Académique Documents

Professionnel Documents

Culture Documents

Cemented Tunsten Carbide Metalforming Grades Chart

Transféré par

flytorahulCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cemented Tunsten Carbide Metalforming Grades Chart

Transféré par

flytorahulDroits d'auteur :

Formats disponibles

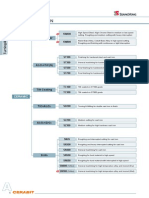

Grade & Application Guide

Conventional Cemented Tungsten Carbide Metalforming Grades

KENNAMETAL GRADE

BINDER %

GRAIN FAMILY

HARDNESS (HRA)

DENSITY (g/cm)

CD630 KF306

6.0

Submicron

93.3

14.90

CD636 KF310

10.0

Submicron

92.2

14.50

CD750

15.0

Submicron

91.0

13.95

CD650 KF315

15.0

Submicron

90.2

13.95

K313

6.0

Fine

93.0

14.90

K96

5.5

Fine

92.1

15.00

CD30

6.0

Fine

92.5

14.90

CD18

12.0

Fine

90.1

14.35

K94

11.5

Fine

89.8

14.30

K92

15.7

Fine

88.4

13.80

K91

19.7

Fine

86.8

13.30

K90

24.8

Fine

84.8

12.90

CD35

10.0

Medium

90.3

14.50

K3833

11.0

Medium

89.8

14.40

CD40

13.0

Medium

89.0

14.20

CD50

15.0

Medium

88.0

14.00

K3135

9.0

Coarse

89.5

14.55

CD337

11.0

Coarse

88.5

14.35

K3109

12.1

Coarse

88.0

14.20

K3150

15.0

Coarse

87.0

13.95

CD60 K3520

20.0

Extra Coarse

84.2

13.45

CD70

25.0

Extra Coarse

82.2

13.20

Mixed Binder (Corrosion Resistant) Metalforming Grades

KR855

10.9

Submicron

91.8

14.40

KR466

13.2

Coarse

90.0

14.20

KR887

15.6

Submicron

90.4

13.90

Gall-Resistant (TiC & TaC additives) Metalforming Grades

K84

10.3

Fine

91.0

12.90

K82

12.6

Fine

90.2

11.65

www.kennametal.com

Grade & Application Guide

Application Guide

GRADES

DESCRIPTION

APPLICATIONS

K96, CD30

HIGHLY WEAR RESISTANT

LIGHT SHOCK

Draw dies, compacting dies, burnishing tools, drills, reamers, stamping dies for light blanking.

KF306, CD630,

K313

HIGH WEAR RESISTANCE

LOWER SHOCK

Used in high abrasion, high wear applications for: light draw dies, fine blanking dies, stamping dies for mylar,

fine wire draw dies, compacting dies.

CD35

GOOD WEAR RESISTANCE

LIGHT SHOCK

Valve lifter discs, knurling wheels, bandsaw guides, draw dies, bar and tube dies, powder metal compacting

dies (normal) stamping dies, medium size wire bending.

K3833, K3135

GOOD WEAR RESISTANCE

MEDIUM SHOCK

Punch and dies for electrical laminations, draw dies (severe), backward extrusion punches, compressive

strength >300,000 psi, or L:D >7:1, lamination dies-silicon steel and stainless.

KF310, CD636

VERY GOOD WEAR RESISTANCE

LIGHT SHOCK

Coining brass (.010" thick), can die ironing rings, drills (mica), non-gummy steels, rotary drills, crush rolls,

compacting dies, stamping dies for razor blades, lead frames (thin copper .030"), annealed copper, draw dies

(300 series stainless).

CD337, K3109

VERY HIGH STRENGTH

HEAVY IMPACT

MEDIUM WEAR RESISTANCE

Impacting punches, coining dies, forming dies, can die punches, swaging dies, cold forming, back extrusion

punches and dies, high-impact extrusion dies, nail grip dies, very severe draw dies for .075" thick cold rolled

steel, piercing punches-305 stainless, works well on gummy steel.

K94, CD18

HIGH ABRASION RESISTANCE

Light blanking diessilicon steel up to .020", medium blankingmild steel to .030" lamination

dies-silicon steel, scroll dies, burnishing rolls, backward and forward extrusion dies (light impact).

CD40

MEDIUM IMPACT

GOOD WEAR

Stamping dies, compacting dies (severe), bronze, copper, can die rings, metal forming dies, draw dies (severe),

slitter rings, razor blade dies, coining dies, drill bits.

K92, CD50

MEDIUM IMPACT

MEDIUM WEAR RESISTANCE

Lamination diessilicon steel .004"-.040", blanking diesmild steel up to .040", forming dies, scroll dies,

mandrels, cut-off knives, compacting dies, boring bars, deep draw dies for oil filters, pulverizing blades,

stamping dies-chain saw teeth, light cold heading dies, gripper jaws, swaging dies-aluminum.

KF315, CD650,

CD750

LOW IMPACT

VERY GOOD WEAR

VERY HIGH STRENGTH

Stamping dies for razor blades, electronic stamping, lead frame dies, laminations, spring steel stampings,

crush rolls, coining dies (hard metal), not good for stamping thick stainless.

K3150, K91,

K3520, CD60

HEAVY SHOCK

HEAVY IMPACT

Heavy metalforming applications such as: header dies, washer dies, light-heavy blanking up to .062" steel,

crushing hammers, rivet sets, backward or forward extrusion dies, heavy piercing punches.

K90, CD70

HEAVY SHOCK

HEAVY IMPACT

Used in hot and cold metalforming applications where very severe shock loads are applied such as: hot

forming dies, swaging dies, hex dies, trapped extrusion dies, very heavy blanking dies, and very heavy piercing

punches, cold heading dies, nail heading dies, swaging dies, coiling dies, shears and cutoff dies.

Corrosion-Resistant Binder Grades Optimized for the Wire EDM Process

KR855

VERY GOOD WEAR

LIGHT SHOCK

10% corrosion-resistant binder with submicron grain structure. Excellent for EDM operations and good in nonferrous applications. Applications: ISO K-30 grade with ideal wear resistance in high-speed stamping, medium,

thin sheetscoining brass (.010" thick), can die ironing rings, non-gummy steels, compacting dies, stamping

dies for razor blades, lead frames (thin copper .030"), annealed copper, draw dies (300 series stainless steel).

KR466

GOOD WEAR RESISTANCE

MEDIUM SHOCK

12% corrosion-resistant binder with coarse grain structure. Very high strength for heavy impact with low

wear properties. Applications: for standard stampingimpacting punches, coining dies, forming dies, can die

punches, swaging dies, cold forming, very severe draw dies for .075" thick cold-rolled steel, piercing punches

(305 stainless steel), gummy steel.

KR887

LOW IMPACT

VERY GOOD WEAR RESISTANCE

VERY HIGH STRENGTH

15% corrosion-resistant binder with submicron grain structure for lead frame and connector stamping. Very

high strength and excellent wear resistance for low-impact applications. Applications: stamping dies for razor

blades, electronic stamping, lead frame dies, laminations, spring steel stampings, crush rolls, coining dies

(hard metal). Not recommended for stamping thick stainless steel.

Gall-Resistant Grades

K84

GOOD WEAR RESISTANCE, LIGHT SHOCK

General purpose, draw dies and tube sizing mandrels.

K82

MEDIUM IMPACT,

MEDIUM WEAR RESISTANCE

Large diameter draw dies, tube sizing mandrels, and impact extrusion dies.

This is a reference guide only. Please consult with a Kennametal applications engineer prior to choosing a grade.

Local Contact Information

2013 Kennametal Inc. l All rights reserved. l B-13-03484

Originating Country

North America (U.S. & Canada)

Brazil

Phone

Fax

1.800.227.2434

1.724.864.2443

55.19.3936.9200

China

86.21.38608269

Europe

India

49.9279.80500

49.9279.80100

91.80.2839.1300

91.80.2219.8444

91.80.2839.4321

65.6.265.9222

65.6861.0922

02.2109.6100

Singapore

South Korea

86.21.50326778

E-mail

irwin.service@kennametal.com

bra.marketing@kennametal.com

k-cn.service@kennametal.com

k-mstl.service@kennametal.com

bangalore.information@kennametal.com

k-sg.sales@kennametal.com

k-kr-service@kennametal.com

Vous aimerez peut-être aussi

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Welding Inspection CSWIP (ANSWER)Document131 pagesWelding Inspection CSWIP (ANSWER)Manoj PaudelPas encore d'évaluation

- Wire Mesh Steel Reinforcement BarsDocument6 pagesWire Mesh Steel Reinforcement Barssattar12345Pas encore d'évaluation

- Technical DataDocument17 pagesTechnical Datat_syamprasadPas encore d'évaluation

- Types of Steel AlloyDocument47 pagesTypes of Steel AlloyArpit Thumar100% (2)

- Banco Alu Radiator Price ListDocument8 pagesBanco Alu Radiator Price Listflytorahul0% (1)

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShwePas encore d'évaluation

- Steel FachaDocument59 pagesSteel FachaviyfPas encore d'évaluation

- Beml Vendor ListDocument30 pagesBeml Vendor ListPrashanth Kumar Nagraj Ganiga100% (1)

- Basic Steel Selection Based On BS 970 en SeriesDocument8 pagesBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranPas encore d'évaluation

- Rail Specifications and Corrosion GuideDocument94 pagesRail Specifications and Corrosion GuideGowthami Priya HanumuthuPas encore d'évaluation

- Brochure EC250D EC300D T3 EN 30 20035491 CDocument28 pagesBrochure EC250D EC300D T3 EN 30 20035491 CLU YO100% (1)

- METALLURGY AND MATERIALS PROPERTIESDocument55 pagesMETALLURGY AND MATERIALS PROPERTIESTina Miller100% (2)

- Norma AISIDocument21 pagesNorma AISImaria elena castañedaPas encore d'évaluation

- Master Tungsten Carbide Rotary Burrs PDFDocument12 pagesMaster Tungsten Carbide Rotary Burrs PDFFred AksoPas encore d'évaluation

- A10VSO Repair ManualDocument29 pagesA10VSO Repair ManualAlexandru Ganziuc97% (29)

- Duplex Stainless SteelDocument24 pagesDuplex Stainless SteeljeffreymacaseroPas encore d'évaluation

- API-570 - Data Sheets (2018 Test)Document6 pagesAPI-570 - Data Sheets (2018 Test)mahmoud alwasif100% (1)

- BS3100 A2Document11 pagesBS3100 A2AlexPas encore d'évaluation

- Conversão de Correias CumminsDocument93 pagesConversão de Correias CumminsRafael Fernando67% (6)

- 2002catalog PDFDocument21 pages2002catalog PDFPH "Pete" PetersPas encore d'évaluation

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesPas encore d'évaluation

- Distributor List 24.02.2021Document2 pagesDistributor List 24.02.2021Hoang TuPas encore d'évaluation

- STS Pulley Data Sheet Provides Technical Specs and Designation ExamplesDocument34 pagesSTS Pulley Data Sheet Provides Technical Specs and Designation Examplesvietkham100% (1)

- 18 Ni CR Mo 5Document2 pages18 Ni CR Mo 5lavius_mPas encore d'évaluation

- Presentasi AotaiiiDocument37 pagesPresentasi Aotaiiiindo jasunPas encore d'évaluation

- Canlin Castings - Guide to Cast Iron Grades and Their PropertiesDocument2 pagesCanlin Castings - Guide to Cast Iron Grades and Their PropertieshooijschuurPas encore d'évaluation

- TOOL AND DIE STEEL FinalDocument73 pagesTOOL AND DIE STEEL FinalSapan KansaraPas encore d'évaluation

- ABB IRC5 Motion+Functions+and+Events+World+Zones+3HAC18152 1Document54 pagesABB IRC5 Motion+Functions+and+Events+World+Zones+3HAC18152 1inigo17Pas encore d'évaluation

- Hes C 071-04 Hot-Dip Galvannealed Steel Sheets and Strip For Automobile UsesDocument23 pagesHes C 071-04 Hot-Dip Galvannealed Steel Sheets and Strip For Automobile UsesDouglas A. da SilvaPas encore d'évaluation

- Materialqualitaeten EDocument2 pagesMaterialqualitaeten EjvilamaiorPas encore d'évaluation

- Steel Selection Guide for BS 970 GradesDocument2 pagesSteel Selection Guide for BS 970 GradescolinneillPas encore d'évaluation

- FsafsaDocument45 pagesFsafsapvmssonPas encore d'évaluation

- CR StandardsDocument6 pagesCR Standardsalpha_beta48Pas encore d'évaluation

- ERD Tin Product BrochureDocument10 pagesERD Tin Product BrochureLaura ElgarristaPas encore d'évaluation

- Secco Catalogo 1Document16 pagesSecco Catalogo 1emilio_707Pas encore d'évaluation

- Effects of Steel Alloys on PropertiesDocument9 pagesEffects of Steel Alloys on PropertiesMina RemonPas encore d'évaluation

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKPas encore d'évaluation

- Okicat07 StoodyDocument12 pagesOkicat07 StoodyGianfranco CopelloPas encore d'évaluation

- EN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelDocument4 pagesEN1A Carbon Steel - EN1A Forging - EN1A Flat - Saaj SteelNaiduPas encore d'évaluation

- STOODY 965-G, 965-O HARD FACING ALLOY GUIDEDocument1 pageSTOODY 965-G, 965-O HARD FACING ALLOY GUIDEARTHURS316Pas encore d'évaluation

- Tool Steel Properties & ApplicationsDocument1 pageTool Steel Properties & ApplicationsTejas KumarPas encore d'évaluation

- 16MnCr5 SteelDocument3 pages16MnCr5 SteelaravindhPas encore d'évaluation

- 60Si2Mn Spring Steel PDFDocument4 pages60Si2Mn Spring Steel PDFShubhamPas encore d'évaluation

- Metal Pipe SystemsDocument14 pagesMetal Pipe SystemsAthanasoulis KostasPas encore d'évaluation

- Assab MM40 140331Document8 pagesAssab MM40 140331underscore1992Pas encore d'évaluation

- Cosmos Alminium-Technical SpecificationsDocument2 pagesCosmos Alminium-Technical SpecificationsmindsopenPas encore d'évaluation

- Industrial Steels Properties & MachiningDocument68 pagesIndustrial Steels Properties & Machiningsav33Pas encore d'évaluation

- 014 ToolsteelDocument36 pages014 ToolsteelSamrat SinghPas encore d'évaluation

- Electrodes GuideDocument4 pagesElectrodes GuideGregor SamsaPas encore d'évaluation

- 625 Alloy PowderDocument3 pages625 Alloy PowderSuperalloys GaoPas encore d'évaluation

- Assab TableDocument8 pagesAssab TableIhfan MohdPas encore d'évaluation

- Tapping Feed and Speed Viking Drill and ToolDocument1 pageTapping Feed and Speed Viking Drill and ToolDaniele TropepePas encore d'évaluation

- Importers, Stockiest & Suppliers of Ferrous, Non Ferrous Metals & Industrial Raw MaterialsDocument22 pagesImporters, Stockiest & Suppliers of Ferrous, Non Ferrous Metals & Industrial Raw MaterialsVvipul MaheshwariPas encore d'évaluation

- Material Grades enDocument30 pagesMaterial Grades enEmmanuel Lugo BeltranPas encore d'évaluation

- CA65 PR11: For Stainless Steel MachiningDocument12 pagesCA65 PR11: For Stainless Steel MachiningmachineCanPas encore d'évaluation

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinPas encore d'évaluation

- Lanmentodanova Class Epc9025Document8 pagesLanmentodanova Class Epc9025Ardeleana TisaPas encore d'évaluation

- 3-1 Steel-BarsDocument29 pages3-1 Steel-BarsKarl Jade LabucayPas encore d'évaluation

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsPas encore d'évaluation

- Tata Steel Cutting Edges GuideDocument2 pagesTata Steel Cutting Edges GuideKen SmithPas encore d'évaluation

- Knock OUT: IntroducingDocument10 pagesKnock OUT: IntroducingMuhammad QusyairiPas encore d'évaluation

- TurningDocument64 pagesTurningSerhat DoğandemirPas encore d'évaluation

- Brand new NC3000 series Wide roughing coverage turning grade for steel and stainless steelDocument4 pagesBrand new NC3000 series Wide roughing coverage turning grade for steel and stainless steeldemoracingeduPas encore d'évaluation

- Plates PDFDocument10 pagesPlates PDFkarthiksaadhanaPas encore d'évaluation

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigPas encore d'évaluation

- POSCO Korea - Galvanized SheetDocument27 pagesPOSCO Korea - Galvanized SheetFrancis BoeyPas encore d'évaluation

- week9Document60 pagesweek9Belmonte, Jhon Romel C.Pas encore d'évaluation

- Alkyl Phenolic Resin - 1 (TDS) PDFDocument1 pageAlkyl Phenolic Resin - 1 (TDS) PDFflytorahulPas encore d'évaluation

- Goods Rates Booklet 03july2017Document176 pagesGoods Rates Booklet 03july2017Vaishnavi JayakumarPas encore d'évaluation

- Srma Steel News: Steel Re-Rolling Mills Association of IndiaDocument20 pagesSrma Steel News: Steel Re-Rolling Mills Association of Indiaflytorahul100% (1)

- Mechemco - R-30102017 PDFDocument7 pagesMechemco - R-30102017 PDFflytorahulPas encore d'évaluation

- SERIE 80M20 - 2C: Wing Style ComponentsDocument8 pagesSERIE 80M20 - 2C: Wing Style ComponentsflytorahulPas encore d'évaluation

- Heavy equipment swing bearing replacement guideDocument2 pagesHeavy equipment swing bearing replacement guideflytorahul100% (1)

- Airline Mobile Marine BrochureDocument16 pagesAirline Mobile Marine BrochureflytorahulPas encore d'évaluation

- Exe Summ RajatCement Eng PDFDocument12 pagesExe Summ RajatCement Eng PDFflytorahulPas encore d'évaluation

- List of Sanctioned Cases Under IIPP 98th SLCDocument43 pagesList of Sanctioned Cases Under IIPP 98th SLCflytorahulPas encore d'évaluation

- Tariff Schedule for FY 2018-19Document29 pagesTariff Schedule for FY 2018-19flytorahulPas encore d'évaluation

- Commercial Vehicle Gearbox Main Shaft AssemblyDocument12 pagesCommercial Vehicle Gearbox Main Shaft AssemblyflytorahulPas encore d'évaluation

- WipexDocument20 pagesWipexflytorahulPas encore d'évaluation

- JSPL Hydra InquiryDocument5 pagesJSPL Hydra InquiryflytorahulPas encore d'évaluation

- RaipurDocument9 pagesRaipurflytorahulPas encore d'évaluation

- Ac Spares OrderDocument2 pagesAc Spares OrderflytorahulPas encore d'évaluation

- Us Er Plugged in The Last MileDocument16 pagesUs Er Plugged in The Last MileflytorahulPas encore d'évaluation

- Latest Supreme Court ruling on cruelty and divorceDocument5 pagesLatest Supreme Court ruling on cruelty and divorceflytorahulPas encore d'évaluation

- Replacement Spare Parts For ZF: Made in ItalyDocument29 pagesReplacement Spare Parts For ZF: Made in Italyflytorahul100% (2)

- HSN Code DetailsDocument6 pagesHSN Code DetailsflytorahulPas encore d'évaluation

- Nit 1Document29 pagesNit 1flytorahulPas encore d'évaluation

- Ag13034 Ag Cat Uk WebDocument172 pagesAg13034 Ag Cat Uk WebflytorahulPas encore d'évaluation

- Alfacurrate AAA PMS Jul16Document39 pagesAlfacurrate AAA PMS Jul16flytorahulPas encore d'évaluation

- 00 ConversionsDocument28 pages00 ConversionsrandyooiscribdPas encore d'évaluation

- Crisil Analysis 50 Leading SmesDocument64 pagesCrisil Analysis 50 Leading Smesflytorahul100% (1)

- NGZAM125-Product Release GuideDocument4 pagesNGZAM125-Product Release GuideIshmael WoolooPas encore d'évaluation

- Is 1730Document11 pagesIs 1730maheshkbandari0% (1)

- Literfue SurveyDocument8 pagesLiterfue SurveyAravind Raj SPas encore d'évaluation

- Att - 2-1 - DS-103-0001-1 - Engineering Specification For Pressure VesselsDocument78 pagesAtt - 2-1 - DS-103-0001-1 - Engineering Specification For Pressure VesselsDinh Nguyen DaoPas encore d'évaluation

- 300 Series: FLAT Metal Hinge WITH BORE Right ThroughDocument2 pages300 Series: FLAT Metal Hinge WITH BORE Right ThroughbenciusilviuPas encore d'évaluation

- DETERMINATIN OF THECONTENTOfDELTAFERRITE IN AUSTENITIC STAINLESS STEEL NITRONIC 60 PDFDocument4 pagesDETERMINATIN OF THECONTENTOfDELTAFERRITE IN AUSTENITIC STAINLESS STEEL NITRONIC 60 PDFEmad A.AhmadPas encore d'évaluation

- Astm 4140Document3 pagesAstm 4140Ramiz KhanPas encore d'évaluation

- D11 Caterpillar Ripper TipDocument2 pagesD11 Caterpillar Ripper TipMax SashikhinPas encore d'évaluation

- Welding Technology SyllabusDocument1 pageWelding Technology SyllabusShankaranarayanan100% (1)

- Elkem FoundryDocument4 pagesElkem Foundrymelara2338Pas encore d'évaluation

- Formula Weld CalculateDocument6 pagesFormula Weld CalculateHoangPas encore d'évaluation

- Cutting oil drilling tapping technical sheetDocument1 pageCutting oil drilling tapping technical sheetgopalakrishna100% (1)

- Tig 200P AcdcDocument36 pagesTig 200P AcdcAlejandro CKPas encore d'évaluation

- BS Iso 13899-2 2005Document20 pagesBS Iso 13899-2 2005Wan Cheung LaiPas encore d'évaluation

- Bab 12 - Nota A+Document7 pagesBab 12 - Nota A+Azemi AhmadPas encore d'évaluation

- ISO 898-1 Mechanical Properties of Metric FastenersDocument2 pagesISO 898-1 Mechanical Properties of Metric Fastenersshafie.buangPas encore d'évaluation

- Weller Soldering Tips BrochureDocument20 pagesWeller Soldering Tips Brochurehaha2012Pas encore d'évaluation

- Ashish Bhateja, Aditya Varma, Ashish Kashyap and Bhupinder Singh _ TheStudy the Effect on the Hardness of Three Sample Grades of Tool Steel i.e. En-31, En-8, And D3 After Heat Treatment Processes Such As Annealing, Normalizing, and Hardening & TemperingDocument7 pagesAshish Bhateja, Aditya Varma, Ashish Kashyap and Bhupinder Singh _ TheStudy the Effect on the Hardness of Three Sample Grades of Tool Steel i.e. En-31, En-8, And D3 After Heat Treatment Processes Such As Annealing, Normalizing, and Hardening & TemperingProf.Bhateja AshishPas encore d'évaluation

- Catalogo Machuelos Threading Tools To Jis StandardDocument68 pagesCatalogo Machuelos Threading Tools To Jis StandardnabilahanakhairunnidaPas encore d'évaluation

- High-Strength Low-Alloy (HSLA) Steels For Cold Forming: DescriptionDocument20 pagesHigh-Strength Low-Alloy (HSLA) Steels For Cold Forming: Descriptionnandi_engineerPas encore d'évaluation

- Bapp 14399 9 Dti Washer AssemblyDocument8 pagesBapp 14399 9 Dti Washer AssemblySUMANTAPas encore d'évaluation

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahPas encore d'évaluation

- NC-Code MillingDocument6 pagesNC-Code MillingCoeg MemoriesPas encore d'évaluation

- Study of Factors Causing Alpha Case Formation on Heat Treated Ti-6-4 AlloyDocument3 pagesStudy of Factors Causing Alpha Case Formation on Heat Treated Ti-6-4 AlloyWK LamPas encore d'évaluation

- A Study On Zirconium Rich Uranium-Zirconium Alloys PDFDocument8 pagesA Study On Zirconium Rich Uranium-Zirconium Alloys PDFOmar VillanuevaPas encore d'évaluation

- Standard Info Malleable Fittings PDFDocument6 pagesStandard Info Malleable Fittings PDFKaran AggarwalPas encore d'évaluation

- List Harga ConsumbaleDocument1 pageList Harga ConsumbaleYusuf Azizi RahmanPas encore d'évaluation