Académique Documents

Professionnel Documents

Culture Documents

Enventure SET Technology

Transféré par

zapspazCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Enventure SET Technology

Transféré par

zapspazDroits d'auteur :

Formats disponibles

How SET Technology Works

DATA S H E E T

SET technology is the

result of a cold-working

process that permanently

deforms the pipe without

any additional heat.

The procedure inherent to expanding tubulars takes the steel beyond its

elastic limit into the plastic region of the stress-strain curve, while remaining

safely below ultimate yield. Our unparalleled level of industry expertise enables

us to apply the technology safely and with a high degree of reliability.

The pipe used in SET Systems, EX-80, meets standards beyond those specified

by API for oil and gas well use, but with pre-expansion properties similar to

those of API L-80 material. The metallurgical composition of the pipe allows

greater ductility while still retaining its strength properties. Enventure utilizes

electric resistance welded (ERW) pipe, which provides greater uniformity of

wall thickness and ovality, required for consistent expansion results.

To facilitate the expansion process, the wellbore section is drilled and often

underreamed, after which the expandable casing is run. In cased-hole

applications the existing casing is cleaned to ensure successful expansion.

The housing at the bottom of the SET system, known as the launcher, contains

an expansion assembly as well as a float assembly and is typically constructed

of thin-wall, high-strength steel.

The custom-designed expansion assembly contains a solid cone that is

driven through the expandable tubulars using hydraulic pressure or mechanical

force, or a combination of both, which enlarges the pipe radially. During the

expansion process, the enlargement of the pipe diameter causes the overall

pipe length to shorten from the top as a result of material balance. As the liner

is expanded, its outer diameter (OD) increases significantly, while the wall

thickness decreases only slightly. This preserves the greatest post-expansion

burst and collapse values possible.

How SET Technology Works

DATA S H E E T

The cone moves up from the bottom

of the liner through the EX-80 pipe

which has a proprietary coating on

the inside diameter and proprietary

pin-up connections. This bottom-to-top

expansion process is completed when

the anchor hanger seals the expandable

liner against the previous pipe string

referred to as the base casing.

Enventure is able to tailor pipe expansion

and wall thickness to exact needs. The

expandable system provides a positive

seal in the liner lap, thus eliminating often

needed cement squeeze at the liner top.

Enventure Global Technology

15995 North Barkers Landing, Suite 350 | Houston, Texas 77079

p 281.552.2200 | f 281.552.2201 | www.EnventureGT.com

2009 Enventure Global Technology Enventure and SET are trademarks of Enventure Global Technology All Rights Reserved 2/09

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Acidizing Oil Natural Gas Briefing Paper v2Document5 pagesAcidizing Oil Natural Gas Briefing Paper v2Radu Teodor GoranPas encore d'évaluation

- Top CO - Catalog February 2015 - R6 PDFDocument36 pagesTop CO - Catalog February 2015 - R6 PDFzapspazPas encore d'évaluation

- PDC Drill Bits Optimized For Shale DevelopmentDocument2 pagesPDC Drill Bits Optimized For Shale DevelopmentzapspazPas encore d'évaluation

- PDF SMB PDFDocument6 pagesPDF SMB PDFzapspazPas encore d'évaluation

- Foraco Reverse Circulation DrillingDocument4 pagesForaco Reverse Circulation DrillingzapspazPas encore d'évaluation

- ALS Corpro Core Quickview DatasheetDocument2 pagesALS Corpro Core Quickview DatasheetzapspazPas encore d'évaluation

- Carbonate Matrix Acidizing TreatmentsDocument23 pagesCarbonate Matrix Acidizing TreatmentszapspazPas encore d'évaluation

- Drillbit Class If I ErDocument19 pagesDrillbit Class If I ErCharly Oswald ArgolloPas encore d'évaluation

- Hydril Ram Annular Good Diagrams BOP ProductsDocument44 pagesHydril Ram Annular Good Diagrams BOP ProductsSharad Chandra Naik100% (7)

- Drilling Fluid AdditivesDocument4 pagesDrilling Fluid AdditiveszapspazPas encore d'évaluation

- PDCTechnology DC P52-54 MarApr2005 PDFDocument4 pagesPDCTechnology DC P52-54 MarApr2005 PDFzapspazPas encore d'évaluation

- API Standards and Well ControlDocument9 pagesAPI Standards and Well ControlRobertok1234Pas encore d'évaluation

- SWOT TemplatesDocument11 pagesSWOT TemplateszapspazPas encore d'évaluation

- Specialty Casing ConnectorsDocument24 pagesSpecialty Casing ConnectorszapspazPas encore d'évaluation

- Cut and Thread ProcedureDocument4 pagesCut and Thread ProcedurezapspazPas encore d'évaluation

- Composition of Crude OilDocument2 pagesComposition of Crude Oilzapspaz100% (1)

- 1101 Sandface Comp PosterDocument1 page1101 Sandface Comp Posterdavid_avilesPas encore d'évaluation

- Calendar TemplatesDocument12 pagesCalendar TemplateszapspazPas encore d'évaluation

- Fiche Circulation Inverse PDFDocument4 pagesFiche Circulation Inverse PDFzapspazPas encore d'évaluation

- 1.11 Fracture GradientsDocument36 pages1.11 Fracture GradientszapspazPas encore d'évaluation

- Api Purchasing Guide 2015-08-29 PDFDocument20 pagesApi Purchasing Guide 2015-08-29 PDFQaiser HafeezPas encore d'évaluation

- Cut and Thread ProcedureDocument4 pagesCut and Thread ProcedurezapspazPas encore d'évaluation

- Backoff Basics - Stuck Pipe PDFDocument4 pagesBackoff Basics - Stuck Pipe PDFzapspazPas encore d'évaluation

- PDF SMB PDFDocument6 pagesPDF SMB PDFzapspazPas encore d'évaluation

- GrantPrideco Drill Pipe Data TablesDocument24 pagesGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezPas encore d'évaluation

- Casing Sizes and DriftsDocument2 pagesCasing Sizes and DriftsAbdulaziz AbdullahPas encore d'évaluation

- GP Tool Joint Dimensional ValueDocument3 pagesGP Tool Joint Dimensional ValuecalamarejoPas encore d'évaluation

- Grand Prideco Drill Collars CatalogDocument13 pagesGrand Prideco Drill Collars CatalogzapspazPas encore d'évaluation

- Construction of VSP Gun-PitDocument7 pagesConstruction of VSP Gun-PitzapspazPas encore d'évaluation

- API Standards and Well ControlDocument9 pagesAPI Standards and Well ControlRobertok1234Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Electrolysis ProcessesDocument180 pagesElectrolysis ProcessesEngineering Office Shahrak100% (1)

- CRPNS R1 Application FormDocument5 pagesCRPNS R1 Application FormQuek Keng LengPas encore d'évaluation

- HVAC Cooling Load CalculationDocument98 pagesHVAC Cooling Load CalculationVishnupriya B.100% (3)

- REFRIGERANTSDocument72 pagesREFRIGERANTSSka dooshPas encore d'évaluation

- Clarus500 580UserGuideDocument442 pagesClarus500 580UserGuideSelvaraj VenkatesanPas encore d'évaluation

- OrganicCarbonTotalDirectTNT DOC316.53.01093Document8 pagesOrganicCarbonTotalDirectTNT DOC316.53.01093yocam2Pas encore d'évaluation

- En 1.4301Document1 pageEn 1.4301sheinilaPas encore d'évaluation

- Epri Chemical Cleaning PDFDocument50 pagesEpri Chemical Cleaning PDFARSALAN GOPALPas encore d'évaluation

- Chemical Engineering Department Journals Level 4: Holding InformationDocument6 pagesChemical Engineering Department Journals Level 4: Holding Informationmubi_lovePas encore d'évaluation

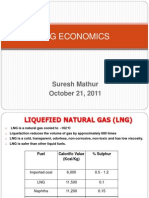

- LNG EconomicsDocument19 pagesLNG EconomicsCal67% (3)

- Example Chemical and Biological CompositionDocument8 pagesExample Chemical and Biological CompositioniskandarPas encore d'évaluation

- Process Flow Chart Dairy ProductsDocument5 pagesProcess Flow Chart Dairy Productslokesh jainPas encore d'évaluation

- EP 1108 Photoelectric EffectDocument12 pagesEP 1108 Photoelectric EffectAryam SharmaPas encore d'évaluation

- Rate Law and The Eyring EquationDocument11 pagesRate Law and The Eyring EquationManjunath.RPas encore d'évaluation

- Raghavendra Bhat. GPUC High School Section, MegaravalliDocument8 pagesRaghavendra Bhat. GPUC High School Section, Megaravallisyedyaseen39375Pas encore d'évaluation

- Wear Plate SpecsDocument4 pagesWear Plate SpecsJuan Carlos EspinozaPas encore d'évaluation

- NTU MethodDocument15 pagesNTU MethodVenkatesh KandalamPas encore d'évaluation

- European Cat 08 2009-10Document92 pagesEuropean Cat 08 2009-10sitiodossitesPas encore d'évaluation

- Atv-Reg ElwerkDocument41 pagesAtv-Reg ElwerkNoureddine MerahPas encore d'évaluation

- Comparative Evaluation of The Physicochemical and Sensorial Quality of Dragon Fruit Jams Made With Diferent Types of Citrus Juices As Acidulants - Turnitin SubmissionDocument59 pagesComparative Evaluation of The Physicochemical and Sensorial Quality of Dragon Fruit Jams Made With Diferent Types of Citrus Juices As Acidulants - Turnitin SubmissionCheng KaiPas encore d'évaluation

- Class 10 Science Super 20 Sample PapersDocument85 pagesClass 10 Science Super 20 Sample PapersParas Tyagi100% (1)

- Journal of Molecular Liquids: Sonu, Sayantan Halder, Sunita Kumari, Rishika Aggrawal, Vinod K. Aswal, Subit K. SahaDocument11 pagesJournal of Molecular Liquids: Sonu, Sayantan Halder, Sunita Kumari, Rishika Aggrawal, Vinod K. Aswal, Subit K. SahaAbiel Angel GarciaPas encore d'évaluation

- 1.7 Evaporative Air Cooling EquipmentDocument8 pages1.7 Evaporative Air Cooling EquipmentRio BananPas encore d'évaluation

- Deaerator Post MCQ'sDocument50 pagesDeaerator Post MCQ'sEhtisham ul haqPas encore d'évaluation

- Gas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWDocument3 pagesGas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWJulioPas encore d'évaluation

- UC Bracing Gusset - ASDDocument14 pagesUC Bracing Gusset - ASDFunny & InformativePas encore d'évaluation

- DeflocculationDocument19 pagesDeflocculationJames LagaloPas encore d'évaluation

- SG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323Document10 pagesSG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323vDraqPas encore d'évaluation

- Modern Extraction of Citrus Wastes - Foods-08-00523-V2 PDFDocument81 pagesModern Extraction of Citrus Wastes - Foods-08-00523-V2 PDFjimmyboy111Pas encore d'évaluation

- Electrolysis O LevelDocument17 pagesElectrolysis O LevelInnocent EbilPas encore d'évaluation