers to be installed. Based on these runs, 11 ICDs and

5 MPas Packers were recommended to be installed to

achieve better production profile compared with the open

hole completion. During the workover the opportunity

was taken and a new completion string using Inflow

Control Device (ICD) in the horizontal section was

installed to achieve better production profile along the

horizontal section and reduce water production. The final

down hole completion string is presented in Figure 12.

The well was tied-in and produced some 2,500 stb/d with

traces of water cut compared to some 7% water cut before

workover. A PLT survey was carried out with 2 different

production rates (2,000 and 3,000 stb/d) to evaluate the

impact of the ICD on the well performance in case of

high production rates. The PLT interpretation (Figure 13)

indicated uniform production profile across the horizontal

hole with ICD completion compared with the one with

barefoot completion which was carried out in 2002.

Moreover, the comparison between the production

profiles at different production rates showed minor

change of the well performance in the presence of ICD

completion. The PLT results are inline with the NetTool

simulation results.

In order to justify the expenditure associated with the

Equalizer (ICD), a detailed economic analysis was carried out

based on the planned well production forecasts using ADCOs

economic guidelines. The case with Equalizer was compared

to the barefoot completion case on a single well model and the

economics calculations indicated the following incremental

economics indicators:

NPV @ 8 % Discount Rate

UTC @ 8 % Discount Rate

PIR @ 8 % Discount Rate

Incremental Oil

:

:

:

:

1.9 Million $

4.4 $/bbl

4

1.4 MMstb

For field wide implementation, it was assumed that the ICD

will be installed in 70% of the planned future wells as issued

in the Full Field Development Plan. The economics

calculations indicated the following incremental economics

indicators:

NPV @ 8 % Discount Rate

UTC @ 8 % Discount Rate

PIR @ 8 % Discount Rate

Incremental Oil

:

:

:

:

43.9 Million $

2.9 $/bbl

6.7

36.3 MMstb

Operational feasibility

The operational procedures were discussed within a

multidisciplinary team and it was decided to run an image log

in well D prior to the ICD completion to assist in defining the

required number and locations of ICDs & MPas packers for

the purpose of achieving uniform production profile and

controlling water progress. Based on the reservoir model

permeability profile, the original design was to run 10 ICDs

and 9 MPas packers with possibility to reduce it as deemed

necessary. Moreover, testing procedures and the involved risks

along with its mitigations were also discussed to ensure proper

implementation and safety precautions are met in accordance

to industry standards.

Technique Implementation & Evaluation

Horizontal hole segmentation using ICD (Inflow Control

Device) completion was found to be the optimum option to be

tested as pilot in a new and an existing wells. The new well

was expected to penetrate highly fractured area and the

existing well is also located in highly fractured area. The

implementation and evaluation of the ICD completion are

discussed below:

The results from the two ICD completions were positive, as

the PLT results indicated better inflow profile compared to the

existing openhole completions. Both wells (Well B & D) have

been considered as an economic success and will recover the

targeted oil reserves. The installations of the ICD completions

were successfully implemented in both wells as a result of

proper well planning and wellbore cleaning.

Field-Scale Implementation

The Full Field Development plan is driven by optimizing

ultimate recovery while maintaining / developing sustainable

production capacity throughout longer production plateau

SPE 113563

length.

A

comprehensive

techno-economical

field

development plan covering the optimum development scheme

considered the application of ICD as part of enhancing

production efficiency. Different development options were

studied along with the impact of ICD on sweep efficiency and

in-fill drilling program. The main conclusion from this work

was that the application of ICD helps improving the field

economics by optimizing ultimate recovery and can assist in

optimizing the future development drilling & workover

program.

Nomenclature

ICD

PLT

NPV

UTC

PIR

ESP

STB

=

=

=

=

=

=

=

Inflow Control Device

Production Logging Tool

Net Present Value

Unit Technical Cost

Profit Investment Ratio

Electrical Submersible Pump

Stock Tank Barrel

N 70E

Figure 1 Fracture Maps Shown the Two Main

Directions (N40E and N70E)

Reservoir Units

UPPER

Reservoir

MEMBERS

LOWER Reservoir

Conclusions & Recommendations

1. The reliability of the ICD completion to achieve uniform

production profile across the horizontal section was

proved, as both wells showed uniform and better inflow

profile compared to the existing open hole conventional

completions.

2. These jobs were the first application of this technique in

United Arab Emirates (UAE).

3. The simulation results are inline with the PLT results.

4. The installations of the ICD completions were

successfully implemented in both wells as a result of

proper well planning and wellbore cleaning.

5. The ICD technique proved effective in minimizing well

water cut as indicated by the PLT (Well B). The latest

well test results showed traces of water production

(almost one year since the installation of the ICD

completion).

6. It is recommended to install the ICD completion in some

70% of the future wells (35 wells). This will improve the

field ultimate recovery by 1% (36 MMstb).

N 40E

RESERVOIR

UNIT

Unit1

Unit2

Unit3

Figure 2

Reservoir Units

Figure 3

Well A Location on the fracture map

Acknowledgement

We wish to thank ADNOC for giving the permission to

publish the result of this field case. Also, we are grateful for

continuous support provided by ADCO Management during

the course of the study, from building the business case to

implementation.

References

Jody R. Augustine An Investigation of Economic Benefit on

Inflow Control Devices on Horizontal Well Completions

Using a Reservoir-Wellbore Coupled Model SPE 78293

(October 2002).

SPE 113563

Sy-24PLT/Flagship(ProductionProfile)

Figure 7

Figure 4

Well A PLT Results

Sy-50 Proposed Surface, Landing Point and Bottom Hole Locations

with Respect to Fractures at Simsima R2

Figure 8

Figure 5

Well C PLT Results.

Planned Location of Well D

Well B Location on the fracture map.

Well D

Figure 6

Well B PLT Results

Figure 9

Well D Down hole Completion

SPE 113563

Well D PLT Results, 2007

S

E

q

N

u

u

- 5

a

m

1

Unit 2

Cumulative

Zonal

l i z e r

b e r

( P

D

o

p

l a

t h

Well B

r i s

l c

u

R

l t s

l a t e

a t e

d

b

o i l F

b l / d

7

l o

Figure 12 Well B Down Hole Completion

Well B PLT Results

Figure 10 Well D PLT Results

Rate2, ICD, 2007

Rate1, ICD, 2007

Bare Foot, 2002

3%

1%

8% O ,7 %

W

3%

5 % O ,0 %

W

3%

2%

13%

21%

70 % O ,80 %

W

12%

20%

Figure 11 Well B NetTool Simulation Results

3 % O ,8 % W

21%

3%

3%

2%

2%

15% O ,5%

W

2%

4%

2%

13%

13%

20%

20%

18%

Figure 13 Well B PLT Results Before and after ICD

installation

SPE 113563

21%

Vous aimerez peut-être aussi

- IPTC 16616 A Case Study: Innovative Open Hole Well Completion Provides Superior Results in Tight Gas Formation in Jilin District, ChinaDocument12 pagesIPTC 16616 A Case Study: Innovative Open Hole Well Completion Provides Superior Results in Tight Gas Formation in Jilin District, ChinaAmr HegazyPas encore d'évaluation

- SPE 81443 Rigless Water Shut-Off Experience in Offshore Saudi ArabiaDocument6 pagesSPE 81443 Rigless Water Shut-Off Experience in Offshore Saudi ArabiaJose AntonioPas encore d'évaluation

- Unconventional Shale Gas Development: Lessons LearnedD'EverandUnconventional Shale Gas Development: Lessons LearnedRouzbeh G. MoghanlooPas encore d'évaluation

- SPE/IADC 118806 Use of Liner Drilling Technology As A Solution To Hole Instability and Loss Intervals: A Case Study Offshore IndonesiaDocument13 pagesSPE/IADC 118806 Use of Liner Drilling Technology As A Solution To Hole Instability and Loss Intervals: A Case Study Offshore IndonesiarealzeusPas encore d'évaluation

- Integration of Drilling, Geology and Geophysical Data - Develop. High Res Predill Wellbore Satablility For Ultra Deep Water Kumar2019Document15 pagesIntegration of Drilling, Geology and Geophysical Data - Develop. High Res Predill Wellbore Satablility For Ultra Deep Water Kumar2019Juan P MSPas encore d'évaluation

- Cased Hole Gravelpack CsDocument2 pagesCased Hole Gravelpack CsSanjyogPas encore d'évaluation

- OTC 6041 Gravel Pack in Offshore Wells: by A.N. de Sa, A.F.C. Tavares, and L.C. Do Carmo Marques, Petrobras SADocument10 pagesOTC 6041 Gravel Pack in Offshore Wells: by A.N. de Sa, A.F.C. Tavares, and L.C. Do Carmo Marques, Petrobras SAStephanMarquesPas encore d'évaluation

- HPWBM Exceeds SBMDocument7 pagesHPWBM Exceeds SBMAnonymous JMuM0E5YOPas encore d'évaluation

- Improvements in Horizontal Gravel PackingDocument11 pagesImprovements in Horizontal Gravel PackingzapspazPas encore d'évaluation

- A Case Study of An Efficient and Cost-Saving ICD Completion Design To Manage Production Flow Heterogeneity in Filanovskogo Russia FieldDocument18 pagesA Case Study of An Efficient and Cost-Saving ICD Completion Design To Manage Production Flow Heterogeneity in Filanovskogo Russia FieldSara Kamil Abd Al-RedahPas encore d'évaluation

- Drilling and Completions SandstoneDocument71 pagesDrilling and Completions SandstoneidownloadbooksforstuPas encore d'évaluation

- Completion Challenge PaperDocument7 pagesCompletion Challenge Papergregorio2407Pas encore d'évaluation

- SPE-30 Years of Fracturing ShalesDocument50 pagesSPE-30 Years of Fracturing ShalesPaulo IvoPas encore d'évaluation

- Spe 87896 PaDocument6 pagesSpe 87896 PaThiagoHenriquePas encore d'évaluation

- S2 2015 336441 Chapter1Document15 pagesS2 2015 336441 Chapter1arispriyatmonoPas encore d'évaluation

- SPE 88525 Hybrid Monobore Completion Design: An Application For Multilayer ReservoirDocument6 pagesSPE 88525 Hybrid Monobore Completion Design: An Application For Multilayer ReservoirAhmadFauziPas encore d'évaluation

- SPE-193424-MS Chevron 2018Document17 pagesSPE-193424-MS Chevron 2018LawPas encore d'évaluation

- SPE-169245-MS Overcoming Ultradeepwater Cementing Challenges in The CaribbeanDocument16 pagesSPE-169245-MS Overcoming Ultradeepwater Cementing Challenges in The CaribbeanAhmed Ali AlsubaihPas encore d'évaluation

- Spe 103184 MSDocument7 pagesSpe 103184 MSRamanamurthy PalliPas encore d'évaluation

- Sand ControlDocument3 pagesSand ControlPaolo CavaioniPas encore d'évaluation

- Mexicos Deepest Well Drill String SPE-52822-MSDocument10 pagesMexicos Deepest Well Drill String SPE-52822-MSYaqoob IbrahimPas encore d'évaluation

- Well Integrity Analysis Applied To WorkoDocument8 pagesWell Integrity Analysis Applied To WorkoAdolfo AnguloPas encore d'évaluation

- Hydraulic FracturingDocument3 pagesHydraulic FracturingTarek TarkanPas encore d'évaluation

- IPTC 17668 Installation of Long Interval Conductor String Across Challenging Offshore Drilling EnvironmentDocument17 pagesIPTC 17668 Installation of Long Interval Conductor String Across Challenging Offshore Drilling EnvironmentAnre Thanh HungPas encore d'évaluation

- A New and Practical Model For Amount and Rate of Sand Production Estimation OTC-26508-MSDocument18 pagesA New and Practical Model For Amount and Rate of Sand Production Estimation OTC-26508-MSNik Mohammad FadhlanPas encore d'évaluation

- Well CompletionDocument22 pagesWell CompletionRobot100% (1)

- How Offshore Capping Stacks WorkDocument3 pagesHow Offshore Capping Stacks WorkLaloMendietaPas encore d'évaluation

- BG - Well Integrity HandbookDocument9 pagesBG - Well Integrity Handbookwalter.tajuPas encore d'évaluation

- Ace 2018 Tpra 011618Document100 pagesAce 2018 Tpra 011618BilboPas encore d'évaluation

- Reeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuideDocument5 pagesReeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuidealiPas encore d'évaluation

- SPE-187682-MS Successful Hydraulic Fracturing Techniques in Shallow Unconsolidated Heavy Oil SandstonesDocument6 pagesSPE-187682-MS Successful Hydraulic Fracturing Techniques in Shallow Unconsolidated Heavy Oil SandstonesAndre YudhistiraPas encore d'évaluation

- 03 - CP-Horizontal Wells - Multilaterals VenezuelaDocument90 pages03 - CP-Horizontal Wells - Multilaterals VenezuelaJuan Carlos TaboadaPas encore d'évaluation

- Module 2Document46 pagesModule 2Lhealyn Matibag BantugonPas encore d'évaluation

- SPE-WVS-829: Evolving Technologies in The New Age of Horizontal Drilling in EcuadorDocument28 pagesSPE-WVS-829: Evolving Technologies in The New Age of Horizontal Drilling in Ecuadormiguel freitesPas encore d'évaluation

- Sickwellanalysis 2013Document28 pagesSickwellanalysis 2013mts1234Pas encore d'évaluation

- To Uploadc OCW Well ControlDocument59 pagesTo Uploadc OCW Well ControlMuhammad FauzanPas encore d'évaluation

- SPE-192670-MS Preserving Great Discoveries by Using Non-Damaging Killing Fluid During The Temporary Abandonment of HPHT Exploratory WellsDocument9 pagesSPE-192670-MS Preserving Great Discoveries by Using Non-Damaging Killing Fluid During The Temporary Abandonment of HPHT Exploratory WellsAli mohammadPas encore d'évaluation

- Effective Laboratory Coreflood TestsDocument15 pagesEffective Laboratory Coreflood TestsJj WeetlandPas encore d'évaluation

- Spe 160429 MS P PDFDocument11 pagesSpe 160429 MS P PDFahmalisha2Pas encore d'évaluation

- Well Blueprint: Lost CirculationDocument8 pagesWell Blueprint: Lost CirculationapsekarPas encore d'évaluation

- Well CompletionDocument82 pagesWell CompletionFlorian Ananias ByarugabaPas encore d'évaluation

- M 2 Prosper AideyanDocument32 pagesM 2 Prosper AideyanJorgito AriasPas encore d'évaluation

- Well Production Problems For Libya 10-8-2020Document12 pagesWell Production Problems For Libya 10-8-2020حسين رامي كريم A 12Pas encore d'évaluation

- Low Cost Deep Water Wells - by John Normann Gundersen - 2Document105 pagesLow Cost Deep Water Wells - by John Normann Gundersen - 2Amir O. Osho100% (1)

- 04-Well Planning PDFDocument22 pages04-Well Planning PDFemekePas encore d'évaluation

- Section08 - Drilling Deviated HoleDocument28 pagesSection08 - Drilling Deviated HoleMohamed ElshoraPas encore d'évaluation

- 04b Anti CollisionDocument30 pages04b Anti CollisionAli BoubeniaPas encore d'évaluation

- Tubular Designer Rule SetDocument28 pagesTubular Designer Rule SetSudish BhatPas encore d'évaluation

- SPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyDocument14 pagesSPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyErika Daniela ReyesPas encore d'évaluation

- Evolving Khuff FormationsDocument11 pagesEvolving Khuff FormationsrajkumarfPas encore d'évaluation

- SPE-65140-MS Open Hole Sand CompletionDocument19 pagesSPE-65140-MS Open Hole Sand CompletionLawPas encore d'évaluation

- Well Completion: Conventional Single Zone CompletionDocument18 pagesWell Completion: Conventional Single Zone CompletionChristian WelshPas encore d'évaluation

- Bit SelectionDocument19 pagesBit SelectionFernando AybarPas encore d'évaluation

- 2.8.a Frac-Packing FluidsDocument35 pages2.8.a Frac-Packing FluidsBrenda Ortiz SolizPas encore d'évaluation

- SPE 130768 Multi-Field Asset Integrated Optimization BenchmarkDocument19 pagesSPE 130768 Multi-Field Asset Integrated Optimization BenchmarkIndo UtamaPas encore d'évaluation

- Spe 49165 MSDocument16 pagesSpe 49165 MSamramazon88Pas encore d'évaluation

- Regaining Sand Control: Ricky J. Armentor Michael R. WiseDocument10 pagesRegaining Sand Control: Ricky J. Armentor Michael R. WiseChristian PintoPas encore d'évaluation

- SPE 124121 Salt Drilling While Underreaming Behaviors Illuminated by Distributed Downhole MeasurementsDocument14 pagesSPE 124121 Salt Drilling While Underreaming Behaviors Illuminated by Distributed Downhole MeasurementsDamir986Pas encore d'évaluation

- Drilling FluidsDocument20 pagesDrilling Fluidsdekra abdo100% (1)

- Gas Flaring Reduction StrategyDocument30 pagesGas Flaring Reduction StrategyklibiPas encore d'évaluation

- Oudna Operation Risk AssessmentDocument9 pagesOudna Operation Risk AssessmentklibiPas encore d'évaluation

- MCBURiggingStandard PDFDocument79 pagesMCBURiggingStandard PDFJean David ChanPas encore d'évaluation

- Lifting PlanDocument66 pagesLifting Planklibi100% (6)

- Operation and Maintenance Cost EstimatorDocument50 pagesOperation and Maintenance Cost Estimatorklibi100% (1)

- Management System Auditing CriteriaDocument8 pagesManagement System Auditing CriteriaklibiPas encore d'évaluation

- Manual Shore Assess Aug2013Document154 pagesManual Shore Assess Aug2013klibiPas encore d'évaluation

- Cost Estimate HDBK 2005Document262 pagesCost Estimate HDBK 2005klibi100% (2)

- River Management PlanDocument185 pagesRiver Management PlanklibiPas encore d'évaluation

- Role of Third Party Agency in Fpsofso Epcic ProjectDocument26 pagesRole of Third Party Agency in Fpsofso Epcic ProjectklibiPas encore d'évaluation

- 1 Fuel Save CasestudyDocument10 pages1 Fuel Save CasestudyklibiPas encore d'évaluation

- Addition To QC Veritas PresentationDocument9 pagesAddition To QC Veritas PresentationklibiPas encore d'évaluation

- 2-Epa Guidance Note Energy Efficiency AuditingDocument29 pages2-Epa Guidance Note Energy Efficiency AuditingklibiPas encore d'évaluation

- Risk and Contengency Planning in Oil&gas ProjectsDocument18 pagesRisk and Contengency Planning in Oil&gas ProjectsklibiPas encore d'évaluation

- (Risk Managment P Stollsteiner IFP 20110518 1 (Mode de Compatibilité) )Document32 pages(Risk Managment P Stollsteiner IFP 20110518 1 (Mode de Compatibilité) )klibiPas encore d'évaluation

- Oil Based Rig Maintenance ReportDocument12 pagesOil Based Rig Maintenance Reportelmaadawy2002Pas encore d'évaluation

- Project Management Plan DreddgingDocument113 pagesProject Management Plan DreddgingklibiPas encore d'évaluation

- NRSP 0008 - An Approach To Successful Shipyard Planning and SchedulingDocument20 pagesNRSP 0008 - An Approach To Successful Shipyard Planning and SchedulingklibiPas encore d'évaluation

- AACEI Houston Jan 2008Document84 pagesAACEI Houston Jan 2008klibiPas encore d'évaluation

- Jack Up Barge Rig Move ProceduresDocument10 pagesJack Up Barge Rig Move Proceduresklibi67% (3)

- Addition To QC Veritas PresentationDocument9 pagesAddition To QC Veritas PresentationklibiPas encore d'évaluation

- QA QC PresentationDocument109 pagesQA QC Presentationklibi89% (9)

- Addition To QC Veritas PresentationDocument9 pagesAddition To QC Veritas PresentationklibiPas encore d'évaluation

- Cost Estimation MethodologyDocument23 pagesCost Estimation MethodologyklibiPas encore d'évaluation

- Project Performance Management - Chris VizzuetDocument29 pagesProject Performance Management - Chris VizzuetklibiPas encore d'évaluation

- Addition To QC Veritas PresentationDocument9 pagesAddition To QC Veritas PresentationklibiPas encore d'évaluation

- Z 014Document334 pagesZ 014Makiber100% (1)

- Aashto M288-17 Product Selection GuideDocument1 pageAashto M288-17 Product Selection GuideDem DemPas encore d'évaluation

- Pearson R CorrelationDocument2 pagesPearson R CorrelationAira VillarinPas encore d'évaluation

- Dec 2-7 Week 4 Physics DLLDocument3 pagesDec 2-7 Week 4 Physics DLLRicardo Acosta Subad100% (1)

- Poster-Shading PaperDocument1 pagePoster-Shading PaperOsama AljenabiPas encore d'évaluation

- Waste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFDocument11 pagesWaste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFdatinov100% (1)

- Prediction of Compressive Strength of Research PaperDocument9 pagesPrediction of Compressive Strength of Research PaperTaufik SheikhPas encore d'évaluation

- Daftar ObatDocument18 pagesDaftar Obatyuyun hanakoPas encore d'évaluation

- 2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - LibroDocument82 pages2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - Librovallejo13Pas encore d'évaluation

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainPas encore d'évaluation

- Ultra Electronics Gunfire LocatorDocument10 pagesUltra Electronics Gunfire LocatorPredatorBDU.comPas encore d'évaluation

- E7d61 139.new Directions in Race Ethnicity and CrimeDocument208 pagesE7d61 139.new Directions in Race Ethnicity and CrimeFlia Rincon Garcia SoyGabyPas encore d'évaluation

- I. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)Document5 pagesI. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)thmeiz.17sPas encore d'évaluation

- Mahindra&mahindraDocument95 pagesMahindra&mahindraAshik R GowdaPas encore d'évaluation

- Building Material Supplier in GurgaonDocument12 pagesBuilding Material Supplier in GurgaonRodidustPas encore d'évaluation

- Core CompetenciesDocument3 pagesCore Competenciesapi-521620733Pas encore d'évaluation

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocument13 pagesStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorPas encore d'évaluation

- Tomb of Archimedes (Sources)Document3 pagesTomb of Archimedes (Sources)Petro VourisPas encore d'évaluation

- 5.1 Behaviour of Water in Rocks and SoilsDocument5 pages5.1 Behaviour of Water in Rocks and SoilsHernandez, Mark Jyssie M.Pas encore d'évaluation

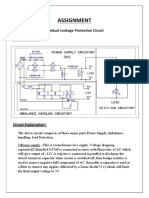

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaPas encore d'évaluation

- BECED S4 Motivational Techniques PDFDocument11 pagesBECED S4 Motivational Techniques PDFAmeil OrindayPas encore d'évaluation

- The Pneumatics of Hero of AlexandriaDocument5 pagesThe Pneumatics of Hero of Alexandriaapi-302781094Pas encore d'évaluation

- Pyramid Type Plate Bending MachineDocument10 pagesPyramid Type Plate Bending MachineAswin JosephPas encore d'évaluation

- Leveriza Heights SubdivisionDocument4 pagesLeveriza Heights SubdivisionTabordan AlmaePas encore d'évaluation

- Rsi r2 Super Rsi FaqDocument14 pagesRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- Puma PypDocument20 pagesPuma PypPrashanshaBahetiPas encore d'évaluation

- Raiders of SuluDocument1 pageRaiders of SuluBlexx LagrimasPas encore d'évaluation

- The Bio-Based Economy in The NetherlandsDocument12 pagesThe Bio-Based Economy in The NetherlandsIrving Toloache FloresPas encore d'évaluation

- SSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Document22 pagesSSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Ivy JeannePas encore d'évaluation

- CL Honours Report NamanDocument11 pagesCL Honours Report NamanNaman VermaPas encore d'évaluation

- Ethernet/Ip Parallel Redundancy Protocol: Application TechniqueDocument50 pagesEthernet/Ip Parallel Redundancy Protocol: Application Techniquegnazareth_Pas encore d'évaluation