Académique Documents

Professionnel Documents

Culture Documents

BHGJ

Transféré par

Ram NetiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BHGJ

Transféré par

Ram NetiDroits d'auteur :

Formats disponibles

purpose of cooling:

water is king as in heat capacity?

What it means-can store large amount of heat as compare air.

Free of cost ? But now a day we are paying money for water.

Water is silent killer mean no noise but air is too noise .

I need pump to pump water.

water will freeze when?

As air is ubiquitous but water is not.

In places where water is scarce, air cooled engine is an advantage.rajasathan me air ka

use karo more better.

advantage

The absence of radiator, cooling jackets,

coolant and pumps make the engine

lighter.

The engine can be operated in cold

climate where liquid may freeze.

In places where water is scarce, air

cooled engine is an advantage.

Handling of liquid coolant requires

piping and pumping auxiliaries.

Air cooled engines have no coolant

leakage or freezing problems.therefore

no antifrezzer is required

disadvantage

Relatively large amount of power is

used to drive the cooling fan.

Engines give low power output

Cooling fins under certain conditions may

vibrate and amplify the noise level

Cooling is not uniform

Engines are subjected to high

working temperature

Difficult to get engine to run at most

efficient temperature on ground and at

altitude.

Water cooling system

advantage

disadvantage

Because of even cooling of cylinder barrel

and head (due to jacketing) makes it

possible to reduce the cylinder head and

valve seat temperatures.

The volumetric efficiency of water cooled

engines is higher than that of air-cooled

engines

Compact design of engines with

appreciably smaller frontal area is possible.

The system requires more maintenance

In case of water cooled engines,

installation is not

necessarily at the front of

the mobile vehicles, aircraft etc. as the

cooing system can be conveniently located

In the event of failure of the cooling

system serious damage may be caused

to the engine

The power

absorbed by the pump is

considerable and affects the power

output of the engine

The engine performance becomes

sensitive to climatic conditions

http://www.slideshare.net/spiccychora/bhupender-ppt

for forced cooling diagram

Spherical shape

Open combustion chamber

I-shape

Pre-combustion chambers

L-shape

Swirl combustion chambers

T-shape

Squish combustion chamber

F-shape

Air cell & energy cel

Chapter 4 + gupta chapter

http://www.ustudy.in/node/4025

crdi

The common rail direct injections core function is the

initiation of high fuel pressure in the common rail in order

that fuel is injected directly and continuously. Fuel is

sprayed, like powder, into the combustion chamber to

increase its ability to mix with intake air and improve

burning efficiency. CDI starts with the high-pressure pump

that has fuel injection capacity of 1,377 bars or 8 times

higher than a Direct Injection diesel engine.

Fuel is pumped with high pressure into the common rail for

storage. The common rail is installed with a pressure

regulator and a pressure sensor at its end. They are equipped

to maintain and control fuel pressure delivered from the

high-pressure pump at an appropriate level for driving

conditions before 6-port electronically-controlled unit

injectors sprays fuel directly to the combustion chamber.

The injectors work two times per stroke. The injectors spray

pilot injection before the real injection, which helps reduce

noises arising from the ignition.

Every procedure of the common rail direct injection is

controlled by a computer system gathering data sent from

other parts i.e. sensors of crank shaft, accelerator,

temperature, air, etc. This data is interpreted to allow fuel

injected correctly and in compliance with engine speed,

enhancing the engine performances more power, fuel

economy, quietness, less vibration, less pollution in the

exhaust, less maintenance costs and high durability.

Vous aimerez peut-être aussi

- Design and Analysis of IC Engine FinsDocument52 pagesDesign and Analysis of IC Engine FinsShiva KumarPas encore d'évaluation

- Internal Combustion Engine Cooling Syste1Document16 pagesInternal Combustion Engine Cooling Syste1zohaib704876100% (3)

- Cooling System of Internal Combustion EngineDocument8 pagesCooling System of Internal Combustion EnginePathfinderPas encore d'évaluation

- AEMSDocument28 pagesAEMSGARVIT SRIVASTAVAPas encore d'évaluation

- Detailed Crank Shaft DescriptionDocument110 pagesDetailed Crank Shaft DescriptionDharmendra PalPas encore d'évaluation

- Pros & Cons Vehicle Cooling SystemDocument4 pagesPros & Cons Vehicle Cooling SystemKuda BelangPas encore d'évaluation

- Lec-9 - MCE 4805 - Diesel Power PlantDocument44 pagesLec-9 - MCE 4805 - Diesel Power PlantWinden CavePas encore d'évaluation

- Need For Cooling System in IC EngineDocument19 pagesNeed For Cooling System in IC EngineKINTUPas encore d'évaluation

- Air Powered EngineDocument19 pagesAir Powered EngineSurjith Bharathi SelvakumarPas encore d'évaluation

- Diesel Engine PPDocument52 pagesDiesel Engine PPSushanthPas encore d'évaluation

- New Microsoft Word DocumentDocument7 pagesNew Microsoft Word DocumentAnil KandakatlaPas encore d'évaluation

- Jurnal TermoDocument9 pagesJurnal TermoAnonymous hlcl57mNj5Pas encore d'évaluation

- Ijaret 11 11 202Document7 pagesIjaret 11 11 202Abhisekh PattanaikPas encore d'évaluation

- Internal Combustion Engine Cooling SystemDocument6 pagesInternal Combustion Engine Cooling Systemzohaib sattarPas encore d'évaluation

- Air and Water Cooled EngineDocument3 pagesAir and Water Cooled Engineneeraj0309Pas encore d'évaluation

- Journal Engine Cooling SystemDocument8 pagesJournal Engine Cooling SystemFaqih BahrudinPas encore d'évaluation

- Power Plant AssinmentDocument8 pagesPower Plant Assinmentfawad javadPas encore d'évaluation

- Diesel EngineDocument3 pagesDiesel EngineHarpreet SinghPas encore d'évaluation

- 8 1turbochargerDocument24 pages8 1turbochargerkedir67Pas encore d'évaluation

- Qip Ice 25 Cooling SystemsDocument32 pagesQip Ice 25 Cooling SystemsBala Chandran100% (1)

- Chapter 3Document29 pagesChapter 3Hasif EnazPas encore d'évaluation

- Ic CH-11Document31 pagesIc CH-11Essa YimerPas encore d'évaluation

- 05 Starting SystemDocument9 pages05 Starting SystemAHMADPas encore d'évaluation

- 2 Stroke 4 Stroke RefrigerationDocument6 pages2 Stroke 4 Stroke RefrigerationJhay SustiguerPas encore d'évaluation

- Effects of OverheatingDocument46 pagesEffects of OverheatingSajjad Hossain ShuvoPas encore d'évaluation

- Diesel Power StationDocument30 pagesDiesel Power StationGerald EmmanuelPas encore d'évaluation

- Steam Power PlantDocument9 pagesSteam Power PlantAnne Gabrielle DavidPas encore d'évaluation

- How Does A Thermal Power Plant Work - Learn Engineering PDFDocument9 pagesHow Does A Thermal Power Plant Work - Learn Engineering PDFferayiPas encore d'évaluation

- Batch 3 - Roll Nos:52 To 58: Multi Cylinder Four Stroke Diesel Engine Test RigDocument6 pagesBatch 3 - Roll Nos:52 To 58: Multi Cylinder Four Stroke Diesel Engine Test RigArundevSArundevSPas encore d'évaluation

- Compressed Air Engines SynopsisDocument6 pagesCompressed Air Engines Synopsisalfambar902100% (1)

- Stirling EngineDocument20 pagesStirling EngineSano SanojPas encore d'évaluation

- CH 7 Heat Transfer From 24 To EndDocument12 pagesCH 7 Heat Transfer From 24 To EndaliPas encore d'évaluation

- Gas Turbine Power PlantDocument42 pagesGas Turbine Power PlantMuralikrishnan GM100% (3)

- Engine and Pump SpecificationDocument23 pagesEngine and Pump SpecificationRadamirPas encore d'évaluation

- Central RailwayDocument14 pagesCentral RailwayLazy ManPas encore d'évaluation

- The Emerging Prime Mover: Authored By: Martin Leduc, March 2001Document8 pagesThe Emerging Prime Mover: Authored By: Martin Leduc, March 2001Fait HeePas encore d'évaluation

- Motorcycle Engine Cooling SystemDocument9 pagesMotorcycle Engine Cooling SystemGODPas encore d'évaluation

- 742 Engine Cooling Broschuere NKW TM14 HELLA ENDocument20 pages742 Engine Cooling Broschuere NKW TM14 HELLA ENagvlogs5741Pas encore d'évaluation

- AEH307 2 Cooling SystemDocument28 pagesAEH307 2 Cooling SystemsiphulwazijamesPas encore d'évaluation

- Supercharging and Turbocharging in I.C. EnginesDocument7 pagesSupercharging and Turbocharging in I.C. Enginesمصطفى العباديPas encore d'évaluation

- Unit 1-Engine Room LayoutDocument15 pagesUnit 1-Engine Room LayoutKevin HadlyPas encore d'évaluation

- Chapter 9Document47 pagesChapter 9Siraj MohammedPas encore d'évaluation

- Diesel Power Plant-1Document7 pagesDiesel Power Plant-1Ankit OlaPas encore d'évaluation

- Unit-3: Diesel Power Plant LayoutDocument12 pagesUnit-3: Diesel Power Plant LayoutPavankumar PavankumarpvPas encore d'évaluation

- Diesel Powep Plant: CNSC College of EngineeringDocument26 pagesDiesel Powep Plant: CNSC College of EngineeringMark LimboyPas encore d'évaluation

- Energy Technology Notes UNIT-2Document29 pagesEnergy Technology Notes UNIT-2Dhanush JCSPas encore d'évaluation

- Diesel Power PlantDocument9 pagesDiesel Power PlantNishanth NishPas encore d'évaluation

- Air EngineDocument5 pagesAir EngineVinay MohanPas encore d'évaluation

- Turbo Xflow Project InfoDocument6 pagesTurbo Xflow Project InfoJohnPas encore d'évaluation

- Applications of Diesel Power PlantDocument3 pagesApplications of Diesel Power PlantAljebeth D. TuraPas encore d'évaluation

- KOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentDocument6 pagesKOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentArjun KhindrePas encore d'évaluation

- Diesel EngineDocument15 pagesDiesel EnginePankaj TripathiPas encore d'évaluation

- Gas Turbine PerformanceDocument24 pagesGas Turbine PerformanceAmmar Bany Ata100% (1)

- Cooling Systems in Automobiles & Cars: Gogineni. Prudhvi, Gada - Vinay, G.Suresh BabuDocument9 pagesCooling Systems in Automobiles & Cars: Gogineni. Prudhvi, Gada - Vinay, G.Suresh Babupankaj645924Pas encore d'évaluation

- Final PPT On Gas TurbinesDocument31 pagesFinal PPT On Gas TurbinesKRISHNA KUMARI100% (2)

- CYLINDER FINS Final ProjectDocument84 pagesCYLINDER FINS Final ProjectUttam Animireddy100% (1)

- Energy Conservation in Cooling TowersDocument13 pagesEnergy Conservation in Cooling TowersMohamad ChaudhariPas encore d'évaluation

- Comparison of Diesel and Petrol EnginesD'EverandComparison of Diesel and Petrol EnginesÉvaluation : 2.5 sur 5 étoiles2.5/5 (3)

- High-Performance Automotive Cooling SystemsD'EverandHigh-Performance Automotive Cooling SystemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Ahmad ShahDocument4 pagesAhmad ShahRam NetiPas encore d'évaluation

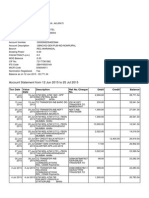

- Account Statement From 12 Jun 2015 To 25 Jul 2015Document2 pagesAccount Statement From 12 Jun 2015 To 25 Jul 2015Ram NetiPas encore d'évaluation

- Property Extensive Vs Intensive 2. Type of System Closed, Open, Isolated With Practical Example 3. 0 Law of TD 4. Temperature Measuring Instrument PropertyDocument1 pageProperty Extensive Vs Intensive 2. Type of System Closed, Open, Isolated With Practical Example 3. 0 Law of TD 4. Temperature Measuring Instrument PropertyRam NetiPas encore d'évaluation

- Rest Is BestDocument1 pageRest Is BestRam NetiPas encore d'évaluation

- Namaskar World DDocument1 pageNamaskar World DRam NetiPas encore d'évaluation

- Hellow World DDocument1 pageHellow World DRam NetiPas encore d'évaluation

- MTech Entrance 13thmay 2012Document9 pagesMTech Entrance 13thmay 2012Ram NetiPas encore d'évaluation

- BhaskarDocument1 pageBhaskarRam NetiPas encore d'évaluation

- Vibration inDocument1 pageVibration inRam NetiPas encore d'évaluation

- Bhaskar JiDocument1 pageBhaskar JiRam NetiPas encore d'évaluation

- PoojaDocument1 pagePoojaRam NetiPas encore d'évaluation

- Hello World DDocument1 pageHello World DRam NetiPas encore d'évaluation

- 02 - Fundamentals of IPEDocument25 pages02 - Fundamentals of IPEJohn Lexmar LeynesPas encore d'évaluation

- 2014 - 34 - EU - ATEX - Summary List of Harmonised Standards - Generated On 26.02.2020Document13 pages2014 - 34 - EU - ATEX - Summary List of Harmonised Standards - Generated On 26.02.2020MichałPas encore d'évaluation

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaPas encore d'évaluation

- Description: Wattstopper Occupancy SensorDocument1 pageDescription: Wattstopper Occupancy SensorJeffery OsvoldPas encore d'évaluation

- NDC SheetDocument2 pagesNDC SheetAr RadzPas encore d'évaluation

- Lamp Ba t302Document16 pagesLamp Ba t302Yeni EkaPas encore d'évaluation

- Hyosung PlanetDocument8 pagesHyosung PlanetErcan BAYRAKCIPas encore d'évaluation

- Lecture No.4 The Ideal Regenerative Rankine CycleDocument22 pagesLecture No.4 The Ideal Regenerative Rankine CycleJohn Michael Go AbalosPas encore d'évaluation

- 4l40e 5l40e 5l50e A5s360r A5s390rDocument2 pages4l40e 5l40e 5l50e A5s360r A5s390rtadeuPas encore d'évaluation

- Flush Bottom ValvesDocument3 pagesFlush Bottom ValvesErkan TakPas encore d'évaluation

- Spe 131758 Ms - GL and EspDocument11 pagesSpe 131758 Ms - GL and EspSamuel VmPas encore d'évaluation

- How Does Variable Turbine Geometry WorkDocument3 pagesHow Does Variable Turbine Geometry WorkRowan CorneliusPas encore d'évaluation

- Oscilloscope and Rc-Circuits Physics 230, Lab 5 Objective: Name PartnerDocument5 pagesOscilloscope and Rc-Circuits Physics 230, Lab 5 Objective: Name PartnerSanira LasanthaPas encore d'évaluation

- Class 12 Cbse Investigatory Project On RC CircuitDocument4 pagesClass 12 Cbse Investigatory Project On RC CircuitRishav Sureka0% (1)

- Manual Manlift 600A - Service - 3120718Document322 pagesManual Manlift 600A - Service - 3120718Yeison RamirezPas encore d'évaluation

- Case Study in Industrial Plant EngineeringDocument11 pagesCase Study in Industrial Plant EngineeringRenz Gabrielle Montalbo SomatizaPas encore d'évaluation

- Searchable Text2Document547 pagesSearchable Text2ChrisPas encore d'évaluation

- Bara Press Club BOQDocument21 pagesBara Press Club BOQIjaz AhmadPas encore d'évaluation

- Peerless Fire ProtectionDocument24 pagesPeerless Fire ProtectionAwaz E HaqPas encore d'évaluation

- Agua de Mar en Lixiviacion de CalcopiritaDocument8 pagesAgua de Mar en Lixiviacion de CalcopiritaMatias Varas AlarconPas encore d'évaluation

- PADHLENOTES - 9 - SCIENCE - CH11-Work Energy and PowerDocument13 pagesPADHLENOTES - 9 - SCIENCE - CH11-Work Energy and PowerMehul GautamPas encore d'évaluation

- Week-2 Module-1 Laws of Radiation and Their Relevance in Remote SensingDocument21 pagesWeek-2 Module-1 Laws of Radiation and Their Relevance in Remote SensingTrambak BhattacharyaPas encore d'évaluation

- Tech Talk Presentation - Emerson PDFDocument34 pagesTech Talk Presentation - Emerson PDFHemanth KumarPas encore d'évaluation

- Metal FoamsDocument135 pagesMetal FoamsShahzaib B. AbbasiPas encore d'évaluation

- Common Rail Fuel Sytem - April 07Document23 pagesCommon Rail Fuel Sytem - April 07Juan Asarcado100% (2)

- DPP Physics Class-12Document252 pagesDPP Physics Class-12tirth_diwani0% (1)

- Inspection Checklist For Installation of Earthing System123 PDFDocument1 pageInspection Checklist For Installation of Earthing System123 PDFKuljinder VirdiPas encore d'évaluation

- 2023 Beacon New Machine CatalogueDocument51 pages2023 Beacon New Machine CatalogueJair OmarPas encore d'évaluation

- Fme ProcedureDocument95 pagesFme ProcedureHowardCarpenter100% (1)