Académique Documents

Professionnel Documents

Culture Documents

Speed Control Design of A PMSM Based On Functional Model Predictive Approach

Transféré par

hieuhuech1Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Speed Control Design of A PMSM Based On Functional Model Predictive Approach

Transféré par

hieuhuech1Droits d'auteur :

Formats disponibles

Journal of Engineering Sciences, Assiut University, Vol. 40, No. 4, pp.

1121 -1135, July 2012

SPEED CONTROL DESIGN OF A PMSM BASED ON

FUNCTIONAL MODEL PREDICTIVE APPROACH

A. A. Hassan 1 and Ahmed M. Kassem 2

1

Electrical Dep., Faculty of Engineering, El-Minia University, Egypt

Control Tech. Dep., Industrial Education College, Beni-Suef University,

Egypt, Email:Kassem_ahmed53@hotmail.com

2

(Received January 19, 2012 Accepted May 5, 2012)

This paper investigates the application of the model predictive control

(MPC) approach to control the speed of a permanent magnet synchronous

motor (PMSM) drive system. The MPC is used to calculate the optimal

control actions including system constraints. To alleviate computational

effort and to reduce numerical problems, particularly in large prediction

horizon, an exponentially weighted functional model predictive control

(FMPC) is employed. In order to validate the effectiveness of the proposed

FMPC scheme, the performance of the proposed controller is compared with

a classical PI controller through simulation studies. Obtained results show

that accurate tracking performance of the PMSM has been achieved.

KEYWORDS: Predictive control, Functional model predictive control,

permanent magnet synchronous motor.

1. INTRODUCTION

Permanent magnet synchronous motors fed by PWM inverters are widely used for

industrial applications, especially servo drive applications, in which constant torque

operation is desired. In traction and spindle drives, on the other hand, constant power

operation is desired [1]. The inherent advantages of these machines are light weight,

small size, simple mechanical construction, easy maintenance, good reliability, and

high efficiency. Generally speaking, the applications of the PMSM drive system

include two major areas: the adjustable-speed drive system and the position control

system. The adjustable-speed drive system has two control-loops: the current-loop and

the speed loop. To improve the performance of the PMSM drive system, a lot of

research has been done. In general, the research has focused on improvement of the

performance related to current-loop, speed loop, and/or position loop.

The PMSM drive system has been controlled using a PI controller due to its

simplicity. The PI controller, however, can not provide good performance in both

transient and load disturbance conditions. Several researchers have investigated the

speed controller design of adjustable speed PMSM systems to improve their transient

responses, load disturbance rejection capability, tracking ability, and robustness [2-11].

The MPC controller generally requires a significant computational effort. As

the performance of the available computing hardware has rapidly increased and new

faster algorithms have been developed, it is now possible to implement MPC to

command fast systems with shorter time steps, as electrical drives. Electric drives are

of particular interest for the application of MPC for at least two reasons:

1) They fit in the class of systems for which a quite good linear model can be

1121

A. A. Hassan and Ahmed M. Kassem

1122

obtained both by analytical means and by identification techniques;

Bounds on drive variables play a key role in the dynamics of the system;

indeed, two main approaches are available to deal with system constraints:

antiwindup techniques widely used in the classical PI controllers, and MPC.

The presence of the constraint is one of the main reasons why, for example,

state space controllers have limited application in electrical drives.

In spite of these advantages, MPC applications to electrical drives are still

largely unexplored and only few research laboratories are involved on them. For

example Generalized Predictive Control (GPC) a special case of MPC has been

applied to induction motors for only current regulation [12] and later for speed and

current control [13]. In [14], the more general MPC solution has been adopted for the

design of the current controller in the same drive.

In this paper a centralized MPC with large prediction horizon for PMSM speed

control is presented. The proposed centralized scheme improves the control

performance in a coordinated manner.

Another challenge of centralized MPC for PMSM is its large computational effort

needed. To overcome this drawback, a functional MPC with orthonormal basis

Laguerre function [15] is presented. The presented functional MPC reduces

computational effort significantly which makes it more appropriate for practical

implementation. In addition, an exponential data weighting is used to reduce numerical

issue in MPC with large prediction horizon [16,17]. To verify the effectiveness of the

proposed scheme, time-based simulations are carried out. The results obtained proved

that the functional MPC is able to control successfully the PMSM system in the

transient and steady state cases.

2)

2. DYNAMIC MODEL OF PMSM

The dynamic model of the PMSM can be described in the d-q rotor frame as follows

[18]:

1

d

P

id = vd rid + r Liq

2

dt

L

1

d

P

iq = vq riq r (Lid + m )

dt

L

2

d

1

r = (Te TL B r )

dt

J

(1)

(2)

(3)

Where

Te =

3P

m iq = k t i q

2 2

d

r = r

dt

(4)

where r is the stator resistance, id is the d-axis stator current, iq is the q-axis stator

current, L is the stator inductance, d/dt is the differential operator, P is the pole

numbers, r is the mechanical rotor speed, m is the flux linkage generated from the

permanent magnet material, Te is the electromagnetic torque and r is the rotor

position.

SPEED CONTROL DESIGN OF A PMSM BASED ON

1123

3. LINEARISED MODEL

The basic principle in controlling the PMSM is based on field orientation. This is

obtained by letting the permanent magnet flux linkage be aligned with the d-axis, and

the stator current vector is kept along the q-axis direction. This means that the value of

id is kept zero in order to achieve the field orientation condition. Since the permanent

magnet flux is constant, therefore the electromagnetic torque is linearly proportional to

the q-axis current which is determined by closed loop control. As a result, maximum

torque per ampere can be obtained from the machine in addition to the achievement of

high dynamic performance. Applying the field orientation concept in equations (1-4),

the linearised model of the PMSM can be described in a state space form as :

x& = Ax + Bu

y = Cx + Du

(5)

Where

x = id

iq

r r

, d = [TL ]

p

p

r

ro

i qo

0

L

2

2

p

m

p

r

(

i

+

)

0

do

A = 2 ro

L

2

L

kt

B

0

0

J

J

0

0

1

0

u = vq

vd

E = 0 0

1

0

J

B = L

0

0

1

L

0 0

,

0 0

4. FUNCTIONAL MODEL PREDICTIVE CONTROL

A. Model predictive Control

Model predictive control uses an explicit model of system to predict future trajectory

of system states and outputs. This prediction capability allows solving optimal control

problem online, where prediction error (i.e. containing difference between the

predicted output and reference output) and control input action are minimized over a

future horizon, possibly subject to constraints on the manipulated inputs, states and

outputs. The optimization yields an optimal control sequence as input and only the first

input from the sequence is used as the input to the system. At the next sampling

interval, the horizon is shifted and the whole optimization procedure is repeated. The

main reason for using this procedure, which is called receding horizon control (RHC),

is that it allows compensating for future disturbance and modeling error.

The basic structure of model predictive control is depicted in Fig. 1. An

explicit model of the system is used to predict future output response chain y . Based on

the predicted system output and current system output, the error is calculated. The

A. A. Hassan and Ahmed M. Kassem

1124

errors, then, are fed to the optimizer. In the optimizer, the future optimal control

sequence, u, is calculated based on the objective function and system constraints.

In this paper, the state space model of the system is used in the model

predictive control. The general discrete form of the state space model used in model

predictive control is of the form:

x(k + 1) = Az x(k ) + Bz u (k ) + E z d (k ) + Fz w(k )

y (k ) = C z x (k )

(6)

where k is the sampling instant, x is state vector, u is input vector, d represents system

disturbance and w represents system noise model. Az, Bz, Cz, Ez and Fz are coefficients

of system state space model and reflect the PMSM model in (5).

The final aim of model predictive control is to provide zero output error with

minimal control effort.

Therefore, the cost function J that reflects the control objectives, is defined as:

Np

Nc

J (n) = k y(n + k ) yref (n + k ) 2 + vk u (n + k )2

k =1

Where

k and vk

respectively, the weighting factors for the prediction error and control

yref (n + k )

energy

kth step output prediction;

kth step reference trajectory;

u (n + k )

kth step control action.

y (n + k )

(7)

k =1

where the first term reflects the future output error and second term reflects the

consideration given to the control effort. The predicted output vector has dimension of

1Np where Np is the prediction horizon. u is control action vector with dimension of

1Nc that Nc is control horizon. In the model predictive control, the control horizon, Nc

, is always smaller than or equal to prediction horizon (Np ). k and vk reflecting the

weights on the predicted error of predicted outputs and change in the control action.

The constraints of model predictive control include constraints of magnitude and

change of input, state and output variables that can be defined in the following form.

u min u (n + k ) u max ,

xmin x (n + k ) xmax ,

ymin y (n + k ) ymax ,

umin u (n + k ) umax

xmin x(n + k ) xmax

(8)

ymin y (n + k ) ymax

Solving the objective function (7) with system constraint (8) gives the optimal input

control sequence.

B. Laguerre Based Model Predictive Control

In the classical model predictive control, the future control signal is modeled as a

vector of forward shift operator with length of Nc .

SPEED CONTROL DESIGN OF A PMSM BASED ON

U = [u (n),..., u (n + k ),..., u (n + N c 1)]

1125

(9)

where Nc unknown control variables in the optimization procedure. However, large

prediction horizon is needed to achieve high closed loop performance. That would

require large computational burden. Therefore, MPC may not be fast enough to be used

as a real time optimal control for such case.

A solution to this drawback is the use of functional MPC. In the functional

MPC, future input is assumed to be a linear combination of a few simple base

functions. In principle, these could be any appropriate functions. However in practice,

a polynomial basis is usually used [19]. This approximation of input trajectory can be

more accurate by proper selection of base function. Using functional MPC, the term

used in the optimization procedure can be reduced to a fraction of that required by

classical MPC. Therefore, the computational load will be reduced largely.

In this paper, orthonormal basis Laguerre function is used for modeling input

trajectory. Laguerre polynomial is one of the most popular orthonormal base functions

which has extensive applications in system identification [15]. The z-transform of mth

Laguerre function is given by:

m =

1 a 2 1 az

z a z a

m 1

(10)

where 0a1 is the pole of Laguerre polynomial and is called scaling factor in the

literature. The control input sequence can be described by the following Laguerre

functions:

N

u (n + k ) cm lm (k )

m =1

(11)

where lm is the inverse z-transform of m in the discrete domain. The coefficients cm are

unknowns and should be obtained in the optimization procedure. The parameters a and

N are tuning parameters and should be adjusted by user. Usually the value of N is

selected smaller than 10 that is enough for most practical applications. Generally,

choosing larger value for N increases the accuracy of input sequence estimation.

C. Exponentially Weighted Model Predictive Control

Closed loop performance of MPC depends on the magnitude of prediction horizon Np.

Generally, by increasing the magnitude of prediction horizon, the closed loop

performance will be improved. However, practically, selection of large prediction

horizon is limited by numerical issue, particularly in the process with high sampling

rate. One approach to overcome this drawback is to use exponential data weighting in

model predictive control [16].

D. Design of the proposed Functional Model Predictive Control

In this section, the Laguerre based model predictive control and exponentially

weighted model predictive control are combined in order to alleviate computational

effort and reduce numerical problems. At first, a discrete model predictive control with

exponential data weighting is designed. The input, state and output vectors are

changed in the following way:

A. A. Hassan and Ahmed M. Kassem

1126

U T = 0 u (n),..., ( Nc 1) u (n + N c 1)

N p

X T = 1 x(n + 1),...,

x(n + N p )

N p

Y T = 1 y (n + 1),...,

x (n + N p )

(12)

where is tuning parameter in exponential data weighting and is larger than 1. The

state space representation of system with transformed variable is:

x (n + 1) = A x (n) + B u (n)

y (n) = C x (n)

(13)

Where A = A / , B = B / , C = C /

The optimal control trajectory with transformed variables can be achieved by

solving the new objective function and constraints.

Np

Nc

J (n) = k y (n + k ) yref (n + k ) + vk u (n + k )2

k =1

k =1

(14)

k u min u (n + k ) k u max ,

k u min u (n + k ) k u max

k x min x (n + k ) k x max

x min x (n + k )

x max

k y min y (n + k ) k y max

(15)

k y min y (n + k ) k y max

By choosing a>1, the condition number of hessian matrix will be reduced

significantly, especially for large values of prediction horizon (Np).This leads to a more

reliable numerical approach.

After solving new objective function with new variables, the calculated input

trajectory should be transformed into standard variable with the following equation.

U T = a o u (k ), ... , a ( N c 1 ) u (k + N c 1)

(16)

The Laguerre based model predictive control and exponentially weighted

model predictive control can be combined using the following systematic procedure:

- Choosing of the proper tuning parameter .

- Transforming the system parameters (A, B, C) and the system variables (U, X, Y) are

transformed using equations (13) and (14).

- The objective function with its constraints is created based on equations (15) and

(16).

- Optimizing objective function based on Laguerre polynomial and then calculating

unknown Laguerre coefficients.

SPEED CONTROL DESIGN OF A PMSM BASED ON

1127

- Calculating input chain from equation (11).

- The calculated weighted input chain is transformed into unweighted input chain

using equation (16) and applied on the plant.

Fig. (1): Basic structure of model predictive control

5. SYSTEM CONFIGURATION

The block diagram of the field oriented PMSM with the proposed FMPC is shown in

figure (2). All the commanded values are superscripted with asterisk in the diagram.

The proposed system control consists of three loops. The first loop for the speed based

on FMPC and the others for the d-q currents based on PI controllers. Simulations are

carried out to compare the performance of designed speed controller by FMPC with

conventional PI controller. The input and the output of the FMC are considered as

speed error and reference q-axis current respectively. The control parameters are

assumed as in the following

input weight matrix: =0.15INcNc

output weight matrix: v=1INpNp

The constraints are chosen such that, the q-axis stator current is normalized to

be between 0 and 1, where 0 corresponds to zero and 1 corresponds to maximum stator

current. Thus,

umin = 0 u 1 = umax .

The constraints imposed on the control signal are hard, whereas the constraints

on the states are soft, i.e., small violations can be accepted. The constraints on the

states are chosen to guarantee signals stay at physically reasonable values as follows:

0 i

xmin = q

0 r

22

= xmax

430

The speed error is fed to the speed controller (FMPC) in order to generate the

torque current command i q* . The flux current command i d* is set to zero to satisfy the

field orientation condition. The reference currents i q* and i d* are compared with their

respective actual currents. The resulted errors are used to generate the voltage

1128

A. A. Hassan and Ahmed M. Kassem

commands vd* and vq* which are converted to three phase reference values va* , vb* and

v c* in the stator frame. These voltage signals are compared with triangular carrier

signal and the output logic is used to control the PWM inverter.

The entire system has been simulated on the digital computer using the Matlab

/ Simulink / Powerlib software package. The motor used in the simulation procedure

has the following specifications [20]:

PMSM : 1.5 kw, 2-pole, 4250 rpm

Stator resistance : 1.6 ohm

Stator inductances: L= 6.37 m.H.

Permanent magnet flux : 0.19 Wb.

Moment of inertia : 0.0001854kg.m2

Friction coefficient : 5.396e-005 N.m.s/rad

Fig. (2): block diagram of the proposed PMSM speed control system

6. SIMULATION RESULTS

Computer simulations have been carried out in order to validate the effectiveness of the

proposed scheme. The simulation tests are carried out using Matlab/Simulink software

package. Wherever, the state space model of the permanent magnet synchronous motor

is programmed with the functional model predictive algorithms in MATLAB work

space.

The MPC control algorithm depends on the solution of a constrained

optimization problem. Most designers choose Np (prediction horizon) and Nc (control

horizon) in a way such that the controller performance is insensitive to small

adjustments in these horizons. Here are typical rules of thumb for obtaining a stable

process:

1. Choose the control interval such that the plant's open-loop settling time is

approximately 2030 sampling periods (i.e., the sampling period is approximately

one fifth of the dominant time constant).

2. Choose prediction horizon to be the number of sampling periods used in step 1.

3. Use a relatively small control horizon, e.g., 35.

SPEED CONTROL DESIGN OF A PMSM BASED ON

1129

Selection of suitable values of a and N will increase the system output

predicted values accuracy and help to improve the system performance with small

control effort. The tuning parameter is chosen in order to decrease the numerical

problems and decrease the simulation time and hence make the system more suitable

for implementation. Therefore, the system state space with transformed values A , B ,

C and D are obtained using the system state space model A, B, C and D and tuning

parameter , where, A = A / , B = B / , C = C / and D = D / . Then, the control

objectives are achieved by solving the new cost function J and new constraints.

In the proposed system under study, the parameters of the FMPC are adjusted

to be a=0.38, N=6, =1.04, Np=200 and Nc=5. The system performance with the

proposed FMPC controller is compared with the corresponding one using the

conventional PI controller. The gains of the PI controller are adjusted as: proportional

gain Kp=6 and integral gain Ki=2.5. The following simulation tests are carried out to

show the validity of the proposed FMPC controller:

a- High speed case:

It is assumed that the machine follows a certain speed trajectory starting from 400

rad/sec., stepped to 300 rad/sec. at time t=0.03 sec., then returned back to 400 rad/sec

at t=0.05 sec. The load torque is kept constant at the value 3 N.m. during the

simulation period. Figures (3) to (7) show the dynamic responses of the speed, torque,

rotor position and stator currents of the PMSM system based on both FMPC and PI

controllers. It has been shown that the proposed system has better transient response.

This is clear in figures (3) and (4) where the system with PI controller oscillates many

times before the steady state values are attained. In contrast, the system with the

proposed controller has attained the steady state value very quickly. That is can be

shown in fig. (3) to fig. (9), where overshoot and settling time of system are reduced

when FMPC controller is used. The settling time of PI controller is 18 ms, where in the

case of FMPC the settling time equal 5 ms as shown in fig 3. Also, Fig. (5) illustrates

that the PI controller produces large phase difference in the rotor position response

which adversely affecting the axes transformation and the flux orientation, and thereby

reducing the system performance. On the other hand, the FMPC tracks well the rotor

position reference and the field orientation condition is satisfied..

Figures (6) and (7) show the stator current response based on FMPC and PI

controllers. It is obvious that with the FMPC controller, the stator current has less

ripple content and over shoot than using PI controller.

b- Low speed case:

The performance of the PMSM scheme with the proposed FMPC controller is

investigated at low speed (10 rad/sec). The load torque is assumed to be stepped from 2

N.m. to 5 N.m. at time t=0.035 second. Figures (8) and (9) show the system responses

using the FMPC and PI controllers. It is clear that the system has poor transient

response using PI controller especially at starting and at the instant of load change.

Also, more ripples are noticed in the torque response. These drawbacks are nearly

eliminated using the FMPC controller.

Also in the FMPC, the unknown variables are 16 times less than the classical

MPC. In each time interval, the calculation time needed for classical MPC is 4.6 ms,

A. A. Hassan and Ahmed M. Kassem

1130

whereas this time is reduced to 0.48 ms in the FMPC. This is a great computational

advantage of using functional MPC.

(a) using FMPC controller

rotor speed (rad/sec)

500

400

300

200

100

0

ref

FMPC

0.01

0.02

0.03

0.04

0.05

0.06

0.07

time (sec)

(b) using PI controller

rotor speed (rad/sec)

500

400

300

200

100

0

ref

PI

0.01

0.02

0.03

0.04

0.05

0.06

0.07

time (sec)

Fig. (3): speed response of the PMSM system based on FMPC and PI controllers.

lo a d to rq u e (N m )

40

20

-20

PI

FMPC

-40

0.01

0.02

0.03

0.04

0.05

0.06

0.07

time (sec)

Fig. (4): Torque response of the PMSM system based on FMPC and PI controllers.

SPEED CONTROL DESIGN OF A PMSM BASED ON

1131

4

ref.

PI

FMPC

3

roto r p o s ition (ra d )

2

1

0

-1

-2

-3

-4

0.01

0.02

0.03

0.04

0.05

0.06

0.07

time(sec)

Fig. (5): Rotor position response of the PMSM system based on FMPC and PI

controllers.

40

the phase c urrents (A)

30

20

10

0

-10

-20

-30

-40

0.01

0.02

0.03

0.04

0.05

0.06

0.07

time (sec)

Fig. (6): stator current response of the PMSM system based on the FMPC controller.

A. A. Hassan and Ahmed M. Kassem

1132

40

three phas e c urrents (A )

30

20

10

0

-10

-20

-30

0.01

0.02

0.03

0.04

0.05

0.06

0.07

time (sec)

Fig. (7): stator current response of the PMSM system based on PI controller.

20

18

ref. speed

PI

FMPC

rotor speed (rad/sec)

16

14

12

10

8

6

4

2

0

-2

0.01

0.02

0.03

0.04

time (sec)

0.05

0.06

0.07

Fig. (8): Low speed response at variable load based on proposed FMPC and PI

controllers.

SPEED CONTROL DESIGN OF A PMSM BASED ON

1133

40

PI

FMPC

load torque (Nm)

30

20

10

0

-10

-20

-30

0.01

0.02

0.03

0.04

time (sec)

0.05

0.06

0.07

Fig. (9): Torque response based on FMPC and PI controllers at low speed.

7. CONCLUSIONS

In this paper, a centralized functional model predictive controller is proposed to control

the speed and torque of the permanent magnet synchronous motor drive system. The

proposed predictive controller uses orthonormal Laguerre functions to describe control

input trajectory which reduces real time computation largely. Also, exponential data

weighing is used to decrease numerical issue, particularly with large prediction

horizon. Constraints are imposed on both the q-axis current and the motor speed.

Computer simulations have been carried out in order to evaluate the

effectiveness of the proposed controller. The results proved that the proposed system

has accurate tracking performance at low speeds as well as high speeds. Also, small

ripple contents are noticed in the torque and stator current waveforms. Moreover, the

proposed controller has significantly better performance relative to PI controller

especially at starting and load change conditions. The main reasons of this superiority

are: centralized structure of the proposed controller which reduces negative interaction

between local control actions, proper constraints that improve optimal calculation of

control trajectory using large prediction horizon gives a performance close to global.

REFERENCES

[1] Morimoto S, Sanda M, Takeda Y. "Wide speed operation of interior permanent

magnet synchronous motors with high performance current regulator". .IEEE

Transactions on industry applications, Vol. 30, pp. 920-926, Aug 1994.

[2] Y. A. R. I. Mohamed, Adaptive self-tuning speed control for permanent-magnet

synchronous motor drive with dead time, IEEE Transactions on Energy

Conversion, Vol. 21, No. 4, pp. 855-862, Dec. 2006.

[3] C. H. Fang, C. M. Huang, and S. K. Lin, Adaptive sliding-mode torque control of

a PM synchronous motor, IEE Proceedings-Electric Power Applications, Vol.

149, No. 3, pp. 228-236, May 2002.

1134

A. A. Hassan and Ahmed M. Kassem

[4] Abdul Motin Howladery, Naomitsu Urasaki, Tomonobu Senjyu, Atsushi Yona,

and Ahmed Yousuf Saber, " optimal pam control for a buck boost dc-dc converter

with a wide-speed-range of operation for a pmsm", Journal of Power Electronics,

Vol. 10, No. 5, pp.477-484, 2010.

[5] Y. S. Kung, and M. H. Tsai, FPGA-based speed control IC for PMSM drive with

adaptive fuzzy control, IEEE Transactions on Industrial Electronics, Vol. 22, No.

6, pp. 2476-2486, Nov. 2007.

[6] Nung-Seo Park, Min-Ho Jang, Jee-Sang Lee, Keum-Shik Hong, and Jang-Mok

Kim," Performance Improvement of a PMSM Sensorless Control Algorithm Using

a Stator Resistance Error Compensator in the Low Speed Region", Journal of

Power Electronics, Vol. 10, No. 5, pp.485-490, 2010.

[7] Ying-Shieh Kung and Ming-Hung Tsai, "FPGA-based speed control ic for pmsm

drive with adaptive fuzzy control". IEEE transactions on power electronics, Vol.

22, No. 6, November 2007.

[8] YAN Dahu, JI Zhicheng, "Backstepping Speed Control of PMSM Based on

Equivalent Input Disturbance Estimator". Proceedings of the 29th Chinese Control

Conference, China, pp. 3377-3382, July 2010.

[9] Rong-Maw Jan, Chung-Shi Tseng and Ren-Jun Liu, " Robust PID control design

for permanent magnet synchronous motor: A genetic approach". Electric Power

Systems Research, Vol. 78, No.7, pp. 1161-1168, 2008.

[10] Fayez F. M. El-Sousy," A Vector-Controlled PMSM Drive with a Continually OnLine Learning Hybrid Neural-Network Model-Following Speed Controller",

Journal of Power Electronics, Vol. 5, No. 2, pp.129-141, 2005.

[11] Murat Karabacak, H. Ibrahim Eskikurt, " Speed and current regulation of a

permanent magnet synchronous motor via nonlinear and adaptive backstepping

control". Mathematical and Computer Modelling, Vol. 53, No. 9-10, pp. 20152030, 2011.

[12] L. Zhang, R. Norman, and W. Shepherd, LongRange Predictive Control of

current regulated PWM for induction motor drives using the synchronous reference

frame, IEEE Transactions on Control System. Technology., Vol. 5, No. 1, pp.

119126, 1997.

[13] R. Kennel, A. Linder, and M. Linke, Generalized predictive control (GPC)

ready for use in drive applications? in Proc. of the IEEE Power Electronics

Specialists Conference PESC 01, pp. 18391844, 2001.

[14] A. Linder and R. Kennel, Model predictive control for electrical drives, in Proc.

of the IEEE Power Electronics Specialists Conference PESC 05, pp. 17931799,

2005.

[15] Wang L, Discrete model predictive control design using Laguerre functions.

Journal of Process Control, pp. 131-142, 2004.

[16] Wang L, Use of exponential data weighting in model predictive control design.

Proc 40th IEEE Conf. on Decision and Control, 2001.

[17] Ahmed M. Kassem, " Robust Voltage control of a Stand Alone Wind Energy

Conversion System Based on Functional Model Predictive Approach".

International Journal of Electrical Power and Energy Systems, Vol. 41, pp. 124132, 2012.

[18] S. zra, N. Bekirolu, and E. Ayiek, "Speed Control of Permanent Magnet

Synchronous Motor Based on Direct Torque Control Method". IEEE International

1135

SPEED CONTROL DESIGN OF A PMSM BASED ON

Symposium on Power Electronics, Electrical Drives, Automation and Motion, pp

268-272, June, 2008.

[19] Maciejowski J.M, Predictive Control with Constraints, Pearson Education, POD,

2002.

[20] "MATLAB Math Library User's Guide", by the Math Works. Inc., 2010.

) (model predictive control

.

.

) (large prediction horizon

. (Functional

) model predictive control .

PI

.

.

Vous aimerez peut-être aussi

- Research ArticleDocument8 pagesResearch Articletariq76Pas encore d'évaluation

- 2018 - A Comparison of Finite Control Set and Continuous Control Set Model Predictive Control Schemes For Speed Control of Induction MotorsDocument13 pages2018 - A Comparison of Finite Control Set and Continuous Control Set Model Predictive Control Schemes For Speed Control of Induction MotorsjemmyducPas encore d'évaluation

- Machine Learning Based Adaptive PredictionDocument9 pagesMachine Learning Based Adaptive PredictionnhatvpPas encore d'évaluation

- Design and Implementation of Model Predictive Control For Electrical Motor DrivesDocument12 pagesDesign and Implementation of Model Predictive Control For Electrical Motor Drivestariq76Pas encore d'évaluation

- Computationally Efficient Self Tuning Controller For DC DC Switch Mode Power Converters Based On Partial Update Kalman Filter SingleDocument24 pagesComputationally Efficient Self Tuning Controller For DC DC Switch Mode Power Converters Based On Partial Update Kalman Filter SingleMairaj-ud-din MuftiPas encore d'évaluation

- On-Line Adaptive Artificial Neural Network Based Vector Control Permanent MagnetDocument8 pagesOn-Line Adaptive Artificial Neural Network Based Vector Control Permanent MagnetKushagra KhamesraPas encore d'évaluation

- Runge-Kutta Model Predictive Speed Control For PerDocument17 pagesRunge-Kutta Model Predictive Speed Control For PerAmir KrzPas encore d'évaluation

- Discrete-Time Sliding Mode Control of Permanent Magnet Linear Synchronous Motor in High-Performance Motion With Large Parameter UncertaintyDocument4 pagesDiscrete-Time Sliding Mode Control of Permanent Magnet Linear Synchronous Motor in High-Performance Motion With Large Parameter UncertaintyElzan AgungPas encore d'évaluation

- Finite Control Set Model Predictive Control With Feedback Correction For Power ConvertersDocument8 pagesFinite Control Set Model Predictive Control With Feedback Correction For Power ConvertersPhùng Tiến ĐạtPas encore d'évaluation

- 2019-Field Weakening Operation Control Strategies of PMSM Based On LinearizationDocument18 pages2019-Field Weakening Operation Control Strategies of PMSM Based On LinearizationKiki RamadhanPas encore d'évaluation

- Wind Turbine Control With Multiple Model Predictive ControlDocument6 pagesWind Turbine Control With Multiple Model Predictive ControlAngelo Sanchez IafantiPas encore d'évaluation

- 2017 - Finite-Control Set MPC Method For Tourque Control of IM Using A State Tracking Cost IndexDocument13 pages2017 - Finite-Control Set MPC Method For Tourque Control of IM Using A State Tracking Cost IndexjemmyducPas encore d'évaluation

- A New Self-Healing DSTATCOM For Volt-VAR and Power Quality ControlDocument8 pagesA New Self-Healing DSTATCOM For Volt-VAR and Power Quality ControlMahutaPas encore d'évaluation

- Model Reference Adaptive Control Based Parameters Estimation of Permanent Magnet Synchronous Motor DriveDocument9 pagesModel Reference Adaptive Control Based Parameters Estimation of Permanent Magnet Synchronous Motor DriveInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- PDFDocument10 pagesPDFramunitPas encore d'évaluation

- Model Predictive Control of A Permanent Magnet Synchronous Motor With Experimental ValidationDocument19 pagesModel Predictive Control of A Permanent Magnet Synchronous Motor With Experimental ValidationAlimamy KoromaPas encore d'évaluation

- 2019-Model Predictive Control of Quadruple Tank SystemDocument5 pages2019-Model Predictive Control of Quadruple Tank SystemAravindan MohanPas encore d'évaluation

- UntitledDocument11 pagesUntitledapi-197704391Pas encore d'évaluation

- Modulated Model Predictive Speed Controller For PMSM Drives Employing Voltage Based Cost FunctionDocument10 pagesModulated Model Predictive Speed Controller For PMSM Drives Employing Voltage Based Cost FunctionGlobal PapersPas encore d'évaluation

- 1 s2.0 S0378779616303650 Main PDFDocument16 pages1 s2.0 S0378779616303650 Main PDFKhaled M. AboalezPas encore d'évaluation

- Backstepping Control of Speed Sensorless Permanent Magnet Synchronous Motor Based On Slide Model ObserverDocument7 pagesBackstepping Control of Speed Sensorless Permanent Magnet Synchronous Motor Based On Slide Model ObserverLê Đức ThịnhPas encore d'évaluation

- Vector Control System of Induction Motor Based On Fuzzy Control MethodDocument5 pagesVector Control System of Induction Motor Based On Fuzzy Control MethodjhonnydesaPas encore d'évaluation

- Long-Horizon Model Predictive Control of Induction Motor DriveDocument15 pagesLong-Horizon Model Predictive Control of Induction Motor DriveabbasPas encore d'évaluation

- IPMSM Model Predictive Control in Flux-Weakening Operation Using An Improved AlgorithmDocument10 pagesIPMSM Model Predictive Control in Flux-Weakening Operation Using An Improved Algorithmalaref elhajPas encore d'évaluation

- Sliding ModeDocument13 pagesSliding ModeSiva Ganesh MallaPas encore d'évaluation

- Preprints202305 1094 v1Document18 pagesPreprints202305 1094 v1Adrian MarinPas encore d'évaluation

- Wa0000 PDFDocument8 pagesWa0000 PDFAlvaajid SaleemPas encore d'évaluation

- High Performance Position Control of Permanent Magnet Synchronous DrivesDocument11 pagesHigh Performance Position Control of Permanent Magnet Synchronous DrivesdjoodjooPas encore d'évaluation

- A Novel Technique For The Design of Controller of A Vector-Controlled Permanent Magnet Synchronous Motor DriveDocument6 pagesA Novel Technique For The Design of Controller of A Vector-Controlled Permanent Magnet Synchronous Motor Driveshoebhussain01Pas encore d'évaluation

- Model Predictive Control of An Inverted Pendulum, MPCDocument4 pagesModel Predictive Control of An Inverted Pendulum, MPCerdsan100% (1)

- Điều chỉnh tốc độ cho ổ đĩa PMSM dựa trên bộ điều khiển chế độ trượt mớiDocument8 pagesĐiều chỉnh tốc độ cho ổ đĩa PMSM dựa trên bộ điều khiển chế độ trượt mớiNguyễn Văn HoàPas encore d'évaluation

- Constraintoptimal Control For GyroscopeDocument7 pagesConstraintoptimal Control For GyroscopeInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Speed Control of DC Motor Using Sliding Mode Control ApproachDocument5 pagesSpeed Control of DC Motor Using Sliding Mode Control ApproachIOSRjournalPas encore d'évaluation

- Electromagnetic Transients Simulation As An Objective Function Evaluator For Optimization of Power System PerformanceDocument6 pagesElectromagnetic Transients Simulation As An Objective Function Evaluator For Optimization of Power System PerformanceAhmed HussainPas encore d'évaluation

- The Speed and Torque Control of Direct Current Servo Motors by Using Cascade Fuzzy PI ControllerDocument5 pagesThe Speed and Torque Control of Direct Current Servo Motors by Using Cascade Fuzzy PI ControllerAndy MeyerPas encore d'évaluation

- Sliding Mode Control PHD ThesisDocument7 pagesSliding Mode Control PHD Thesisaflodnyqkefbbm100% (1)

- Research Article: Sensorless Speed Control of Permanent Magnet Synchronous Motors by Neural Network AlgorithmDocument8 pagesResearch Article: Sensorless Speed Control of Permanent Magnet Synchronous Motors by Neural Network AlgorithmfvijayamiPas encore d'évaluation

- Constrained Model-Based Predictive Controller For A High-Frequency Low-Power DC-DC Buck ConverterDocument24 pagesConstrained Model-Based Predictive Controller For A High-Frequency Low-Power DC-DC Buck ConverterShaheer DurraniPas encore d'évaluation

- Adaptive IM ControlDocument16 pagesAdaptive IM ControlAli AltahirPas encore d'évaluation

- Icee2015 Paper Id3911Document4 pagesIcee2015 Paper Id3911Zellagui EnergyPas encore d'évaluation

- Sensorless Control of Permanent Magnet Synchronous Motor A Survey WWW - Daneshpajooh.irDocument8 pagesSensorless Control of Permanent Magnet Synchronous Motor A Survey WWW - Daneshpajooh.ira1690074Pas encore d'évaluation

- Decentralized Model Predictive Control of Cooperating Uavs: Arthur Richards and Jonathan HowDocument6 pagesDecentralized Model Predictive Control of Cooperating Uavs: Arthur Richards and Jonathan HowjamestppPas encore d'évaluation

- Energies 17 00147Document13 pagesEnergies 17 00147Global PapersPas encore d'évaluation

- 08598921外文1Document11 pages08598921外文11392297140sPas encore d'évaluation

- Speed Anti-Windup PI Strategies Review For Field Oriented Control of Permanent Magnet Synchronous MachinesDocument6 pagesSpeed Anti-Windup PI Strategies Review For Field Oriented Control of Permanent Magnet Synchronous MachinesOmegalpha5Pas encore d'évaluation

- Research Article: A DSP-Controlled Permanent Magnet Synchronous Motor Control System For Hybrid VehiclesDocument9 pagesResearch Article: A DSP-Controlled Permanent Magnet Synchronous Motor Control System For Hybrid VehiclesMeryouma LarbPas encore d'évaluation

- Using The PMSM Vector Control eTPU Function: Covers The MCF523x, MPC5500, MPC5600 and All eTPU-Equipped DevicesDocument27 pagesUsing The PMSM Vector Control eTPU Function: Covers The MCF523x, MPC5500, MPC5600 and All eTPU-Equipped Devicesbadro1980Pas encore d'évaluation

- Space Vector Flux Weakening Control of PMSM DriverDocument8 pagesSpace Vector Flux Weakening Control of PMSM DriverOsama AttookPas encore d'évaluation

- Accepted Manuscript - Schenker Et Al - Application and Improvement of A Direct Method OptimizationDocument19 pagesAccepted Manuscript - Schenker Et Al - Application and Improvement of A Direct Method OptimizationEzana EzanaPas encore d'évaluation

- Predictive Current Trajectory Control For PMSM atDocument10 pagesPredictive Current Trajectory Control For PMSM atsurya bobbiliPas encore d'évaluation

- Nghiên cứu hệ thống điều khiển suy yếu từ thông của động cơ đồng bộ nam châm vĩnh cửu nội thất dựa trên cơ chế điều khiển trượt mờDocument6 pagesNghiên cứu hệ thống điều khiển suy yếu từ thông của động cơ đồng bộ nam châm vĩnh cửu nội thất dựa trên cơ chế điều khiển trượt mờNguyễn Văn HoàPas encore d'évaluation

- A0408 05-0112 PDFDocument12 pagesA0408 05-0112 PDFIJMERPas encore d'évaluation

- Sensorless Direct Torque Control Based On Nonlinear Integral Sliding Mode Controllers For An Induction Motor Drive: Experimental VerificationDocument20 pagesSensorless Direct Torque Control Based On Nonlinear Integral Sliding Mode Controllers For An Induction Motor Drive: Experimental VerificationMuhammad UmarPas encore d'évaluation

- Model Predictive Control Based Hybrid MPPT... Irmak2019Document28 pagesModel Predictive Control Based Hybrid MPPT... Irmak2019hafiz858Pas encore d'évaluation

- Prediction of Critical Clearing Time Using Artificial Neural NetworkDocument5 pagesPrediction of Critical Clearing Time Using Artificial Neural NetworkSaddam HussainPas encore d'évaluation

- Model Predictive Control Based On Adaptive Hinging Hyperplanes ModelDocument11 pagesModel Predictive Control Based On Adaptive Hinging Hyperplanes ModelssuthaaPas encore d'évaluation

- Control of DC Motor Using Different Control StrategiesD'EverandControl of DC Motor Using Different Control StrategiesPas encore d'évaluation

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsD'EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsPas encore d'évaluation

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorD'EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorPas encore d'évaluation

- Advantest r6441 DMM User ManualDocument263 pagesAdvantest r6441 DMM User Manualhieuhuech1Pas encore d'évaluation

- 2SP0115T Control IGBT ManualDocument21 pages2SP0115T Control IGBT Manualhieuhuech1Pas encore d'évaluation

- Real-Time Interface Dspace DSDocument12 pagesReal-Time Interface Dspace DShieuhuech1Pas encore d'évaluation

- Tektronix A6303 070390504Document34 pagesTektronix A6303 070390504hieuhuech1Pas encore d'évaluation

- TDS7000 SeriesDocument254 pagesTDS7000 Serieshieuhuech1Pas encore d'évaluation

- Sanwa pc500Document42 pagesSanwa pc500hieuhuech1Pas encore d'évaluation

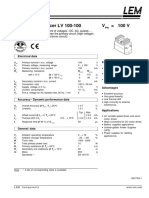

- Lem Voltage 100-500Document2 pagesLem Voltage 100-500hieuhuech1Pas encore d'évaluation

- Msp-Exp430G2 Launchpad Workshop: - Meet The Launchpad - Lab 1: Blink Launchpad LedsDocument16 pagesMsp-Exp430G2 Launchpad Workshop: - Meet The Launchpad - Lab 1: Blink Launchpad Ledshieuhuech1Pas encore d'évaluation

- Stator Flux and Speed - HADocument6 pagesStator Flux and Speed - HAhieuhuech1Pas encore d'évaluation

- Simulation Study On Speed Control of Permanent Magnet Direct-Driven System For Mining ScraperDocument11 pagesSimulation Study On Speed Control of Permanent Magnet Direct-Driven System For Mining Scraperhieuhuech1Pas encore d'évaluation

- Fod8316 108263Document30 pagesFod8316 108263hieuhuech1Pas encore d'évaluation

- Design of A Microcontroller-Based Circuit For Software ProtectionDocument6 pagesDesign of A Microcontroller-Based Circuit For Software Protectionhieuhuech1Pas encore d'évaluation

- Nonlinear Model of Permanent-Magnet Synchronous MotorsDocument8 pagesNonlinear Model of Permanent-Magnet Synchronous Motorshieuhuech1Pas encore d'évaluation

- Ansys Chu y Chicago Modeling and Simulation of Brushless DC Motor Drive SystemDocument25 pagesAnsys Chu y Chicago Modeling and Simulation of Brushless DC Motor Drive Systemhieuhuech1Pas encore d'évaluation

- Sensorless Foc of PMSM Chu YDocument42 pagesSensorless Foc of PMSM Chu Yhieuhuech1Pas encore d'évaluation

- Gauss Method - Nisan 15Document1 pageGauss Method - Nisan 15Otis ArmsPas encore d'évaluation

- SpiralDocument47 pagesSpiralEr. Vicky MakawanaPas encore d'évaluation

- Physics Lab - Detailed - Answer KeyDocument6 pagesPhysics Lab - Detailed - Answer KeyJasdeepSinghPas encore d'évaluation

- Demag KBK Alu Enclosed Track SystemDocument2 pagesDemag KBK Alu Enclosed Track SystemMAGSTPas encore d'évaluation

- 30 - MACRS DepreciationDocument4 pages30 - MACRS Depreciationidriwal mayusdaPas encore d'évaluation

- AtomDocument15 pagesAtomdewi murtasimaPas encore d'évaluation

- HPC168 Passenger CounterDocument9 pagesHPC168 Passenger CounterRommel GómezPas encore d'évaluation

- Spelling RulesDocument5 pagesSpelling RulesvijthorPas encore d'évaluation

- Ss 1 Further Mathematics Lesson 4Document7 pagesSs 1 Further Mathematics Lesson 4Adio Babatunde Abiodun CabaxPas encore d'évaluation

- TribunaloLo Ex#6Document14 pagesTribunaloLo Ex#6Jaylou OpondaPas encore d'évaluation

- A Report On Traffic Volume StudyDocument33 pagesA Report On Traffic Volume StudyManoj Durairaj100% (1)

- ELEMAGDocument1 pageELEMAGJasper BantulaPas encore d'évaluation

- 00.concrete Mix Design-RailwayDocument38 pages00.concrete Mix Design-RailwaySoundar PachiappanPas encore d'évaluation

- D4304-Syllabus-Neural Networks and Fuzzy SystemsDocument1 pageD4304-Syllabus-Neural Networks and Fuzzy Systemsshankar15050% (1)

- Awodey, Categories For Everybody - PsDocument196 pagesAwodey, Categories For Everybody - PsΣωτήρης Ντελής100% (3)

- Gantt ChartDocument4 pagesGantt ChartSyed FaridPas encore d'évaluation

- Astm A394 2008 PDFDocument6 pagesAstm A394 2008 PDFJavier Ricardo Romero BohorquezPas encore d'évaluation

- Template Question BankDocument11 pagesTemplate Question Bankeshwar_worldPas encore d'évaluation

- 0606 Additional Mathematics: MARK SCHEME For The May/June 2015 SeriesDocument9 pages0606 Additional Mathematics: MARK SCHEME For The May/June 2015 Serieswai yanPas encore d'évaluation

- Optical Properties of Gem Substances Educational Objective: This Exercise, Unit 7 in The Above Syllabus, Will Introduce Students To Skills andDocument19 pagesOptical Properties of Gem Substances Educational Objective: This Exercise, Unit 7 in The Above Syllabus, Will Introduce Students To Skills andCarl SoriaPas encore d'évaluation

- Photo Luminescence of Surfaces and InterfacesDocument25 pagesPhoto Luminescence of Surfaces and InterfacesNick KellerPas encore d'évaluation

- Pelod Vs Sofa Scoring in PediatricDocument6 pagesPelod Vs Sofa Scoring in PediatricAdrian KhomanPas encore d'évaluation

- 8.2.2.2.1.1 Batch Operation ManagementDocument10 pages8.2.2.2.1.1 Batch Operation ManagementbernardPas encore d'évaluation

- IIM Nagpur Test 1 Version 1 2016Document6 pagesIIM Nagpur Test 1 Version 1 2016Saksham GoyalPas encore d'évaluation

- 6100 SQ Lcms Data SheetDocument4 pages6100 SQ Lcms Data Sheet王皓Pas encore d'évaluation

- Chem Cheat Sheet MasterDocument6 pagesChem Cheat Sheet MasteradamhamelehPas encore d'évaluation

- Rr410209 High Voltage EngineeringDocument7 pagesRr410209 High Voltage EngineeringSrinivasa Rao GPas encore d'évaluation

- en Product OverviewDocument81 pagesen Product OverviewShakeel AhmedPas encore d'évaluation

- Commissioning PFDC DriveDocument45 pagesCommissioning PFDC DriveFonoaudióloga Gisele RezendePas encore d'évaluation

- Fil Mur Filter FM Alt P61e5Document23 pagesFil Mur Filter FM Alt P61e5ALlan ABiangPas encore d'évaluation