Académique Documents

Professionnel Documents

Culture Documents

7075 Tin PVD

Transféré par

09m008_159913639Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

7075 Tin PVD

Transféré par

09m008_159913639Droits d'auteur :

Formats disponibles

Available online at www.sciencedirect.

com

Procedia Engineering 10 (2011) 19361942

ICM11

The effect of a heat treatment on improving the fatigue

properties of aluminium alloy 7075-T6 coated with TiN by

PVD

R.H. Oskoueia* and R.N. Ibrahima

a

Department of Mechanical & Aerospace Engineering, Monash University, Clayton, VIC 3800, Australia

Abstract

In this paper, fatigue properties of coated aluminium alloy 7075-T6 with a TiN deposit of 3 m using physical vapour

deposition (PVD) have been studied. It was determined that the application of a PVD hot process significantly

decreased the tensile and fatigue strength of the substrate-coating system due to the effect of a high operating

temperature (450 C). Fatigue life of the coated aluminium showed a considerable reduction of 94% in the fatigue life

after experiencing the deposition temperature. Taking into consideration the effect of the high deposition temperature

to remove the benefits of T6 from the aluminium alloy, it was therefore believed that re-applying the T6 cycle could

recover the lost properties of the aluminium substrate. The tensile and fatigue tests results after applying the post heat

treatment revealed large improvements in the yield, ultimate and fatigue strength of the coated material to approach

initial properties of the uncoated 7075-T6.

2011 Published by Elsevier Ltd. Open access under CC BY-NC-ND license.

Selection and peer-review under responsibility of ICM11

Keywords: Low and high cycle fatigue; 7xxx Aluminium alloys; PVD hard coatings; heat treatment.

1. Introduction

Single metal nitrides such as TiN, CrN and ZrN are classified as hard physical vapour deposition

(PVD) coatings which have been commercially used in cutting applications because of their high

hardness. However, these PVD coatings are also extensively used in wear and corrosion protection

applications and they are now widespread in global manufacturing for reducing production costs and

* Corresponding author. Tel.: +61-3-99053647.

E-mail address: reza.oskouei@monash.edu.

1877-7058 2011 Published by Elsevier Ltd. Open access under CC BY-NC-ND license.

Selection and peer-review under responsibility of ICM11 doi:10.1016/j.proeng.2011.04.321

R.H. Oskouei and R.N. Ibrahim / Procedia Engineering 10 (2011) 19361942

improving productivity, all of which is essential if industry is to remain economically competitive [1].

Titanium nitride (TiN) is the most common PVD hard coating which is well-known as a wear resistance

coating material with a low friction coefficient that can eliminate fretting and adhesive wear, and provide

smooth operation between moving components such as mechanically fastened joints under fatigue loading

conditions. It may be therefore considered as a good coating material to improve wear and fretting wear as

well as corrosion behaviour of aerospace structural components made from high strength aluminium

alloys. However, generally, the PVD processes used to deposit such coatings require depositional

temperatures of 400-500 C that may considerably affect mechanical properties of the coating-substrate

system.

A survey of the literature confirmed that mechanical properties of structural coatings have been the

subject of intensive research. There are many studies conducted on properties such as corrosion, hardness,

tribological, and thermal conductivity for a wide variety of coatings [2-7]. However, fatigue failure

analysis of coated materials is much more complicated than that of the uncoated, as failure occurs in an

adhesively bonded bi-material system, including a thin layer of the coating material and a substrate. The

fatigue response of a SAE 4340 steel substrate coated with TiCN (4 m in thickness) by plasma assisted

physical vapour deposition (PAPVD) was studied in air and in a 3 wt.% NaCl solution [8]. The results

showed a considerable increase of 140%-180% in the fatigue life of the coated steel tested in air and a

marginal increase of 25% in the corrosive environment. This revealed that the TiCN coating was

susceptible to the corrosive solution under fatigue loading conditions.

It was reported that coating aluminium alloy 7075-T6 with an electroless nickel-phosphorous (Ni-18P)

film of 3840 m in thickness improved the fatigue and corrosion fatigue behaviour of the aluminium

substrate [9]. However, PVD-ZrN coatings of 3 m in thickness significantly reduced both the tensile and

fatigue properties of the aluminium alloy (7075-T6) substrate [10]. 43% and 28% reductions in the yield

and tensile strength of the aluminium substrate were noted, respectively. This was in association with a

73%82% decrease in fatigue life during air testing and 11%-51% in the 3 wt.% NaCl solution. It was

therefore concluded that the ZrN coating could partially compensate for the decrease in the fatigue

strength of the coating-substrate system in corrosive conditions. The high operating temperature of the

PVD process was believed to decrease the yield, tensile and fatigue properties of the coated material.

Considering detrimental effect of the PVD high operating temperature on the tensile and fatigue

properties of alloy 7075-T6, this work is to study the effect of a post heat treatment on improving the

fatigue properties of Al 7075-T6 coated with TiN by a PVD process. To accomplish this, fatigue strength

of uncoated substrate, coated material and coated material subjected to the applied heat treatment were

evaluated.

2. Details of experimental work

According to the ASTM E466 standard, flat fatigue test specimens were manufactured from an

aluminium alloy 7075-T6 plate (bare condition) with a thickness of 3.175 mm, as shown in Fig. 1. The

longitudinal axis of all the specimens was aligned with the rolling direction of the plate. The specimens

were initially polished with silicon carbide papers of 600, 800 and 1200 grits and then subsequently

polished with a sisal mop (white BBB U-lime) and a cotton mop (BBB green rouge) to achieve a mirrorlike finish without leaving any small scratches on the surface. A number of tensile test specimens were

also made from the aluminium plate according to the ASTM E8 standard.

The aluminium substrate specimens were coated with 3-m-thick titanium nitride (TiN) coatings using

a Physical Vapour Deposition (PVD) process with a high-purity titanium target (99.999 at.%) by Guhring

Australia Pty. Ltd. Before mounting the substrates onto the fixtures of the PVD vacuum chamber, the

specimens were cleaned in order to remove dust, oils and fingerprints to produce a clean surface. The

1937

1938

R.H. Oskouei and R.N. Ibrahim / Procedia Engineering 10 (2011) 19361942

specimens were then loaded into the chamber and subjected to an argon ion plasma etching process to

remove any oxide film prior to the coating deposition. The maximum operating temperature of 450 C

was applied to the aluminium specimens during the pre-heating, argon etching and coating stages for two

hours. The coating thickness was determined by the CSEM ball cratering technique to be 3 m.

Prior to design of fatigue tests, tensile properties of coated specimens as well as uncoated specimens

were evaluated. The yield strength of Al 7075-T6 largely decreased from 520 MPa to 110 MPa (78%)

when coated with TiN. Similarly, a considerable reduction of 54% was observed in the ultimate strength

(from 580 MPa to 263 MPa). Such a significant decrease in the tensile properties ensured a considerable

reduction in the fatigue strength of the coated material. It was therefore believed that performing an

appropriate post heat treatment could restore the lost tensile properties caused by the PVD hot process.

Fig. 1. Fatigue test specimen, dimensions are in mm.

The high operating temperature of the PVD process (450 C) applied to the Al 7075-T6 substrate for 2

hrs was believed to soften the material and diminish the advantages of the T6 temper process. Therefore,

repeating the solution heat treatment followed by artificial aging (T6) after the deposition process was

considered as the PHT for the coated specimens. To do that, the specimens were heated up to 485 C

rapidly and held at 485 C for 1 hr followed by two-stage quenching; initially hot quenched into 60 C

water for 6 seconds and then promptly transferred to a cold water quench bath (25 C). Then, the

quenched specimens were heated up again to 121 C and held at 121 C for 24 hrs followed by cooling in

the air to room temperature. The post heat treatment could successfully restore most of the lost tensile

properties of the coated specimens. Large improvements of 243% and 77% were observed in the yield and

ultimate strength of coated specimens respectively as a result of the applied PHT.

A MTS fatigue testing machine (model 858) was used to conduct the fatigue tests with constantamplitude at a load frequency of 15 Hz (sinusoidal loading) with a load ratio of R=0.1. Three batches of

Al 7075-T6, Al 7075-T6 coated with TiN and Al 7075-T6 coated with TiN+PHT were fatigue tested. For

each batch of specimens, four tests were performed at four different levels of cyclic loading. At each

level, a minimum of three fatigue tests was carried out. The average values of the obtained fatigue lives

were then determined in order to obtain the S-N curve of best fit for each batch. The number of cycles to

completely fracture the specimen was recorded as the fatigue life of the specimens.

3. Results

Fatigue life results were plotted in a semi-log S-N diagram, as shown in Fig. 2. It can be clearly seen

that the coated specimens experienced significantly less number of fatigue cycles compared to Al 7075T6. Approximately, a 94% reduction in the fatigue life was found when the coated material was tested at

a maximum alternating stress of Smax=244 MPa. Such a considerable decrease was therefore attributed to

R.H. Oskouei and R.N. Ibrahim / Procedia Engineering 10 (2011) 19361942

improve the fatigue life of the coated specimens substantially. A 468% improvement in the fatigue life

was observed at Smax=244 MPa, although the PHT could not fully regain the lost fatigue properties to

achieve those of the original Al 7075-T6.

Fig. 2. Stress versus life (S-N) curves for tested batches at R=0.1.

4. Fractographic analysis

Fatigue fracture surfaces of selected coated and coated+PHT specimens were examined at high

magnifications using scanning electron microscopy (SEM) to identify fatigue crack initiation locations

and to determine the occurrence of delamination of the coating from the substrate. The fracture surfaces

of two specimens from the coated and coated+PHT batches are shown in Figs. 3 and 4, respectively. A

general view of the fracture surface is firstly shown which comprises of fatigue and final fracture regions.

Moreover, a further magnification better highlights the crack nucleation site at which possible fatigue

crack origins are indicated. Macro- and micro-fractographic features of the coated+PHT specimens were

similar to those of the coated specimens. Also, as can be seen in both Fig. 3b and 4b, fatigue cracks

initiated from the corner of the fracture surface at or near the outer surfaces of the aluminium substrate.

Generally, fractography of the coated and coated+PHT specimens at high magnifications did not reveal

any significant delamination of the TiN coating layer from the aluminium substrate under the applied

cyclic loading with low and moderate maximum stresses. However, substantial delaminations were

locally observed in the coated and coated+PHT specimens that failed under high alternating loads. For

example, Figure 5 displays the delaminated regions with further magnifications of the coated+PHT

specimen which failed at the highest maximum alternating stress.

1939

1940

R.H. Oskouei and R.N. Ibrahim / Procedia Engineering 10 (2011) 19361942

Final fracture

region

Fatigue

region

Final

fracture

region

Fatigue

region

(a)

(a)

Fatigue

origins

Fatigue

origins

(b)

Fig. 3. Al 7075-T6 coated with TiN specimen failed at

Smax=244 MPa: (a) Fatigue fracture surface; (b) Detailed

view of the fatigue crack nucleation site.

(b)

Fig. 4. Al 7075-T6 coated with TiN+PHT specimen failed at

Smax=422 MPa: (a) Fatigue fracture surface; (b) Detailed

view of the fatigue crack nucleation site.

R.H. Oskouei and R.N. Ibrahim / Procedia Engineering 10 (2011) 19361942

TiN coatings

Delaminated

region

7075-T6

substrate

Fig. 5. Delamination of TiN coating layer from aluminium substrate; coated+PHT specimen failed at high maximum stress of 422

MPa.

5. Discussion

It is noted that the high operating temperature of the PVD process (450 C applied for 2 hrs) could

remove the expected benefits of T6 from the previously heat treated aluminium alloy (Al 7075-T6). The

large reduction in the tensile properties of the alloy exposed to the deposition heat was believed to be due

to the growth of the strengthening precipitates as a consequence of overaging the previously T6-treated

alloy. Consequently, a significant reduction was observed in the fatigue strength of the coated specimens.

The low tensile strength of the coated Al 7075-T6 reduced the endurance limit of the coating-substrate

system considerably. However, re-applying the T6 cycle re-dissolved the grown precipitates and

produced a solute rich solid solution again. Therefore, the tensile properties and fatigue strength of the

coating-substrate system were considerably increased.

6. Conclusions

Aluminium alloy 7075-T6 substrate coated with 3 m thick TiN by PVD showed large

reductions of 78% and 54% in the yield and tensile strength respectively. Also, a significant

decrease of 94% in fatigue life of the coating-substrate system was noted comparing with the

original Al 7075-T6. The high operating temperature during the deposition process was

responsible for the decrease in the tensile and fatigue properties of the coated Al 7075-T6.

The applied post heat treatment satisfactorily restored most of the lost tensile and fatigue

properties, although they were not fully recovered. The fatigue life of the coating-substrate

system was substantially prolonged by approximately 450% after application of the post heat

treatment.

1941

1942

R.H. Oskouei and R.N. Ibrahim / Procedia Engineering 10 (2011) 19361942

Under low and moderate alternating loads, the thin TiN film was well-adhered to the aluminium

substrate and no delamination was observed. However, significant delaminations occurred under

high fatigue loads.

References

[1] Harris SG, Doyle ED, Vlasveld AC, Audy J, Long JM, Quick D. Influence of chromium content on the dry machining

performance of cathodic arc evaporated TiAlN coatings. Wear 254 (2003) 185194.

[2] Abdel Aal A. Hard and corrosion resistant nanocomposite coating for Al alloy. Materials Science and Engineering A 474

(2008) 181187.

[3] Yu Q, Ma X, Wang M, Yu C, Bai T. Influence of embedded particles on microstructure, corrosion resistance and thermal

conductivity of CuO/SiO2 and NiO/SiO2 nanocomposite coatings. Applied Surface Science 254 (2008) 50895094.

[4] Aruna ST, William Grips VK, Rajam KS. Ni-based electrodeposited composite coating exhibiting improved microhardness,

corrosion and wear resistance properties. Journal of Alloys and Compounds 468 (2009) 546552.

[5] Gu C, Lian J, He J, Jiang Z, Jiang Q. High corrosion-resistance nanocrystalline Ni coating on AZ91D magnesium alloy.

Surface & Coatings Technology 200 (2006) 54135418.

[6] Snchez-Lpez JC, Martnez-Martnez D, Lpez-Cartes C, Fernndez A. Tribological behaviour of titanium

carbide/amorphous carbon nanocomposite coatings: From macro to the micro-scale. Surface & Coatings Technology 202 (2008)

40114018.

[7] Conde A, Navas C, Cristbal AB, Housden J, de Damborenea J. Characterisation of corrosion and wear behaviour of

nanoscaled e-beam PVD CrN coatings. Surface & Coatings Technology 201 (2006) 26902695.

[8] Puchi-Cabrera ES, Staia MH, Quinto DT, Villalobos-Gutirrez C, Ochoa-Prez E. Fatigue properties of a SAE 4340 steel

coated with TiCN by PAPVD. International Journal of Fatigue 29 (2007) 471480.

[9] Puchi-Cabrera ES, Villalobos-Gutirrez C, Irausqun I, La Barbera-Sosa J, Mesmacque G. Fatigue behavior of a 7075-T6

aluminum alloy coated with an electroless NiP deposit. International Journal of Fatigue 28 (2006) 18541866.

[10] Puchi-Cabrera ES, Staia MH, Lesage J, Gil L, Villalobos-Gutirrez C, La Barbera-Sosa J, Ochoa-Prez EA, Le Bourhis E.

Fatigue behavior of AA7075-T6 aluminum alloy coated with ZrN by PVD. International Journal of Fatigue 30 (2008) 12201230.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- New Microsoft Office Word DocumentDocument4 pagesNew Microsoft Office Word Document09m008_159913639Pas encore d'évaluation

- Safety Stock: Safety Stock (Also Called Buffer Stock) Is A Term Used byDocument3 pagesSafety Stock: Safety Stock (Also Called Buffer Stock) Is A Term Used by09m008_159913639Pas encore d'évaluation

- Namiq 11Document6 pagesNamiq 1109m008_159913639Pas encore d'évaluation

- SpriDocument2 pagesSpri09m008_159913639Pas encore d'évaluation

- New Microsoft Office Word DocumentDocument59 pagesNew Microsoft Office Word Document09m008_159913639Pas encore d'évaluation

- New Microsoft Office Word DocumentDocument6 pagesNew Microsoft Office Word Document09m008_159913639Pas encore d'évaluation

- PSG College of Technology: Coimbatore - 4 Registration For Wi-Fi Internet ConnectionDocument1 pagePSG College of Technology: Coimbatore - 4 Registration For Wi-Fi Internet Connection09m008_159913639Pas encore d'évaluation

- Research On Manufacturing Resource ModelingDocument2 pagesResearch On Manufacturing Resource Modeling09m008_159913639Pas encore d'évaluation

- Item Code On Handsafety Stockallocated Lot Size Scheduled Receipt Qty. Lead Times (Weeks)Document8 pagesItem Code On Handsafety Stockallocated Lot Size Scheduled Receipt Qty. Lead Times (Weeks)09m008_159913639Pas encore d'évaluation

- MDocument3 pagesM09m008_159913639Pas encore d'évaluation

- Certificate MP MLA Gazetted OfficerDocument1 pageCertificate MP MLA Gazetted OfficerParth Semwal0% (1)

- PSG College of Technology Coimbatore: TopicDocument5 pagesPSG College of Technology Coimbatore: Topic09m008_159913639Pas encore d'évaluation

- V Be SW Production - CognizantDocument19 pagesV Be SW Production - Cognizant09m008_159913639Pas encore d'évaluation

- ps1 1Document1 pageps1 109m008_159913639Pas encore d'évaluation

- Week 2Document1 pageWeek 209m008_159913639Pas encore d'évaluation

- B TechDocument1 pageB Tech09m008_159913639Pas encore d'évaluation

- ps1 2Document2 pagesps1 209m008_159913639Pas encore d'évaluation

- Computers & Industrial Engineering: Lama Moussawi-Haidar, Mohamad Y. JaberDocument10 pagesComputers & Industrial Engineering: Lama Moussawi-Haidar, Mohamad Y. Jaber09m008_159913639Pas encore d'évaluation

- Case Study On MRP IiDocument2 pagesCase Study On MRP Ii09m008_159913639Pas encore d'évaluation

- Welcome To The M Notebook For Word!: AtlabDocument3 pagesWelcome To The M Notebook For Word!: AtlabDEEPAK KUMAR MALLICKPas encore d'évaluation

- 1 s2.0 S0043164808004407 MainDocument7 pages1 s2.0 S0043164808004407 Main09m008_159913639Pas encore d'évaluation

- 1 s2.0 S0957417408000602 MainDocument12 pages1 s2.0 S0957417408000602 Main09m008_159913639Pas encore d'évaluation

- Welcome To The M Notebook For Word!: AtlabDocument3 pagesWelcome To The M Notebook For Word!: AtlabDEEPAK KUMAR MALLICKPas encore d'évaluation

- Welcome To The M Notebook For Word!: AtlabDocument3 pagesWelcome To The M Notebook For Word!: AtlabDEEPAK KUMAR MALLICKPas encore d'évaluation

- Group DiscussionDocument19 pagesGroup Discussion09m008_159913639Pas encore d'évaluation

- Dialogue PracticeDocument3 pagesDialogue PracticeElena StanislavPas encore d'évaluation

- PROD Scheme ComplDocument101 pagesPROD Scheme Complsajay_suryaPas encore d'évaluation

- NLRC Spoken English Training Slides in Tamil - New Method For FluencyDocument35 pagesNLRC Spoken English Training Slides in Tamil - New Method For Fluencyksjayakumar88% (52)

- PROD Scheme ComplDocument101 pagesPROD Scheme Complsajay_suryaPas encore d'évaluation

- Iris g5653 PDFDocument7 pagesIris g5653 PDFalexgoagaPas encore d'évaluation

- Pen Gen AlanDocument16 pagesPen Gen AlanAin Syamimi KhairuddinPas encore d'évaluation

- Physics Investigatory ProjectDocument19 pagesPhysics Investigatory ProjectYeshrun prakash Minz100% (3)

- Low-Power, Fixed and Adjustable Reference With Shutdown in SOT23Document17 pagesLow-Power, Fixed and Adjustable Reference With Shutdown in SOT23Alex WongPas encore d'évaluation

- Fingertip Hall Effect Joystick - RT600Document5 pagesFingertip Hall Effect Joystick - RT600RunnTechPas encore d'évaluation

- Experiment 1Document7 pagesExperiment 1ydsrajuPas encore d'évaluation

- Simulation of A Wireless Power Transfer System For Electric Vehicles With Power Factor CorrectionDocument6 pagesSimulation of A Wireless Power Transfer System For Electric Vehicles With Power Factor Correctionwalidghoneim1970Pas encore d'évaluation

- Module 2 - PPT - Expanded Hybrid Pie Equivalent and Short Circuit Current Gain PDFDocument16 pagesModule 2 - PPT - Expanded Hybrid Pie Equivalent and Short Circuit Current Gain PDFGokulnath SPas encore d'évaluation

- Fuzz PedalDocument14 pagesFuzz PedalMario Yee100% (2)

- 1n53xx PDFDocument6 pages1n53xx PDFFrantsiskoPas encore d'évaluation

- Basic Triac-SCR Projects Circuits TutorialDocument7 pagesBasic Triac-SCR Projects Circuits TutorialAmmar YasserPas encore d'évaluation

- Session 33 NonVolatile Memory and ComputeInMemoryDocument14 pagesSession 33 NonVolatile Memory and ComputeInMemory吴川斌Pas encore d'évaluation

- Electronic and Optical Properties of Three Phases of Titanium Dioxide Rutile, Anatase, and Brookite PDFDocument10 pagesElectronic and Optical Properties of Three Phases of Titanium Dioxide Rutile, Anatase, and Brookite PDFRaghav MehraPas encore d'évaluation

- How To Make A Laser Diode Driver That Enables YouDocument5 pagesHow To Make A Laser Diode Driver That Enables YoubabalguitarPas encore d'évaluation

- Design of Integrated Cmos Circuits For Parallel Detection and Storage of Optical DataDocument178 pagesDesign of Integrated Cmos Circuits For Parallel Detection and Storage of Optical DataaurybPas encore d'évaluation

- Cpu's PackageDocument1 pageCpu's PackagepangaeaPas encore d'évaluation

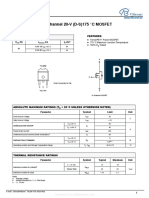

- N-Channel 20-V (D-S) 175 - C MOSFET: Features Product SummaryDocument6 pagesN-Channel 20-V (D-S) 175 - C MOSFET: Features Product SummarySivaPas encore d'évaluation

- 40193Document9 pages40193Merényi OszkárPas encore d'évaluation

- Electric Power Distribution - Wikipedia, The Free EncyclopediaDocument3 pagesElectric Power Distribution - Wikipedia, The Free EncyclopediasacuarsPas encore d'évaluation

- Infineon Iraudamp23 Datasheet v01 00 enDocument22 pagesInfineon Iraudamp23 Datasheet v01 00 enAliPas encore d'évaluation

- CD4015Document7 pagesCD4015Lucilia Dos SantosPas encore d'évaluation

- Robot Sensors: An OverviewDocument59 pagesRobot Sensors: An OverviewsafeerkkPas encore d'évaluation

- Sensors and Field Transmitters: Industrial Automation SolutionsDocument4 pagesSensors and Field Transmitters: Industrial Automation Solutionsranita senPas encore d'évaluation

- What Is An InverterDocument24 pagesWhat Is An InverterIqbal UsmanPas encore d'évaluation

- Offline UPS Reference Design Using The dsPIC DSCDocument86 pagesOffline UPS Reference Design Using The dsPIC DSCthietdaucongPas encore d'évaluation

- Uprating of Electrolytic CapacitorsDocument13 pagesUprating of Electrolytic CapacitorsOsanebi Chukwudi LuckyPas encore d'évaluation

- Solar Cell Efficiency Tables (Version 50)Document9 pagesSolar Cell Efficiency Tables (Version 50)Tvarit PatelPas encore d'évaluation

- Chapter 13Document57 pagesChapter 13VINCENT TUNG HUA TANGPas encore d'évaluation

- Band Theory of PolymersDocument17 pagesBand Theory of PolymerssjktnknsjgrgPas encore d'évaluation

- LDC 1000Document29 pagesLDC 1000Elias ChavezPas encore d'évaluation