Académique Documents

Professionnel Documents

Culture Documents

244 650 1 SM

Transféré par

Mohd Yazid Mohamad YunusTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

244 650 1 SM

Transféré par

Mohd Yazid Mohamad YunusDroits d'auteur :

Formats disponibles

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

FACTORS INFLUENCING SAFETY MANAGEMENT

SYSTEMS IN PETROCHEMICAL PROCESSING PLANTS

Norfaridatul Akmaliah Othman1, Juhaini Jabar1,

Murzidah Ahmad Murad1, Mohd Fauzi Kamarudin2

Faculty of Technology Management and Technopreneurship

Centre for Languages and Human Development

Universiti Teknikal Malaysia Melaka

ABSTRACT

The accident rate in the Malaysian construction industry is among the

highest compared to other developing countries. The Malaysian government

has recommended the self-regulation of safety management systems (SMS)

for construction projects with the hope of improving the situation; however,

the readiness of the local contractors to implement SMS is questionable.

Based on the critical review of literature, this research intends to uncover

the factors influencing SMS implementation and development among

Malaysian contractors working in processing plants. Additionally, this

paper highlights studies on the systemic issues of the contractors, during

the development and implementation of SMS in construction industry

during project execution in the processing plants. From the review of

literature, this paper has uncovered interrelated obstacles encountered

by contractors, namely cultural factors, working conditions and the

organizational processes. The next step of the research aims to identify the

most influencing factors on SMS development and implementation among

Malaysian contractors as identified in this paper.

KEYWORDS: Safety management systems, contractors, processing

plants, construction supply chain

I. INTRODUCTION

The growth of petrochemical processing plants (hereafter referred to

as processing plants) has benefited various industries, especially the

construction industry. The construction industry plays a major role

in processing plants; as many construction activities are carry out to

meet the high demands of development. One important role of the

construction industry is to provide civil and mechanical maintenance

tasks.

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

27

Journal of Technology Management and Technopreneurship

The use of contractors for maintenance tasks in processing plants is

necessary to cope with the large scale of work and engineering problems

(Mueller et al., 1996). Contractors play a significant role during

maintenance tasks due to the amount of work to be accomplished

in a short time (Duffuaa and Daya, 2004). Other reasons for using

contractors include: experience and professionalism; specialization in

certain areas; productivity, cost and efficiency (Lenahan, 2006; Duffuaa

and Daya, 2004).

Despite its important contribution to processing plant development,

the Malaysian construction industry is still saddled with serious safety

problems. For instance, there have been 700 negligence cases in the

construction industry since 2002, which include high-profile incidents

(Basri and Kumar, 2006; The Star, 2006). The construction industry

continues to contribute towards the high fatal accident rate in Malaysia

(DOSH, 2011; MOHR, 2008; Berita Harian, 2007; Kong, 2001).

This research focuses on the factors influencing safety management

systems (SMS) development and implementation faced by Malaysian

contractors working in petrochemical processing plants. It is intended

that the findings of the study contributes towards better implementation

of safety management systems (SMS) in processing plants.

II.

SAFETY MANAGEMENT SYSTEMS IN THE

CONSTRUCTION INDUSTRY

Safety Management Systems

Safety management systems (SMS) have emerged from the industrial

accident causation theories introduced by H. W. Heinrich in 1931, and

function as comprehensive, integrated systems for managing safety.

The principal aim of SMS is to impede the causation process that leads

to accidents and incidents (Booth and Lee, 1995). SMS is fundamental

to successful accident prevention (Grayham and Rosario, 1997), and

has become a matter for concern in recent years (Hale et al., 1997).

A series of catastrophic incidents have occurred in the past (Hale et

al., 1997; Kirchsteiger, 2002; Mitchison and Papadakis, 1999; Summers,

2007), which led to the development of safety regulations (Gun, 1993;

Hale et al., 1997) and emphasized the need for SMS (Osborne, 1993).

These major incidents involved Flixborough (1974), Seveso (1976),

Mexico City (1984), Bhopal (1984), Chernobyl (1987) and Piper Alpha

(1988) (Summers, 2007; Santos-Reyes and Beard, 2008).

28

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

Since then, SMS is used widely in various industries as an accident

prevention mechanism. In the processing plant industry, the

possibility of fire, explosions and toxic emissions is frequent, which

could potentially kill a large number of people, including employees,

processing plant contractors and the population, as well as causing

catastrophic damage to the environment (Huat, 1997; FernandezMuniz et al., 2007). As a result, the use of SMS in processing plants

is more extensive, and is where the development and publication of

safety standards or guidelines and good engineering practices started

(Knegtering, 2002).

Construction Supply Chain

Past studies have discovered that the successful development and

implementation of sms can help to prevent accidents in the construction

industry (Baxendale and Jones, 2000; Wilson and Koehn, 2000; Tam et

al., 2001; Hinze and Gambatese, 2003). However, the use of sms reached

a plateau (Tam et al., 2001). Despite adopting sms, contractors remain

poor in the development and implementation of safety on worksites.

As an organic type of organisation (Wilson, 1989), construction

offers a flexible working environment. Construction involves human

interaction and complex activity and aligns individual objectives into

one process, which is always difficult in practice, especially for large

projects. Projects are complex in nature, as they involve technical,

procedural, organisational and human elements in an integrated

manner (Ruuska and Vartiainen, 2003).

The construction industry consists of various parties such as client/

owner, designer, consultants, general contractor, subcontractors

and suppliers which are known as multi-organization process.

Construction is also a multi-stage process as it includes conceptual,

design, construction, maintenance, replacement and decommission.

The multi-organization and multi-stage process is also known as

construction supply chain (CSC). The CSC has been characterised with

fragmentation and poor coordination among project participants for

a long time, and there are many inter-organization problems, such as

interdependency, inaccurate information transfer and wrong deliveries

which resulted in poor performance (Xue et al., 2007; Vrijhoef and

Koskela, 1999). This complexity clearly demands efficient and effective

implementation of SMS as an accident prevention mechanism.

Construction Safety In Processing Plants

In the case of contractors working in processing plants, apart from

the complexity of construction working condition, contractors face a

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

29

Journal of Technology Management and Technopreneurship

greater risk during maintenance tasks (Kim et al., 2002). Contractors

could be exposed to a number of inevitable hazards: large numbers

of workers - mostly employed by the contractors who are unfamiliar

with the plant in a confined space; the presence of hazardous materials;

large number of tasks performed under high pressure, and in various

weather conditions (Ahmadun et al., 2003). The number of workers

involved in a processing plant maintenance shutdown can be anywhere

between 700 and 3000 at peak time (Ahmadun et al., 2003).

Due to the hazards and risks present in processing plants, the clients

set high safety requirements and effective approaches to monitor and

control the safety of contractors (Jannadi and Bu-Khamsin, 2002).

However, accidents among contractors still happen (Kong, 2001;

Mohd-Salleh, 2002; New Straits Times, 2002; Shaluf and Ahmadun,

2006; Zainudin et al., 2006). Fatalities and injuries are commonplace

among contractors due to the heavy physical activities necessary during

maintenance tasks and the presence of a large number of workers (Hale

et al., 1998; Ahmadun et al., 2003; Duffaa and Daya, 2004). The number

of accidents involving contractors is often more than five times higher

than those involving the processing plants own personnel (as cited in

Hale et al., 1998).

Malaysian Construction Safety

The concepts of sms are relatively new in malaysia. The occupational

safety and health act 1994 (Osha 1994) is quite comprehensive

with improvements over earlier pieces of legislation however, the

level of awareness and practicability of such regulations within the

construction industry are generally lower than expected (rampal and

nizam, 2006). In addition, sms in malaysia is still under self-regulation

without nationally applied models (Kogi, 2002). Hence the number

of malaysian companies subscribing to sms is still small compared

to the total number of industries in the country (thye, 2001). A study

by the malaysian trade union congress (MTUC) (2001) affirmed that

the implementation of safety in malaysia is poor in the workplace.

Furthermore, there are currently no specific guidelines or a master plan

for the implementation of sms programmes to help the construction

industry players to improve their performance (CIDB, 2008).

Industrial accidents happen mainly due to non-compliance of OSHA

1994 by employers (New Straits Times, 2002). However, in the case of

contractors working in processing plants, safety is a requirement of

the clients. Many clients have introduced various safety approaches

to improve the safety performance of contractors (Simon and Piquard,

30

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

1991; Ibrahim et al., 2002). It is compulsory to include a safety plan

in the tender documentation during the bidding process (Kong, 2001).

However, previous researches (Fitts, 1996; Smallwood, 1998; Yule and

Mearns, 2004; Abraham et al., 2004) confirm that contractors adopt SMS

just for the sake of the tender requirements and to satisfy the clients

during the bidding process. Hence the implementation of safety is still

lacking (Fitts, 1996). In the context of Malaysia, according to Husin

et al. (2008), the current SMS practices do have sound features and

characteristics, but lacks mission, vision, objective and awareness due

to the over-emphasis on productivity. SMS is under self-regulation and

it requires more constructive and practical ideas for implementation

(Husin et al., 2008). Furthermore, occupational safety is still in the early

development stage in Malaysia (Husin et al., 2008).

Some important examples of accidents in Malaysian processing plants

are the Tiram Kimia Depot chemical explosion (1992), the Shell Bintulu

explosion (1997), the Petronas Gas Berhad fire and explosion (2002), the

Petronas LNG Complex Bintulu fire incident (2003), the refinery fire in

West Malaysia (1999), the Fatty Chemicals methanol blast (2006) and

the Petronas LNG Complex Bintulu gas leakage (2009) (Mohd-Salleh,

2002; Shaluf and Ahmadun, 2006; Ismail and Stuart, 2005; Utusan

Malaysia Online, 2009). Fatalities involving contractors is the worst

consequences due to processing plants accidents. Some examples are

three fatalities in the Petronas Gas Berhad explosion in 2002 (New

Straits Times, 2005; Shaluf and Ahmadun, 2006) and two fatalities in

the Fatty Chemicals Methanol blasts in 2006.

There are many issues involved in developing and implementing

SMS. Failures are still common despite advances in the SMS approach.

Little has been written on the views of contractors in processing plants

about the issue they have with SMS development and implementation.

Therefore, an investigation of SMS development and implementation

can help to identify the problems encountered by contractors.

III.

FACTORS INFLUENCING SMS DEVELOPMENT AND

IMPLEMENTATION

For this research, a literature review has surveyed the scenario of

the CSC as well as enabling an understanding of its impact on SMS

development and implementation during project execution in the

processing plants. A literature review was undertaken to identify

factors that influenced SMS development and implementation among

contractors in processing plant.

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

31

Journal of Technology Management and Technopreneurship

It is evident that many obstacles encountered by contractors during

SMS development and implementation including cultural factors,

working conditions and the organizational processes are interrelated

(Othman, 2010). These factors have formed the underlying factors of

ineffective SMS development and implementation - the misperception

of safety responsibility. The misperception of safety responsibilities

occurs by the parties involved in the CSC. However, this study explains

only relationship between clients and contractors, clients and contract

workers and contractor and contract workers. Based on the literature

review, the barriers to effective SMS implementation can be divided into

external factors (clients) and internal factors (contractors and contract

workers). Several distinct misperceptions of safety responsibility

between clients, contractors and contract workers emerged from these

barriers that will discussed further in the following sections.

Reliance Culture Of Safety Management Systems

The research indicates that a reliance culture does exist between

contractors and client, and between contractors and parents company/

headquarters. Several factors have contributed to this condition.

Obviously, safety performance is being taken into consideration prior

to contract approval. This has led to contractors disregarding safety

measures in order to gain contract approval. Generally, SMS policy and

procedure, which was drawn by the parents company/headquarters

was included in the tender documents as a standard image of companys

safety implementation.

Subsequently, contractors rely on headquarters in organizing the safety

measures to be utilized. As a result, contractors are in a vulnerable

situation as they need to work in an environment, location and

condition that they are not familiar with. In order to familiarize with

the in-house safety requirements set by headquarters, contractors are

required to collaborate with clients. However, the different levels of

responsibilities between contractors and clients in the alliance have led

to misperceptions in the process of developing and implementing SMS.

The reliance culture leaves the contractor in a vulnerable position due

to different environment, location and condition between the entities.

The Uncertainty Of Organic Types Of Organisation

The development and implementation of SMS is highly influenced

by the companys external environment such as the uncontrollable

risk and uncertainty that is easily overlooked by contractor in the

processing plant. Safety requirements and standards will vary based on

32

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

clients requirements such as work progress, datelines, and schedule.

Consequently, safety enforcement is not standardized for contractors

and clients when profit is placed as a higher priority compared to

safety.

As contractors work under pressure to complete the task in a specified

period, this study reveals the bureaucracy of safety procedures, which

leads to ineffective SMS development and implementation, for example,

the procedures for bringing in equipment; therefore contractors choose

to take short cuts by using inappropriate equipment for the job.

Another issue which relates to the working conditions, is the physical

environment. In this case, the physical environment refers to the

geographical location and climate of the workplace. Santos-Reyes and

Beard (2008; 2002) stated that the physical environment might affect

some aspects of SMS. It is common that contractors will frequently

change their working location, and therefore the working conditions

also change (Laukkanen, 1999). Safety requirements become more

stringent and more demanding according to the project and client. SMS

development and implementation becomes tougher due to this type of

physical environment.

Disintegration And Inconsistency Organisational Process

Organising is critical to ensure the effectiveness of SMS development

and implementation and has a significant influence upon it (Fitts,

1996; Santos-Reyes and Beard, 2002; Rundmo et al., 1998; Basso et al.,

2004; McDonald et al., 2000). Therefore, the development of safety

department is crucial to cater safety issues in a company. However,

contractors reluctant to do that as it can reduce the budget.

The main concern of a contractor is how to save money and reduce

costs. Thus safety is usually considered a secondary priority in the

companys plans. In this study, the interviewees views indicate that

it is common practice in Malaysia to discount safety purposely to win

the tender. The clients who demand the lowest contract costs have

influenced this scenario. As such, the contractors search for lower

quality supplies and neglect safety issues. It is not surprising to find

that the majority of contractors in this study do not encompass safety

costs in their tenders. This seems to suggest that these contractors find

it difficult to develop and implement the most effective safety during

the construction phase of their projects.

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

33

Journal of Technology Management and Technopreneurship

The SMS development and implementation was also affected by the

project and company size. Safety attention is higher on bigger projects

compared to smaller projects. For a small size company, financial

constrain is common which led to hiring temporary workers. This

condition contributed to poor safety training and lack of qualified

taskforce.

IV. CONCLUSION

The research indicates that misperception of safety responsibility

issues has a strong influence on contractors SMS implementation. This

finding is an interesting one, as previous studies of SMS give little or

no attention to this issue. Addressing this issue is essential to create

awareness by the parties involved to improve SMS development and

implementation.

This research has contributed to furthering the understanding of the

main factors influencing safety development and implementation by

Malaysian contractors working in processing plants. It has identified

factors that are peculiar to, or exacerbated by, the internal and external

environment of the companies. Factors such as financial constrictions,

cultural dimensions and working conditions are prominent influences.

Further step is to identify the most influencing factors on SMS

development and implementation by distributing survey questionnaire

to Malaysian contractors working in processing plants.

ACKNOWLEDGEMENT

The authors wish to thank the Centre for Research and Innovation

Management, Universiti Teknikal Malaysia Melaka for the financial

support for this research.

REFERENCES

Abraham, D.M., McGlothin, J.D., Halpin, D.W. and Hinze, J. (2004).

Construction Safety Alliance (CSA) examining causes of construction

injuries and defining best practices that improve safety performance,

Construction Information Quarterly, 6(1), 9-16.

Ahmadun, F-R., Shaluf, I. M., and Mat Said, A. (2003). Review of an incident

at a petrochemical plant, Disaster Prevention and Management, 12(2),

85-90.

34

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

Basri, M.K. and Kumar, S.A. (2006). 700 kes kecuaian di tapak pembinaan dilapor

sejak 2002, Utusan Malaysia Online. Available from: http://www.

utusan.com.my/utusan/content.asp?y=2006&dt=0106&pub=Utusan_

Malaysia&sec=Muka_Hadapan&pg=mh_02.htm.

Retrieved

on

08/01/06.

Basso, B., Carpegna, C., Dibitonto, C., Gaido, G., Robotto, A., and Zonato,

C. (2004). Reviewing the safety management system by incident

investigation and performance indicators, Journal of Loss Prevention in

Process Industries, 17(3), 225-231.

Baxendale, T. and Jones, O. (2000). Construction design and management safety

regulations in practice progress on implementation, International

Journal of Project Management, 18(1), 33-40.

Berita Harian. (2007). Kesedaran keselamatan pekerja meningkat. Available

from:

http://www.bharian.com.my/Current_News/BH/Friday/

Nasional/20071102092752/Article/index_html. Retrieved on 02/11/07.

Booth, R.T. and Lee, T.R. (1995). The role of human factors and safety culture

in safety management, Journal of Engineering Manufacturer, 209(B5),

393-400.

Carruthers, J., Ashill, N. and Rod, M. (2006). Mapping and assessing the key

management issues influencing UK public healthcare purchaserprovider cooperation, Qualitative Market Research: An International

Journal, 9(1), 86-102.

Construction Industry Development Board (CIDB). (2008). Master plan for

occupational safety and health in construction industry 2005-2010.

Available from: http://www.cidb.gov.my/cidbweb/bin/information/

HSE/OHSAS%202006v2.pdf. Retrieved on: 25/11/08.

Department of Occupational Safety and Health (DOSH). (2011). Available

from: http://www.dosh.gov.my/. Retrieved on: 05/09/11.

Dessler, G. (1976). Organization and management: a contingency approach,

Prentice Hall, London.

Duffuaa, S.O. and Daya, M.A.B. (2004). Turnaround maintenance in

petrochemical industry: practices and suggested improvements,

Journal of Quality in Maintenance Engineering, 10(3), 184-190.

Fang, D. P., Xie, F., Huang, X. Y., and Li, H. (2004). Factor analysis-based

studies on construction workplace safety management in China,

International Journal of Project Management, 22(1), 43-49.

Fernandez-Muniz, B., JoseManuel, M-P. and CamiloJose, V-O. (2007).

Safety management system: development and validation of a

multidimensional scale, Journal of Loss Prevention in the Process

Industries, 20(1), 52-68.

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

35

Journal of Technology Management and Technopreneurship

Fitts, T.G. (1996). Safety management systems: off the shelf and into practice, Paper

presented at International Conference on Health, Safety and Environment

in Oil and Gas Exploration and Production, 19-12 June, New Orleans,

Louisiana.

Grayham, D.A. and Rosario, V.O. (1997). The management of health and safety

at work regulations, The Journal of the Royal Society for the Promotion of

Health, 117(1), 47-51.

Gun, R. T. (1993).The role of regulations in the prevention of occupational

injury, Safety Science, 16(1), 47-66.

Hale, A.R., Heming, B.H.J., Carthey, J. and Kirwan, B. (1997). Modelling of

safety management systems, Safety Science, 26(1/2), 121-140.

Hale, A.R., Heming, B.H.J., Smit, K., Rodenburg, F.G.T. and van Leeuwen,

N.D. (1998). Evaluating safety in the management of maintenance

activities in the chemical process industry, Safety Science, 28(1), 21-44.

Hinze, J. and Gambatese, J. (2003). Factors that influence safety performance

of specialty contractors, Journal of Construction Engineering and

Management, 129(2), 159-164.

Husin, H.N., Adnan, H and Jusoff, K. (2008). Management of safety for quality

construction, Journal of Sustainable Development, 1(3), 41-47.

Huat, G.H. (1997). Industrial safety in the oil and petrochemical industry in

Singapore, Chemical Safety, 4(1), 18.

Ibrahim, S., Ason, N., and Jahuri, M.A.M. (2002). Working together in a contract

environment: Angsi, Larut and SSE Teluk Ramunia experience. SPE

International Conference on Health, Safety and Environment in Oil

and Gas Exploration and Production, 20-22 March, Kuala Lumpur,

Malaysia. Paper Number: 73834-MS. Society of Petroleum Engineers

Inc.

Ismail, N and Stuart, T.R. (2005). The Train 7 Fire at Petronas LNG Complex

Bintulu, Malaysia, LNG Journal, July/August, 12-14.

Jannadi, O.A. and Bu-Khamsin, M.S. (2002). Safety factors considered by

industrial contractors in Saudi Arabia, Building and Environment, 37(5),

539-547.

Kartam, N.A., Flood, I. and Koushki, P. (2000). Construction safety in Kuwait:

issues, procedures, problems, and recommendations, Safety Science,

36(3), 163.

Kim, T., Kim J., Kim Y. and Kim K. (2002). Current risk management status of

the Korean petrochemical industry, Journal of Loss Prevention in Process

Industries, 15(4), 311-318.

Kirchsteiger, C. (2002). Review of international industrial safety management

frameworks, Process Safety and Environmental Protection, 80(B5), 235244.

36

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

Knegtering, B. (2002). Safety lifecycle management in the process industries: the

development of a qualitative safety related information analysis technique,

Thesis (PhD), Technische Universiteit Eindhoven.

Kogi, K. (2002). Work improvement and occupational safety and health

management systems: common features and research needs, Industrial

Health, 40, 121-133.

Kong, C.S. (2001). Managing HSE in construction projects through contracts,

The 17th Asia Pacific Occupational Safety & Health Organization

(APOSHO-17) Conference, Taipei, Taiwan.

Laukkanen, T. (1999). Construction work and education: occupational health

and safety reviewed, Construction Management and Economics, 17, 5362.

Lenahan, T. (2006). Turnaround Shutdown and Outage Management, ButterworthHeinemann, U.K.

Malaysian Trade Union Congress (MTUC). (2001). OSH Legislation and its

Implementation,

Available from: http://www.mtuc.org.my/osh_

profile_malaysia.htm. Retrieved on: 08/01/06.

McDonald, N., Corrigan, S., Daly, C. and Cromie, S. (2000). Safety management

systems and safety culture in aircraft maintenance organisations, Safety

Science, 34(1-3), 151-176.

Ministry of Human Resource (MOHR) (2008). Available from: http://www.

mohr.gov.my/Statistik_Perburuhan_2008.pdf as of 05/05/09. Retrieved

on: 17/10/09.

Mitchison, N. and Papadakis, G.A. (1999). Safety management systems under

Seveso II: implementation and assessment, Journal of Loss Prevention in

Process Industries, 12(1), 43-51.

Mueller, J.D., Murphy, A. and Ball, D.F. (1996). The role of process plant

contractors in the energy supply industry, Applied Energy, 55(1), 21-45.

Mohd-Salleh, A.N. (2002). Managing hazard installation: Malaysia experience,

The 18th Asia Pacific Occupational Safety and Health Organisation

(APOSHO) Conference. Vietnam. Available from: http://www.aposho.

org/about/about-Plenary18.htm. Retrieved on 17/10/03.

New Straits Times, (2002). Workplace accidents alarming, Available from:

http://www.aboutsafety.com/article.cfm?id=1373.

Retrieved

on:

13/09/05.

Osborne (1993). Managing professional, Mechanical Engineering Publication

Ltd, The Institution of Mechanical Engineers, London.

Othman, N.A. (2010). An exploratory study into the implementation of safety

management systems of Malaysian contractors in processing plants,

PhD Theses, Loughborough University. England.

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

37

Journal of Technology Management and Technopreneurship

Rampal, K.G. and Nizam, J.M. (2006). Developing regulations for occupational

exposures to health hazards in Malaysia, Regulatory Toxicology and

Pharmacology, 46, 131-135.

Rundmo, T., Hestad, H. and Ulleberg, P. (1998). Organisational factors, safety

attitudes and workload among offshore oil personnel, Safety Science,

29(2), 75-87.

Ruuska, I. and Vartiainen, I. (2003). Critical project competences a case study,

Journal of Workplace Learning, 15(7/8), 307-312.

Santos-Reyes, D. and Beard, A.N. (2008). A systematic approach to managing

safety, Journal of Loss Prevention in the Process Industries, 21, 15-28.

Santos-Reyes, J. and Beard, A.N. (2002). Assessing safety management

systems, Journal of Loss and Prevention in Process Industries, 15(2), 77-95.

Shaluf, I.M. and Ahmadun, F. (2006). Disaster types in Malaysia: an overview,

Disaster Prevention and Management, 15(2), 286-298.

Sharma, S. and Vredenburg, H. (1998). Proactive corporate environmental

strategy and the development of competitively valuable organizational

capabilities, Strategic Management Journal, 19(8), 729-753.

Simon, J.M. and Piquard, P. (1991). Contractor safety performance significantly

improves, Paper presented at SPE Health, Safety and Environment in

Oil and Gas Exploration and Production Conference, 11-14 November,

The Hague, Netherlands.

Smallwood, J. (1998). Client influence on contractor health and safety in South

Africa, Building Research & Information, 26(3), 181-189.

Summers, A. (2007). Achieve continuous safety improvement, Available

from:

http://www.chemicalprocessing.com/articles/2007/063.html,

Retrieved on: 22/11/ 2007).

Tam, C.M., Fung, I.W.H. and Chan, A.P.C. (2001). Study of attitude changes in

people after the implementation of a new safety management system:

the supervision plan, Construction Management and Economics, 19(4),

393-403.

The Star. (2006). What went wrong at 700 sites, ask Fong. Available from:

http://www.cidb.gov.my/cidbweb/bin/corporate/media/20060108%20

What%20went%20wrong%20at%20700%20sites,%20asks%20Fong.

pdf. Retrieved on 23/10/06.

Thye, L.L. (2001). Status of implementation occupational safety and health

management system in Malaysia, Paper presented at Asian-Pacific

Occupational Safety and Health Organisation 17th Conference, Taiwan.

Utusan Malaysia Online. (2009). Malaysia ketinggalan aspek keselamatan,

kesihatan pekerja. Available from: http://www.utusan.com.my/utusan/

info.asp?y=2009&dt=0624&pub=Utusan_Malaysia&sec=Dalam%5FN

egeri&pg=dn_28.htm. Retrieved on: 24/06/09.

38

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

Factors Influencing Safety Management Systems in Petrochemical Processing Plants

Vrijhoef, R. and Koskela, L. (1999). Roles of Supply Chain Management in

Construction, in Proceedings IGLC-7, 26-28 July, University of

California, Berkeley, CA, USA.

Wilson, H. A. (1989). Organizational behaviour and safety management in the

construction industry, Construction Management Economics, 7, 303-319.

Wilson, J.M. and Koehn, E.E. (2000). Safety management: problems encountered

and recommended solutions, Journal of Construction Engineering and

Management, 126(1), 77-79.

Xue, X., Wang, Y., Shen, Q. and Yu, X. (2007). Coordination mechanisms for

construction supply chain management in the internet environment,

International Journal or Project Management, 25, 150-157.

Yule, S. and Mearns, K. (2004). The client has most influence on the contractors

HS&E culture, Paper presented at International Conference on Health,

Safety and Environment in Oil and Gas Exploration and Production,

Canada.

Zainudin, F., Patho, R. and Anwar, M. (2006). 2 maut tangki methanol meletup,

Berita Harian Online. Available from: http://www.bharian.com.

my/m/BHarian/Wednesday/Mukadepan/20060301070845/Article/.

Retrieved on 01/03/06.

ISSN: 2231-7996

Vol. 2

No. 2

July - December 2014

39

Vous aimerez peut-être aussi

- Critical Factors For Implementation of Occupational Safety and Health Management System in Malaysian Petrochemical Based Manufacturing CompaniesDocument6 pagesCritical Factors For Implementation of Occupational Safety and Health Management System in Malaysian Petrochemical Based Manufacturing CompaniesDR. MOHD FAUZI ISMAILPas encore d'évaluation

- Lit Review WeldingDocument9 pagesLit Review Welding666667Pas encore d'évaluation

- A Qualitative Analysis of The Occupational Health and Safety Management Practices in Pakistani Construction IndustryDocument18 pagesA Qualitative Analysis of The Occupational Health and Safety Management Practices in Pakistani Construction IndustryMatilda ValeryPas encore d'évaluation

- Construction Safety Benchmarking: June 2006Document10 pagesConstruction Safety Benchmarking: June 2006Eng-Sharaf Al-smadiPas encore d'évaluation

- Construction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaDocument19 pagesConstruction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaMohd Yazid Mohamad YunusPas encore d'évaluation

- Construction Site Safety in Small Constr PDFDocument16 pagesConstruction Site Safety in Small Constr PDFEng-Sharaf Al-smadiPas encore d'évaluation

- TS07K Muiruri Mulinge 6847 PDFDocument14 pagesTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusPas encore d'évaluation

- Assessment of Safety and Health Measures (Shassic Method) in Construction SitesDocument9 pagesAssessment of Safety and Health Measures (Shassic Method) in Construction SitesMohd Yazid Mohamad YunusPas encore d'évaluation

- The Impact of Construction Supply Chain On The Implementation of Safety Management SystemsDocument9 pagesThe Impact of Construction Supply Chain On The Implementation of Safety Management SystemsamiKKKPas encore d'évaluation

- 1.construction Safety and Performance in Malaysian-1-9Document9 pages1.construction Safety and Performance in Malaysian-1-9guok zisiangPas encore d'évaluation

- Work Pressure Final Work by Koomson 1Document7 pagesWork Pressure Final Work by Koomson 1paintsildaniel9700Pas encore d'évaluation

- Contractors' Compliance with OSH Policies in Malaysia's ConstructionDocument7 pagesContractors' Compliance with OSH Policies in Malaysia's ConstructionabdirahmanPas encore d'évaluation

- Critical Success Factors Influencing Safety Program Performance in Thai Construction ProjectsDocument19 pagesCritical Success Factors Influencing Safety Program Performance in Thai Construction ProjectsConstructionpm Cpm100% (1)

- Dynamic Risk Management - A Contemporary Approach To Process Safety ManagementDocument9 pagesDynamic Risk Management - A Contemporary Approach To Process Safety ManagementVisionPas encore d'évaluation

- Penelitian 2 LatberDocument7 pagesPenelitian 2 LatberMirza KhaeraniPas encore d'évaluation

- Construction Industry in PakistanDocument7 pagesConstruction Industry in Pakistansajjadmubin75% (4)

- Evaluation - of - Safety - and - Health - Performance - On - Con KulaDocument11 pagesEvaluation - of - Safety - and - Health - Performance - On - Con KulaabdirahmanPas encore d'évaluation

- Construction Safety and Health Factors at The Industry Level: The Case of SingaporeDocument19 pagesConstruction Safety and Health Factors at The Industry Level: The Case of SingaporeMohd Yazid Mohamad YunusPas encore d'évaluation

- 140636R Research SummaryDocument7 pages140636R Research SummaryPasan VidanapathiranaPas encore d'évaluation

- Obtaining FMEA’s indices for occupational safety in civil constructionDocument10 pagesObtaining FMEA’s indices for occupational safety in civil constructionBoopathiPas encore d'évaluation

- Risk-Based Maintenance-Techniques and Applications: N.S. Arunraj, J. MaitiDocument9 pagesRisk-Based Maintenance-Techniques and Applications: N.S. Arunraj, J. MaitiBruno MarinsPas encore d'évaluation

- Characteirstic Analysis of Occupationl Accidents at Small Construction EnterprisesDocument10 pagesCharacteirstic Analysis of Occupationl Accidents at Small Construction EnterprisesMaite PrietoPas encore d'évaluation

- The Performance of Safety Implementation Towards Accident Occurrence in Malaysia Construction IndustryDocument9 pagesThe Performance of Safety Implementation Towards Accident Occurrence in Malaysia Construction Industrymuhd amirulPas encore d'évaluation

- System Dynamics Modelling of Construction Safety Culture: Engineering Construction & Architectural Management May 2011Document17 pagesSystem Dynamics Modelling of Construction Safety Culture: Engineering Construction & Architectural Management May 201118rosa18Pas encore d'évaluation

- Factors Affecting Labour Productivity in Building Projects in The Gaza StripDocument10 pagesFactors Affecting Labour Productivity in Building Projects in The Gaza StripSreejithAyyappanPas encore d'évaluation

- Basic Research Proposal TemplateDocument5 pagesBasic Research Proposal TemplateKinniPas encore d'évaluation

- Factor Affecting Safety Performance Construction Industry (#355781) - 367497Document6 pagesFactor Affecting Safety Performance Construction Industry (#355781) - 367497Kobby Ash VilliPas encore d'évaluation

- C A C S: Abdul Rahim Abdul Hamid, Muhd Zaimi Abd Majid, Bachan SinghDocument22 pagesC A C S: Abdul Rahim Abdul Hamid, Muhd Zaimi Abd Majid, Bachan SinghargaPas encore d'évaluation

- Productivity Determinants in Oman Construction IndustryDocument24 pagesProductivity Determinants in Oman Construction IndustryBoy BangusPas encore d'évaluation

- Quantity Surveyor Perception of Construction Health and Safety PDFDocument9 pagesQuantity Surveyor Perception of Construction Health and Safety PDFIbiwumi JohnPas encore d'évaluation

- C A C S: Abdul Rahim Abdul Hamid, Muhd Zaimi Abd Majid, Bachan SinghDocument18 pagesC A C S: Abdul Rahim Abdul Hamid, Muhd Zaimi Abd Majid, Bachan SinghEmelia JosephPas encore d'évaluation

- Factors Affecting Safety of Processes in The Malaysian Oil and Gas IndustryDocument16 pagesFactors Affecting Safety of Processes in The Malaysian Oil and Gas IndustrybelhushePas encore d'évaluation

- A Review of Safety and Quality Issues in The ConstDocument8 pagesA Review of Safety and Quality Issues in The ConstBalaji CreatPas encore d'évaluation

- Review Jurnal Uas Fakman 2 PDFDocument11 pagesReview Jurnal Uas Fakman 2 PDFNajmi TanziilaPas encore d'évaluation

- Construction Safety PaperDocument14 pagesConstruction Safety PaperMuhammad ArslanPas encore d'évaluation

- Risk Based Maintanance PDFDocument9 pagesRisk Based Maintanance PDFRafaelPachecoPas encore d'évaluation

- Assessment of The Benefits of Smart Wearable Devices For Construction Health and Safety in Lagos State, NigeriaDocument9 pagesAssessment of The Benefits of Smart Wearable Devices For Construction Health and Safety in Lagos State, NigeriaAdejumo MosesPas encore d'évaluation

- 1 s2.0 S0022437522000056 MainDocument10 pages1 s2.0 S0022437522000056 MainHakasapra KonveksiPas encore d'évaluation

- Maintenance strategies overview focusing on concepts and approachesDocument14 pagesMaintenance strategies overview focusing on concepts and approachesThaierPas encore d'évaluation

- AJBASR 3 PublishedDocument10 pagesAJBASR 3 PublishedAbdul WazedPas encore d'évaluation

- How Professional Ethics Impact Construction Quality - Abdul-Rahman Et AlDocument8 pagesHow Professional Ethics Impact Construction Quality - Abdul-Rahman Et AlJeeshan IlahiPas encore d'évaluation

- Causes of Accidents at Construction Sites: January 2008Document19 pagesCauses of Accidents at Construction Sites: January 2008Muhamad IrfanPas encore d'évaluation

- ManufactringPublicServiceandConstructionHazard TsHjEsa MLROct2020Document16 pagesManufactringPublicServiceandConstructionHazard TsHjEsa MLROct2020Ummi SyafiqahPas encore d'évaluation

- Relationships Among Factors AffectingDocument21 pagesRelationships Among Factors AffectingYOLO crapperPas encore d'évaluation

- Common Construction Site Hazards in Nairobi County, Kenya: American Journal of Construction and Building MaterialsDocument8 pagesCommon Construction Site Hazards in Nairobi County, Kenya: American Journal of Construction and Building MaterialsAmirul AmmarPas encore d'évaluation

- Kuwait Issues Problems KartamDocument22 pagesKuwait Issues Problems KartamSyeda Fatima aliPas encore d'évaluation

- Risk and Safety Management in The Construction Industry PDFDocument18 pagesRisk and Safety Management in The Construction Industry PDFReshma RamPas encore d'évaluation

- Customised Safety Behaviour Checklist at Construction SiteDocument13 pagesCustomised Safety Behaviour Checklist at Construction Sitekartikay jhaPas encore d'évaluation

- Planning Petrochemical Industry Using Multi-Objective OptimizationDocument12 pagesPlanning Petrochemical Industry Using Multi-Objective OptimizationvasucristalPas encore d'évaluation

- Buildings 11 00139 v2Document24 pagesBuildings 11 00139 v2Priyasha RayPas encore d'évaluation

- Construction Safety in Design ProcessDocument8 pagesConstruction Safety in Design ProcessShahab HosseinianPas encore d'évaluation

- BSC SafetyDocument10 pagesBSC SafetyEmad ElshaerPas encore d'évaluation

- A Review On Risk Management Implementation in The Construction IndustryDocument6 pagesA Review On Risk Management Implementation in The Construction IndustrySanthiya MogenPas encore d'évaluation

- Methods and Tools Used in Criticality Analysis in Industrial SystemsDocument18 pagesMethods and Tools Used in Criticality Analysis in Industrial SystemsLeandro Baran100% (1)

- Safety Performance in The Construction Industry of Saudi ArabiaDocument10 pagesSafety Performance in The Construction Industry of Saudi ArabiaReaz UddinPas encore d'évaluation

- Construction Safety: Who Is Responsible?: Akhmad SurajiDocument10 pagesConstruction Safety: Who Is Responsible?: Akhmad SurajiAbdilah SPas encore d'évaluation

- Success Factors Influencing Safety PerformanceDocument47 pagesSuccess Factors Influencing Safety PerformanceYusmin Jaffar100% (1)

- The Management of Additive Manufacturing: Enhancing Business ValueD'EverandThe Management of Additive Manufacturing: Enhancing Business ValuePas encore d'évaluation

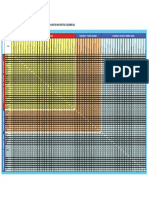

- KTM KOMUTER FARES EFFECTIVE DEC 2ND 2015Document1 pageKTM KOMUTER FARES EFFECTIVE DEC 2ND 2015Hamka HidayahPas encore d'évaluation

- Construction Safety and Health Factors at The Industry Level: The Case of SingaporeDocument19 pagesConstruction Safety and Health Factors at The Industry Level: The Case of SingaporeMohd Yazid Mohamad YunusPas encore d'évaluation

- Lab SignageDocument11 pagesLab SignageMohd Yazid Mohamad YunusPas encore d'évaluation

- How to make chemical solutions from solidsDocument6 pagesHow to make chemical solutions from solidsMohd Yazid Mohamad YunusPas encore d'évaluation

- Paper Keng RazakDocument19 pagesPaper Keng RazakNur MajPas encore d'évaluation

- Ask Bab 3Document50 pagesAsk Bab 3Mohd Yazid Mohamad YunusPas encore d'évaluation

- KLSM KBSM KSSMDocument1 pageKLSM KBSM KSSMMohd Yazid Mohamad YunusPas encore d'évaluation

- Jurnal Teknologi: Nilai Profesionalisme Bakal Guru Berteraskan Indikator Standard Guru Malaysia (SGM)Document7 pagesJurnal Teknologi: Nilai Profesionalisme Bakal Guru Berteraskan Indikator Standard Guru Malaysia (SGM)jayanthanPas encore d'évaluation

- Job Application Form - IIUM SchoolsDocument1 pageJob Application Form - IIUM SchoolsMohd Yazid Mohamad YunusPas encore d'évaluation

- Application Form Osh Award 2016Document23 pagesApplication Form Osh Award 2016Mohd Yazid Mohamad YunusPas encore d'évaluation

- Ujian Mac TMP Tahun 5Document89 pagesUjian Mac TMP Tahun 5Mohd Yazid Mohamad YunusPas encore d'évaluation

- Paper Keng RazakDocument19 pagesPaper Keng RazakNur MajPas encore d'évaluation

- Jilid 11 Artikel 01Document15 pagesJilid 11 Artikel 01munirahPas encore d'évaluation

- Matecconf Ibcc2016 00107Document9 pagesMatecconf Ibcc2016 00107Mohd Yazid Mohamad YunusPas encore d'évaluation

- Rizwan 2015Document63 pagesRizwan 2015Mohd Yazid Mohamad YunusPas encore d'évaluation

- TS07K Muiruri Mulinge 6847 PDFDocument14 pagesTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusPas encore d'évaluation

- Job Application FormDocument4 pagesJob Application FormMohd Yazid Mohamad YunusPas encore d'évaluation

- Ijerph 14 00045Document17 pagesIjerph 14 00045Mohd Yazid Mohamad YunusPas encore d'évaluation

- Research Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranDocument15 pagesResearch Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranMohd Yazid Mohamad YunusPas encore d'évaluation

- Ijaiem 2015 01 11 16Document10 pagesIjaiem 2015 01 11 16International Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Rizwan 2015Document63 pagesRizwan 2015Mohd Yazid Mohamad YunusPas encore d'évaluation

- TS07K Muiruri Mulinge 6847 PDFDocument14 pagesTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusPas encore d'évaluation

- Assessment of Safety and Health Measures (Shassic Method) in Construction SitesDocument9 pagesAssessment of Safety and Health Measures (Shassic Method) in Construction SitesMohd Yazid Mohamad YunusPas encore d'évaluation

- Research Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranDocument15 pagesResearch Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranMohd Yazid Mohamad YunusPas encore d'évaluation

- Ch2 Literature ReviewDocument11 pagesCh2 Literature ReviewMohd Yazid Mohamad YunusPas encore d'évaluation

- Ijaiem 2015 01 11 16Document10 pagesIjaiem 2015 01 11 16International Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- 555Document4 pages555Mohd Yazid Mohamad YunusPas encore d'évaluation

- Challenges and Needs For Support in Managing Occupational Health and Safety From Managers' ViewpointsDocument21 pagesChallenges and Needs For Support in Managing Occupational Health and Safety From Managers' ViewpointsMohd Yazid Mohamad YunusPas encore d'évaluation

- D6950D6950M-04 (2012) E1 Standard Practice For Application of Heat Weldable Atactic Polypropylene (APP) Modified Bituminous Waterproofing Membranes Systems For New Building DecksDocument4 pagesD6950D6950M-04 (2012) E1 Standard Practice For Application of Heat Weldable Atactic Polypropylene (APP) Modified Bituminous Waterproofing Membranes Systems For New Building DecksSatya kaliprasad vangaraPas encore d'évaluation

- Naukri AshwaniKumarSingh (2y 6m)Document3 pagesNaukri AshwaniKumarSingh (2y 6m)rohit sharmaPas encore d'évaluation

- The Water Transmission CodeDocument74 pagesThe Water Transmission CodeabdulkadhirPas encore d'évaluation

- Risk Assessment Connors HouseDocument2 pagesRisk Assessment Connors HouseConnor CallonPas encore d'évaluation

- Mumbai Dabbawala Case Study TQM AnalysisDocument9 pagesMumbai Dabbawala Case Study TQM AnalysisananyaPas encore d'évaluation

- Safeguarding Against Falling Objects (Draft)Document21 pagesSafeguarding Against Falling Objects (Draft)lwin_oo2435Pas encore d'évaluation

- 15 Mettler Toledo Mp70 User ManualDocument48 pages15 Mettler Toledo Mp70 User ManualJessica LeitePas encore d'évaluation

- QNBN Tech Spec For F& C Rev August 2014Document21 pagesQNBN Tech Spec For F& C Rev August 2014raghebom100% (1)

- Disaster Risk Reduction and Management PlanDocument10 pagesDisaster Risk Reduction and Management PlanHaffiz AtingPas encore d'évaluation

- Metal Detector With Conveyor Application: Operator Set-Up ManualDocument69 pagesMetal Detector With Conveyor Application: Operator Set-Up ManualRafa 7nitePas encore d'évaluation

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument8 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingewhf weGJOPas encore d'évaluation

- MSDS-HPMC Under REACH R5150Document10 pagesMSDS-HPMC Under REACH R5150Guilherme FreitasPas encore d'évaluation

- 111 310 - Falk Orange Peel Coupling Guards - CatalogDocument28 pages111 310 - Falk Orange Peel Coupling Guards - CatalogNickPas encore d'évaluation

- Workplace Learning Record: VCE VET Agriculture, Horticulture and Conservation and Land ManagementDocument35 pagesWorkplace Learning Record: VCE VET Agriculture, Horticulture and Conservation and Land ManagementBob CrossPas encore d'évaluation

- CHAPTER 6 Workplace Environment and ErgonomicsDocument30 pagesCHAPTER 6 Workplace Environment and Ergonomicsadlirazin24Pas encore d'évaluation

- Example Fire and Emergency Evacuation PlanDocument4 pagesExample Fire and Emergency Evacuation PlanXes VeritasPas encore d'évaluation

- POA CH - 19 Physical SecurityDocument196 pagesPOA CH - 19 Physical SecurityNeal Patrick SacdalanPas encore d'évaluation

- Silicone SealantDocument8 pagesSilicone SealantSaurabh RungtaPas encore d'évaluation

- APEGBC Guidelines Professional Structural Engineering Services For Part 3 Building ProjectsDocument32 pagesAPEGBC Guidelines Professional Structural Engineering Services For Part 3 Building Projectsdovi01100% (1)

- XXX Hospital Safety Inspection Rounds ReportDocument3 pagesXXX Hospital Safety Inspection Rounds Reportrashmi elizabeth easow100% (1)

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedPas encore d'évaluation

- Worksheets TLE 8 Household ServicesDocument14 pagesWorksheets TLE 8 Household ServicesMarison Calista100% (2)

- Emal 10G MsdsDocument6 pagesEmal 10G MsdstopguitarPas encore d'évaluation

- Calcium Acetate Safety Data SheetDocument4 pagesCalcium Acetate Safety Data SheetQamir Ullah Khan NiaziPas encore d'évaluation

- Industrial Hygiene CSTDocument93 pagesIndustrial Hygiene CSTClaude De GuzmanPas encore d'évaluation

- Before.. After..: © Open Source Six Sigma, LLCDocument9 pagesBefore.. After..: © Open Source Six Sigma, LLCELSAYED KhalfPas encore d'évaluation

- Safety in The LaboratoryDocument12 pagesSafety in The LaboratoryMary Ella Mae PilaPas encore d'évaluation

- Declaración Jurada de Salud y Autorización de GeolocalizaciónDocument1 pageDeclaración Jurada de Salud y Autorización de GeolocalizaciónLucia ChuquillanquiPas encore d'évaluation

- OHS For Bread and PastryDocument56 pagesOHS For Bread and PastrysonPas encore d'évaluation

- Al2 Series Software ManualDocument124 pagesAl2 Series Software Manualsebastan1997Pas encore d'évaluation