Académique Documents

Professionnel Documents

Culture Documents

Collapsedcentertubes PDF

Transféré par

Rajumhaveri Haveri0 évaluation0% ont trouvé ce document utile (0 vote)

27 vues1 pageAutomotive engines incorporate a By-Pass Valve across the inlet and outlet of the full flow filter. When an element has collapsed, it is usually the result of a "sticky" or otherwise malfunctioning valve. A collapsed filter can lead to a loss of filtration and oil flow to the engine.

Description originale:

Titre original

collapsedcentertubes.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAutomotive engines incorporate a By-Pass Valve across the inlet and outlet of the full flow filter. When an element has collapsed, it is usually the result of a "sticky" or otherwise malfunctioning valve. A collapsed filter can lead to a loss of filtration and oil flow to the engine.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

27 vues1 pageCollapsedcentertubes PDF

Transféré par

Rajumhaveri HaveriAutomotive engines incorporate a By-Pass Valve across the inlet and outlet of the full flow filter. When an element has collapsed, it is usually the result of a "sticky" or otherwise malfunctioning valve. A collapsed filter can lead to a loss of filtration and oil flow to the engine.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Technical Information

Diagnosing Filters With Collapsed

Center Tubes or Elements

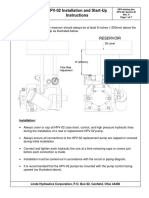

When a collapsed filter element is discovered, the

natural tendency is to assume something is wrong

with the filter itself (Figure 1). Generally, this is not the

case, but is usually a symptom of problems elsewhere

in the engine.

Automotive engines incorporate a by-pass valve across

the inlet and outlet of the full flow filter, which serves

to by-pass oil around the filter if its restriction becomes

excessive (Figure 2). The by-pass flow circuit insures oil

flow to the engine when there is a significant restriction

across the filter due to loading or cold start conditions.

Typically, engine manufacturers design by-pass valves

to open at a filter differential pressure of 10 psi (70 K

Pa), with some opening as high as 30 psi (206k Pa).

Some engines have the by-pass valve mounted in the

engine block, while others locate the by-pass valve in

the filter.

Bearings

Spin-On Filter

By-Pass

Valve

(Closed Under

Normal Conditions)

Normal

Oil Filter

Collapsed

Oil Filter

Figure 1

Pressure Regulating

Valve in Open Position

Pump

Excess Oil

Figure 2 Normal Pressure

Automotive lube oil filters are designed to withstand

differential pressures significantly greater than those

experienced under normal operating conditions without

collapsing. Therefore, when an element has collapsed,

it is usually the result of a sticky or otherwise malfunctioning by-pass valve.

The malfunction of by-pass valves and regulating valves

has been traced to:

In some instances, a sticky filter by-pass valve alone

is not enough to collapse a filter. The oil pressure regulating valve may also stick, resulting in increased pressure and flow through the filter. Although this condition

may be only momentary, it can quickly collapse the

filter center tube if the by-pass valve fails to relieve

the pressure.

Neglect extended oil drain and filter change

intervals;

A collapsed filter can lead to a loss of filtration and oil

flow to the engine; there is the possibility that interior

parts of the filter or filtering material may be torn away

and move into the fluid system and interfere with the

oil flow.

Sticky surfaces caused by cold, highly viscous oil;

Oil contaminated by excessive condensation, coolant,

or oxidation;

Carbon grit that temporarily jams a valve;

Sudden acceleration of the engine with any of the

above conditions.

Discovery of a collapsed filter calls for inspection

of the filter by-pass valve and the pressure regulator

valve and a review of the engine and its performance

and maintenance history.

The malfunction of the by-pass and oil pressure regulating valves and the subsequent collapse of the filter

may not cause noticeable damage but at times it can

result in a catastrophic failure to the engine; seizure of

a piston or of rod or main crankshaft bearings.

May 2003

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- FJ44-2C Line Maintenance Manual - FJ44-2CDocument1 049 pagesFJ44-2C Line Maintenance Manual - FJ44-2CLuisJunniorRomeroManzueta88% (8)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- HPV02 Installation and Start-Up Instructions PDFDocument7 pagesHPV02 Installation and Start-Up Instructions PDFxxshPas encore d'évaluation

- Operation & Maintenance Manual: P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIDocument226 pagesOperation & Maintenance Manual: P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIjulio cesar navaPas encore d'évaluation

- Hyderabad Metro Rail - Reducing The Negative Impact On City Environment - M.arch Thesis Report - J.v.umamAHESWARA RAO - ARCHITECTDocument188 pagesHyderabad Metro Rail - Reducing The Negative Impact On City Environment - M.arch Thesis Report - J.v.umamAHESWARA RAO - ARCHITECTUmamaheswara Rao100% (4)

- Diesel Engines Fourth Edition by Tim Bartlett PDFDocument97 pagesDiesel Engines Fourth Edition by Tim Bartlett PDFMayrym Rey ConPas encore d'évaluation

- Astm G85Document13 pagesAstm G85Rajumhaveri Haveri100% (3)

- 8015Document8 pages8015Rajumhaveri HaveriPas encore d'évaluation

- Chapter 11 Fuel System ActivityDocument3 pagesChapter 11 Fuel System ActivityRajumhaveri HaveriPas encore d'évaluation

- Proe TutorialDocument15 pagesProe TutorialRajumhaveri HaveriPas encore d'évaluation

- Chapter 11 Fuel System ActivityDocument3 pagesChapter 11 Fuel System ActivityRajumhaveri HaveriPas encore d'évaluation

- T1 ProE Revised AP 9-6-11Document10 pagesT1 ProE Revised AP 9-6-11Rajumhaveri HaveriPas encore d'évaluation

- SpringsDocument1 pageSpringsRajumhaveri HaveriPas encore d'évaluation

- Pro ENGINEER Wildfire Hands-On WorkshopDocument61 pagesPro ENGINEER Wildfire Hands-On Workshopmithunsingh90Pas encore d'évaluation

- Investment Casting: Expendable Mould and PatternDocument44 pagesInvestment Casting: Expendable Mould and PatternRajumhaveri HaveriPas encore d'évaluation

- Surface RoughnessDocument23 pagesSurface Roughnesswawawa1Pas encore d'évaluation

- Admission ExemptionDocument2 pagesAdmission ExemptionRajumhaveri HaveriPas encore d'évaluation

- Pressure Washer MachineDocument4 pagesPressure Washer MachinepressurewashermachinePas encore d'évaluation

- SERIES 9100A Pumps and Dispensers Installation/Operation ManualDocument68 pagesSERIES 9100A Pumps and Dispensers Installation/Operation ManualEstacion AvenidaPas encore d'évaluation

- NTPC Badarpur MechanicalDocument15 pagesNTPC Badarpur Mechanicalakshay2992100% (1)

- Engine Control Avanza SDocument3 pagesEngine Control Avanza SMurham MunirPas encore d'évaluation

- Wankel Engine: Jump To Navigation Jump To SearchDocument37 pagesWankel Engine: Jump To Navigation Jump To SearchRajeshwar SinghPas encore d'évaluation

- Oil Cooler and GasketDocument2 pagesOil Cooler and GasketDavid NguyenPas encore d'évaluation

- FMDVSPLTR InstructionsDocument5 pagesFMDVSPLTR InstructionsFatosYañezPas encore d'évaluation

- Risks of Operating Candu 6 Nuclear Power PlantsDocument66 pagesRisks of Operating Candu 6 Nuclear Power PlantsART'S PLACE100% (2)

- F & M Act 1967 and Regulations For Steam Boilers PDFDocument19 pagesF & M Act 1967 and Regulations For Steam Boilers PDFأمير حارثPas encore d'évaluation

- Caterpillar 816FDocument20 pagesCaterpillar 816FForomaquinas100% (1)

- Installation RecommendationsDocument64 pagesInstallation RecommendationsMdava0% (1)

- Liebherr LR 1200Document24 pagesLiebherr LR 1200Shailesh KhodkePas encore d'évaluation

- Sr. No City Name of Petrol Station AddressDocument3 pagesSr. No City Name of Petrol Station AddressHimanxaar100% (1)

- Forklift Operator ManualDocument23 pagesForklift Operator ManualCris SuyamPas encore d'évaluation

- Jaguar S-TYPE 2004 Quick GuideDocument2 pagesJaguar S-TYPE 2004 Quick GuideFerexPas encore d'évaluation

- Long Shutdown Management Dr. Pothala Kotewswara Rao ILAMDocument8 pagesLong Shutdown Management Dr. Pothala Kotewswara Rao ILAMP Koteswara RaoPas encore d'évaluation

- Rocket and Jet PropulsionDocument40 pagesRocket and Jet PropulsionsmuralichinnaPas encore d'évaluation

- Construction Inc - QTN3255Document1 pageConstruction Inc - QTN3255denciopo61Pas encore d'évaluation

- POSCO in Power Plant BussinessDocument32 pagesPOSCO in Power Plant BussinessbadbenzationPas encore d'évaluation

- Greddy SBD ManualDocument22 pagesGreddy SBD ManualKenneth ChanPas encore d'évaluation

- PX7301-Power Electronics For Renewable Energy Systems Question Bank PDFDocument6 pagesPX7301-Power Electronics For Renewable Energy Systems Question Bank PDF1balamanianPas encore d'évaluation

- AURLTE102Document30 pagesAURLTE102sruthiPas encore d'évaluation

- LH Max Expandable Liner Hanger System PsDocument2 pagesLH Max Expandable Liner Hanger System Psharshpatel18Pas encore d'évaluation

- ICE Civil Engineering ProceedingsDocument52 pagesICE Civil Engineering ProceedingsYasela100% (1)

- Alexia Ls - TdsDocument2 pagesAlexia Ls - TdsBeryl FernandesPas encore d'évaluation