Académique Documents

Professionnel Documents

Culture Documents

Technical Instructions 1: Supplies Tools

Transféré par

servicerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Instructions 1: Supplies Tools

Transféré par

servicerDroits d'auteur :

Formats disponibles

NEWLEXMARKT520TECH

Technical Instructions

Tools

Spring Hook

Philips Screwdriver

Small Flat blade Screwdriver

X-Acto Knife

Toner

Drum

Lint free cloth

99% Isopropyl Alcohol

Cotton Swabs

Wiper Blade

CORPORATE

LOS ANGELES, USA

US 1 800 394.9900

Intl +1 818 837.8100

FAX 1 800 394.9910

Intl +1 818 838.7047

ATLANTA, USA

US 1 877 676.4223

Intl +1 678 919.1189

FAX 1 877 337.7976

Intl +1 770 516.7794

Supplies

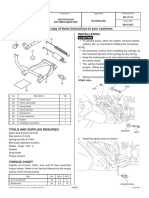

Photo 1

Step 1

Place the cartridge upside down on the work

bench so the drum faces up and the gear end

of the toner hopper is facing towards you.

(See Photo 1)

KANSAS CITY, USA

US 1 913 871.1700

FAX 1 913 888.0626

MIAMI, USA

US 1 800 595.4297

Intl +1 305 594.3396

FAX 1 800 522.8640

Intl +1 305 594.3309

NEW YORK, USA

US 1 800 431.7884

Intl +1 631 588.7300

FAX 1 800 431.8812

Intl +1 631 588.7333

Photo 2

Step 2

Using a small flat blade screwdriver, pry the

developer roller drive gear from the shaft of

the roller. (See Photo 2)

TORONTO, CAN

CAN 1 877 848.0818

Intl +1 905 712.9501

FAX 1 877 772.6773

Intl +1 905 712.9502

BUENOS AIRES, ARG

ARG 0810 444.2656

Intl +011 4583.5900

FAX +011 4584.3100

MELBOURNE, AUS

Photo 3

AUS 1 800 003. 100

Intl +62 03 9561.8102

FAX 1 800 004.302

Intl +62 03 9561-7751

Step 3

Rotate the cartridge so the toner hopper

label faces you. Using needle nose pliers or a

spring hook, remove the tension springs from

each side of the toner hopper.

(See Photo 3 and Photo 4)

SYDNEY, AUS

AUS 1 800 003.100

Intl +62 02 9648.2630

FAX 1800 004.302

Intl +62 02 9548.2635

MONTEVIDEO, URY

URY 02 902.2001

Intl +5982 902.2001

FAX +5982 900.0858

Photo 4

JOHANNESBURG, S.A.

S.A. +27 11 974.6155

FAX +27 11 974.3593

SO PAULO, BRAZIL

Intl +55 11 5524.8000

RAANANA, ISRAEL

ISR 09 760.12.39

Intl +972 9760.12.39

ISR 052.38.555.82

Intl +972 5238.555.82

E-mail: info@futuregraphicsllc.com

REV. 1/25/05

Website:

www.futuregraphicsllc.com

New Lexmark T520 Technical Instructions

Photo 5

Step 4

While holding onto the toner hopper with

your left hand, carefully bend the waste

hopper away from the gear side of the toner

hopper using your right hand. Lift the right

side of the toner hopper up away from the

waste hopper. (See Photo 5)

Notes

Photo 6

Step 5

Separate the toner hopper and waste hopper.

(See Photo 6) Set the toner hopper aside.

Photo 7

Step 6

Using a small flat blade screwdriver remove

the C clip from the drum axle on the drive

gear end of the drum. (See Photo 7)

Photo 8

Step 7

While holding onto the drive gear on the

drum, slide the drum axle out from the small

(contact) gear end of the waste hopper.

(See Photo 8)

Photo 9

Step 8

Lift the drum from the waste hopper.

(See Photo 9) If you plan on reusing the

drum, place the drum in a protected area

and out of the light.

Need trust-worthy, detailed Technical

Instructions for another engine?

Visit: www.futuregraphicsllc.com

New Lexmark T520 Technical Instructions

Photo 10

Step 9

Lift the waste hopper by the handle so the

hopper is up on its end. Using a X-Acto knife

cut the wiper blade sealing foam that

attaches the wiper blade to the waste

hopper. (See Photo 10)

Photo 11

Step 15

Apply padding powder to the

drum. Place the drum into the

waste hopper. (See Photo 15)

Step 10

Once again place the waste hopper flat on

the work bench. Using a Philips screwdriver

remove the two screws that hold the wiper

blade to the waste hopper. (See Photo 11)

Photo 15

Step 11

Photo 12

Using a small flat blade screwdriver pry the

wiper blade away from the waste hopper.

(See Photo 12) Remove the wiper blade.

Step 12

Dump the waste toner from the hopper.

Using dry compressed air or a vacuum,

clean the waste hopper. Visually inspect the

waste hopper recovery blade. If the blade is

wavy, nicked, or torn the blade will have to

be replaced.

Photo 13

Step 13

Step 16

Slide the drum axle through the

drum starting from the small (contact) gear side of the waste hopper. (See Photo 16)

Foto 16

Apply padding powder to the new wiper

blade. Place the new blade onto the waste

hopper and install the two screws that hold

the blade in place. (See Photo 13)

Photo 14

Step 14

Flip the waste hopper over. Place a strip of

sealing tape over the area where the wiper

blade and waste hopper meet.

(See Photo 14)

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

New Lexmark T520 Technical Instructions

Photo 19

Step 20

Carefully remove the doctor blade tension

spring from the hopper.

(See Photo 19)

Step 17

Install the C clip onto the drum

axle. (See Photo 17)

Photo 17

NOTE: Do not let the tension spring slip and

hit the developer roller. This will scratch the

roller and could cause print defects.

Photo 20

Step 21

Remove the developer roller contact from the

side of the toner hopper.

(See Photo 20)

Step 18

Photo 21

Step 22

Set the waste hopper aside in a

protected area out of the light.

Slide the brass developer roller contact

bearing from the end of the hopper.

(See Photo 21)

Step 19

Remove the two square white plastic tabs that secure the doctor

blade tension spring in place.

(See Photo 18) These plastic tabs

are new to the Lexmark cartridges

and are used to prevent the tension spring from moving during

shipping. It is recommended that

they be reinstalled during the

assembly process.

Photo 18

Step 23

While holding the shaft of the developer

roller, lift the roller out from the hopper and

slide the developer roller axle out from the

toner hopper gear end plate.

(See Photo 22)

Photo 22

Photo 23

Step 24

Remove the mylar shims from the ends of the

developer roller (See Photo 23)

Clean the shims using a lint free cloth.

E-mail: info@futuregraphicsllc.com

Website:

www.futuregraphicsllc.com

New Lexmark T520 Technical Instructions

Photo 24

Step 25

Photo 25

Photo 26

To clean the developer roller to take a lint

free cloth, add a small amount of alcohol,

then soak the cloth with distilled water.

Place the axle of the developer roller into a

drill. Clean the roller using the lint free cloth

while the roller is rotating in the drill.

(See Photo 24)

NOTE: DO NOT USE straight alcohol to

clean the developer roller. Straight alcohol

will cause the roller to swell and could

cause the roller to crack.

NOTE: Removal of the doctor blade in the

new style cartridges is easier due to the fact

that no sealing tape or putty is used to hold

the blade in place. A foam strip has been

added behind the doctor blade to prevent

toner leaking. The doctor blade is held in

place by two white plastic tabs found on

each end of the toner hopper.

(See Photo 25)

Step 29

Dump out the toner from the toner

hopper. Using dry compressed

air or a vacuum clean the toner

hopper. NOTE: Make sure you clean

the doctor bar sealing foam well.

Step 30

Clean the developer roller end

sealing gills using a swab and

alcohol. (See Photo 29)

NOTE: The gills on the new style

cartridges are different than those

on the old style cartridges. They

are narrower and there are more of

them. Cleaning the gills will help

prevent toner from leaking out

from the ends of the developer

roller.

Step 26

To remove the doctor blade press down on the

ends of the blade. (See Photo 26)

Photo 27

NOTE: To ensure the best print quality when

remanufacturing the new style cartridges it is

important that the doctor bar is replaced.

When remanufacturing the old style cartridges

it was possible the flip the doctor bar around

giving you a new unworn surface area on the

bar. With the new style cartridges the doctor

bar wears in the center of the bar so flipping

the bar is not an option.

Step 27

Pull the encoder wheel off the end of the

toner hopper. (See Photo 27)

Photo 28

Step 28

Remove the fill plug from the side of the

hopper. (See Photo 28)

NOTE: The fill plugs on the new style

cartridges dont have the filters on them like

the old style cartridges. A vent has been

added to the top of the toner hopper and

covered with tape.

Photo 29

Step 31

Visually inspect the inner toner

hopper sealing blade. If the blade is

damaged it will cause leaking and

must be replaced. The inner toner

hopper sealing blade is now

attached to a plastic support piece

that serves as the outer toner

hopper blade. To replace the blade

pry the plastic support piece out

from the toner hopper. Attach the

new inner sealing blade to the

plastic support piece and attach

the support piece to the toner

hopper.

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

New Lexmark T520 Technical Instructions

Photo 30

Step 32

Slide the new doctor bar under the white

plastic tabs on each side of the toner hopper.

Lift the doctor bar contact and push the bar

up till the bar is positioned against the last

two posts of the plastic tabs. (See Photo 30)

Notes

Photo 31

Step 33

Place the two mylar shims on the ends of the

developer roller. Slide the keyed end of the

developer roller axle into the gear assembly

end plate. (See Photo 31)

Photo 32

Step 34

Install the brass contact bearing onto the

opposite end of the developer roller axle.

Slide the developer roller contact into place.

(See Photo 32)

Photo 33

Step 35

Reinstall the doctor bar tension spring so the

Vstamp on the spring points away from the

toner hopper. Place the white plastic tabs

onto the doctor bar next to the ends of the

spring. (See Photo 33)

Photo 34

Step 36

Fill the toner hopper with the correct amount

of toner. (See Photo 34) Reinstall the toner

hopper fill plug.

E-mail: info@futuregraphicsllc.com

Website:

www.futuregraphicsllc.com

New Lexmark T520 Technical Instructions

Photo 35

Step 37

Place the encoder wheel onto the toner

hopper agitator shaft. (See Photo 35)

Step 41

Install the developer roller drive

gear onto the developer roller axle.

(See Photo 40)

Photo 36

Step 38

Place the waste hopper top down on the

work bench with the waste hopper away

from you.Turn the toner hopper upside down

install the left side of the toner hopper first.

(See Photo 36)

Photo 40

Photo 37

Step 39

While holding onto the toner hopper with your

left hand, carefully bend the waste hopper

away from the gear side of the toner hopper

using your right hand. Push the right side of

the toner hopper toward the waste hopper.

(See Photo 37)

Photo 38

Step 40

Step 42

Test the cartridge.

Notes

Using a spring hook reattach the tension

springs to each end of the toner hopper.

(See Photo 38 and 39)

Photo 39

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

Our friends in Kentucky have been at it again, making changes to

older established products. This time its not printer firmware thats

been changed but rather the construction of the cartridges used in

the Optra S, Optra Se3455, Optra T, T520/522 and T620/622 family of

printers.

The changes were made to the toner hopper section of these cartridges. The most significant change is that the angle of the doctor

bar has been altered. This results in a centered contact with the

developer roller rather than the offset contact found in the older

style cartridges. For the remanufacturer, this means that the trick of

flipping one-time-used doctor bars to get an unworn contact surface, no longer works. Except for this, the changes appear to actually simplify the remanufacturing process rather than hinder it. As for

the reasoning behind the changes, they were most likely made to

eliminate lingering quality issues with the OEM cartridges, reduce

manufacturing costs and perhaps to even make the cartridges easier to remanufacture for Lexmarks own Return Cartridge Program

(formerly Prebate).

Though the changes Lexmark made to the Optra S style cartridges

relate only to the toner hopper, this How To article covers the entire

remanufacturing process.

Future Graphics (FG) is a distributor of compatible replacement parts and products for imagining equipment.

None of FG's products are genuine OEM replacement parts and no affiliation or sponsorship is to be implied between FG and any OEM.

E-mail: info@futuregraphicsllc.com

Website:

www.futuregraphicsllc.com

Vous aimerez peut-être aussi

- Technical Instructions 1: Printers OEM Info ToolsDocument8 pagesTechnical Instructions 1: Printers OEM Info ToolsSimeon ChalgadzhiyanPas encore d'évaluation

- Technical Instructions 1: Supplies ToolsDocument6 pagesTechnical Instructions 1: Supplies ToolsJose MontielPas encore d'évaluation

- HP4600 Toner Dis AssemblyDocument13 pagesHP4600 Toner Dis AssemblydmaslachPas encore d'évaluation

- Technical Instructions 1: Supplies ToolsDocument8 pagesTechnical Instructions 1: Supplies ToolsOana CiulinPas encore d'évaluation

- Technical Instructions 1: Printers ToolsDocument4 pagesTechnical Instructions 1: Printers ToolsservicerPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument6 pagesTechnical Instructions 1: Printers OEM Info ToolsservicerPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument4 pagesTechnical Instructions 1: Printers OEM Info ToolsservicerPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument6 pagesTechnical Instructions 1: Printers OEM Info ToolsservicerPas encore d'évaluation

- Samsung ML 1610 - 4521 4725 Fml-2010 Xerox Phaser 3117 Cambio de Drum y RecargaDocument5 pagesSamsung ML 1610 - 4521 4725 Fml-2010 Xerox Phaser 3117 Cambio de Drum y RecargaComotu IgualPas encore d'évaluation

- Samsung Ml3050 AKA Dell 1815 Toner Cart. RebuildDocument6 pagesSamsung Ml3050 AKA Dell 1815 Toner Cart. RebuildFred BohnPas encore d'évaluation

- Ibm 4019Document2 pagesIbm 4019Jan SoukupPas encore d'évaluation

- Machine Compatibility OEM Info Tools: Technical Instructions 1Document9 pagesMachine Compatibility OEM Info Tools: Technical Instructions 1servicerPas encore d'évaluation

- Machine Compatibility OEM Info Tools: Technical Instructions 1Document8 pagesMachine Compatibility OEM Info Tools: Technical Instructions 1servicerPas encore d'évaluation

- Samsung ML 1710Document6 pagesSamsung ML 1710AJPas encore d'évaluation

- Remanufacturing The Lexmark E120n: What WorksDocument12 pagesRemanufacturing The Lexmark E120n: What WorksservicerPas encore d'évaluation

- Resethl 6050Document15 pagesResethl 6050VuleticJovanPas encore d'évaluation

- Remanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesDocument8 pagesRemanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesservicerPas encore d'évaluation

- Lexmark Optra E310Document4 pagesLexmark Optra E310Jose QuirozPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument7 pagesTechnical Instructions 1: Printers OEM Info Toolsmjamil0995Pas encore d'évaluation

- Refilare C Artus Samsung CLP 500 - 510Document5 pagesRefilare C Artus Samsung CLP 500 - 510Gabriel DaneaPas encore d'évaluation

- Cartridge Information Tools & Supplies: Step 1Document4 pagesCartridge Information Tools & Supplies: Step 1servicerPas encore d'évaluation

- Lexmark T 520 Summit WebDocument10 pagesLexmark T 520 Summit WebservicerPas encore d'évaluation

- A First Look at The HP Laserjet 1160/ 1320: Tools & Supplies NeededDocument11 pagesA First Look at The HP Laserjet 1160/ 1320: Tools & Supplies NeededservicerPas encore d'évaluation

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 pagesRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoPas encore d'évaluation

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 pagesRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoPas encore d'évaluation

- Canon P Type Toner Summit WebDocument9 pagesCanon P Type Toner Summit WebJaime RiosPas encore d'évaluation

- AFICIO Af220-270 RECONSTRUCCIONDocument14 pagesAFICIO Af220-270 RECONSTRUCCIONLuis Huayhua HuaracaPas encore d'évaluation

- Brother HL6050 TN670 Toner Summit WebDocument9 pagesBrother HL6050 TN670 Toner Summit WebMADAYDIOSESAMORPas encore d'évaluation

- 87 15inch Wagner CoaterDocument50 pages87 15inch Wagner CoaterBrian HodgsonPas encore d'évaluation

- Brother - HL4040CN - "No Waste Toner" ErrorDocument11 pagesBrother - HL4040CN - "No Waste Toner" ErrorajaquilantePas encore d'évaluation

- Remanufacturing The Xerox DC-212/214 Toner Cartridge: VerviewDocument8 pagesRemanufacturing The Xerox DC-212/214 Toner Cartridge: VerviewJaime RiosPas encore d'évaluation

- Samsung SC X 4200 TonerDocument6 pagesSamsung SC X 4200 TonerMarcus RamosPas encore d'évaluation

- Recon Service GuideDocument12 pagesRecon Service GuideJuho KauppinenPas encore d'évaluation

- Remanufacturing The HP 4200-4300 (38A-39A)Document22 pagesRemanufacturing The HP 4200-4300 (38A-39A)azariel.rodrigoPas encore d'évaluation

- 4m41 Carbon Removal Reduced SizeDocument18 pages4m41 Carbon Removal Reduced SizeRomanPas encore d'évaluation

- X-Trail Micro-Filter Installation GuideDocument4 pagesX-Trail Micro-Filter Installation GuideEliécer Agrazal P.Pas encore d'évaluation

- Samsung ML-1710 Recarga PDFDocument6 pagesSamsung ML-1710 Recarga PDFarkittoPas encore d'évaluation

- Duke XC SL Race ServiceDocument10 pagesDuke XC SL Race ServicesilverapePas encore d'évaluation

- Octone 12X Single Shot Manual Refill Kit Instructions: ProcedureDocument6 pagesOctone 12X Single Shot Manual Refill Kit Instructions: ProcedureMuhammad ParvezPas encore d'évaluation

- Remanufacturing The Xerox 4525 Toner Cartridge: VerviewDocument9 pagesRemanufacturing The Xerox 4525 Toner Cartridge: VerviewJaime RiosPas encore d'évaluation

- 00016-47660-Toyota-Prius-Fog-Light-Kit-2012-2013-2014 Installation Instructions - PriusChat - Com/shopDocument13 pages00016-47660-Toyota-Prius-Fog-Light-Kit-2012-2013-2014 Installation Instructions - PriusChat - Com/shopDanny1702100% (1)

- Epson ET-M1120 Assembly ManualDocument25 pagesEpson ET-M1120 Assembly ManualnorbertscribdPas encore d'évaluation

- X-Trail T31 Towbar HarnessDocument8 pagesX-Trail T31 Towbar HarnessAnonymous f6goFflg3TPas encore d'évaluation

- S-91 Triple Drill Installation and Maintenance ManualDocument34 pagesS-91 Triple Drill Installation and Maintenance Manualjuliocesar.caPas encore d'évaluation

- Engine, Dismantling D11MDocument23 pagesEngine, Dismantling D11MAMIT SINGHPas encore d'évaluation

- Cartridge Remanufacturing Instructions: Oasis Imaging Products, Inc. Technical Support: (888) 627-6555Document3 pagesCartridge Remanufacturing Instructions: Oasis Imaging Products, Inc. Technical Support: (888) 627-6555Jan SoukupPas encore d'évaluation

- Use Again: Thrust Washer ReusabilityDocument19 pagesUse Again: Thrust Washer ReusabilityGanbat JargalPas encore d'évaluation

- 03-04 Duke SL Air and Uturn Service GuideDocument11 pages03-04 Duke SL Air and Uturn Service Guidepaul7203Pas encore d'évaluation

- XS2 First Stage Service Manual: Revised 3/2002Document14 pagesXS2 First Stage Service Manual: Revised 3/2002ValdrickPas encore d'évaluation

- RK2 150PE ManualDocument37 pagesRK2 150PE ManualMegat AlexanderPas encore d'évaluation

- HP 1160-1320 KitDocument8 pagesHP 1160-1320 KitwagnervielmondPas encore d'évaluation

- Dropbox ReconditioningDocument47 pagesDropbox ReconditioningRezha50% (2)

- Volvo D6D Shop ArmedDocument45 pagesVolvo D6D Shop ArmedBASILIO JARA HUERTA100% (4)

- Unpacking and Installation Procedure For The Main Body and OptionsDocument11 pagesUnpacking and Installation Procedure For The Main Body and OptionsNistor SilviuPas encore d'évaluation

- Project Photos: Section 1 - Removing The Intake ManifoldDocument33 pagesProject Photos: Section 1 - Removing The Intake ManifoldGabriel Usaga CPas encore d'évaluation

- Brother HL5150 DR510 OPC Summit WebDocument9 pagesBrother HL5150 DR510 OPC Summit WebMADAYDIOSESAMORPas encore d'évaluation

- Blurlt BearingDocument12 pagesBlurlt BearingJavi BaalPas encore d'évaluation

- Two Cycle Carburetor and the Back Alley MechanicD'EverandTwo Cycle Carburetor and the Back Alley MechanicÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Lexmark T 520 Summit WebDocument10 pagesLexmark T 520 Summit WebservicerPas encore d'évaluation

- Printer No PriceDocument156 pagesPrinter No PriceservicerPas encore d'évaluation

- Chip Installation Change Notice and Instructions Lexmark Optra TDocument2 pagesChip Installation Change Notice and Instructions Lexmark Optra TservicerPas encore d'évaluation

- Kyocera Drukarki I MFP ToneryDocument2 pagesKyocera Drukarki I MFP ToneryservicerPas encore d'évaluation

- CEE No Price Sharp CatalogDocument102 pagesCEE No Price Sharp CatalogservicerPas encore d'évaluation

- CEE No Price Toshiba CatalogDocument86 pagesCEE No Price Toshiba CatalogservicerPas encore d'évaluation

- Fax No PriceDocument54 pagesFax No PriceservicerPas encore d'évaluation

- Eame Catalog Final eDocument54 pagesEame Catalog Final eservicerPas encore d'évaluation

- CEE No Price Ricoh June 09Document120 pagesCEE No Price Ricoh June 09servicerPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument6 pagesTechnical Instructions 1: Printers OEM Info ToolsservicerPas encore d'évaluation

- CEE No Price Kyocera Mita CatalogDocument74 pagesCEE No Price Kyocera Mita CatalogservicerPas encore d'évaluation

- Accessories 2014Document72 pagesAccessories 2014servicerPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument4 pagesTechnical Instructions 1: Printers OEM Info ToolsservicerPas encore d'évaluation

- Technical Instructions 1: Printers OEM Info ToolsDocument6 pagesTechnical Instructions 1: Printers OEM Info ToolsservicerPas encore d'évaluation

- 10 Practical ThermometersDocument39 pages10 Practical ThermometersEdna OsmanPas encore d'évaluation

- CH 8 Optical FiberDocument31 pagesCH 8 Optical FibersamarthPas encore d'évaluation

- DM HB0002 14 EngDocument28 pagesDM HB0002 14 EngleptirPas encore d'évaluation

- Surelink 1x8 Micro PLC SplitterDocument4 pagesSurelink 1x8 Micro PLC SplitterJsonPas encore d'évaluation

- b12 b16 Citizen PCM Catalogue 11.2023Document7 pagesb12 b16 Citizen PCM Catalogue 11.2023Diego Martinez CPas encore d'évaluation

- Microcell Technology™ Heated Inspiratory Adult Breathing Circuit and Optiflow™+ Nasal CannulaDocument5 pagesMicrocell Technology™ Heated Inspiratory Adult Breathing Circuit and Optiflow™+ Nasal CannulaAbner MorenoPas encore d'évaluation

- BVNkatalog PDFDocument257 pagesBVNkatalog PDFJamal TahaPas encore d'évaluation

- Pan FeederDocument1 pagePan FeederAngelloPas encore d'évaluation

- 6015 PM Kit - PM 5000 HrsDocument1 page6015 PM Kit - PM 5000 HrsHendra MonoPas encore d'évaluation

- USB ConnectorsDocument5 pagesUSB ConnectorsSaaaaaPas encore d'évaluation

- Current Transformers (CTS)Document34 pagesCurrent Transformers (CTS)Don ThanadonPas encore d'évaluation

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarPas encore d'évaluation

- Drilled Head Bolts AN73 Thru AN81: Superceded by MS20073 (Fine Thread) or MS20074 (Course Thread)Document1 pageDrilled Head Bolts AN73 Thru AN81: Superceded by MS20073 (Fine Thread) or MS20074 (Course Thread)Bogdan RusuPas encore d'évaluation

- Error 02 Warming Up: Density Adjusting PCADocument9 pagesError 02 Warming Up: Density Adjusting PCAlansystem01Pas encore d'évaluation

- VALVE LIST MetpasDocument6 pagesVALVE LIST Metpasmoh_750571194Pas encore d'évaluation

- Troubleshooting Eloma NewDocument1 pageTroubleshooting Eloma Newgene.hardyPas encore d'évaluation

- Lecture 1 Study and Design of Primary and Secondary DistributionDocument74 pagesLecture 1 Study and Design of Primary and Secondary DistributionJade Albert G. FalladoPas encore d'évaluation

- ManitouDocument306 pagesManitouJarosław100% (2)

- 089.11 v2 VH Hev Bn21 SupplyDocument2 pages089.11 v2 VH Hev Bn21 SupplyHung LePas encore d'évaluation

- Miniature Optical Shaft Encoder: Page 1 of 5Document5 pagesMiniature Optical Shaft Encoder: Page 1 of 5hysamPas encore d'évaluation

- (TM) Jeep Manual de Taller Jeep Grand Cherokee 2011Document6 318 pages(TM) Jeep Manual de Taller Jeep Grand Cherokee 2011Pedro Arrieta100% (1)

- Black N Decker Cordless DrillDocument12 pagesBlack N Decker Cordless DrilldusmisPas encore d'évaluation

- Instrucción de Manual de Seccionalizador Jin KwangDocument26 pagesInstrucción de Manual de Seccionalizador Jin KwangOswaldo Ccoñas SandovalPas encore d'évaluation

- Installation Instructions: Honda Dealer: Please Give A Copy of These Instructions To Your Customer. InstallationDocument3 pagesInstallation Instructions: Honda Dealer: Please Give A Copy of These Instructions To Your Customer. InstallationR BPas encore d'évaluation

- Tests and Checks For Acceptance of Eot Cranes: IPSS: 2-02-008-18 (First Revision)Document32 pagesTests and Checks For Acceptance of Eot Cranes: IPSS: 2-02-008-18 (First Revision)Mohammad Safdar SadatPas encore d'évaluation

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchPas encore d'évaluation

- PGCIL - Technical Specifications SF6 Gas Handling PlantDocument2 pagesPGCIL - Technical Specifications SF6 Gas Handling Plantarindam hitechPas encore d'évaluation

- Features:: Advanced Protection TechnologiesDocument2 pagesFeatures:: Advanced Protection Technologiesdnps2011Pas encore d'évaluation

- Scroll Compressors For Refrigeration in Parallel Technical Information en GB 4273624Document8 pagesScroll Compressors For Refrigeration in Parallel Technical Information en GB 4273624Zaid SamhaPas encore d'évaluation

- 9852 2316 01e Operators Instructions Simba M7 C MK 7bDocument185 pages9852 2316 01e Operators Instructions Simba M7 C MK 7bbelaye bekelePas encore d'évaluation