Académique Documents

Professionnel Documents

Culture Documents

Tds Basf Magnafloc Lt20 Lt25 Lt27 Lt27ag Lt30 Lt340

Transféré par

Buenaventura Jose Huamani TalaveranoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tds Basf Magnafloc Lt20 Lt25 Lt27 Lt27ag Lt30 Lt340

Transféré par

Buenaventura Jose Huamani TalaveranoDroits d'auteur :

Formats disponibles

Technical Information

TI/EVW 0058 e/uk

December 2010

Water Solutions

Page 1 of 3

= registered Trademark of

BASF Performance Products plc

MAGNAFLOC LT20,

LT25, LT27, LT27AG,

LT30 and LT340

Potable water grade polyelectrolytes

Description

High molecular weight polyacrylamide based flocculants, which exhibit

varying degrees of ionic charge. They are supplied as free flowing white

powders.

Approved by a range of regulatory bodies (see table overleaf).

Chemical structure

Nonionic Magnafloc LT 20 polyacrylamide

Anionic Magnafloc LT25, LT27, LT27AG, LT30 and LT340

co-polymers of acrylamide and sodium acrylate

Principal use

Polyelectrolytes used as a coagulant aid in the clarification and filtration of

potable water, and for the conditioning of potable water sludges prior to

thickening and dewatering.

Processing and clarification of sugar beet washings and raw cane and

beet juice. Enables production of high brilliance juices and high quality

sugar.

Product

General

Flocculation

Treatment of

Potable Water

Sugar

Processing

Magnafloc LT20

Magnafloc LT25

Magnafloc LT27

Magnafloc LT27AG

9*

Magnafloc LT30

Magnafloc LT340

9*

* Not UK

(Application subject to appropriate registration)

TI/EVW 0058 e December 2010

2 of 3

Benefits

Reduced inorganic coagulant dosage

Increased clarifier throughput

Reduced sludge production

Reduced overall treatment costs

Increased sugar quality and yield

Regulatory Approvals

MAGNAFLOC LT20, LT25, LT27, LT27AG, LT30 and LT340

Product

DWI

NSF60

EN1407

FDA

Magnafloc LT20

Magnafloc LT25

Magnafloc LT27

Magnafloc LT27AG

Magnafloc LT30

Magnafloc LT340

NSF

EN1407 FDA

DWI

National Sanitation Foundation

European Standard Treatment of water intended for

human consumption

Food and Drug Administration (please contact a sales

representative for more information)

Drinking Water Inspectorate (UK)

Typical properties

Product

Bulk Density

Free

Acrylamide

Less than 0.020%

Molecular

Weight

Medium

Ionicity

Approx. 0.7g/cm3

pH of 1%

Solution

Approx. 5.4

MAGNAFLOC LT20

MAGNAFLOC LT25

Approx. 0.7g/cm3

Approx. 7.3

Less than 0.020%

Very High

Med Anionic

MAGNAFLOC LT27

Approx. 0.7g/cm3

Approx. 7.3

Less than 0.020%

Very High

High Anionic

MAGNAFLOC LT27AG

Approx. 0.7g/cm3

Approx. 7.3

Less than 0.050%

Ultra High

High Anionic

MAGNAFLOC LT30

Approx. 0.7g/cm3

Approx. 7.3

Less than 0.020%

Very High

Very High

Anionic

MAGNAFLOC LT340

Approx. 0.7g/cm3

Approx. 7.5

Less than 0.050%

Very High

High Anionic

Nonionic

Treatment dosing

The UK average and maximum doses for water treatment are set, in

accordance with the approval granted by the Secretary for State for the

Environment under Regulation 31(4)(a), at 0.25 mg/l and 0.5 mg/l.

The NSF maximum usage level is 1 mg/l.

For sugar applications, use level not to exceed 5ppm by weight of juice

or 10ppm by weight of liquor.

Storage

Under normal storage conditions within the range 5 25 C, the product

will be stable for at least 24 months. Storage outside the above specified temperature range for long periods may adversely affect the

product over a long period and should thus be avoided, if possible.

It is recommended that stock solutions at 0.25 0.5 % are prepared

regularly and for maximum effect such solutions should be used within

5 days. Beyond this period some loss in efficiency of the product may

occur.

BASF Performance Products plc Water Solutions PO Box 38, Bradford, BD12 0JZ, UK www.watersolutions.basf.com

TI/EVW 0058 e December 2010

3 of 3

MAGNAFLOC LT20, LT25, LT27, LT27AG, LT30 and LT340

Shipping & Handling

Corrosion towards most standard materials of construction is very low.

Stainless steel, fibreglass, polyethylene, polypropylene and rubberised

surfaces are recommended. In some cases aluminium surfaces can be

adversely affected.

Packaging details are available on request from your local sales representative.

Very slippery when wet. Please refer to the MSDS for methods of

removing the polymer.

Technical Service

Account managers and field service technicians are available to give

advice and assistance in the running of laboratory tests and machine

trials to select the correct product and determine the best application

conditions.

Health & Safety

Detailed information on the product described in this leaflet can be

found in our relevant health and safety information (Material Safety Data

Sheet).

Contact

For further information contact your regional office, details of which can

be obtained on our website; http://www.watersolutions.basf.com

Note

The data contained in this publication are based on our current knowledge and experience. In view of the many factors that may affect

processing and application of our product, these data do not relieve

processors from carrying out their own investigations and tests; neither

do these data imply any guarantee of certain properties, nor the suitability of the product for a specific purpose. Any descriptions, drawings,

photographs, data, proportions, weights etc. given herein may change

without prior information and do not constitute the agreed contractual

quality of the product. It is the responsibility of the recipient of our products to ensure that any proprietary rights and existing laws and

legislation are observed.

December 2010

BASF Performance Products plc Water Solutions PO Box 38, Bradford, BD12 0JZ, UK www.watersolutions.basf.com

Vous aimerez peut-être aussi

- Chemicals Zetag DATA Powder Zetag 7650 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 7650 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Magnafloc 336 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 336 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 8165 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8165 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 8190 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8190 - 0410PromagEnviro.comPas encore d'évaluation

- Zetag 7875FS25: Technical Information Water SolutionsDocument2 pagesZetag 7875FS25: Technical Information Water SolutionsPromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Magnafloc LT 22 S - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc LT 22 S - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 8115 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8115 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Beads Zetag 7565 - 0410Document2 pagesChemicals Zetag DATA Beads Zetag 7565 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Beads Magnafloc 156 - 0410Document2 pagesChemicals Zetag DATA Beads Magnafloc 156 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8849 FS - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8849 FS - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8846 FS - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8846 FS - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8816 - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8816 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 8125 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8125 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 4105 - 1110Document2 pagesChemicals Zetag DATA Powder Zetag 4105 - 1110PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag MSDS Powder Zetag 4139 - 1010Document6 pagesChemicals Zetag MSDS Powder Zetag 4139 - 1010PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 4100 - 1110Document2 pagesChemicals Zetag DATA Powder Zetag 4100 - 1110PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 4125 - 1110Document2 pagesChemicals Zetag DATA Powder Zetag 4125 - 1110PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag MSDS Powder Zetag 4105 - 0810Document6 pagesChemicals Zetag MSDS Powder Zetag 4105 - 0810PromagEnviro.com0% (1)

- Chemicals Zetag DATA Beads Zetag 7553 - 0410Document2 pagesChemicals Zetag DATA Beads Zetag 7553 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Beads Zetag 7563 - 0410Document2 pagesChemicals Zetag DATA Beads Zetag 7563 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Zetag 8185 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8185 - 0410PromagEnviro.comPas encore d'évaluation

- Fine Chemicals For Water Treatment: DescriptionDocument1 pageFine Chemicals For Water Treatment: DescriptionsajawalPas encore d'évaluation

- Alpacon Descalant: Cleaning Agent For Plate Heat Exchangers and Centrifugal SeparatorsDocument2 pagesAlpacon Descalant: Cleaning Agent For Plate Heat Exchangers and Centrifugal SeparatorsSubramanian gokulPas encore d'évaluation

- SDS MDC150 PDFDocument7 pagesSDS MDC150 PDFdalton2003Pas encore d'évaluation

- Chemicals Zetag DATA Powder Magnafloc 919 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 919 - 0410PromagEnviro.comPas encore d'évaluation

- Scale Inhibitor - Gyptron IT-265 - MSDS - ENGDocument5 pagesScale Inhibitor - Gyptron IT-265 - MSDS - ENGTHANGVUPas encore d'évaluation

- Material Safety Data Sheet: Hydrex 2911Document4 pagesMaterial Safety Data Sheet: Hydrex 2911JHUPEL ABARIALPas encore d'évaluation

- Betzdearborn Ae1700Document7 pagesBetzdearborn Ae1700dalton2003Pas encore d'évaluation

- NALSPERSE 73550 DetergentDocument3 pagesNALSPERSE 73550 DetergentWaseem Syed100% (1)

- Material Safety Data Sheet: Hydrex 2610Document4 pagesMaterial Safety Data Sheet: Hydrex 2610JHUPEL ABARIALPas encore d'évaluation

- Chemicals Zetag DATA Organic Coagulants Magnafloc LT 7989 - 0410Document2 pagesChemicals Zetag DATA Organic Coagulants Magnafloc LT 7989 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Organic Coagulants Magnafloc LT 7985 - 0410Document2 pagesChemicals Zetag DATA Organic Coagulants Magnafloc LT 7985 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Organic Coagulants Magnafloc LT 7995 - 0410Document2 pagesChemicals Zetag DATA Organic Coagulants Magnafloc LT 7995 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Organic Coagulants Magnafloc LT 7991 - 0410Document2 pagesChemicals Zetag DATA Organic Coagulants Magnafloc LT 7991 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Organic Coagulants Agefloc WT 40-P SPS - 0410Document2 pagesChemicals Zetag DATA Organic Coagulants Agefloc WT 40-P SPS - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Magnafloc 370 - 1110Document2 pagesChemicals Zetag DATA Powder Magnafloc 370 - 1110PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Zetag 7878 FS 25 - 1110Document2 pagesChemicals Zetag DATA LDP Zetag 7878 FS 25 - 1110PromagEnviro.comPas encore d'évaluation

- Magnafloc LT 27 (Tmb-En)Document2 pagesMagnafloc LT 27 (Tmb-En)Deepak SharmaPas encore d'évaluation

- Chemicals Zetag DATA Beads Magnafloc 368 - 0410Document2 pagesChemicals Zetag DATA Beads Magnafloc 368 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Zetag 7879 - 0410Document2 pagesChemicals Zetag DATA LDP Zetag 7879 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Zetag 7878 - 0410Document2 pagesChemicals Zetag DATA LDP Zetag 7878 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8858 FSB - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8858 FSB - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Beads Zetag 8590 - 1110Document2 pagesChemicals Zetag DATA Beads Zetag 8590 - 1110PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Zetag 7875 - 0410Document2 pagesChemicals Zetag DATA LDP Zetag 7875 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Zetag 7873 - 0410Document2 pagesChemicals Zetag DATA LDP Zetag 7873 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Powder Magnafloc LT 20 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc LT 20 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Zetag 7867 - 0410Document2 pagesChemicals Zetag DATA LDP Zetag 7867 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8812 - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8812 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8814 - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8814 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8857 FSB - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8857 FSB - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Magnasol 4000 G - 0410Document2 pagesChemicals Zetag DATA Magnasol 4000 G - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Magnasol 2765 G - 0410Document2 pagesChemicals Zetag DATA Magnasol 2765 G - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Magnasol 4610 G - 0410Document2 pagesChemicals Zetag DATA Magnasol 4610 G - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Zetag 8847 FSB - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Zetag 8847 FSB - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions - 1009Document2 pagesChemicals Zetag DATA Inverse Emulsions - 1009PromagEnviro.com100% (1)

- Chemicals Zetag DATA Magnasol 2605 G - 0410Document2 pagesChemicals Zetag DATA Magnasol 2605 G - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Magnasol 4620 G - 0410Document2 pagesChemicals Zetag DATA Magnasol 4620 G - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions Magnafloc E 38 - 0410Document2 pagesChemicals Zetag DATA Inverse Emulsions Magnafloc E 38 - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Magnafloc 120L - 0410Document2 pagesChemicals Zetag DATA LDP Magnafloc 120L - 0410PromagEnviro.comPas encore d'évaluation

- Chemicals Zetag DATA LDP Magnafloc 110L - 0410Document2 pagesChemicals Zetag DATA LDP Magnafloc 110L - 0410PromagEnviro.comPas encore d'évaluation

- Introduction To Trickling Filters and RBC's Study GuideDocument23 pagesIntroduction To Trickling Filters and RBC's Study GuideBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Introduction To Phosphorus Removal Study GuideDocument40 pagesIntroduction To Phosphorus Removal Study GuideBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Introduction To Tertiary Filtration Study GuideDocument18 pagesIntroduction To Tertiary Filtration Study GuideBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Introduction To Mechanical Sludge Handling Study GuideDocument21 pagesIntroduction To Mechanical Sludge Handling Study GuideBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Introduction To Preliminary & Primary Treatment Study GuideDocument23 pagesIntroduction To Preliminary & Primary Treatment Study GuideBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Introduction To Disinfection Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationDocument27 pagesIntroduction To Disinfection Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Advanced Preliminary and Primary Treatment Study GuideDocument22 pagesAdvanced Preliminary and Primary Treatment Study GuideBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Zetag 8165: Technical Information Water SolutionsDocument2 pagesZetag 8165: Technical Information Water SolutionsBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Msds Rheomax DR 1030 enDocument9 pagesMsds Rheomax DR 1030 enBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- TSB 11 Handling and Dissolving of KEMIRA FERIX-3Document2 pagesTSB 11 Handling and Dissolving of KEMIRA FERIX-3Buenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Millsperse 956 - 2009-01-29 - en - 203403Document7 pagesMillsperse 956 - 2009-01-29 - en - 203403Buenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Nanocolor ReagentsDocument6 pagesNanocolor ReagentsBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Zetag 8165: Technical Information Water SolutionsDocument2 pagesZetag 8165: Technical Information Water SolutionsBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Belclene 440 MSDSDocument5 pagesBelclene 440 MSDSBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Belclene 400 Technical Data Sheet IWT 8.5x11Document2 pagesBelclene 400 Technical Data Sheet IWT 8.5x11Buenaventura Jose Huamani TalaveranoPas encore d'évaluation

- HT Ferroquest FQ7103Document1 pageHT Ferroquest FQ7103Buenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Brochure Osmosis InversaDocument4 pagesBrochure Osmosis InversaBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- Metodo Determinacion de Cadmio Hach DR 3900Document6 pagesMetodo Determinacion de Cadmio Hach DR 3900Buenaventura Jose Huamani TalaveranoPas encore d'évaluation

- NSF or FdaDocument2 pagesNSF or FdaBuenaventura Jose Huamani TalaveranoPas encore d'évaluation

- General Chemistry 2: 2 Semester - Module 2 Types of Solids, Phase Changes and DiagramsDocument20 pagesGeneral Chemistry 2: 2 Semester - Module 2 Types of Solids, Phase Changes and DiagramsKrisha Mae Oao Calumpit100% (2)

- Science10 Q4 M3 W5 6 1Document10 pagesScience10 Q4 M3 W5 6 1Reyydell DelimaPas encore d'évaluation

- Shell Gadus s1 Og 200 PDFDocument1 pageShell Gadus s1 Og 200 PDFMiskaDarainiPas encore d'évaluation

- Brosur Evo FranklinDocument2 pagesBrosur Evo FranklinFargan ThanPas encore d'évaluation

- Year 9 Study Guide ChemistryDocument15 pagesYear 9 Study Guide Chemistryreem halawiPas encore d'évaluation

- ASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsDocument10 pagesASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsAarón Escorza MistránPas encore d'évaluation

- SX2112Document5 pagesSX2112AmenPas encore d'évaluation

- Energy ChangesDocument13 pagesEnergy ChangesLok Jun HaoPas encore d'évaluation

- Design For External Pressure-13022018Document14 pagesDesign For External Pressure-13022018Toni100% (1)

- Cls Jeead-18-19 Xii Che Target-7 Set-2 Chapter-12Document47 pagesCls Jeead-18-19 Xii Che Target-7 Set-2 Chapter-12DxPas encore d'évaluation

- Entropy PDFDocument19 pagesEntropy PDFcarlogarroPas encore d'évaluation

- Magnetic Particle Test (MT) : Level IiDocument18 pagesMagnetic Particle Test (MT) : Level IiAhmed El Morsy100% (1)

- CSSD Central Sterile Supply DepartmentDocument35 pagesCSSD Central Sterile Supply DepartmentAnsari Shariq0% (1)

- RioBooster SDSDocument10 pagesRioBooster SDSpepePas encore d'évaluation

- Is 3025 - 31 - 1 - 2022Document16 pagesIs 3025 - 31 - 1 - 2022Ruby MalhotraPas encore d'évaluation

- Testing Methods of Chemical Resistance For Plastic Parts: Nissan Engineering StandardDocument13 pagesTesting Methods of Chemical Resistance For Plastic Parts: Nissan Engineering StandardDiego Camargo100% (1)

- Pharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)Document13 pagesPharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)wangzahPas encore d'évaluation

- Production Characterization and Treatment of Textile Effluents A Critical Review 2157 7048.1000182 PDFDocument18 pagesProduction Characterization and Treatment of Textile Effluents A Critical Review 2157 7048.1000182 PDFKhoaPas encore d'évaluation

- AQA GCSE Chem Combined End of Topic C1Document9 pagesAQA GCSE Chem Combined End of Topic C1joePas encore d'évaluation

- Polymer Repair PDFDocument3 pagesPolymer Repair PDFamirouche15Pas encore d'évaluation

- PH - Wikipedia, The Free EncyclopediaDocument11 pagesPH - Wikipedia, The Free EncyclopediaShikhar MahajanPas encore d'évaluation

- A Brief Review On Optical Properties of Polymer Composites - Insights Into Light-Matter Interaction From Classical To Quantum Transport Point of ViewDocument28 pagesA Brief Review On Optical Properties of Polymer Composites - Insights Into Light-Matter Interaction From Classical To Quantum Transport Point of Viewomkar BembalgePas encore d'évaluation

- Design of Formwork For Column R0 - 3.7 MTRDocument5 pagesDesign of Formwork For Column R0 - 3.7 MTRrahul1433Pas encore d'évaluation

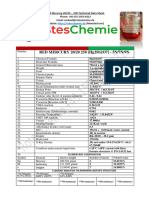

- Red Mercury 2020 Technical Data SheetDocument2 pagesRed Mercury 2020 Technical Data SheetThe UniversPas encore d'évaluation

- Nutrition in Plants PDFDocument2 pagesNutrition in Plants PDFgamparohit75% (4)

- Ce 8381 - Question PaperDocument2 pagesCe 8381 - Question PaperculvertsPas encore d'évaluation

- Porphyry DepositsDocument43 pagesPorphyry DepositsVictor Valdivia100% (2)

- Compounding PracticeDocument19 pagesCompounding PracticeBrix GallardoPas encore d'évaluation

- EmileorConcerningEducation 10106815Document165 pagesEmileorConcerningEducation 10106815Túlio Coelho SampaioPas encore d'évaluation

- AssociationDocument2 pagesAssociationRichmond EresmasPas encore d'évaluation