Académique Documents

Professionnel Documents

Culture Documents

Code Review - Time-Of-Flight Diffraction and Pulse Echo Line Scanning

Transféré par

Satyabrata KunduTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Code Review - Time-Of-Flight Diffraction and Pulse Echo Line Scanning

Transféré par

Satyabrata KunduDroits d'auteur :

Formats disponibles

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

1 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

NDT.net - February 2001, Vol. 6 No. 2

Presented in the Seminar on Automated Ultrasonic Inspection of Welds Using Time-of-Flight Diffraction and Pulse Echo Line

Scanning at Edison Welding Institute in March 2000

E. Ginzel

Materials Research Institute

Waterloo (ON) Canada

M. G. Lozev, Ph.D.

Senior Engineer

Edison Welding Institute

NDE Technology Team

1250 Arthur E. Adams Dr. Columbus, OH 43221

Phone: 614-688-5188, Fax: 614-688-5001

email: mark_lozev@ewi.org

Overview

Definitions: what are Codes

Codes vs. Guides

Some Rules applicable to UT or in which UT is applicable

Codes and Mechanised UT

Codes considering TOFD

Code Cases, communications and future requirements

Summary

Codes, Standardes and Procedures

The terms "code", "standard", "specification" and "procedure" are often confused in NDT. In some

cases these terms are used inter-changeably. However from a technical point of view each refers to a

separate type of document. To avoid even further confusion we will restrict our definitions to the

written documents implied by these terms. This caution is due to the common referral to calibration

blocks or test pieces with known defects used to verify accuracy of a test procedure as a "standard".

A standard is a written document assembled by recognized experts, with the purpose of recommending

actions to achieve certain objectives. An example of a standard is the American Society of

Nondestructive Testing Recommended Practice No. SNT-TC-1A. This is a standard for qualification

and certification of NDT personnel by employers.

A standard is usually enforced or given authority by an organization or agency (typically professional

societies or national institutions). When a set of standards is incorporated into law and thereby

enforceable legally it is considered a code. Examples of codes are:

American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

Canadian Standards Association (CSA) Z184 Gas Pipeline Systems.

A federal agency may reference a Standard and thereby give it code status; e.g. 49 CFR 192 is the

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

2 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

American pipeline regulatory document and it references API Standard 1104 Welding of Pipelines and

Related Facilities. Another example is the Canadian Atomic Energy Act (an Act in Parliament)

referencing CSA Z-285 General Requirements for Pressure Retaining Systems of Components in

Candu Nuclear Power Plants.

When a user or purchaser of a specific product requires assurance of quality level they will often

arrange their own document describing specific test parameters and acceptance criteria. Such a product

specific standard is considered a specification. Although it may reference other codes and standards it

can require more stringent limits than the more general standards or it may avoid any reference to a

Code or Standard.

To avoid the ambiguity of the usually general standards, and to avoid the constant updating of

specifications that refer to national standards which are constantly revised, companies often develop a

procedure.

The procedure can address the company's needs by setting out its standard practices for the various

aspects of the test method, such as; procurement, processing, periodic controls, approved materials and

accessories.

Finally, as a contracted inspection company applies a test to various parts, the variations available to

achieve the desired results can be too myriad to list in the body of a procedure document and

generalisations are again too vague. A common method of addressing the specific inspection

application to a specific part is to use a technique sheet.

In summary, there is a hierarchy of documentation in NDT.

1. Standards and codes, which provide general guidelines and limits

2. Specification, which is a product specific document usually assembled by the customer or owner

3. Procedures, which are usually a company's statement of their standard practices or a document

designed to address the requirements of a specification issued by the company they are providing

a service to.

4. A technique sheet is often part of a procedure and provides a brief description of test application

to a specific part.

Code versus Guide

A special condition exists when a technical committee decides that a method of performing a function

should be better explained. In the American Society for Testing and Materials (ASTM) there is a

special category of a standard called a Guide.

As defined in the ASTM Blue Book, Form and Style for ASTM Standards a Guide is a compendium

of information or series of options that does not recommend a specific course of action. When

referencing ASTM many people refer to the publications as Codes however, the title of the volumes

clearly indicates that these are Standards as opposed to Codes; i.e. the Annual Book of ASTM

Standards vol. 03.03. This applies to other similar documents and organisations; e.g. British Standards

Institution.

A careful look at the wording in standards indicates the prevalence of should instead of shall. This is

especially true when the Standard is a standard Guide.

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

3 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Some Rules applicable to UT or in which UT is applicable

Time-of-Flight-Diffraction is one of the main concerns of this seminar and is quite simply another

ultrasonic inspection technique. Ultrasonic inspections generally can either be required by a Standard

or in turn may be regulated in some way by a Standard.

As an example; ASME Section VIII will require an ultrasonic inspection be carried out on a component

and describe the acceptance criteria for the test method. This Section of the Code does not tell you how

to perform the inspection. ASME VIII references Section V to describe how inspections are to be set

up and carried out.

Therefore we would expect to have to consider two sorts of Standards for TOFD;

One describing how to carry out the test (probes, frequencies, angles, etc.)

One describing on what it will be applied and how to evaluate the results of the test.

In practise however, only one of these exists for TOFD and even that is more informative than

nominative. Guides on the use of TOFD exist but Standards actually requiring TOFD and providing

acceptance criteria are still absent.

Codes and Mechanised UT

Codes and Standards are by their nature, slow to change. The acceptance criteria in many codes we

have to deal with in NDT had their foundation in workmanship standards and these were often based

on the results of what radiography could find. Flaw detection and evaluation by ultrasonic testing was

more difficult to regulate because its results are heavily dependant on the skills of the manual

ultrasonic operator. Codes and Standards have been carefully worded to address how to control the

manual inspection to ensure good probability of detection and repeatability of results. As

mechanisation of ultrasonic inspection became more common the Codes did not change. Instead, the

mechanics of inspections were more likely to be adapted to meet the wording of the Code or Standard

and the many advantages they could have provided were restricted by the rules for inspection.

In 1979 Maurice Silk and his associates in Harwell introduced the TOFD technique to the world. This

came about from the need to more accurately size defects than had been possible using standard

amplitude methods. The success of the method as a detection and sizing tool has been well documented

throughout the literature.

1. Accurate Crack Depth Measurements in Welded Assemblies,Silk,M.G., Eighth World

Conference on NDT, Cannes, France, 1976

2. PISC (1979) Evaluation of the PISC Trial Results, volumes I through V of Report No. EUR

6371 en, Commision of the European Communities, Brussels

3. PISC (1986) A Summary of the PISCII Project, Ultrasonic Inspection of Heavy Steel

Components, R.W.Nichols & S.Crutzen, Elsevier Applied Scienc Publishers, London 1988

4. Depth Measurements in Pressure Tubes Using Crack Tip Diffraction, F.Mastroianni and

M.D.C.Moles, Ontario Hydro Research Division Report #86-293-K, 1986

5. F.H. Dijkstra, T. Bouma, Inspection of complex geometries with Time-of-Flight Diffraction, 14th

International Conference on NDE in the Nuclear and Pressure Vessel Industries, 24-26 Sept.

1996 Conference Proceedings

6. H. Heckhuser, K.-H. Gischler, Das Zipscan -System bei der Ultraschallprfung an plattierten

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

4 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Bauteilen und Rohrleitungen, Tagungsband der DGZfP "Automatisierung in der

Ultraschallprfung , Stand der Technik, Entwicklungstendenzen bei mobilen Prfanlagen"

(1989)

7. B. Bttcher, E. Schulz, H. Wstenberg, A new method of crack determination in ultrasonic

materials testing Proc. 7th Int. Conf. on NDT, Warschau 1973, Reprint No.130

8. M.G. Silk, B.H. Lidington, Defect Sizing using an Ultrasonic Time Delay Approach, British

Journal of NDT, March 1975

9. M.G. Silk, The rapid analysis of TOFD data incorporating the provisions of standards, Proc. 6th

European Conf. on NDT, 24.-28. Oct. 1994, Nice France, Vol. 1

10. T. Just, G. Csapo, Ultrasonic crack depth measurement of surface breaking cracks in piping,

UTonline Journal www.ultrasonic.de (also presented at the DGZfP workshop 1994)

11. Final Draft prENV 583-6, Nondestructive Testing -Ultrasonic Examination- Part 6: Time of

flight diffraction, technique as a method for defect detection and sizing

12. J. Verkooijen, TOFD used to replace radiography, INSIGHT Vol. 37 No 6 June 1995

13. M.G.Silk, Estimates of the probability of detection of flaws in TOFD data with varying levels of

noise, INSIGHT Vol. 38 No 1 January 1996

In spite of the acknowledged success of the TOFD method it has been a 30 year struggle to get

meaningful Codes and Standards that allow its use. Still today, it is difficult to apply TOFD and take

advantage of its benefits of speed in detection as well as its sizing accuracy because it is not described

in most codes referenced by designers.

Codes considering TOFD

In 1989, ten years after its introduction, M. Silk wrote a paper on how TOFD could be applied to

ASME Section XI (Maurice Silk, "Interpretation of TOFD data in the light of ASME XI and similar

rules" British Journal of NDT vol 31, May 1989). At that time ASME Section XI allowed the

application of fracture mechanics to assist in determining the disposition status of a flaw detected by

NDT.

However, in 1989 the applicable Section V, which would have been referenced for any ultrasonic

inspection, would not have even considered computerised imaging techniques (CITs) of which TOFD

would be only one subsequently described. CITs were first introduced in the 1992 Addenda (Dec. 31

1992) of the Article 4 in Section V. This finally allowed TOFD to be used (Non-mandatory Appendix E

Paragraph E-80). This paragraph acknowledged TOFDs ability to both detect and size volumetric and

planar flaws (sizing being limited to planar flaws).

This acceptance in ASME Section XI may be considered the foot in the door that TOFD needed to be

accepted as a viable ultrasonic tool in a regulatory conscious world. However, as just one of the tools

available in Section XI its use was restricted to a tool for sizing and dispositioning flaws found during

in-service inspections of pressure vessels.

Parallel development was being carried out to enlighten the potential hands-on users how to carry out

TOFD inspections. This led to the development of the Standard Guides.

Standard TOFD Guides include:

BS 7706 (1993) Guide to Calibration and setting-up of the ultrasonic time-of-flight

diffraction (TOFD) technique for detection , location and sizing of flaws.

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

5 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

British Standards Institute 1993. CEN prEN 583-6 Time of Flight Diffraction Technique as a

method for defect detection and sizing

Note: Although CEN prEN 583-6 stipulates specific requirements in some aspects of the test, many

aspects are addressed as recommendations as opposed to requirements. For this reason we have

included it with BS 7706 as a guide.

Comparison of BS 7706 and EN 583-6

Item

Scope

BS7706

States that it provides guidance and

suggests that the linear scan (which it

calls a D-scan) is applicable for initial

scanning and a B-scan (motion parallel

to the plane of the beam axis) is done

for accurate sizing

References

References are both Normative and

Informative and all are British

Standards

Definitions

Several common words are defined

(several

such as; hardcopy, probe, transducer,

differences)

flaw height Some special words are

defined: lateral wave, creeping wave,

B-scan and D-scan

Principles of the General description and several

Technique

equations to define flaw depths

(Method in EN

583-6)

Personnel

Equipment

requirements

Probes

Guiding

mechanisms

EN 583-6

States that it defines general

principles for TOFD

Only Normative standards are

referenced and all are EN

standards

Several symbols used in diagrams

are defined

Nonparallel scan and S-scan are

defined and equate to BS 7706

B-scan and D-scan respectively

Very general statement on the

principles is made and then

requirements for surface

condition (as per EN 583-1) and

couplant are made.

Cautions against using TOFD on

coarse grained materials

Requires general familiarity and

Qualification to EN 473 as a

suitable training(Guidelines for training minimum plus additional training

provided in Annex E)

in accordance with a written

practice

Minimum parameters are

General guides are suggested as giving stipulated: e.g. receiver

suitable results: e.g. pulser, receiver and bandwidth, pulser rise time,

digitiser parameters.

A-scan sampling rate (minimum 1

sample per mm)

Guidance suggesting short pulse higher Stipulates 2 probes, Same centre

frequency probes

frequency within +/-20%, Pulse

width not to exceed 2 cycles

Recommends:

Frequency and refracted angles

Not covered

Require the use of mechanics to

ensure probe spacing and encoded

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

6 of 17

Equipment

Set-up

Procedures

Interpretation

and Flaw

Analysis

Estimation of

Flaw

Dimensions

Limitations

Reporting

requirements

Reference

Blocks

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

positioning of probes and

accuracy with respect to reference

line must be within 10% of probe

centre spacing

Extensive discussions on the parameter Special note in Section 7 states

considerations are given: geometry,

that the arrangements of probes

surface conditions, probe

provided are NOT mandatory.

parameters,temporal and spatial

Considers probe parameters,

resolution, sensitivity, and digitising

digitiser window, sensitivity, scan

rates.

resolution, scan speed, and

checking system performance

Reporting or Acceptance criteria to be Reporting or Acceptance criteria

agreed upon by contracting parties

to be agreed upon by contracting

General description of flaw recognition parties Basic information is

is provided with a more detailed

provided on use of phase analysis

description and examples in Annex D to determine flaw extents Three

Five classes of flaw:

classifications of flaw:

1. Planar

1. Top Surface breaking

2. Volumetric

2. Bottom Surface breaking

3. Threadlike

3. Imbedded

4. Point

5. Unclassified

A special section Section 8 is devoted to Analysis of flaw depth and extent

a general principles then a detailed

are covered in the same section

description for accurate sizing is

(Section 8) as the interpretation of

provided in Section 9

findings

EN uses the term Estimation in

regards to all sizing and provides

equations for depth analysis

(similar to those found in BS7706

Section 4, Principles to the

method)

Section 11 covers the many variables Section 10 discusses the variable

that would cause inaccuracies in the

causing errors in the accuracy of

technique

flaw sizing and location.

Caution is also made to not

confuse precision and resolution

Covered in Annex B

Allows TOFD without Data

recording in certain simple

applications

Reporting to conform to EN

583-1 as applicable

Suggests blocks be the same materials Requires

and thickness of the test piece Suggests Blocks be of the same material as

that narrow V-notches or Side Drilled part to be tested

Holes may be used as diffractor targets Blocks must have a wall thickness

equal to or greater than nominal

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

7 of 17

Annexes

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

A (informative) Special

Techniques based on TOFD

B (informative) Application of

TOFD and reporting criteria

C (informative) Suggested Steps

towards characterisation of flaw

echoes in TOFD

D (informative) Examples of

typical scans

E (informative) Suggested

framework for training and

qualification

wall of test part Width and length

of block must be adequate for

probe movement over reference

diffractors

A (normative) Reference

blocks

Table 1

These two guides are very similar, even following a nearly identical outline format.

European countries have been eager to adapt TOFD to inspections but have been no faster in

developing Codes or Standards which can be used with TOFD.

Except for the Guides available there are still no other internationally recognised Standards other than

ASME that have incorporated TOFD as part of the acceptance criteria evaluation tools.

Codes and Standards applicable to TOFD include:

BS 7706 (1993) Guide to Calibration and setting-up of the ultrasonic time-of-flight

diffraction (TOFD) technique for detection, location and sizing of flaws. British Standards

Institute 1993.

Pr EN 583-6

Time of Flight Diffraction Technique as a method for defect detection and

sizing

ASME Boiler & Pressure Vessel Code Section V (as a CIT option in Article 4)

ASME Boiler & Pressure Vessel Code Section VIII (in a Code Case in lieu of RT)

ASME Boiler & Pressure Vessel Code Section XI (for accurate sizing)

ASME adaptations to TOFD are somewhat circuitous.

E.g.

ASME V Article 4 Para T-436 Computerized Imaging Techniques (CITs)

The paragraph states that, CITs may also be used to perform the basic scanning functions for

flaw detection. Then it refers the reader to Appendix E. E-10 lists general requirements for CITs

including instrument specifics, procedure requirements and the need for the dimensional

information on the displays. E-80 then discusses Automated Data and Imaging Technique as one

of the CITs. This describes the basic features of TOFD without calling it a TOFD technique;

including scrolling RF waveforms, and sizing using tip diffracted waves.

ASME VIII Code Case 2235 (2000 Edition)

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

8 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

In the paragraph requiring that ultrasonic examination be performed in accordance with ASME

Section V, Article 4 (this article acknowledges CITs of which TOFD is one). A further statement

is made. Alternatively, for techniques that do not use amplitude recording levels, acceptable

performance is defined as demonstrating that all sized flaws, including the 0.06t flaws have an

indicated length equal to or greater than the actual length of the specified flaws in the

qualification block. This has clearly opened the door for TOFD to be used on Section VIII

pressure vessels.

ASME XI is specific to nuclear applications and is the item Silk pointed to for TOFD to meet

the requirements of. Division 1 IWA-3000 requires that flaws detected during In-service

inspections that exceed acceptance standards of Section III be evaluated to determine

disposition. IWB dealing with Class I components allows acceptance by analytical evaluation

(XI Div.1 IWB 3132.3). This requires the calculations as per IWB-3600 (fracture mechanics).

Appendix I of ASME XI is the mandatory appendix for Ultrasonic Examination. Under Flaw

Sizing of that appendix it states that flaws must be sized in accordance with Sec. XI Appendix

VIII. This essentially requires a statistical assurance that ANY sizing technique meets the lateral

and vertical accuracy stipulated in ASME XI.

In 1996 the Dutch NDT Society (KINT) submitted a Draft European Standard, De ontwikkelig von

acceptatiecriteria voor de TOFD onderzoemethode (Acceptance Criteria for Time of Flight

Diffraction).

This proposes a table of acceptance criteria for all indications that are detected. Detection is based on

the settings set out for TOFD in a separate document (prEN 583-6).

Maximum allowable length (lmax) maximum allowable height (h1)

if height does not exceed h2

when length exceeds lmax

Thickness Range

Lmax

h2

h1

D

2.5

1

6mm < d 8mm

D

3

1

8mm< d 15mm

15

3

2

15mm< d 40mm

20

4

2

40mm < d 60mm

25

5

2

60mm < d 100mm

50

5

3

100mm< d 200mm

D > 200mm

70

6

3

KINT Acceptance Table

(*) d = design thickness

API Adaptations to TOFD

Draft-API 579 Recommended Practice for Fitness-for-Service (The crack depth, length, angle and

distance to other surface breaking or embedded cracks is typically determined using UT examination

techniques, either TOFD or angle beam.

Draft-API 580 Risk Based Inspection Recommended Practice (Base Resource Document recommends

automated ultrasonic shear wave testing as a highly effective inspection technique for crack detection

and sizing. The capability of the AUT technique/type is evaluated using probability of detection

(POD) curves from round-robins in the past where TOFD showed the best performance)

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

9 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Projects, communications, Code Cases and the future

From the apparent lack of Codes and Standards it is difficult to imagine how TOFD became as popular

as it has. But we should keep in mind that there is another level of regulation in the hierarchy;

Specifications.

It has been the recognition of individual companies of the advantages of TOFD that has provided the

necessary venue to prove to the world that TOFD has an important role to play. There are examples of

the application of TOFD on many major projects around the world.

Projects using TOFD

A major oil company (Chevron) accepted the test results by a large fabrication company (DaeWoo

Heavy Industries) on an off-shore oil rig structure in which TOFD was used. Originally the

requirements of API RP2X were required (Recommended Practice for ultrasonic Examination of

Offshore Structural Fabrication and Guidelines for Qualification of Ultrasonic Technicians). The

technique used combined both TOFD and pulse-echo ultrasonics and did NOT use a raster scan to

provide full volume coverage by the pulse-echo probes. Instead, the pulse-echo was used only for the

inner and outer edges while the middle volume was inspected ONLY using TOFD. After verification of

the ability of the technique on several test samples and the acknowledgement of the regulatory body

(DNV) that good probability of detection had been achieved, the project proceeded. Steel butt welds

from 25mm to 100mm thick were reliably inspected faster than possible using standard pulse-echo UT,

much faster and with much more sensitivity than radiography and without the radiation hazards and

other restrictions associated with working around radiation.

Another example of an independent engineering specification using TOFD is in the pipeline industry.

In 1997 TransCanada Pipelines expanded their use of mechanised ultrasonic testing to manually

welded circumferential seams. However, due to the higher probability of off-angle defects in the

SMAW process as compared to the mechanised GMAW process, the new specification issued now

requires the addition of TOFD to carry out any mechanised UT inspections on GMAW welds.

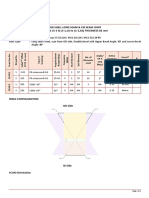

Example of the required display for GMAW welds (includes TOFD and pulse-echo information)

The pipeline application in TCPL eventually led to the development of the new ASTM Standard

E-1961. This application with TOFD combines the rapid detection/evaluation abilities associated with

multiple pulse-echo probe arrays used in a linear scan with the characterisation capabilities of TOFD to

aid in elimination of false calls. The pulse-echo probes required in the system also ensure that the poor

coverage that can occur in the near zone (upper 3-5mm) and mismatched back-wall regions using only

TOFD, are adequately inspected.

In another project submerged-arc-welded seams were being inspected using the standard code

requirements found in CSA Z-245 (essentially the same as ASTM E-273 and API 5L). During routine

sectioning on a lot, some welds were found to have shrinkage cracks. The ultrasonic technique being

used could not reliably detect these defects so a technique was developed to add a TOFD configuration

into the standard set-up. In this case the shortcomings of pulse-echo are overcome by TOFD.

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

10 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Fig:TOFD Results on

Chevron Qualification Weld

48mm Thick

Fig:Example of the

"required" display for

GMAW welds (includes

TOFD and pulse-echo

information)

Fig:Defects Placed in the Chevron Qualification Weld

Fig : Shrink Cracks in SAW Weld

TOFD significantly improved detection over the code required technique

Number of Pipe

Seams tested

149

Number of Indications detected using

Mechanised OD UT (>80% reference)

20

Number of Indications

detected using TOFD

35

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

11 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Fig : TOFD indication of a shrink crack

These three examples are typical of the application of TOFD to solve problems that are not adequately

addressed by the existing Codes and Standards.

What all these examples have in common is a linear scan. A raster scan is the traditional way of

carrying out a manual inspection. This is done by moving the probe perpendicular to the weld axis

allowing the volume to be covered.

Fig : Raster scan volume

coverage of a weld using

forward and backwards

motion.

When mechanised this process moves the probe in a fixture with a series of motions similar to the

manual movement and data collection is done on the forward and backward motions.

Fig : Traditional raster scan in a mechanised set-up

A linear scan moves the probe parallel to the long axis of the weld. Data collection is done on the scan

parallel to the weld and the raster step may not be required if multiple probes are used or if the probes

used provide the coverage required (e.g. TOFD and limited pulse-echo coverage).

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

12 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Fig : Linear scan for increased data collection speed

Communication

In addition to the insistence of various industries to push ahead with the advantages of TOFD there are

also efforts being made to get Codes and Standards changed or made to recognise and incorporate

TOFD more fully.

In November 1996 one of the authors submitted a formal Technical Inquiry to the ASME Section V

committee concerning TOFD. The Question was stated in the required format. This included a

background comment, the question, then a proposed answer and rationale:

Comment:

Article 5 paragraph T542.4.3 references Article 4 Appendices B and C as examples of general

techniques for performing a weld inspection. The paragraph also states; Other techniques may be

used.

Question:

Does this imply that Article 5 paragraph T542.4.3 allows non-amplitude based techniques, such as

Time of Flight Diffraction Technique, to be used as detection methods instead of pulse echo ?

Proposed answer :

YES. Provided that the technique can be demonstrated to detect the basic calibration reflectors in the

basic calibration block and the technique is demonstrated to provide the volume coverage required by

the referencing code section.

The ASME reply was received in Nov. 1997. They disappointingly stated No.

This implied that TOFD was not recognised as a DETECTION method by the committee.

However, in the same letter to the ASME an enquiry as to the use of a linear scan technique was made:

Comment:

Both Article 4 paragraph T-424.1 and Article 5 paragraph T-523.1 consider examination coverage. The

wording assumes that only simple pulse-echo scanning with a raster style scan pattern will be used.

Question:

Are the requirements of Article 4 paragraph T-424.1 and Article 5 paragraph T-523.1 met by

techniques employing a single pass; such as Time of Flight Diffraction, multiprobe arrays and phased

arrays?

Proposed answer :

YES. Provided that the technique can be demonstrated to detect the basic calibration reflectors in the

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

13 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

basic calibration block and the technique is demonstrated to provide the volume coverage required by

the referencing code section.

In this case the committee agreed!

With the ASTM E-1961 Standard then in draft before the ASTM committee it made the case for a

non-raster technique described in E-1961 suitable for ASME style inspections. The standard raster scan

moves the probe perpendicular to the weld axis for the scan step and the small raster parallel to the

weld axis is a non-data collection step. With the usually short scan length of the data collection scan

(typically 50-200mm) the ramp-up and ramp-down requirements in motor controllers makes this a very

slow process. When the main axis of data collection can be the scan parallel to the weld axis the

maximum scan speed can me sustained for a long period of time and less time is wasted in the small

increment step. When phased arrays or multiple probe arrays can be arranged to ensure the coverage in

a linear scan the scan times can be significantly reduced.

There is a difference between the two scans. The traditional raster scan allows the operator to see the

signal peaked in the centre of the beam. Whereas the linear scan may result in a less than maximum

amplitude if the step positions the probe beam at a point either side of the maximised reflection point

(but the same point could be made for length sizing with the traditional raster motion).

A third point was raised to the ASME Section V committee and also received a disappointing negative.

Comment:

Article 5 paragraph T-542.7.2.3 requires scanning to be performed at a gain setting at least two

times the primary reference level. Computerized Imaging Techniques in conjunction with Time

Corrected Gain permit display of signals over a set threshold and can even allow variability of

this threshold after the data has been collected if waveforms are stored. Scanning at a gain setting

over reference could result in saturating signals unless logarithmic amplifiers are used.

Question:

If Computerized Imaging Techniques in conjunction with Time Corrected Gain can the

requirement of Article 5 paragraph T-542.7.2.3 for scanning with extra gain be met by setting

appropriate thresholds?

Proposed answer :

YES. Article 5 paragraph T-542.7.2.3 also states that Evaluation will be performed with respect

to primary reference level. Since the computerized image is the recording that would be used for

evaluation it should correctly indicate amplitude at the primary reference level.

ASME Section V decided that NO was the correct answer but no rationale was provided explaining

how scanning at 6dB over the reference was fundamentally different from reducing the data

collection/evaluation threshold of the raw data by 6dB.

Code Cas

A year later a different committee (ASME Section VIII SC-VIII SG&I) was approached with a

revision to a Code Case. The Code Case 2235 was titled: Use of Ultrasonic Examination in Lieu of

Radiography Section VIII, Division 1 and 2. It was issued in December 1996 and then applied to

materials 4 inches thick and greater using standard UT methods described in Section V. A more recent

visitation of this Code Case was made to extend the thicknesses it was applicable to and to consider

non-amplitude based ultrasonic techniques.

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

14 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Case number 2235 has since passed the approval of the committee and is due to be incorporated into

Code.

Its inquiry asked: Under what conditions and limitations may an ultrasonic examination be used in lieu

of radiography, when radiography is required in accordance with Section VIII, Division 2, Table

AF-241.1?

It the reply, the code case states that: It is the opinion of the Committee that all welds in material 1/2 in.

or greater in thickness in pressure vessels may be examined using the ultrasonic (UT) method in lieu of

the radiography (RT) method, provided that all of the following requirements are met:

It goes on to make several requirements including that ultrasonic examination be performed in

accordance with ASME Section V, Article 4. This would seem to again limit the use of TOFD based on

the Section V committee reply of 1997. However, in the same paragraph requiring that ultrasonic

examination be performed in accordance with ASME Section V, Article 4 a further statement is made.

Alternatively, for techniques that do not use amplitude recording levels, acceptable performance is

defined as demonstrating that all sized flaws, including the 0.06t flaws have an indicated length equal

to or greater than the actual length of the specified flaws in the qualification block.

Other references are also made in the Code Case 2235 to methods or techniques that do not use

amplitude recording levels. This has clearly opened the door for TOFD to be used on pressure vessels.

Where are we heading now

In a Paper from 1991, Weld Metal Fabrication v 59 n 8 Oct 1991 3p ISSN: 0043-2245, J. Lilley and P.

Osborne examined the potential of time-of-flight diffraction (TOFD) to replace the traditional methods

of inspecting fabricated tubular components.

They speculated in this article that TOFD would eventually replace radiography and traditional

ultrasonic testing as the primary method for detecting and sentencing on tubular components. They also

caution that this is a very large step partially because of the lack of suitable codes.

Lilley also suggests that it would be possible to introduce codes and acceptance criteria but it would

take a great deal of time and money for the validation process. As a result, industry will need to wait

many years before the benefits of the method are realised.

Lilley proposed a step-by-step method of introducing TOFD and warned that it would be industry

driven.

This iterative process would involve using TOFD as a screening method for manual

ultrasonics. Having proven the detection capability of the calibration holes (as in a standard ASME

block with side drilled holes) TOFD would be used to detect any indications with a length greater than

allowed by the manual Code. Having found any such indications the manual techniques would be used

to disposition the indication. Comparing TOFD results and manual UT results to excavation results

would be used to establish a database from which a TOFD acceptance criteria could be established.

A parallel programme comparing radiographic results and TOFD to excavations and metallography

would similarly be used to assure industry of TOFDs ability to be used in lieu of radiography.

In 1995 Det Norske Veritas (DNV) adopted a document by Olav Forli, et al (Nordtest). The document

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

15 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

entitled Guidelines for Replacing NDE Techniques with One Another describes options for industries

interested in using one NDE method in lieu of another. This process is much the same as Lilley

suggested in 1991 that industry should do to establish a credibility and assurance of detection for

TOFD to be used in lieu of manual UT or radiography.

The DNV paper goes into lengthy descriptions of how to set up programmes and establish Probability

of Detection (POD) curves.

This document was in fact what was used for the heavywall inspection of the off-shore structure project

(DHI) described above. Having substantiated the abilities of the TOFD method according to this set of

rules the DNV inspection team overseeing the project was able to accept the inspection technique and

results submitted.

Summary

A technical hierarchy of rules exists: Codes, Standards, Specifications, Procedures and Techniques

Until recently no Code existed that recognised TOFD so its use was restricted Two documents (BSI &

CEN) are well known TOFD Standards but both are Guides

A Code using TOFD specific acceptance criteria has been drafted but is as yet still in formulation stage

Presently an ASME Code Case to replace RT with UT has resulted in incorporating TOFD into

pressure vessel work for both detection and sizing of flaws.

Results of the many TOFD projects can be used in a format of statistical studies to allow TOFD to

replace manual UT or radiography.

TOFD has been used on projects where:

Codes are not applicable but POD requirements are high

TOFDsizing can be used in conjunction with fracture mechanics

existingcode requirements have been known to miss defects

speed of detection is an important consideration

Code/Standard Title

Comment

Guide to Calibration and setting-up of the ultrasonic

BS 7706

time-of-flight diffraction (TOFD) technique for

Guide only

(1993)

detection ,location and sizing of flaws

Time of Flight Diffraction Technique as a method

Pr EN 583-6

Guide only

for defect detection and sizing

as a CIT option in

ASME

Section V

Article 4

in a Code Case in lieu

ASME

Section VIII

of RT)

ASME

Section XI

(for accurate sizing)

Draft standard

KINT

norm pr 9Exxx

submitted to CEN based

on 1998 report

List of TOFD Related Codes, Standards and Draft Standards at this time

Finally; after over 20 years TOFD is being recognised as a powerful tool for NDT. But no single NDT

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

16 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

method finds ALL defects. Each method has its advantages and limitations. With the regulatory bodies

now gradually recognising the strengths of TOFD for detection and sizing, it is likely that the financial

benefits of TOFD will now drive industry to promote its use.

In a more general respect, it is obvious to more and more users that automated ultrasonic inspections

are becoming superior to manual UT in many regards, particularly speed and repeatability.

In 1989 the IIW published a Guide entitled Automated Ultrasonic Inspection of Welds; Guidance on its

Merits, Performance Requirements, Selection and Applications.

British Standards has on its listings a Standard BS 3923 part 2 1972 Ultrasonic examination of welds.

Automated examination of fusion welded butt joints in ferritic steel. Presently this standard is still

current but it is acknowledged by most as being very out of date. The Welding Institute proposed a

draft revision to this (Revision #6 was in March 1995 BSI Committee WEE/46/-/13) but as yet no

replacement exists. (The existing standard covers requirements for equipment, surface condition, parent

metal examination, weld examination, evaluation of imperfections, test plates and presentation of

results. Appendices on determination of probe characteristics, use of DGS diagram and method for

setting sensitivities.)

In 1998 ASTM E-1961 became one of the first American standards to be dedicated to the application

of mechanised UT to weld inspections.

Other Standards in which mechanised UT and linear scanning is applicable include:

Mechanised ultrasonic inspection of girth welds using zonal discrimination

with focused search units

API 5L

Steel Line Pipe

CSA Z-245.1 Steel Line Pipe

Ultrasonic examination of welds. Automated examination of fusion welded

BS 3923 part2

butt joints in ferritic steel

ASTM E-273 Ultrasonic examination of longitudinal welded pipe and tubing

ASTM E-1961

In a recent meeting of the Commission V of the IIW, 22/07/99, there was a micro-seminar - 'Automated

UT and TOFD - Techniques. - Acceptance Criteria, Reliability, Cost-effectiveness, Human Factor and

Qualification' (V-1142-99). At this session a German proposal for a new European standard was

introduced in the Sub-commission VC discussion.

Guide draft, September 1998

Ultrasonic testing systems for automatic inspections

(prepared by the German Society for NDT)

This is a guide for users of automatic ultrasonic inspection systems. This guide should help in selection

and application of such systems.

The guideline will give instructive and helpful information to users considering relevant requirements

of clients and of existing inspection standards to

Probes and sensors

7/26/2015 9:27 AM

Code Review: Time-of-Flight Diffraction and Pulse Echo Line Scanning

17 of 17

http://www.ndt.net/article/v06n02/eginzel/eginzel.htm

Manipulation and control systems

Ultrasonic devices

Data recording and data visualisation

Data processing and evaluation

Documentation

Reference

1. Maurice Silk, Interpretation of TOFD data in the light of ASME XI and similar rules British Journal of

NDT vol 31, May 1989

2. Lilley. J. and Osborne P., Weld Metal Fabrication v 59 n 8 Oct 1991 3p

3. BS 7706 (1993) Guide to Calibration and setting-up of the ultrasonic time-of-flight diffraction (TOFD)

technique for detection , location and sizing of flaws. British Standards Institute 1993.

4. Pr EN 583-6, Time of Flight Diffraction Technique as a method for defect detection and sizing

5. ASME Boiler & Pressure Vessel Code, Section V (CIT option in Article 4)

6. ASME Boiler & Pressure Vessel Code, Section VIII (Code Case 2235 UT in lieu of RT)

7. ASME Boiler & Pressure Vessel Code, Section XI (for accurate sizing)

8. Olav Forli, et al, Guidelines for Replacing NDE Techniques with One Another Nordtest. 1994

9. KINT pr EN xxx draft Standard, De ontwikkelig von acceptatiecriteria voor de TOFD

onderzoemethode (Acceptance Criteria for Time of Flight Diffraction).

NDT.net - info@ndt.net

|Top|

7/26/2015 9:27 AM

Vous aimerez peut-être aussi

- Scan Plan 05-82mm Shell Nozzle Scan Plan Out Side - Rev-0Document4 pagesScan Plan 05-82mm Shell Nozzle Scan Plan Out Side - Rev-0Satyabrata KunduPas encore d'évaluation

- CC 35.5mmDocument1 pageCC 35.5mmSatyabrata KunduPas encore d'évaluation

- FOR SHELL LONG SEAM JOINTDocument3 pagesFOR SHELL LONG SEAM JOINTSatyabrata KunduPas encore d'évaluation

- Scan Plan 05a-89 MM Shell Nozzle Scan Plan Out Side - Rev-0Document4 pagesScan Plan 05a-89 MM Shell Nozzle Scan Plan Out Side - Rev-0Satyabrata KunduPas encore d'évaluation

- 44 MM Dish Nozzle - Rev-0Document2 pages44 MM Dish Nozzle - Rev-0Satyabrata KunduPas encore d'évaluation

- CC 33mm THK 2 PDFDocument1 pageCC 33mm THK 2 PDFSatyabrata KunduPas encore d'évaluation

- Shell To Dish Cir Seam - Rev-0Document2 pagesShell To Dish Cir Seam - Rev-0Satyabrata KunduPas encore d'évaluation

- CC 33mm THK 2 PDFDocument1 pageCC 33mm THK 2 PDFSatyabrata KunduPas encore d'évaluation

- ASME SEC VIII 2010ED thickness calculation chartDocument1 pageASME SEC VIII 2010ED thickness calculation chartSatyabrata KunduPas encore d'évaluation

- Prisma Quick Start Guide V18hdDocument57 pagesPrisma Quick Start Guide V18hdSatyabrata KunduPas encore d'évaluation

- CC 34mm THK 2Document1 pageCC 34mm THK 2Satyabrata KunduPas encore d'évaluation

- CC 33mm THK 2 PDFDocument1 pageCC 33mm THK 2 PDFSatyabrata KunduPas encore d'évaluation

- Vaastu and Interior DecorationDocument3 pagesVaastu and Interior DecorationSatyabrata KunduPas encore d'évaluation

- Vaastu and Interior DecorationDocument3 pagesVaastu and Interior DecorationSatyabrata KunduPas encore d'évaluation

- UT Technotes 2011.enDocument11 pagesUT Technotes 2011.enAlexandru StefanPas encore d'évaluation

- Healthy Eating and Active Living: For Your 1 To 4 Year OldDocument32 pagesHealthy Eating and Active Living: For Your 1 To 4 Year OldSatyabrata KunduPas encore d'évaluation

- Prisma Quick Start Guide V18hdDocument57 pagesPrisma Quick Start Guide V18hdSatyabrata KunduPas encore d'évaluation

- Groove WeldsDocument8 pagesGroove WeldsNaveen KumarPas encore d'évaluation

- Suggestions For H 00 Garr GoogDocument131 pagesSuggestions For H 00 Garr GoogSatyabrata KunduPas encore d'évaluation

- Nutritious Recipes For Complementary Feeding of Infants and Young ChildrenDocument43 pagesNutritious Recipes For Complementary Feeding of Infants and Young ChildrenMadhuri SathishPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- مقايسة الكهرباء مجمعDocument6 pagesمقايسة الكهرباء مجمعmohamedPas encore d'évaluation

- Non Conventional Sources of EnergyDocument13 pagesNon Conventional Sources of EnergyAditya Kumar100% (1)

- Molecular ElectronicsDocument14 pagesMolecular ElectronicsShashi Bhushan PrincePas encore d'évaluation

- R5582E RELAY Selection GuideDocument14 pagesR5582E RELAY Selection GuideChandra Hamidi KautsarPas encore d'évaluation

- Micron Transformers: Presented by Richard Lussier and John Levine Levine Lectronics and LectricDocument45 pagesMicron Transformers: Presented by Richard Lussier and John Levine Levine Lectronics and LectricMohammed UsmanPas encore d'évaluation

- Thrubit: Through-The-Bit Logging Services Slim Multiconveyance Formation Evaluation ToolsDocument4 pagesThrubit: Through-The-Bit Logging Services Slim Multiconveyance Formation Evaluation Toolshamed1725Pas encore d'évaluation

- Wind Turbine Blade Geometry PDFDocument9 pagesWind Turbine Blade Geometry PDFchandruPas encore d'évaluation

- Fiziks: Jnu-Entrance Examination-2010 M.Sc. Physics Maximum Marks: 90 Instructions For CandidatesDocument9 pagesFiziks: Jnu-Entrance Examination-2010 M.Sc. Physics Maximum Marks: 90 Instructions For CandidatessairajdreamPas encore d'évaluation

- Mr Example SnaglistDocument13 pagesMr Example SnaglistAnees AhmedPas encore d'évaluation

- Ion Beam Sputtering REV2016Document16 pagesIon Beam Sputtering REV2016Colin QuinnPas encore d'évaluation

- SM CHDocument492 pagesSM CHsandwichnachosPas encore d'évaluation

- Fixed Temperature Thermostats: - 1Nt SeriesDocument3 pagesFixed Temperature Thermostats: - 1Nt Serieschouaib kennichePas encore d'évaluation

- EMF, Gibbs Free Energy, and BatteriesDocument20 pagesEMF, Gibbs Free Energy, and Batteriesjerryck dulinPas encore d'évaluation

- Radiographic Interpretation Answers WIS10 CSWIP 3.2Document3 pagesRadiographic Interpretation Answers WIS10 CSWIP 3.2andrewPas encore d'évaluation

- Risk Register Template Free Download - h4GzPV3NB5EEFnVDocument11 pagesRisk Register Template Free Download - h4GzPV3NB5EEFnVNeo MothaoPas encore d'évaluation

- Ground Flares - Key Considerations for LNG ProjectsDocument8 pagesGround Flares - Key Considerations for LNG ProjectsNurul Atiqah Ahmad Kamal100% (1)

- En - SLLHIHI - Hilton Salalah Resort Sustainability Management PlanDocument12 pagesEn - SLLHIHI - Hilton Salalah Resort Sustainability Management PlanMuhammed NasirPas encore d'évaluation

- Oil & Gas Industry in IraqDocument18 pagesOil & Gas Industry in IraqSuleiman Baruni100% (1)

- NP EX19 11a JinruiDong 2Document11 pagesNP EX19 11a JinruiDong 2Ike DongPas encore d'évaluation

- Haskel Liquid PumpsDocument9 pagesHaskel Liquid PumpsWong JowoPas encore d'évaluation

- Concepts of Chemical Bonding: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument45 pagesConcepts of Chemical Bonding: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenBoNwoawaPas encore d'évaluation

- Group 08 Financial Feasibility Excel 2Document8 pagesGroup 08 Financial Feasibility Excel 2Slindokuhle ThandoPas encore d'évaluation

- Automatic Surge Tester Helps Conduct TestsDocument2 pagesAutomatic Surge Tester Helps Conduct TestsLingaraj Suresh LingaianPas encore d'évaluation

- Cleaning Krisbow 2013 (Low Res) 1Document12 pagesCleaning Krisbow 2013 (Low Res) 1harisPas encore d'évaluation

- Mechanical Science II (2009) by Nag Pati JanaDocument433 pagesMechanical Science II (2009) by Nag Pati Janazenithtutorials12100% (5)

- Determination of Avogadro's Number by Electrolysis: Q M N M Q NDocument4 pagesDetermination of Avogadro's Number by Electrolysis: Q M N M Q NDevi ShriPas encore d'évaluation

- Evolv DNA 250 Color: 400 Watt Variable Power Module With Temperature Protection, Replay, and USBDocument23 pagesEvolv DNA 250 Color: 400 Watt Variable Power Module With Temperature Protection, Replay, and USBMuhammad AswinPas encore d'évaluation

- Electrostatics and Magnetostatics Lecture TopicsDocument2 pagesElectrostatics and Magnetostatics Lecture TopicsSrinivas SamalPas encore d'évaluation

- Commissioing Startup Handbook TemplateDocument4 pagesCommissioing Startup Handbook TemplateMoud SaklyPas encore d'évaluation

- Power Transformer: Laminated CoreDocument8 pagesPower Transformer: Laminated Coreraymond balitePas encore d'évaluation