Académique Documents

Professionnel Documents

Culture Documents

Element 3A1 3A3 E, M Jan 15 03

Transféré par

Manuel CarvalloTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Element 3A1 3A3 E, M Jan 15 03

Transféré par

Manuel CarvalloDroits d'auteur :

Formats disponibles

HP3A1/HP3A3 Element

HP3A1/3A3 series

Interchanges element for Army-Navy

AN6235-3A standard

Hy-Pro G6 Dualglass

High Performance Filter Elements

Performance

Temperature:

Element collapse

Media

G6 media pleat pack features our latest

generation of graded density glass media that

delivers required cleanliness while optimizing

dirt capacity.

Dynamic Filter Efficiency

DFE rated elements perform true to rating even

under demanding variable flow and vibration

conditions. Todays industrial and mobile

hydraulic circuits require elements that deliver

specified cleanliness under all circumstances.

Wire mesh supports the media to ensure against

cyclical flow fatigue, temperature, and chemical

resistance failures possible in filters with

synthetic support mesh.

Tested to ISO quality standards

ISO 2941

ISO 2942

ISO 2943

ISO 3724

ISO 3968

ISO 16889

Collapse and burst resistance

Fabrication and Integrity test

Material compatibility with fluids

Flow fatigue characteristics

Pressure drop vs. flow rate

Multi-pass performance testing

-65f to 275f (buna)

-65f to 300f (EPR)

-65f to 400f (fluorocarbon)

HP3A1 = 300 psid (21 bar)

HP3A3 = 4500 psid (320 bar)

Interchanges by series only:

(See interchange guide for exact cross

Reference and complete part numbers

Army-Navy

Hy-Pro

AN6235-3A

(300 psid collapse)

HP3A1L3-###

AN6235-3A

(4500 psid collapse)

HP3A3L3-###

Available media selections include G5 Dualglass,

Stainless steel mesh media, Dynafuzz (stainless fiber

media), Water removal media. Call or consult the

Hy-Pro on line interchange guide at

www.filterelement.com.

Seal options include Nitrile (buna), Fluorocarbon

(viton), and EPR. See order guide on reverse side for

part numbers.

Fluid Compatibility

Petroleum based fluids, water glycols, polyol

esters, phosphate esters, HWBF

For technical service call 317.849.3535 or fax 317.849.9201

www.filterelement.com

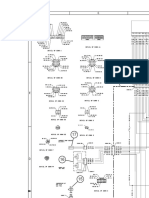

14

19

24

28

33

38

12

0.6

6

12

0.4

25

flow rate gpm

14

19 24

28

33

38

0.8

0.6

12

0.4

25

0.2

0.0

1

0.2

0

0

Dp psi

0

0.8

0.0

0

10

Dp bar

12

Dp psi

3A3L3 Dualglass Dp vs flow rate

flow rate lpm

Dp bar

3A1L3 Dualglass Dp vs flow rate

flow rate lpm

flow rate gpm

10

Pressure Drop Calculation

Pressure drop curves based on oil viscosity of 141 SSU, and specific gravity = 0.86. Dp across element

is proportionally related to viscosity and specific gravity. For new DP use the following conversion formula:

DP element = DP curve x Actual Viscosity/141 x Actual SG/0.86

table 1

table 2

table 3

table 4

HP3A __ L 3 - __ __ __

table 1

code

3

1

collapse

4500 psid

300 psid

TB3A1/3A3-0602

table 2

code

filtration rating

1

B2.5[c] = 1000 (B1 = 200)

3

B5[c] = 1000 (B3 = 200)

6

B7[c] = 1000 (B6 = 200)

12

B12[c] = 1000 (B12 = 200)

25

B22[c] = 1000 (B25 = 200)

or 25u nominal wire mesh

40

40u nominal wire mesh

74

74u nominal wire mesh

149

149u nominal wire mesh

table 3

code

M

SF

W

media type

G6 Dualglass

Dynafuzz

wire mesh

table 4

code

B

E

V

seal

Nitrile (buna)

EPR

Fluorocarbon

Hy-Pro filters are tested to the latest industry

standard ISO16889 (replacing ISO4572) resulting in

A new scale for defining particle sizes and determining

filtration ratio (formerly known as beta ratio)

New (ISO16889) vs Old (ISO4572) size comparison

Bx(c)=1000 (ISO16889)

2.5 5 7 12 22

Bx=200 (ISO4572)

<1 3 6 12 25

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Caterpillar Vane Pump PDFDocument24 pagesCaterpillar Vane Pump PDFManuel Carvallo0% (1)

- Sai Selection GuideDocument8 pagesSai Selection GuideManuel CarvalloPas encore d'évaluation

- Troubleshooting1 PDFDocument40 pagesTroubleshooting1 PDFDanielAlfaroPas encore d'évaluation

- Hy11-3353 CVG UkDocument36 pagesHy11-3353 CVG UkManuel Carvallo100% (1)

- Settima Pompa SMT16BDocument10 pagesSettima Pompa SMT16BManuel CarvalloPas encore d'évaluation

- Element TL4 TX4 E, M Mar 05 02Document2 pagesElement TL4 TX4 E, M Mar 05 02Manuel CarvalloPas encore d'évaluation

- Hydraulic Schematic T2556 (S/N A8FR11001 AND ABOVE) T2566 (S/N A8G311001 AND ABOVE)Document3 pagesHydraulic Schematic T2556 (S/N A8FR11001 AND ABOVE) T2566 (S/N A8G311001 AND ABOVE)Manuel Carvallo100% (3)

- O-Rings and SealsDocument10 pagesO-Rings and SealsManuel CarvalloPas encore d'évaluation

- Catalogo Despiece Vickers PVH131 - 141Document9 pagesCatalogo Despiece Vickers PVH131 - 141Manuel Carvallo0% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Reactor DesignDocument27 pagesReactor Designcheckmeout803100% (3)

- Extremity and Eye-Lens Dosimetry: Issues, Recommendations, and ApproachesDocument2 pagesExtremity and Eye-Lens Dosimetry: Issues, Recommendations, and Approachesmdiaz_784526100% (1)

- AC SchematicDocument6 pagesAC SchematicsuwarjitechnicPas encore d'évaluation

- Manual de Servicio Samsung Awt24famea PDFDocument56 pagesManual de Servicio Samsung Awt24famea PDFJesus TubiñezPas encore d'évaluation

- Construction and Building Materials: L.C. HollawayDocument27 pagesConstruction and Building Materials: L.C. HollawayZain SaeedPas encore d'évaluation

- Turcite T51 Engineering DataDocument1 pageTurcite T51 Engineering DataAntonio Rivera VillavicencioPas encore d'évaluation

- Master Thesis Presentation - Part 1Document28 pagesMaster Thesis Presentation - Part 1Khalil YoussefPas encore d'évaluation

- Seismic Vulnerability Assessment of Pandacan Rail Bridge Wall Pier Using Fragility CurvesDocument93 pagesSeismic Vulnerability Assessment of Pandacan Rail Bridge Wall Pier Using Fragility CurvesRaisah GapayaoPas encore d'évaluation

- Lecture 1 - Imaging Modalities SlidesDocument65 pagesLecture 1 - Imaging Modalities Slidesubcradadmin100% (1)

- Junta de Expanción Macoga PDFDocument2 pagesJunta de Expanción Macoga PDFRaul SebastiamPas encore d'évaluation

- Total Differentiation of A Vector in A Rotating Frame of ReferenceDocument4 pagesTotal Differentiation of A Vector in A Rotating Frame of ReferenceMirza Muneeb AhsanPas encore d'évaluation

- Macromol. Rapid Commun. 2006, 27, 1121-1126Document6 pagesMacromol. Rapid Commun. 2006, 27, 1121-1126scarrascogarridoPas encore d'évaluation

- Diffraction Theory by W. CleggDocument8 pagesDiffraction Theory by W. CleggprasetyoPas encore d'évaluation

- Synthesis of Uio-66 MOFDocument5 pagesSynthesis of Uio-66 MOFأبو البراء اليحيىPas encore d'évaluation

- A003 Dripnet PC Heavywall Dripline BrochureDocument2 pagesA003 Dripnet PC Heavywall Dripline BrochureJonathan Ninapaytan SanchezPas encore d'évaluation

- Catalog of Slurry Testing - EquipmentsDocument20 pagesCatalog of Slurry Testing - EquipmentsbvkvijaiPas encore d'évaluation

- CFD Simulation of Multi Phase Twin Screw PumpDocument56 pagesCFD Simulation of Multi Phase Twin Screw PumpSoumendu Banik100% (1)

- Introduction To Ferrite Nano ParticlesDocument42 pagesIntroduction To Ferrite Nano Particleskhan126100% (2)

- Pressed Instruction ManualDocument63 pagesPressed Instruction ManualMauricio Carestia67% (3)

- Solution Manual The Physics of Vibrations and Waves 6th Edition PainDocument10 pagesSolution Manual The Physics of Vibrations and Waves 6th Edition PainS Devika Sajeev100% (3)

- 7 HT6M 34 Atmospheric Lapse RatesDocument8 pages7 HT6M 34 Atmospheric Lapse RatesNewton WestPas encore d'évaluation

- Bostik Rheology Training Nov2nd, 2011 in AsiaDocument13 pagesBostik Rheology Training Nov2nd, 2011 in Asiapopmart21Pas encore d'évaluation

- Quarter 4-Interactive Summative TestDocument11 pagesQuarter 4-Interactive Summative TestJessy James CardinalPas encore d'évaluation

- Student ID: 111 4271Document37 pagesStudent ID: 111 4271Vikash Peerthy0% (2)

- Uniformity of Dosage UnitsDocument4 pagesUniformity of Dosage Unitsandrea.ctba82Pas encore d'évaluation

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDocument8 pagesStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Separation: EngineeringDocument13 pagesSeparation: EngineeringandriPas encore d'évaluation

- 2-D NMR SpectrosDocument20 pages2-D NMR SpectrosHussein Talal KenaanPas encore d'évaluation

- Lsk1820cl Mibi Split LGDocument71 pagesLsk1820cl Mibi Split LGIsidro MendozaPas encore d'évaluation

- CH - 4 - KinematicsDocument81 pagesCH - 4 - KinematicsVISHESH SEHRAWATPas encore d'évaluation