Académique Documents

Professionnel Documents

Culture Documents

N 7

Transféré par

Bhushan PatilTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

N 7

Transféré par

Bhushan PatilDroits d'auteur :

Formats disponibles

VOL. 10, NO.

5, MARCH 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

FE ANALYSIS OF KNUCKLE JOINT PIN USEDIN TRACTOR TRAILER

Dinesh Shinde and Kanak Kalita

Department of Mechanical Engineering, MPSTME, SVKMs NMIMS, Shirpur Campus, Dhule, Maharashtra, India

E-Mail: dinesh.shinde@nmims.edu

ABSTRACT

Tractor trailer is a useful equipment used in agriculture field for carrying heavy goods. To connect trailer to the

tractor flexibly, a knuckle joint is used which consist of forks and a pin, a fork is attached to tractor rigidly and another fork

is attached to the trailer by a pin. During acceleration of tractor, force acting on the joint is tensile and during deceleration

it is compressive. Force acting over the joint is calculated by considering Newtons Second Law of motion. At the time of

carrying heavy weights, due to its fluctuation a pin is subjected to high stresses. As the pin is a flexible element which can

easily be replaced, it is considered separately for the analysis and finite element analysis is done on it.

Keywords: finite element analysis, knuckle joint, tractor-trailer, acceleration, deceleration.

INTRODUCTION

Tractor-trailer finds widespread use as a means of

transportation in rural like agriculture field and in urban

like goods transport as it is often cheaper. The effective

design of any mechanical device or assembly demands the

predictive knowledge of its behavior in working condition.

It becomes a dire necessity for the designer to know the

forces and stresses developed during its operation. This is

also important from the view of selecting the right

material. In recent years, the failure of assemblies due to

stress accumulation has been a major concern for design

engineers [1]. The analytical treatments of stress

concentration can be traced back to 1900s [2]. Various

experimental techniques have been developed over the

years to calculate these localized stresses. However, it

often becomes difficult to obtain these calculations either

by mathematically or by experiments if the geometry is

complex or requires significant resources to manufacture a

prototype. Finite Element Method (FEM) has emerged as a

viable option in this context. Over the years many a

researchers have published numerous studies by using

FEM.

Design of vehicles, especially effect of various

operational loadings has been area of interest for many

researches. The effect of such operational loads and hence

the induced stresses was investigated FEA by Roslan Abd

Rahman et al. [3].As it is used to carry heavy loads it is

analyzed by some investigators partly, by considering

different part of the assembly. Sufficient literatures on FE

analysis of Chassis of trolley are available [4]. Another

researcher did three dimensional finite element analyses of

the chassis consist of a computer model or design that is

stressed and analyzed for specific results [5]. The axle of

trolley is also one of the important parts for critical failure

modes [6]. Knuckle joint is designed and used in so many

equipment for transmitting load. Some researchers have

analyzed it as a part of steering mechanism of automobile

for its weight reduction [7, 8]. Knuckle joint which is used

in steering mechanism of racing car is also dealt and

analyzed for optimization of weight, because weight is the

important parameter that affects transmission efficiency of

device [9]. Trailers used other than with tractor have been

simulated and the stress analysis was performed. Another

study show the use of models simulated in CATIA [10].

Koszalkaet et al. [11] used FEM to analyze the frame of a

low loader truck. An iterative procedure has been used by

Sane et al. [12] analyzing the developed stresses in a light

commercial automobile.

Knuckle joint is a joint among two parts

permitting movement in one plane only. It is atype of

hinge joint. More often than not two parts of a machine are

to be connected and restrained, for example two rods may

be joined coaxially and when these rods are pulled apart

they should not separate i.e. should not have relative

motion and continue to transmit force. The paper presents

a FE analysis for a pin used in the knuckle joint assembly

of tractor trailers. The required solid model based on the

real life application and dimension is modeled in ANSYS

Workbench. The model is then discretized and meshed.

Suitable constraints and load conditions are applied to it.

The papers open with a short introduction on the use and

need of stress analysis. Section 1 also contains a brief

review of related literature. The problem is defined in

section 2 followed by description of solid model in section

3. The obtained results are critically examined in section 4

and conclusions are drawn in the final section.

PROBLEM DEFINITION

Mass of trailer with weight placed on it alone is

not responsible for the force acting over the knuckle joint.

Rather acceleration with which tractor pulls trailer is

responsible. Here a reference is taken in the current study

from Newtons Second Law of Motion for the

consideration. According to that a Force is equal to the

mass of the body multiplied by the acceleration of the

body.

2227

VOL. 10, NO. 5, MARCH 2015

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

, a=

a=

Figure-1. Block diagram showing direction of force

during Acceleration.

When the tractor decelerates, direction of force

becomes opposite to the direction shown in Figure-1. To

calculate the force acting on the joint, a constant speed of

40 Km/hr i.e. 11.11 m/s is considered with time period of

5 minutes i.e. 300 Seconds during acceleration and 0.5

minute i.e. 30 seconds during deceleration. Trailer which

is pulled by a tractor is having a mass 500 Kg when it is

empty and 10000 Kg when it is full. According to

Newtons Law of Motion, Force F= mass x Acceleration.

And acceleration,

= 0.037 m/s2

Therefore, Tangential Force Acting on the joint,

when the trailer is empty, F1 = 500 x 0.037 = 18.57 N.

Tangential Force Acting on the joint, when the trailer is

full, F2 = 10000 x 0.037 = 370 N. Due to braking or any

other interruptions during the driving, the tractor get

decelerate, which changes the direction and nature of

tangential force from tensile to the compressive.

= - 0.37 m/s2

Deceleration, a1 =

The Tangential Force Acting on the joint, when

the trailer is empty, during deceleration,F3 = 500 x (- 0.37)

= 185 N (Compressive). Tangential Force Acting on the

joint, when the trailer is full, F4 = 10000 x (-0.37) = 3700

N (Compressive). Similar to this sample calculation,

forces has been calculated at different speed for

acceleration as well as deceleration and for empty as well

as full trailer.

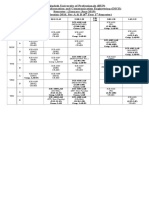

Table-1. Tangential force during acceleration for empty trailer.

Force (N)

8.333333

Acceleration

(m/s2)

0.027777

40

11.11111

0.037037

18.51851

50

13.88889

0.046296

23.14814

60

16.66667

0.055555

27.77777

V(KMPH)

V (m/s)

30

13.8888

Table-2. Tangential force during deceleration for empty trailer.

V

(KMPH)

30

V (m/s)

8.333333

Deceleration

(m/s2)

0.27777

Force (N)

138.8889

40

11.11111

0.3703

185.1852

50

13.88889

0.462962

231.4815

60

16.66667

0.555

277.7778

Table-3. Tangential force during acceleration for full trailer.

8.333333

Deceleration

(m/s2)

0.02777

277.77777

40

11.11111

0.03703

370.3703

50

13.88889

0.0462

462.962

60

16.66667

0.05555

555.5555

V (KMPH)

V (m/s)

30

Force (N)

2228

VOL. 10, NO. 5, MARCH 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Table-4. Tangential force during deceleration for full trailer.

V

(KMPH)

30

40

50

60

V (m/s)

8.333

11.11

13.88889

16.66

MODELING OF KNUCKLE JOINT PIN

The first step in analyzing any machine assembly

using FEM package is to draw a solid model. The solid

model should incorporate all the complexities and features

of the real life assembly. It is often seen in literature that

the accuracy of obtained results from ANSYS are always

directly dependent on the accuracy of the solid model to

its physical form. In this case based on the dimensions

actually measured for a trailer, a model has been prepared.

Deceleration

(m/s2)

0.2777

0.3703

0.46296

0.55555

Force (N)

2777.778

3703.704

4629.63

5555.556

Location of Forks and a pin is similar to as it is in actual

case. The solid model is than imported into the FEM

module and meshed using solid 186 elements.

As shown in Figure-2, boundary conditions have

been given in processor stage of finite element analysis of

knuckle pin. Material properties considered here are:

Density=7850 kg/m3, Youngs Modulus E=2x1011 Pa,

Poissons ratio = 0.3, Bulk modulus G= 1.667x 1011,

Shear modulus = 7.69x1010.

Figure-2. Knuckle joint assembly and pin.

RESULTS

The simulated problem is solved by using

ANSYS workbench. Figure-3 shows the relation between

the generated stress in the pin and the load intensity. In all

the plots the stress monotonically increases with increase

in load intensity. As can be predicated by simple

mathematical calculation based on fundamental equations

of mechanics forces generated during deceleration is in

general more than acceleration. Hence the stress produced

in deceleration phase is much higher than in acceleration.

Figures 4-6 shows the simulated results for force 13.34 N,

which is the case acceleration of empty trailer. The stress,

strain and deformation plots for other cases are not shown

to avoid redundancy of figures. The basic trend is similar

in all the cases. The pin is connects the forks of tractor and

the trailer. It behaves like a short column. A short column

when compared with a long column is much stiffer. It

simply means that it offers larger resistance to the applied

force and hence a much larger force is needed to deform it.

Figure-5 shows the total deformation the pin undergoes.

Maximum deflection is seen at the midpoint. This is due to

the fact that the pin is constrained (by the forks) in upper

and lower position as shown by schematic in Figure-7.

2229

VOL. 10, NO. 5, MARCH 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Figure-3. Von Misses stress vs. tangential forces.

Figure-4. Typical equivalent strain generated.

Figure-5. Total Deformation contour plot.

2230

VOL. 10, NO. 5, MARCH 2015

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Figure-7. Graphical representation of reaction due to

fixed support.

For the purpose of validation, consider Bending

Equation as,

=

Figure-6. Von Mises Stress contour plot.

MATHEMATICAL VALIDATION OF RESULTS

Neglecting effect of mass we can treat the pin as

a simply supported beam assuming that the tangential

pulling force occurs at the centre of the pin (Figure-7).

For the case of 13.8 N tangential force, the

Bending moment, M = 1.93 N-m, considering area

moment of inertia (I) for the circular pin and the distance

of its application (y) as d/2. Here diameter d is 0.02 m.

After the calculation,

= 1.562 N/m2 which is much

closer to ANSYS results.

Table-5. Validation of results for Acceleration when trailer is empty.

S. No.

Tangential force

(N)

1

2

3

4

13.8

18.5

23.14

27.7

Von Misses stress (N/m2)

ANSYS

Mathematically

1.43E+05

1.51E+05

1.91E+05

2.01 E+05

2.39E+05

2.51 E+05

2.86E+05

2.98 E+05

% error

5.2

4.9

4.7

4.02

Table-6. Validation of results for Acceleration when trailer is full.

S. No.

Tangential force

(N)

1

2

3

4

138

185

231

277

Von Misses stress (N/m2)

ANSYS

Mathematically

1.42E+06

1.35 E+06

1.90E+06

2.05 E+06

2.38E+06

2.47 E+06

2.86E+06

2.98 E+06

% error

4.9

7.3

4.3

4.02

Table-7. Validation of results for deceleration when trailer is empty.

S. No.

Tangential force

(N)

1

2

3

4

277

370

462

555

Von Misses stress (N/m2)

ANSYS

Mathematically

2.03E+06

2.18 E+06

2.72E+06

2.59 E+06

3.39E+06

3.505 E+06

4.08E+06

4.26 E+06

% error

6.8

4.7

3.32

4.25

2231

VOL. 10, NO. 5, MARCH 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Table-8. Validation of results for deceleration when trailer is full.

Von Misses stress (N/m2)

S. No.

Tangential force

(N)

ANSYS

Mathematically

2777.78

2.04E+07

2.18 E+07

6.42

3708.7

2.72E+07

2.805 E+07

3.03

4629.6

3.40E+07

3.57 E+07

4.7

5555.56

4.08E+07

4.29 E+07

4.86

CONCLUSIONS

After studying knuckle joint used in tractor-trailer

and analysis a pin for Von Misses stresses the following

conclusions can be drawn:

Knuckle joint is the most preferable joint in

commercial field to join a shaft which is axial having

no eccentricity.

Knuckle pin is the flexible element of the joint, which

can be remove to disconnect trailer from tractor.

Numerical value of tangential force acting on the

knuckle joint is maximum in case of deceleration at

the same speed of the tractor.

Obviously as tangential force increases the Von

misses stresses increase, their intensity is maximum in

case of deceleration.

Conditions may become worst in case deceleration of

a trailer full of load.

REFERENCES

[1]

[2]

K. Kalita. Stress Concentration Mitigation in Clamped

Steel Plates. International Journal of Scientific World

(IJSW). 2(1).

Neuber, Heinz, Theory of Notch Stresses, J. W.

Edwards, Inc., Ann Arbor, Mich., 1946 (translation of

the original German version published in 1937).

[3]

Roslan Abd Rahman, Mohd Nasir Tamin, Ojo Kurdi.

2011. Stress analysis of heavy duty truck chassis

using finite element method. Skudai Journal, Johor.

201-204.

[4]

Ms. Kshitija A. Bhat, Prof. Harish V. Katore. The

Failure Analysis of Tractor Trolley Chassis an

Approach using Finite Element Method- A Review.

Journal of Mechanical and Civil Engineering, 2320334X PP, 24-27.

[5]

Bhat K.A., Untawale S.P., Katore H.V. 2014. Failure

Analysis and Optimization of Tractor Trolley Chassis:

An Approach Using Finite Element Analysis.

IJPRET. 2(12): 71-84.

[6]

I.D. Paul, G.P. Bhole, J.R. Chaudhari. 2013.

Optimization of Tractor Trolley Axle for Reducing

the Weight and Cost Using Finite Element Method.

% error

Journal of Engineering, Computers and Applied

Sciences. 2(3): 31-35.

[7]

VirajRajendra Kulkarni, Amey Gangaram Tambe.

2013. Optimization and Finite Element Analysis of

Steering Knuckle. Altair Technology Conference.

[8]

Kirpal Singh, Automobile Engineering, New Age

publication.

[9]

PurushottamDumbre, A. K. Mishra, V. S. Aher. 2014.

Structural Analysis of Steering Knuckle for Weight

Reduction. International Journal of Emerging

Technology and Advanced Engineering. 4(6): 221226.

[10] Mohd Azizi Muhammad Nora B., Helmi Rashida,

Wan Mohd Faizul Wan Mahyuddinb. 2012. Stress

Analysis of a Low Loader Chassis. International

Symposium on Robotics and Intelligent Sensors 2012

(IRIS 2012), Procedia Engineering, 41: 995-1001.

[11] Grzegorz Kolzalka, G., Debski, H., Dziurka, M.,

Kazor, M. 2011. Design of a Frame to a Semi Low

Loader. Journal of KONES Powertrain and Transport.

18(2).

[12] Sane S. S., Jadhav G., Anandraj H. 1955. Stress

Analysis of Light Commercial Vehicle Chassis by

FEM. Piaggio Vehicle Pvt. Ltd, Pune, India.

2232

Vous aimerez peut-être aussi

- Gate SurvingDocument114 pagesGate SurvingBhushan PatilPas encore d'évaluation

- Gate Ee CivilDocument240 pagesGate Ee CivilBhushan PatilPas encore d'évaluation

- Yan Trik 2013Document48 pagesYan Trik 2013Bhushan PatilPas encore d'évaluation

- Shashank Mittal: EducationDocument2 pagesShashank Mittal: EducationBhushan PatilPas encore d'évaluation

- Matlab Program For The Problem Is As Follows-: OutputDocument2 pagesMatlab Program For The Problem Is As Follows-: OutputBhushan PatilPas encore d'évaluation

- Guidelines For Analysis of Electromeric Sound Deadner (Under Seal) SilencerDocument10 pagesGuidelines For Analysis of Electromeric Sound Deadner (Under Seal) SilencerBhushan PatilPas encore d'évaluation

- Sagar V. Shilwant: EducationDocument2 pagesSagar V. Shilwant: EducationBhushan PatilPas encore d'évaluation

- Name of The Experiment: Aim: Theory of Actuator: Appratus: Hydraulic Trainer, Stop Watch, Stop WatchDocument6 pagesName of The Experiment: Aim: Theory of Actuator: Appratus: Hydraulic Trainer, Stop Watch, Stop WatchBhushan PatilPas encore d'évaluation

- Theories of Failure FinalDocument21 pagesTheories of Failure FinalBhushan PatilPas encore d'évaluation

- Converting UHTML File Into HTMLDocument0 pageConverting UHTML File Into HTMLBhushan PatilPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDocument5 pagesLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALAPas encore d'évaluation

- Angle ModulationDocument26 pagesAngle ModulationAtish RanjanPas encore d'évaluation

- InterviewDocument8 pagesInterviewswapnadip kumbharPas encore d'évaluation

- UntitledDocument5 pagesUntitledapril montejoPas encore d'évaluation

- Bosch KE-Jetronic System DescriptionDocument3 pagesBosch KE-Jetronic System DescriptionJack Tang50% (2)

- Sop GC6890 MS5973Document11 pagesSop GC6890 MS5973Felipe AndrinoPas encore d'évaluation

- Scope and Sequence 2020 2021...Document91 pagesScope and Sequence 2020 2021...Ngọc Viễn NguyễnPas encore d'évaluation

- Auto CadDocument67 pagesAuto CadkltowerPas encore d'évaluation

- 5 Grade: Daily MathDocument130 pages5 Grade: Daily MathOLIVEEN WILKS-SCOTT100% (3)

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocument4 pagesPH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahPas encore d'évaluation

- HCH - 15 04 004Document5 pagesHCH - 15 04 004NarvaxisPas encore d'évaluation

- Combinational Logic-Part-2 PDFDocument25 pagesCombinational Logic-Part-2 PDFSAKSHI PALIWALPas encore d'évaluation

- A Presentation On-: E-Paper TechnologyDocument19 pagesA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruPas encore d'évaluation

- A New Procedure For Generalized Star Modeling Using Iacm ApproachDocument15 pagesA New Procedure For Generalized Star Modeling Using Iacm ApproachEdom LazarPas encore d'évaluation

- Biography Worksheet: Name: Gerardo Angeles MartinezDocument1 pageBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesPas encore d'évaluation

- WT Capability Statement PE 2020Document1 pageWT Capability Statement PE 2020Muhannad SuliemanPas encore d'évaluation

- Headlight Washer System: Current Flow DiagramDocument3 pagesHeadlight Washer System: Current Flow DiagramLtBesimPas encore d'évaluation

- Storage Tanks Overfill Prevention Better PracticesDocument2 pagesStorage Tanks Overfill Prevention Better PracticesRicardo Bec100% (1)

- Class Routine Final 13.12.18Document7 pagesClass Routine Final 13.12.18RakibPas encore d'évaluation

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocument61 pagesSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASPas encore d'évaluation

- Drilling Jigs Italiana FerramentaDocument34 pagesDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezPas encore d'évaluation

- ToiletsDocument9 pagesToiletsAnonymous ncBe0B9bPas encore d'évaluation

- 19 71 Hydrologic Engineering Methods For Water Resources DevelopmentDocument654 pages19 71 Hydrologic Engineering Methods For Water Resources DevelopmentMartha LetchingerPas encore d'évaluation

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocument194 pagesThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedPas encore d'évaluation

- Surge Protection Devices CatalogueDocument134 pagesSurge Protection Devices CatalogueNguyen Doan QuyetPas encore d'évaluation

- Causal Emergence - HoelDocument18 pagesCausal Emergence - HoelFelipe LopesPas encore d'évaluation

- PCM 2.4l Turbo 5 de 5Document2 pagesPCM 2.4l Turbo 5 de 5Felix VelasquezPas encore d'évaluation

- Unit 13 Dialogue Writing: ObjectivesDocument8 pagesUnit 13 Dialogue Writing: ObjectivesAkg GuptPas encore d'évaluation

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaPas encore d'évaluation

- Moc3040 MotorolaDocument3 pagesMoc3040 MotorolaBryanTipánPas encore d'évaluation