Académique Documents

Professionnel Documents

Culture Documents

LF 251-1100 - D300483

Transféré par

Anshuman AgrawalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LF 251-1100 - D300483

Transféré par

Anshuman AgrawalDroits d'auteur :

Formats disponibles

PRESSURE FILTER

Series LF 251-1100

Sheet No

1117 M

464 PSI

1. Type index:

1.1. Complete filter: (ordering example)

LF. 401. 10VG. 30. E. P. -. FS. 8. -.

1

1

2

3

4

5

8

9

10

11

12

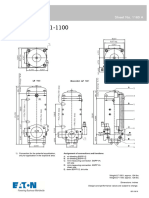

3. Dimensions: inch

type

connection

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

weight lbs.

volume tank

EDV 08/12

LF 251

SAE 1

13.94

10.00

10.24

1.54

3.15

5.51

5.12

3.15

M10x.47 deep

2.64

2.83

1.40

2.75

M12x.74deep

35

.63 Gal

LF 401

SAE 2

21.65

15.91

16.14

3.35

3.15

9.84

5.91

5.12

3.15

M10x.47 deep

2.64

2.76

1.68

3.06

M10x.74 deep

55

1.0 Gal

LF 631

SAE 2

22.09

15.98

16.14

3.39

3.15

9.84

6.69

6.30

3.15

M12x.71 deep

3.23

3.39

2.00

3.50

M12x.74 deep

77

1.4 Gal

LF 1001

SAE 3

23.03

15.91

16.14

3.94

3.54

9.84

8.66

8.07

4.57

M12x.71 deep

4.17

4.17

2.44

4.19

M16x.94 deep

99

3,0 Gal

LF 1100

SAE 5

25.24

16.93

16.14

5.19

4.57

9.84

8.66

8.07

4.57

M12x.71 deep

4.17

4.17

3.62

6.00

M16x.94 deep

112

3,0 Gal

10

-. AE

11

12

series:

LF = inl-line filter

nominal size: 251, 401, 631, 1001, 1100

filter-material and filter-fineness:

80 G = 80 m, 40 G = 40 m, 25 G = 25 m stainless steel wire mesh,

25 VG = 20 m (c),16 VG = 15 m (c),10 VG = 10 m (c),6 VG = 7 m (c),3 VG = 5 m (c) Interpor fleece (glass fiber)

resistance of pressure difference for filter element:

10 = p 145 PSI (01NR.)

30 = p 435 PSI (01NL.)

filter element design:

E

= single-end open

S = with by-pass valve p 29 PSI

B

= both sides open (LF 1001/1100) S1 = with by-pass valve p 51 PSI

sealing material:

P

= Nitrile (NBR)

V

= Viton (FPM)

filter element specification: (see catalog)

= standard

IS06 = see sheet-no. 31601

VA = stainless steel

IS07 = see sheet-no. 31602

connection:

FS = SAE-flange connection 3000 PSI

connection size:

7

= 1 (LF 251)

9 = 2 (LF 631)

C = 5 (LF 1100)

8

= 2

(LF 401)

A = 3 (LF 1001)

filter housing specification: (see catalog)

= standard

IS06 = see sheet-no. 31605

internal valve:

= without

S

= with by-pass valve p 29 PSI (LF 1001/1100)

S1 = with by-pass valve p 51 PSI (LF 1001/1100)

clogging indicator or clogging sensor:

= without

AOR = visual, see sheet-no. 1606

AOC = visual, see sheet-no. 1606

AE = visual-electrical, see sheet-no. 1609

OP = visual, see sheet-no. 1628

OE = visual-electrical, see sheet-no. 1628

VS1 = electronical, see sheet-no. 1607

VS2 = electronical, see sheet-no. 1608

1.2. Filter element: (ordering example)

01NL. 400. 10VG. 30. E. P. 1

1

series:

01NL. = standard filter element according to DIN 24550, T3

01NR. = standard return line filter element according to DIN 24550, T4

nominal size: 250, 400, 630 (01NL.), 1000 (01NR.)

see type index-complete filter

2. Accessories:

- measure- and bleeder connections, see sheet-no. 1650

- evacuation and bleeder-conections, see sheet-no. 1651

- counter flanges, see sheet-no. 1652

Changes of measures and design are subject to alteration!

Friedenstrasse 41, 68804 Altlussheim, Germany

e-mail

phone

+49 (0)6205 - 2094-0

url

fax

+49 - 06205 - 2094-40

info-internormen@eaton.com

www.eaton.com/filtration

6. Technical data:

4. Spare parts:

item

designation

qty.

dimension

and article-no.

LF 251

01NL. 250

40 x 3

304389 (NBR)

304391 (FPM)

115 x 3

303963 (NBR)

307762 (FPM)

qty.

qty.

qty.

filter element

O-ring

O-ring

O-ring (LF 401-1001)

O-ring (LF 1100)

screw plug

BSPP

304678

BSPP

304678

BSPP

304678

screw plug

clogging indicator,

visual

clogging indicator,

visual

clogging indicator,

visual-electrical

clogging indicator,

visual-electrical

clogging sensor,

electronical

clogging sensor,

electronical

13

O-ring

14

O-ring

15

O-ring

16

screw plug

9

10

11

12

1

1

1

1

1

dimension

and article-no.

LF 631

01NL. 630

60 x 3,5

304377 (NBR)

304398 (FPM)

125 x 3

306025 (NBR)

307358 (FPM)

69,45 x 3,53

305868 (NBR)

307357 (FPM)

dimension

and article-no.

LF 401

01NL. 400

40 x 3

304389 (NBR)

304391 (FPM)

115 x 3

303963 (NBR)

307762 (FPM)

56,75 x 3,53

306035 (NBR)

310264 (FPM)

1

1

dimension

and article-no.

LF 1001/1100

01NR. 1000

90 x 4

306941 (NBR)

307031 (FPM)

185 x 4

305593 (NBR)

306309 (FPM)

85,32 x 3,53

305590 (NBR)

306308 (FPM)

136,12 x 3,53

320162 (NBR)

320163 (FPM)

BSPP

304678

BSPP

305003

AOR or AOC

see sheet-no. 1606

OP

see sheet-no. 1628

OE

see sheet-no. 1628

AE

see sheet-no. 1609

VS1

see sheet-no. 1607

VS2

see sheet-no. 1608

15 x 1,5

315357 (NBR)

315427 (FPM)

22 x 2

304708 (NBR)

304721 (FPM)

14 x 2

304342 (NBR)

304722 (FPM)

BSPP

305003

temperature range:

operating medium:

max. operating pressure:

test pressure:

connection system:

housing material:

sealing material:

installation position:

mini-measuring connection:

evacuation-or bleeder-connection:

+14F to +176F (for a short time +212F))

mineral oil, other media on request

464 PSI

900 PSI

SAE-flange connection 3000 PSI

EN-GJS-400-18-LT

Nitrile (NBR) or Viton (FPM), other materials on request

vertical

BSPP

BSPP

Classified under the Pressure Equipment Directive 97/23/EC for mineral oil (fluid group 2),

Article 3, Para. 3.

Classified under ATEX Directive 94/9/EC according to specific application (see questionnaire

sheet-no. 34279-4).

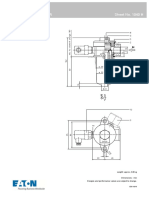

7. Symbols:

filter without

internal valve

filter with

by-pass valve

with visual electrical indicator

AE 50 and AE 62

with visual electrical indicator

AE 70 and AE 80

with visual electrical indicator

OE

with electronical

clogging sensor

VS1

item 16 execution only without clogging indicator or clogging sensor

5. Description:

In-line filters of the type LF 251-1100 are suitable for a working pressure up to 464 PSI. Pressure peaks are absorbed with a sufficient margin of safety.

The filter is mounted in such a way that inlet and outlet are on the same level. It can be used as suction filter, pressure filter and retu rn-line filter. The filter element

consists of star-shaped, pleated filter material which is supported on the inside by a perforated core tube and is bonded to the end caps with a high-quality adhesive.

The flow direction is from outside to inside.

For cleaning (see special leaflets 21070-4 and 34448-4) the mesh element respectively to change the glass fibre element remove the cover and take out the element.

Filter finer than 40 m should use throw-away elements made of paper or Interpor fleece (glass fibre). Filter elements as fine as

5 m (c) microns are available; finer filter elements on request.

Internormen Product Line filter elements are known as elements with a high intrinsic stability and an excellent filtration capability, a high dirt-retaining capacity and a

long service life.

Internormen Product Line filter are suitable for all petroleum based fluids, HW -emulsions, most synthetic hydraulic fluids and lubrication oils

Approvals according to TV, and the major Shipyard Classification Societies D.N.V.; B.V.; G.L.; L.R.S.; R.I.N.A.; A.B.S. and others are possible.

The internal valve is integrated in the filter cover. After reaching the opening pressure the by-pass valve causes that an unfiltered partial flow passes the filter.

US 1117 M

8. Pressure drop flow curves:

Precise flow rates see Interactive Product Spedifier, respectively

p- curves; depending on filter fineness and viscosity.

9. Test methods:

Filter elements are tested according to the following ISO standards:

ISO 2941

ISO 2942

ISO 293

ISO 3723

ISO 3724

ISO 3968

ISO 16889

Verification of collapse/burst resistance

Verification of fabrication integrity

Verification of material compatibility with fluids

Method for end load test

Verification of flow fatigue characteristics

Evaluation of pressure drop versus flow characteristics

Multi-pass method for evaluating filtration performance

with electrical indicator

AE 30 and AE 40

with visual

indicator

AOR/AOC/OP

with electronical

clogging sensor

VS2

Vous aimerez peut-être aussi

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Edu251 401Document2 pagesEdu251 401ckmuneesPas encore d'évaluation

- Series TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LDocument4 pagesSeries TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LRaid BekaltiPas encore d'évaluation

- Arlon TTF BgtsDocument11 pagesArlon TTF BgtsSamad A BakarPas encore d'évaluation

- Bomba de Vacio Sihi LPHX 40516Document12 pagesBomba de Vacio Sihi LPHX 40516Dante Coloma JimenezPas encore d'évaluation

- 2040 2e6Document6 pages2040 2e6Jaikishan KumaraswamyPas encore d'évaluation

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicPas encore d'évaluation

- Inline Filter DFN/LFN/LFNF To DIN 24550: Up To 400 L/min, Up To 400 BarDocument4 pagesInline Filter DFN/LFN/LFNF To DIN 24550: Up To 400 L/min, Up To 400 BarAmitPas encore d'évaluation

- Uniworld: Series Pneumatic ValvesDocument2 pagesUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- Gas and Air Filter (DUNGS Model GF Catalog)Document8 pagesGas and Air Filter (DUNGS Model GF Catalog)Julio OrtegaPas encore d'évaluation

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbPas encore d'évaluation

- Eaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFDocument405 pagesEaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFMahesh DegaonkarPas encore d'évaluation

- Eaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFDocument405 pagesEaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFjithanPas encore d'évaluation

- RegulatorDocument6 pagesRegulatorFlorin GoiaPas encore d'évaluation

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroPas encore d'évaluation

- Ap TTF BGTS 3Document12 pagesAp TTF BGTS 3Madhu RajagopalanPas encore d'évaluation

- PCT 3557915Document4 pagesPCT 3557915earquaz23Pas encore d'évaluation

- Manual Ecoflux en - KrohneDocument14 pagesManual Ecoflux en - Krohnemmihai_popa2006Pas encore d'évaluation

- 2020 2e6Document6 pages2020 2e6Jaikishan KumaraswamyPas encore d'évaluation

- Unitor Cylinder RegulatorDocument8 pagesUnitor Cylinder RegulatorChristis SavvaPas encore d'évaluation

- (NBR)Document4 pages(NBR)Youghorta TIRPas encore d'évaluation

- List of TradinDocument161 pagesList of Tradinguita riefPas encore d'évaluation

- Doneldson Air Breather FilterDocument14 pagesDoneldson Air Breather FilterParinpa KetarPas encore d'évaluation

- Air System ComponentsDocument6 pagesAir System ComponentsEliasPas encore d'évaluation

- C72H NorgrenDocument4 pagesC72H NorgrenHernando HerreraPas encore d'évaluation

- Handbook v1.0Document23 pagesHandbook v1.0Kiran KommireddyPas encore d'évaluation

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111Pas encore d'évaluation

- Unique SSV - Tank OutletDocument6 pagesUnique SSV - Tank OutletlggomezupbPas encore d'évaluation

- ARO Flo 1500 SeriesDocument11 pagesARO Flo 1500 SeriesEliasPas encore d'évaluation

- Donaldson Visokotlačni FilteriDocument86 pagesDonaldson Visokotlačni FilteriViktor -stPas encore d'évaluation

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456Pas encore d'évaluation

- Catalogo ASCODocument4 pagesCatalogo ASCOIkaro MatosPas encore d'évaluation

- LPHX 45008 45311 45316 e 0213Document16 pagesLPHX 45008 45311 45316 e 0213Jonson CaoPas encore d'évaluation

- Hydraulic TechnologyDocument76 pagesHydraulic TechnologyOgulcan CafPas encore d'évaluation

- Il2 RF2 CF2 PDFDocument14 pagesIl2 RF2 CF2 PDFjuliocanel2009Pas encore d'évaluation

- Donaldson AccessoriesDocument74 pagesDonaldson AccessoriesCentral HydraulicsPas encore d'évaluation

- 40SS Series: High Pressure Stainless Steel FilterDocument8 pages40SS Series: High Pressure Stainless Steel FilterYair Alexis Muñoz RojasPas encore d'évaluation

- Parker TTF FilteriDocument11 pagesParker TTF Filterisealion72Pas encore d'évaluation

- 6850/6890 GC Column Installation and Instrument Setup Guide - PPIP/TCDDocument18 pages6850/6890 GC Column Installation and Instrument Setup Guide - PPIP/TCDWaleed El-azabPas encore d'évaluation

- SMC Neumatic CatalogDocument98 pagesSMC Neumatic CataloganderssonpcPas encore d'évaluation

- Operating Manual: Pneumatic Crimping and Assembly ToolDocument8 pagesOperating Manual: Pneumatic Crimping and Assembly Toolanilp12rPas encore d'évaluation

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDocument20 pagesFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790Pas encore d'évaluation

- Reg RedQ Specialy Regulators PDFDocument20 pagesReg RedQ Specialy Regulators PDFDavid SaldarriagaPas encore d'évaluation

- 01 Excelon FiltersDocument16 pages01 Excelon Filtersalex_alfonso9407Pas encore d'évaluation

- Convertidor Mechanical S108KDocument8 pagesConvertidor Mechanical S108KALBERTOPas encore d'évaluation

- 12AT/50AT Series: Spin-On FiltersDocument8 pages12AT/50AT Series: Spin-On FiltersPartsGopher.comPas encore d'évaluation

- 2030 3eDocument6 pages2030 3eJaikishan KumaraswamyPas encore d'évaluation

- ProMinent Beta Solenoid Diaphragm Metering PumpsDocument6 pagesProMinent Beta Solenoid Diaphragm Metering PumpsRoga29Pas encore d'évaluation

- Radiator and Lockshield Valves: Series 340 - 411 - 415Document6 pagesRadiator and Lockshield Valves: Series 340 - 411 - 415L Lucas AraújoPas encore d'évaluation

- Compresor 5120Document32 pagesCompresor 5120Cesar GongoraPas encore d'évaluation

- Series TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 HDocument4 pagesSeries TEF 41 DN15 PN10: Return Line Filter Sheet No. 1040 Hnemi90Pas encore d'évaluation

- 31 ARC enDocument6 pages31 ARC enlggomezupbPas encore d'évaluation

- Duplex-40 - 160-LD - Nov'11Document6 pagesDuplex-40 - 160-LD - Nov'11Sagar NaduvinamaniPas encore d'évaluation

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777Pas encore d'évaluation

- Comp 5120Document40 pagesComp 5120Román Arturo Guerrero Uc100% (1)

- Control Valve System: PN 16 / 40 DN 15 - 150 ApplicationDocument0 pageControl Valve System: PN 16 / 40 DN 15 - 150 Applicationcico_ctPas encore d'évaluation

- WDWDDocument5 pagesWDWDAnshuman AgrawalPas encore d'évaluation

- SwwswsDocument7 pagesSwwswsAnshuman AgrawalPas encore d'évaluation

- B-T1a B-T1C: Slope 1:250 Slope 1:250Document1 pageB-T1a B-T1C: Slope 1:250 Slope 1:250Anshuman AgrawalPas encore d'évaluation

- Annexure 5 Exceptions To Bid Terms and Conditions/ Compliance StatementDocument1 pageAnnexure 5 Exceptions To Bid Terms and Conditions/ Compliance StatementAnshuman AgrawalPas encore d'évaluation

- 10 NA 1000054791 20 NA: Quoted/Not Quoted Table - Do Not Mention Any Prices in This SheetDocument3 pages10 NA 1000054791 20 NA: Quoted/Not Quoted Table - Do Not Mention Any Prices in This SheetAnshuman AgrawalPas encore d'évaluation

- FedfefDocument2 pagesFedfefAnshuman AgrawalPas encore d'évaluation

- Gulf Synthetic Gear Oil 320 PDFDocument6 pagesGulf Synthetic Gear Oil 320 PDFAnshuman AgrawalPas encore d'évaluation

- Indian Oil Corporation Limited Panipat Naptha Cracker Complex, PanipatDocument2 pagesIndian Oil Corporation Limited Panipat Naptha Cracker Complex, PanipatAnshuman AgrawalPas encore d'évaluation

- Astron Garden Special: Your Confirmed Booking atDocument2 pagesAstron Garden Special: Your Confirmed Booking atAnshuman AgrawalPas encore d'évaluation

- Hindustan Aeronautics Limited Sukhoi Engine Division, KoraputDocument1 pageHindustan Aeronautics Limited Sukhoi Engine Division, KoraputAnshuman AgrawalPas encore d'évaluation

- Acknowledgement of Tender SubmissionDocument1 pageAcknowledgement of Tender SubmissionAnshuman AgrawalPas encore d'évaluation

- Award of Contract (AOC) : For and On Behalf, Tender Inviting Authority, Indian Oil Corporation LimitedDocument1 pageAward of Contract (AOC) : For and On Behalf, Tender Inviting Authority, Indian Oil Corporation LimitedAnshuman AgrawalPas encore d'évaluation

- Enquiry Cum Offer: Enquiry No.:NCM1111046/1765838 Date:13.09.2011Document5 pagesEnquiry Cum Offer: Enquiry No.:NCM1111046/1765838 Date:13.09.2011Anshuman AgrawalPas encore d'évaluation

- INDEX For Transformer Oil Filteration at Helicopter DivisionDocument25 pagesINDEX For Transformer Oil Filteration at Helicopter DivisionAnshuman AgrawalPas encore d'évaluation

- Notice Inviting Tender Tender Notification No:NITR/TS/FC/35 DT: 21.01.2014Document5 pagesNotice Inviting Tender Tender Notification No:NITR/TS/FC/35 DT: 21.01.2014Anshuman AgrawalPas encore d'évaluation

- Annexure-V (Bank Guarantee in Lieu of Earnest Money Deposit)Document2 pagesAnnexure-V (Bank Guarantee in Lieu of Earnest Money Deposit)Anshuman AgrawalPas encore d'évaluation

- Aiims - PatnaDocument22 pagesAiims - PatnaAnshuman AgrawalPas encore d'évaluation

- ITT For Supply & Fixing of Conference Table & ChairDocument17 pagesITT For Supply & Fixing of Conference Table & ChairAnshuman AgrawalPas encore d'évaluation

- An Iso 9001-2000 and 14001-2004 Certified Power StationDocument1 pageAn Iso 9001-2000 and 14001-2004 Certified Power StationAnshuman AgrawalPas encore d'évaluation

- TDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Document2 pagesTDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Mallampati RamakrishnaPas encore d'évaluation

- Physical Chemistry - R. L. MadanDocument1 pagePhysical Chemistry - R. L. MadanOscar Santos EstofaneroPas encore d'évaluation

- R304 0307 Env HHDocument221 pagesR304 0307 Env HHsyamsundariitmiitmPas encore d'évaluation

- (Caustic Soda) : Material Safety Data SheetDocument2 pages(Caustic Soda) : Material Safety Data SheetKumbang KambingPas encore d'évaluation

- Light-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorDocument20 pagesLight-Exposure Test Method by Xenon-Arc Lamp For Automotive InteriorMahmood KhanPas encore d'évaluation

- Chapter RDocument21 pagesChapter RmanoharandaPas encore d'évaluation

- Nanomaterials in Structural EngineeringDocument19 pagesNanomaterials in Structural EngineeringAniket DubePas encore d'évaluation

- DC Values Compendium - EN - 2014 PDFDocument96 pagesDC Values Compendium - EN - 2014 PDFLeandro DarquiPas encore d'évaluation

- Nuclear Technology and EnergyDocument4 pagesNuclear Technology and EnergyJessica Anna LuchkaPas encore d'évaluation

- EVA Resin 2018Document1 pageEVA Resin 2018AminulIslamPas encore d'évaluation

- Ultra-Violet Coatings Tricks and TipsDocument1 pageUltra-Violet Coatings Tricks and TipsAdriano AraujoPas encore d'évaluation

- Preparation and Properties of Compounds - 01-TheoryDocument45 pagesPreparation and Properties of Compounds - 01-TheoryRaju SinghPas encore d'évaluation

- Air Pollution - A Review: October 2020Document29 pagesAir Pollution - A Review: October 2020NasrinTalebpourPas encore d'évaluation

- Royal Ultra 865MDocument9 pagesRoyal Ultra 865Mjuanfdez42368Pas encore d'évaluation

- Numerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaDocument8 pagesNumerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaAlexander ProkhorenkoPas encore d'évaluation

- Is-1479-Part-1.1960-Rapid Examinations of MilkDocument44 pagesIs-1479-Part-1.1960-Rapid Examinations of MilkStacy WilsonPas encore d'évaluation

- RWTSSGDocument54 pagesRWTSSGObscuredSolutionsPas encore d'évaluation

- Ecotoxicology and Environmental SafetyDocument10 pagesEcotoxicology and Environmental SafetyUlfa Mudia SariPas encore d'évaluation

- ElectrophoresisDocument47 pagesElectrophoresisEllah GutierrezPas encore d'évaluation

- Growth and Characterization of L-Alanine Potassium Nitrate Single Crystals For Nonlinear Optical ApplicationsDocument5 pagesGrowth and Characterization of L-Alanine Potassium Nitrate Single Crystals For Nonlinear Optical ApplicationsPalaniswamy SankariahPas encore d'évaluation

- Isomerism Revision SlideDocument104 pagesIsomerism Revision SlideV.Pas encore d'évaluation

- Materials and Processes For Agricultural and Biosystems EngineeringDocument17 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioPas encore d'évaluation

- Copper and The Copper-Base AlloysDocument32 pagesCopper and The Copper-Base AlloysVIVEK UPADHYAYPas encore d'évaluation

- Condensed Mode Cooling in Ethylene Polymerisation Droplet EvaporationDocument6 pagesCondensed Mode Cooling in Ethylene Polymerisation Droplet EvaporationyamakunPas encore d'évaluation

- SRU UnitDocument33 pagesSRU UnitCenk Yağız ÖzçelikPas encore d'évaluation

- Framo Operation ManualDocument16 pagesFramo Operation Manualcaptulcc100% (2)

- Universitas Ahmad Dahlan - JellyDocument15 pagesUniversitas Ahmad Dahlan - JellyMaqfirotul LailyPas encore d'évaluation

- T5300 Titan Superflex WhiteDocument8 pagesT5300 Titan Superflex WhiteLola TesiePas encore d'évaluation

- PROTEINSDocument5 pagesPROTEINSYLADE, ERICCA ANDREAPas encore d'évaluation

- Avogadro ActivityDocument4 pagesAvogadro ActivityShazmie Mohammad NadziriPas encore d'évaluation