Académique Documents

Professionnel Documents

Culture Documents

AWS Specifications For Filler Material

Transféré par

Exsan OthmanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AWS Specifications For Filler Material

Transféré par

Exsan OthmanDroits d'auteur :

Formats disponibles

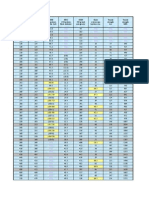

AWS

Description

A5.6

COPPER & COPPER ALLOY ARC WELDING ELECTRODES

A5.7

COPPER AND COPPER ALLOY BARE WELDING RODS AND

ELECTRODES

A5.15

SPECIFICATION FOR WELDING ELECTRODES AND RODS FOR

CAST IRON

A5.19

SPECIFICATION FOR MAGNESIUM ALLOY WELDING ELECTRODES

AND RODS

A5.2

SPECIFICATION FOR CARBON AND LOW ALLOY STEEL RODS FOR

OXYFUEL GAS WELDING

A5.22

STAINLESS STEEL ELECTRODES FOR FLUX CORED ARC

WELDING AND STAINLESS STEEL FLUX CORED RODS FOR GAS

TUNGSTEN ARC WELDING

A5.17/A5.17M

CARBON STEEL ELECTRODES AND FLUXES FOR SUBMERGED

ARC WELDING

A5.23/A5.23M

LOW ALLOY STEEL ELECTRODES AND FLUXES FOR SUMERGED

ARC WELDING

A5.25/A5.25M

SPECIFICATION FOR CARBON AND LOW ALLOY STEEL

ELECTRODES AND FLUXESFOR ELECTROSLAG WELDING

A5.26/A5.26M

SPECIFICATION FOR CARBON AND LOW ALLOY STEEL

ELECTRODES FOR ELECTROGAS WELDING

A5.12/A5.12M

SPECIFICATION FOR TUNGSTEN AND TUNGSTEN ALLOY

ELECTRODES FOR ARC WELDING AND CUTTING

A5.10/A5.10M

SPECIFICATION FOR BARE ALUMINUM AND ALUMINUM-ALLOY

WELDING ELECTRODES AND RODS

A5.13

SPECIFICATION FOR SURFACING ELECTRODES FOR SHIELDED

METAL ARC WELDING

A5.21

SPECIFICATION FOR BARE ELECTRODES AND RODS FOR

SURFACING

A5.31

SPECIFICATION FOR FLUXES FOR BRAZING AND BRAZE

WELDING

A5.1/A5.1M

SPECIFICATION FOR CARBON STEEL ELECTRODES FOR

SHIELDED METAL ARC WELDING

A5.16/A5.16M

SPECIFICATION FOR TITANIUM AND TITANIUM-ALLOY WELDING

ELECTRODES AND RODS

A5.8/A5.8M

SPECIFICATION FOR FILLER METALS FOR BRAZING AND BRAZE

WELDING

A5.11/A5.11M

SPECIFICATION FOR NICKEL AND NICKEL ALLOY WELDING

ELECTRODES FOR SHIELDED METAL ARC WELDING

A5.14/A5.14M

SPECIFICATION FOR NICKEL AND NICKEL ALLOY BARE WELDING

ELECTRODES AND RODS

A5.18/A5.18M

SPECIFICATION FOR CARBON STEEL ELECTRODES AND RODS

FOR GAS SHEILDED ARC WELDING

A5.20

CARBON STEEL ELECTRODES FOR FLUX CORED ARC WELDING

A5.24 / A5.24M

ZIRCONIUM AND ZIRCONIUM ALLOY WELDING ELECTRODES AND

RODS

A5.28

SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES FOR GAS

SHEILDED ARC WELDING

A5.29

LOW ALLOY STEEL ELECTRODES FOR FLUX CORED ARC

WELDING

A5.4/A5.4M

SPECIFICATION FOR STAINLESS STEEL ELECTRODES FOR

SHIELDED METAL ARC WELDING

A5.5/A5.5M

SPECIFICATION FOR LOW-ALLOY STEEL ELECTRODES FOR

SHIELDED METAL ARC WELDING

A5.9/A5.9M

SPECIFICATION FOR BARE STAINLESS STEEL WELDING

ELECTRODES AND RODS

Remarks

This specification provides requirements for the classification of covered copper and copper alloy electrodes for shielded metal arc welding. It includes compo

Essential to todays purchaser. Learn to state clearly, concisely, and completely the required filler metal specification, including the heat, lot, testing, and certifi

The chemical composition requirements for electrodes and rods for welding cast iron are specified. Copper-base rods used for braze welding of cast iron are

This specification prescribes requirements for the classification of bare magnesium all welding electrodes and rods for use with the gas metal arc, gas tungste

This specification prescribes the requirements for classification of carbon and low alloy steel rods for oxyfuel gas welding. The classification requirements inc

Classification and other requirements are specified for more than 40 grades of flux cored stainless steel electrodes and rods. New classifications include dup

This specification provides requirements for the classification of solid and composite carbon steel electrodes and fluxes for submerged arc welding. Electrode

This specification provides requirements for the classification of solid and composite low-alloy steel electrodes and fluxes for submerged arc welding. Electro

Classification requirements are specified for fluxes and solid and composite metal cored electrodes for electroslag welding. The requirements for electrodes i

Classification requirements are specified for solid and composite flux cored and metal cored) electrodes for electrogas welding. The requirements include che

This specification prescribes the requirements for the classification of bare tungsten and tungsten-alloy electrodes for gas tungsten arc welding and cutting an

This specification prescribes requirements for the classification of bare, wrought and cast aluminum-alloy electrodes, and rods for use with the gas metal arc,

This specification prescribes the requirements for classification of surfacing electrodes for shielded metal arc welding. Classification is based upon the chemi

This specification prescribes the requirements for classification of bare electrodes and rods for surfacing. Solid surfacing electrodes and rods, are classified o

Essential to todays purchaser. Learn to state clearly, concisely, and completely the required filler metal specification, including the heat, lot, testing, and certifi

This specification establishes the requirements for classification of carbon steel electrodes for shielded metal arc welding. The requirements include mechani

The compositions specified for each classification represent the state of the art. The specification contains testing procedures, standard sizes and forms, and

This specification prescribes the requirements for the classification of filler metals for brazing and braze welding. The chemical composition, physical form, an

This specification prescribes the composition, dimensions, soundness, and properties of weld metal from more than 30 classifications of nickel and nickel-allo

The chemical compositions of nearly fifty nickel and nickel-alloy welding electrodes and rods are specified, including thirteen compositions not previously clas

This specification prescribes the requirements for classification of solid carbon steel electrodes and rods, composite stranded carbon steel electrodes, and co

This specification prescribes the requirements for classification of carbon steel electrodes for flux cored arc welding. The requirements include chemical comp

This specification prescribes the requirements for classification of zirconium and zirconium alloy electrodes and rods for GTA, GMA, and PA welding. AWS A5

This specification prescribes the requirements for classification of solid low-alloy steel electrodes and rods, composite stranded low-alloy steel electrodes, an

This specification prescribes the requirements for classification of low-alloy steel electrodes for flux cored arc welding. The requirements include chemical com

Composition and other requirements are specified for more than forty classifications of covered stainless steel welding electrodes. These classifications inclu

This specification prescribes the requirements for classification of low-alloy steel covered electrodes used for shielded metal arc welding. The requirements in

This specification prescribes the requirements for classification of solid and composite stainless steel electrodes (both as wire and strip) for gas metal arc wel

al arc welding. It includes compositions in which the copper content exceeds that of any other element.

the heat, lot, testing, and certification requirements. ANSI Approved.

r braze welding of cast iron are not included. Major topics include general requirements, testing, packaging, and application guidelines.

h the gas metal arc, gas tungsten arc, oxyfuel gas, and plasma arc welding processes. Classification is based upon chemical composition of the welding wire. Standard sizes

classification requirements include the mechanical properties of the weld metal. Additional requirements are included for chemical composition of the rod and for manufactur

New classifications include duplex alloys not previously classified and flux cored rods for gas tungsten arc welding. Designations indicate the chemical composition of the wel

bmerged arc welding. Electrode classification is based on chemical composition of the electrode for solid electrodes, and chemical composition of the weld metal for composi

submerged arc welding. Electrode classification is based on chemical composition of the electrode for solid electrodes, and chemical composition of the weld metal for compo

he requirements for electrodes include chemical composition of the electrode for solid electrodes and of weld metal for metal cored electrodes. Requirements for fluxes includ

g. The requirements include chemical composition of the electrode for solid electrodes and of weld metal for composite (cored) electrodes, in addition to the mechanical prope

gsten arc welding and cutting and plasma arc welding and cutting. Classification is based upon the chemical composition of the electrode. Standard sizes, finish, lengths, qua

s for use with the gas metal arc, gas tungsten arc, oxyfuel gas, and plasma arc welding processes. This specification makes use of both U.S. Customary Units and the Interna

cation is based upon the chemical composition of the deposited weld metal except for tungsten carbide electrodes where classification is based on the mesh range, quantity,

rodes and rods, are classified on the basis of the composition of the material as manufactured. Metal cored and flux cored composite (tubular) surfacing electrodes and rods,

the heat, lot, testing, and certification requirements. ANSI Approved.

e requirements include mechanical properties of weld metal, weld metal soundness, and usability of electrode. Requirements for composition of the weld metal, moisture conte

standard sizes and forms, and identification and marking practices. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Sin

l composition, physical form, and packaging of more than 75 brazing filler metals are specified. The filler metal groups described include aluminum, cobalt, copper, gold, mag

ications of nickel and nickel-alloy covered electrodes. Major topics include general requirements, testing, manufacturing, identification, and packaging. A guide to using the sp

ompositions not previously classified. Major topics include general requirements, testing, packaging and application guidelines. This specification makes use of both U.S. Cus

carbon steel electrodes, and composite metal cored carbon steel electrodes for gas shielded arc welding. Classification is based on chemical composition of the electrode for

irements include chemical composition and mechanical properties of the weld metal and certain usability characteristics. The AWS A5.20/A5.20M specification also includes o

GMA, and PA welding. AWS A5.24/A5.24M:2005 is a revision of the zirconium welding electrode document last revised in 1990. The compositions specified for each classific

d low-alloy steel electrodes, and composite metal cored low-alloy steel electrodes for gas shielded arc welding. Classification is based on chemical composition of the electro

quirements include chemical composition and mechanical properties of the weld metal and certain usability characteristics. Optional, supplemental designators are also includ

des. These classifications include the duplex stainless steels which previously were not classified. A new designation of electrode coverings, EXXX-17, has been added. Th

rc welding. The requirements include chemical composition and mechanical properties of weld metal, weld metal soundness, usability tests of electrodes, and moisture tests

and strip) for gas metal arc welding, submerged arc welding, and other fusion welding processes. It also includes wire and rods for use in gas tungsten arc welding. Classifica

he welding wire. Standard sizes, finish, winding requirements, package forms and weights, product identification, and chemical composition limits are specified.

n of the rod and for manufacture, sizes, lengths, and packaging. A guide is appended to the specification as a source of information concerning the classification system emp

chemical composition of the weld metal, the position of welding (newly introduced in this revision of the standard), and the external shielding medium required (for those class

n of the weld metal for composite electrodes. Flux classification is based on the mechanical properties of weld metal produced with the flux and an electrode classified herein

ion of the weld metal for composite electrodes. Flux classification is based on the mechanical properties and deposit composition of weld metal produced with the flux and an

Requirements for fluxes include the mechanical properties and soundness of weld metal taken from a groove weld made with a particular electrode using a prescribed weldi

addition to the mechanical properties and soundness of weld metal taken from a groove weld made with these electrodes using the prescribed welding procedure. Standard e

ndard sizes, finish, lengths, quantities, product identification, color coding and chemical composition limits are specified. This specification makes use of both U.S. Customary

Customary Units and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

d on the mesh range, quantity, and composition of the tungsten carbide granules. A guide is appended to the specification as a source of information as to the characteristics

) surfacing electrodes and rods, are classified on the basis of the chemical composition of the deposited weld metal. Tubular tungsten carbide bare rods are classified on the

f the weld metal, moisture content of low-hydrogen electrode coverings, standard sizes and lengths, marking, manufacturing, and packaging are also included. A guide to the

ational System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

num, cobalt, copper, gold, magnesium, nickel, silver, and brazing filler metals for vacuum service. Information is provided concerning the liquidus, the solidus, the brazing tem

ckaging. A guide to using the specification is included in an annex. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Sinc

ion makes use of both U.S. Customary Units and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other

composition of the electrode for solid electrodes and rods, chemical composition of weld metal for composite stranded and composite metal cored electrodes and the as-weld

0M specification also includes optional, supplemental designators for improved toughness and diffusible hydrogen and to indicate conformance to special mechanical proper

ions specified for each classification represent the latest state-of-the-art. Additional requirements are included for testing procedures, manufacture, sizes, lengths, and packag

mical composition of the electrode for solid electrodes and rods, chemical composition of weld metal for composite stranded and composite metal cored electrodes and the as

ntal designators are also included for improved toughness and diffusible hydrogen. Additional requirements are included for standard sizes, marking, manufacturing, and pac

EXXX-17, has been added. The EXXX-25 and EXXX-26 designations have been restored for electrodes intended specifically for welding only in the flat and horizontal po

electrodes, and moisture tests of the low-hydrogen electrode covering. Requirements for standard sizes and lengths, marking, manufacturing, and packaging are also includ

tungsten arc welding. Classification is based on chemical composition of the filler metal. Additional requirements are included for manufacture, sizes, lengths, and packaging

mits are specified.

g the classification system employed and the intended use of the rods.

edium required (for those classifications for which one is required). A special designation (K) is used to identify those classifications that are intended specifically for cryogenic

d an electrode classified herein. Other requirements include sizes, marking, manufacturing and packaging. The form and usability of the flux are also included. This specifica

al produced with the flux and an electrode (solid or composite) classified herein. Other requirements include sizes, marking, manufacturing, and packaging. The form and usa

ctrode using a prescribed welding procedure. Standard electrode sizes, marking, and packaging requirements are included. This specification makes use of both U.S. Custom

welding procedure. Standard electrode sizes, marking, and packaging requirements are included. This specification makes use of both U.S. Customary Units and the Interna

kes use of both U.S. Customary Units and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

mation as to the characteristics and applications of the classified electrodes.

bare rods are classified on the basis of the mesh range, quantity, and composition of the tungsten carbide granules. A guide is appended to the specification as a source of in

are also included. A guide to the use of the standard is included in an Annex. Optional supplemental requirements include improved toughness and ductility, lower moisture co

dus, the solidus, the brazing temperature range, and general areas of application recommended for each filler metal. Additional requirements are included for manufacture, si

tional System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

used independently of the other.

ored electrodes and the as-welded mechanical properties of the weld metal for each. Additional requirements are included for manufacture, sizes, lengths, and packaging. A g

ce to special mechanical property requirements when the weld metal is deposited using both low heat input, fast cooling rate and high heat input, slow cooling rate procedures

cture, sizes, lengths, and packaging. A guide is appended to the specification as a source of information concerning the classification system employed and the intended use o

etal cored electrodes and the as-welded or postweld heat treated mechanical properties of the weld metal for each. Additional requirements are included for manufacture, siz

marking, manufacturing, and packaging. A guide is appended to the specification as a source of information concerning the classification system employed and the intended us

only in the flat and horizontal positions. Requirements include general requirements, testing, and packaging. The Appendix provides application guidelines and other useful inf

, and packaging are also included.

e, sizes, lengths, and packaging. A guide is appended to the specification as a source of information concerning the classification system employed and the intended use of th

tended specifically for cryogenic service. The requirements include general requirements, testing, and packaging. The Annex provides general application guidelines for indiv

are also included. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Since these are not equivalent, each system must be

d packaging. The form and usability of the flux are also included. The specification makes use of both U.S. Customary Units and the International System of Units (SI). Since

makes use of both U.S. Customary Units and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

Customary Units and the International System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

dependently of the other.

e specification as a source of information concerning the characteristics and applications of the classified electrodes.

and ductility, lower moisture contents, and diffusible hydrogen limits. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Si

are included for manufacture, sizes, lengths, and packaging. A guide is appended to the specification as a source of information concerning the classification system employe

zes, lengths, and packaging. A guide is appended to the specification as a source of information concerning the classification system employed and the intended use of the el

ut, slow cooling rate procedures. Additional requirements are included for standard sizes, marking, manufacturing and packaging. A guide is appended to the specification as

mployed and the intended use of the zirconium alloy filler metal. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Since t

re included for manufacture, sizes, lengths, and packaging. A guide is appended to the specification as a source of information concerning the classification system employed

m employed and the intended use of low-alloy steel flux cored electrodes. This specification makes use of both U.S. Customary Units and the International System of Units (S

n guidelines and other useful information about the electrodes.

oyed and the intended use of the stainless steel filler metal. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Since these

l application guidelines for individual alloys and other useful information about welding electrodes.

quivalent, each system must be used independently of the other.

onal System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

d independently of the other.

national System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

e classification system employed and the intended use of the filler metals for brazing and braze welding. This specification makes use of both U.S. Customary Units and the In

d and the intended use of the electrodes and rods. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Since these units ar

ppended to the specification as a source of information concerning the classification system employed and the intended use of carbon steel flux cored electrodes. This specif

nal System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

classification system employed and the intended use of the electrodes and rods. This specification makes use of both U.S. Customary Units and the International System of U

nternational System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

System of Units (SI). Since these are not equivalent, each system must be used independently of the other.

U.S. Customary Units and the International System of Units (SI). Since these are not equivalent, each must be used independently of the other.

Units (SI). Since these units are not equivalent, each system must be used independently of the other.

ux cored electrodes. This specification makes use of both U.S. Customary Units and the International System of Units (SI). Since these are not equivalent, each system must

nd the International System of Units (SI). Since these units are not equivalent, each system must be used independently of the other.

equivalent, each system must be used independently of the other.

Vous aimerez peut-être aussi

- Non Metallic Flat GasketsDocument4 pagesNon Metallic Flat GasketsMarko ZoricicPas encore d'évaluation

- Piping Material: Modular Fabrication Yard Piping Module - Part IiDocument45 pagesPiping Material: Modular Fabrication Yard Piping Module - Part Iibryandown100% (1)

- FTP PDFDocument16 pagesFTP PDFPankaj RanePas encore d'évaluation

- Online Test On Chemical Thermodynamics and Energetic PDFDocument3 pagesOnline Test On Chemical Thermodynamics and Energetic PDFrvignesh2809Pas encore d'évaluation

- ASME B31.3 InterpretationsDocument44 pagesASME B31.3 InterpretationsChickenChick07Pas encore d'évaluation

- Asme Ix Interpretation Part6 PDFDocument36 pagesAsme Ix Interpretation Part6 PDFNaza GavaputriPas encore d'évaluation

- (WWW - Entrance Exam - Net) NSTSE Class 11 PCM Solved Paper 2009Document20 pages(WWW - Entrance Exam - Net) NSTSE Class 11 PCM Solved Paper 2009RishiPas encore d'évaluation

- Asme Y14.5m GD&T (Chs-En)Document82 pagesAsme Y14.5m GD&T (Chs-En)VQuadrosPas encore d'évaluation

- Chap 11Document96 pagesChap 11noscribdyoucantPas encore d'évaluation

- Physics Formula Sheet PDFDocument4 pagesPhysics Formula Sheet PDFmd hasaanPas encore d'évaluation

- Adobe Scan Jun 12, 2023Document25 pagesAdobe Scan Jun 12, 2023Deeksha MahadevPas encore d'évaluation

- Piping ConstructionDocument17 pagesPiping Constructionadel rihana100% (1)

- 26 Solution of TriangleDocument20 pages26 Solution of TriangleSachin KumarPas encore d'évaluation

- Aws 1208Document80 pagesAws 1208ndrarlyPas encore d'évaluation

- Liquid Nitrogen MSDSDocument9 pagesLiquid Nitrogen MSDSsalcabesPas encore d'évaluation

- Volksbolts Additional Options Stainless S Visit Our Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale LinksDocument12 pagesVolksbolts Additional Options Stainless S Visit Our Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale LinksAllan EscobarPas encore d'évaluation

- Stress Analysis of Ammonia Storage Tank, Providing A Basis For In-Service InspectionDocument6 pagesStress Analysis of Ammonia Storage Tank, Providing A Basis For In-Service InspectionRohit RastogiPas encore d'évaluation

- Design of ShellDocument18 pagesDesign of Shellanon_660004464Pas encore d'évaluation

- NSTSE 10 SamplepaperDocument7 pagesNSTSE 10 SamplepaperShreyansh DuggarPas encore d'évaluation

- 6 44 0006 Rev6Document415 pages6 44 0006 Rev6karunaPas encore d'évaluation

- ASME Section II Part A - Ferrous Material SpecificationsDocument8 pagesASME Section II Part A - Ferrous Material SpecificationsGato Sesa100% (1)

- IS:2002Document14 pagesIS:2002Madhavi YerurPas encore d'évaluation

- ASME B16.11 - Socket Welding and Threaded Forged FittingsDocument71 pagesASME B16.11 - Socket Welding and Threaded Forged FittingspremPas encore d'évaluation

- Udhe 2.standardsDocument1 pageUdhe 2.standardsom dhamnikarPas encore d'évaluation

- Experience ListDocument23 pagesExperience ListKarthik AnandanPas encore d'évaluation

- DAM DesuperheaterDocument4 pagesDAM DesuperheaterangeloPas encore d'évaluation

- Is 3074 2005Document16 pagesIs 3074 2005Kuldeep SinghPas encore d'évaluation

- GRB Organic Chemistry IIT JEE 851 PDFDocument2 pagesGRB Organic Chemistry IIT JEE 851 PDFSAYAN PALPas encore d'évaluation

- Api600 Valve Trim ChartDocument2 pagesApi600 Valve Trim ChartBoankPas encore d'évaluation

- Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesCastings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationWin DarPas encore d'évaluation

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenPas encore d'évaluation

- Base and Hanger Spring Data SheetsDocument4 pagesBase and Hanger Spring Data SheetsxkokarcaxPas encore d'évaluation

- Introduction To Gaskets: Prepared By: Salahuddin SRV.# 313326Document17 pagesIntroduction To Gaskets: Prepared By: Salahuddin SRV.# 313326uddinsalahPas encore d'évaluation

- Effects of Alloying ElementDocument4 pagesEffects of Alloying Elementamber2211Pas encore d'évaluation

- Is 3502 2009 PDFDocument10 pagesIs 3502 2009 PDFRajashekar.PPas encore d'évaluation

- Firelite 2600 Li Metric Data SheetDocument1 pageFirelite 2600 Li Metric Data SheetPranabesh MallickPas encore d'évaluation

- Pipes and Fittings BrochureDocument8 pagesPipes and Fittings BrochurehaggPas encore d'évaluation

- Weld Map Pressure VesselDocument32 pagesWeld Map Pressure Vesselarun yPas encore d'évaluation

- Extended Surface/ Finned Heat ExchangersDocument55 pagesExtended Surface/ Finned Heat ExchangersAdhan AkbarPas encore d'évaluation

- Astm A108-3Document8 pagesAstm A108-3Shahid RehmanPas encore d'évaluation

- Day 6 Welding Process, Electrode - FCAW, GTAW & SAWDocument65 pagesDay 6 Welding Process, Electrode - FCAW, GTAW & SAWRohit Kamble100% (1)

- Dissimilar Metal WeldsDocument15 pagesDissimilar Metal WeldsOsvaldo Ulises Lopez BaltazarPas encore d'évaluation

- Valve Material ApplicationDocument16 pagesValve Material Applicationswapneel_kulkarniPas encore d'évaluation

- DD - 046973 - Clearances Between Underground ServicesDocument2 pagesDD - 046973 - Clearances Between Underground ServicesvincentPas encore d'évaluation

- Procedure To Model API 650 Nozzle1Document4 pagesProcedure To Model API 650 Nozzle1Vishal KandPas encore d'évaluation

- Consumable LasDocument35 pagesConsumable LasAfifYantoMutuHPas encore d'évaluation

- Nfa 49 215 Grade Tu 37c Tubes PDFDocument1 pageNfa 49 215 Grade Tu 37c Tubes PDFMitul MehtaPas encore d'évaluation

- PmsDocument94 pagesPmssdk1978100% (1)

- Piping Questionnaire - Piping Study-NDocument14 pagesPiping Questionnaire - Piping Study-NBhanu Prakash100% (1)

- AWS Code LibraryDocument2 pagesAWS Code Libraryyoonchankim0911Pas encore d'évaluation

- Classification System For Submerged Arc ElectrodesDocument2 pagesClassification System For Submerged Arc ElectrodesPravin KumarPas encore d'évaluation

- Lesson X Specification No. DescriptionDocument1 pageLesson X Specification No. DescriptioncrysPas encore d'évaluation

- Spesifikasi ElektrodaDocument1 pageSpesifikasi ElektrodaDwi CahyoPas encore d'évaluation

- Gas Metal Arc Welding ElectrodeDocument1 pageGas Metal Arc Welding Electrodeadib nassarPas encore d'évaluation

- D10.4 R1986PVDocument7 pagesD10.4 R1986PVGabriela AxintePas encore d'évaluation

- Covered Welding ElectrodesDocument11 pagesCovered Welding ElectrodesAqsa BanoPas encore d'évaluation

- 10.3 The American Welding Society (Aws) : Lesson XDocument1 page10.3 The American Welding Society (Aws) : Lesson XcrysPas encore d'évaluation

- AWS Welding Standard PreviewDocument5 pagesAWS Welding Standard PreviewRavi YadavPas encore d'évaluation

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanPas encore d'évaluation

- Remote Field Eddy CurrentDocument4 pagesRemote Field Eddy CurrentExsan OthmanPas encore d'évaluation

- A-Health Advance-I Premium RatesDocument2 pagesA-Health Advance-I Premium RatesExsan OthmanPas encore d'évaluation

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanPas encore d'évaluation

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanPas encore d'évaluation

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- MaterialsDocument181 pagesMaterialsExsan OthmanPas encore d'évaluation

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanPas encore d'évaluation

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanPas encore d'évaluation

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanPas encore d'évaluation

- Chat For Organization of CodeDocument1 pageChat For Organization of CodeExsan OthmanPas encore d'évaluation

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanPas encore d'évaluation

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanPas encore d'évaluation

- Piping TableDocument59 pagesPiping TableExsan Othman100% (1)

- Hardness Conversion For Ferrous AlloysDocument2 pagesHardness Conversion For Ferrous AlloysExsan OthmanPas encore d'évaluation

- Actvities On Boiler Maintenance: I. FurnaceDocument5 pagesActvities On Boiler Maintenance: I. FurnaceExsan OthmanPas encore d'évaluation

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariPas encore d'évaluation

- Boiler Feedwater ControlDocument6 pagesBoiler Feedwater ControlExsan OthmanPas encore d'évaluation

- I) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerDocument1 pageI) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerExsan OthmanPas encore d'évaluation

- AB-522 Standard Pneumatic Test Procedure RequirementsDocument16 pagesAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerPas encore d'évaluation

- How To Measure MTFDocument64 pagesHow To Measure MTFamtcorporationPas encore d'évaluation

- Jacky Smith Resume Project ManagerDocument1 pageJacky Smith Resume Project ManagerGrey GrayPas encore d'évaluation

- Schematic Lenovo ThinkPad T410 NOZOMI-1Document99 pagesSchematic Lenovo ThinkPad T410 NOZOMI-1borneocampPas encore d'évaluation

- Makita 2708Document29 pagesMakita 2708Reuel JacintoPas encore d'évaluation

- Grundfos S Pump 5 - 29 KW Super VortexDocument20 pagesGrundfos S Pump 5 - 29 KW Super Vortexdalveerchoudhary100% (1)

- Unit-II Some PPT NetDocument2 pagesUnit-II Some PPT NetbandisaidaiahPas encore d'évaluation

- SemDocument31 pagesSemkaushik4208Pas encore d'évaluation

- Compact 40/25Document58 pagesCompact 40/25znim04Pas encore d'évaluation

- Rigaku Progeny Spec Sheet LTR 3.14Document2 pagesRigaku Progeny Spec Sheet LTR 3.14DATA24Pas encore d'évaluation

- Tutorial - 05 - Excavation Settle 3DDocument13 pagesTutorial - 05 - Excavation Settle 3DAlejandro Camargo SanabriaPas encore d'évaluation

- 2013 11 DUPLEX EasyDocument21 pages2013 11 DUPLEX EasyAnonymous HC0tWePas encore d'évaluation

- Meai Mar 2010Document36 pagesMeai Mar 2010Daneshwer VermaPas encore d'évaluation

- Online Order Processing SystemDocument34 pagesOnline Order Processing SystemMuhammad ShujaPas encore d'évaluation

- BD+ CD+ XD+ - tcm833-3534072Document20 pagesBD+ CD+ XD+ - tcm833-3534072MisterMMPas encore d'évaluation

- Geotechnical Engineering 1 (RMIT) Course RevisionDocument53 pagesGeotechnical Engineering 1 (RMIT) Course RevisionSaint123Pas encore d'évaluation

- Doing Hot Work On Gas ShipDocument5 pagesDoing Hot Work On Gas ShipAnonymous icnhaNsFPas encore d'évaluation

- Pioneer XDP - 30R ManualDocument213 pagesPioneer XDP - 30R Manualmugurel_stanescuPas encore d'évaluation

- Biodegradability of SurfactantsDocument1 pageBiodegradability of SurfactantsTinnysumardiPas encore d'évaluation

- CH 4 Data CommDocument4 pagesCH 4 Data CommHenna ShainaPas encore d'évaluation

- 2019 All PDFDocument27 pages2019 All PDFvishesh bhatiaPas encore d'évaluation

- Cbse PMT 2012Document33 pagesCbse PMT 2012Vishal RamakrishnanPas encore d'évaluation

- Applying Six Sigma at 3MDocument13 pagesApplying Six Sigma at 3MdchPas encore d'évaluation

- ChemCAD and ConcepSys AIChE Spring 09Document28 pagesChemCAD and ConcepSys AIChE Spring 09ConcepSys Solutions LLCPas encore d'évaluation

- Woodworking Plans - Wheelbarrow PlanterDocument3 pagesWoodworking Plans - Wheelbarrow PlanterMirel HotescuPas encore d'évaluation

- PACSystemsRX3i CS GFA559G (2010)Document4 pagesPACSystemsRX3i CS GFA559G (2010)Omar Alfredo Del CastilloPas encore d'évaluation

- " " Reach: Ordering InformationDocument8 pages" " Reach: Ordering InformationTrong TranPas encore d'évaluation

- Coal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Document17 pagesCoal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Keith Danae SuquibPas encore d'évaluation

- Pds 55930Document2 pagesPds 55930ekosuryonoPas encore d'évaluation

- Alien Vault Lab2Document28 pagesAlien Vault Lab2DukePas encore d'évaluation