Académique Documents

Professionnel Documents

Culture Documents

Assessment Task 2

Transféré par

Lê Ngọc TúCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assessment Task 2

Transféré par

Lê Ngọc TúDroits d'auteur :

Formats disponibles

Assessment Task 2

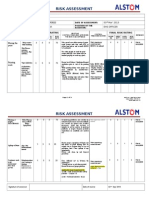

Prepare a Risk Register for your organisation or selected Division/ area and document this process. Include a copy of the risk assessment methodology that

was used to assess risk.

Area: Chemical room

Function/Activity :

Chemical Room

Complied By:

Shristee Thapaliya

Date:

10-05-12

15-05-12

Reviewed by:

Jack M

Date:

15-05-12

Date of Risk Review:

Reference

no

Risk

Hazard Source

Impact

Likelihood

Risk

Rating

Chemical Exposure- acute or

chronic i.e

Risk Controls

Residual

Risk

rating

Risk Control

Priority

Assigned

2XD

Low Risk

Subscribe Chemwatch for MSDS manifest and inventory system.

Mechanical ventilation to be installed in the chemical room

Use of appropriate PPE while handling chemicals i.e mask (Refer

to MSDS of the particular chemical).

First aid Kit to be provided in the chemical room.

Employee health monitoring to be conducted annually.

4

Inhalation

E

(Extreme

Risk)

Lock the chemical room and key to be given only to relevant

staff.

Install a sign," authorised personnel only" in the door of

chemical room.

Only purchase quantities immediately required. The amount of

dangerous goods must not exceed the maximum permitted

amounts for minor quantities detailed in the Dangerous Goods

Act, including that which is currently in stock within a company

Chemical management training to all the relevant staff.

Use of appropriate PPE while handling chemicals (Gloves, long

sleeve, apron). (Refer to MSDS of the particular chemical).

Absorption

E

(Extreme

Risk)

Eye wash and emergency shower to be installed in the chemical

room

2XD

Low Risk

3XD

Moderate

Risk

3XD

Moderate

Risk

2XD

Low Risk

Chemical management training to all the relevant staff.

Do not wear wet clothing while handling the chemical.

Subscribe Chemwatch for MSDS manifest and inventory system.

MSDS will be available in chemical room for all the chemicals.

Chemical management training to all the relevant staff.

Ingestion

E

(Extreme

Risk)

Ensure all the chemicals are correctly labelled.

Only authorised person access to the chemical room.

Eating, drinking prohibited in the chemical room. Staff to wash

their hands and face before eating, drinking and smoking.

Contact with eye

Fire and/or explosion throughincorrect storage, handling,

labelling or mixing of chemicals

E

(Exteme

Risk)

Eye wash and emergency shower to be installed in the chemical

room

Chemical management training to all the relevant staff.

Use of appropriate PPE while handling chemicals i.e eye

protection(Refer to MSDS of the particular chemical).

Fire Extinguisher to be installed in the chemical room

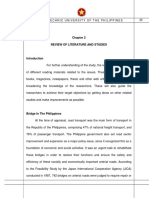

3

H (High

Risk)

Purpose built storage areas for cylinders compressed gases,

outside in the compound of Sydney Fish Market.

Only purchase quantities immediately required. The amount of

dangerous goods must not exceed the maximum permitted

amounts for minor quantities detailed in the Dangerous Goods

Act, including that which is currently in stock within a company

Correct labelling, storage and segregation of chemicals to be

implemented.

Chemical management training to all the relevant staff.

Smoking is prohibited in the chemical room.

Do not reuse the chemical container.

All the chemicals will be stored on spill contaminate pallets/

trays.

Environmental contamination

due to accidental leakage, spills,

emissions:

E

(Extreme

Risk)

Only purchase quantities immediately required. The amount of

dangerous goods must not exceed the maximum permitted

amounts for minor quantities detailed in the Dangerous Goods

Act, including that which is currently in stock within a company

2XD (L)

Low Risk

3XD (M)

Moderate

Risk

Review the Emergency procedure to include accidental spillage

and release of chemical

Check regularly for leaks and damage in the containers.

Chemical management training to all the relevant staff.

Spill kit to be kept in chemical room.

Electrical equipments in

chemical room-

Use of faulty equipments/

appliances

Use of uncertified

electrical equipment/appliances

Pre-purchase safety considerations; SFM pre purchase checklist

must be completed before buying any equipments or tools.

5

E

(Extreme

Risk)

Visual inspections for damage prior to use

Scheduled testing and tagging of all portable electrical

equipment

Tag out and remove from service for any damaged or faulty

equipment.

Qualified and competent electrical workers for design,

manufacture and testing.

Electrical installation is done only by licensed electricians

Use of RCDs

Manual Handling

Manual handling training to all relevant staff

Lifting & Carrying of chemical

containers ( 20-100 Lit)

5

Mechanical aids and lifting devices for lifting and transporting

chemicals (trolleys hoist, forklift etc).

3

H (High

risk)

Reduce the size of the chemical containers (50 Lit container

Maximum)

2XD (L)

Low Risk

2XD (L)

Low Risk

2XD (L)

Low Risk

All the chemicals will be stored below the shoulder height.

Team lifting for carrying the chemical containers when required.

Chemical room design &

Housekeeping

Regular cleaning of the room.

Poor storage area

6

Inadequate lighting

H (High

risk)

Ensure emergency exit are not blocked by chemical containers or

anything at anytime.

Regular Inspection done during workplace inspection.

Emergency access & Egress

Emergency Evacuation Map to be posted in the chemical room.

Doors to be locked at all the times; key is accessed to relevant

person.

unauthorised person access to

chemical room

H (High

risk)

Only authorised person sign to be posted on the door.

Haz-chem sign to be installed on the door.

Appendix-1 Risk Ranking Chart

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- ENV18 Aspects Register Procedure 2014 - UpdatedDocument5 pagesENV18 Aspects Register Procedure 2014 - UpdatedsametggtPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Impacts of HazardsDocument10 pagesImpacts of HazardsCharline A. RadislaoPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- MSDS PyridineDocument4 pagesMSDS PyridineSiddhant ChhabraPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- TH I Gian Làm Bài 150'Document5 pagesTH I Gian Làm Bài 150'THỌ NGUYỄN VĂNPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Why It Is Needed: The Hns ConventionDocument6 pagesWhy It Is Needed: The Hns ConventionKarina ChamPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Teoh Zi Wei 0323372 Vivian Tay 0323869 Vinnie Tan 0323706 Yeoh Sin Yuen 0323737 Tey Cheng Fern 0323912Document22 pagesTeoh Zi Wei 0323372 Vivian Tay 0323869 Vinnie Tan 0323706 Yeoh Sin Yuen 0323737 Tey Cheng Fern 0323912api-292027950Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Nef Upper Endtest ADocument8 pagesNef Upper Endtest ACarlos JúlioPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Electronic Waste Essay LessonDocument7 pagesElectronic Waste Essay LessonAna Carnero BuenoPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Case Study: ProblemDocument2 pagesCase Study: ProblemArashdeep SinghPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- NSTP 2Document7 pagesNSTP 2Andrew SanchezPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Painting WorksDocument2 pagesPainting WorksAhoyAoaPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Prevention of Flood in Brgy. 293, Binondo, Manila Through Waste ManagementDocument55 pagesPrevention of Flood in Brgy. 293, Binondo, Manila Through Waste ManagementSidney MarianoPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Methyl Cellulose MsdsDocument6 pagesMethyl Cellulose MsdsKenan FengPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Argumentative EssayDocument4 pagesArgumentative Essayapi-44415045233% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Paint Master Bonding Liquid - SDSDocument3 pagesPaint Master Bonding Liquid - SDSMichael JoudalPas encore d'évaluation

- Cause and Effect DiagramDocument3 pagesCause and Effect DiagramSomya Harsh100% (3)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Clauses of ConcessionDocument2 pagesClauses of ConcessionNancy Bedros100% (1)

- Methods and Devices For The Prevention of Backflow and Back-SiphonageDocument9 pagesMethods and Devices For The Prevention of Backflow and Back-SiphonagesauroPas encore d'évaluation

- FOSC-R Training: US Coast Guard Federal On-Scene Coordinator RepresentativeDocument12 pagesFOSC-R Training: US Coast Guard Federal On-Scene Coordinator Representativediegocely700615Pas encore d'évaluation

- Thesis TitleDocument12 pagesThesis TitleVincent Adolph Caranog FrigillanaPas encore d'évaluation

- Environmental: Systems SocietiesDocument19 pagesEnvironmental: Systems SocietiesVIVIANA LISETTE MEDINA NARANJOPas encore d'évaluation

- Unit 1: Atmosphere, Environment and Climate ChangeDocument24 pagesUnit 1: Atmosphere, Environment and Climate Changenidhi140286Pas encore d'évaluation

- Related Studies About BridgesDocument38 pagesRelated Studies About BridgesJenica Cariño AcuñaPas encore d'évaluation

- Bo de Thi Lop 8 Cuoi Ki 2 Mon Tieng AnhDocument35 pagesBo de Thi Lop 8 Cuoi Ki 2 Mon Tieng AnhLe Thi Luyen QP1138Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Rio de Janeiro Climate Change Case StudyDocument22 pagesRio de Janeiro Climate Change Case StudyCharlesLaffiteauPas encore d'évaluation

- Acid Content of VinegarDocument5 pagesAcid Content of VinegaramyPas encore d'évaluation

- 10 Questions For Safe Work in Confined SpacesDocument2 pages10 Questions For Safe Work in Confined Spacesdilesh100% (2)

- EnviscieDocument20 pagesEnviscieAnGel Jay PonchinlanPas encore d'évaluation

- NYC B14 FEMA - Ted Monette FDR - Draft Interview QuestionsDocument3 pagesNYC B14 FEMA - Ted Monette FDR - Draft Interview Questions9/11 Document ArchivePas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Acros Sodium SulfateDocument4 pagesAcros Sodium SulfateMuhammad HairuddinPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)