Académique Documents

Professionnel Documents

Culture Documents

Installation LG

Transféré par

khantoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Installation LG

Transféré par

khantoDroits d'auteur :

Formats disponibles

INSTALL-MHS/LG: 99901230: 20070220

PARTS-1

Crane Installation Manual

Model 2.5/18

Model 3.2/23

Model 4/29

Model 5/35

Model 6/45

Model 7/51

Model 9/63

Model 11/76

Model 12/89

Model 15/113

Model 16/117

Model 18/129

Model 20/141

Model 22/155

Model 25/180

Model 28/198

Model 34/235

Model 37/266

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

641-923-3711

TECHNICAL SUPPORT FAX: 641-923-2424

MANUAL PART NUMBER: 99901230

Iowa Mold Tooling Co., Inc. is an Oshkosh Truck Corporation company.

INSTALL-MHS/LG: 99901230:

19990707

PARTS-2

In addition to the information presented in this manual,

read and understand the IMT Crane Operator's Safety

Manual before operating or performing any maintenance

on your crane.

REVISIONS LIST

DATE

20010618

20020312

LOCATION

p.23

p. 6-9, 15

20030522

20040930

20050728

20070220

p. 6-9, 15

p. 4,6,8

COVER

DESCRIPTION OF CHANGE

REMOVED PAGE 23

CHANGED TORQUE SPECIFICATIONS. RAISED SPECS TO MEET IMT STANDARD TORQUE

VALUES, AND ADDED NOTE IN REFERENCE TO STOP BLOCKS.

REVERTED TO ORIGINAL TORQUE VALUES.

UPDATED PER REVISED OEM MANUAL.

UPDATED TORQUES, ADDED HARDENED WASHERS FOR MOUNTING.

UPDATED WITH OSHKOSH INFORMATION

INSTALL-MHS/LG: 99901230:

20010618

PARTS-3

TABLE OF CONTENTS

REVISIONS LIST ............................................................................ 2

INTRODUCTION ............................................................................ 3

MOUNTING TYPES ........................................................................ 4

MOUNTING BOLT LOCATIONS ..................................................... 5

MOUNTING FITTINGS ................................................................... 6

MOUNTING FITTINGS (CONT) ...................................................... 7

MOUNTING BOLTS INFORMATION .............................................. 8

WELDING OF STOP ....................................................................... 9

CHASSIS REINFORCEMENT ..................................................... 10

INSTALLATION WITHOUT CHASSIS REINFORCEMENT ......... 12

INSTALLATION BEHIND CAB ..................................................... 13

FRONT MOUNTED CRANE PLUS TIPPING GEAR .................... 14

REAR MOUNTED CRANE ........................................................... 15

FLAT IRON REINFORCEMENT ................................................... 16

STABILITY CALCULATION .......................................................... 17

SUPPLEMENT TO STABILITY CALCULATIONS ........................ 20

PUMP & HYDRAULIC SYSTEM .................................................. 22

PUMP MOUNTING ....................................................................... 23

PUMP HYDRAULIC LINES .......................................................... 23

SYSTEM CHECK ......................................................................... 24

INTRODUCTION

A truck chassis and hydraulically operated crane

(loader) are advanced technical products. When these

products are combined into one efficient tool, it is

important that the installation of the crane on the

chassis, reinforcement of the chassis, and choice of

pump and hydraulic connections be performed in a

professional and correct manner.

Installation of the crane (loader), and reinforcement of

the chassis, must be performed in accordance with

the instructions of the carrier vehicle manufacturer

and the information provided in this Installation

Manual. The crane must always be installed on the

chassis with the suspension traverse pointing

forward. This applies to rear mounted cranes also.

WARNING

FAILURE TO ADHERE TO THE INSTRUCTIONS

PROVIDED BY THE VEHICLE AND CRANE

MANUFACTURER CAN RESULT IN EQUIPMENT

FAILURE, SERIOUS INJURY, OR DEATH.

WARNING

READ AND UNDERSTAND THE IMT CRANE

OPERATORS SAFETY MANUAL AND ALL OTHER

APPLICABLE INSTRUCTION MANUALS WHICH

ACCOMPANIED YOUR CRANE. FAILURE TO DO SO

MANY RESULT IN EQUIPMENT FAILURE, SERIOUS

INJURY, OR DEATH.

INSTALL-MHS/LG: 99901230: 20050801

MOUNTING TYPES

MOUNTING

PARTS-4

TYPE

KIT NO.

BOLT SIZE

PLACES

T0N-M

1260080

M20X500

2-4

66598401

7/8"X710

6.5-12

MODEL

350

Older types can be used

instead of 6659800

68814004

6659780

M30X600

M30X710

M30X1050

1

4

7/8"X710

19.5-21.5

2000/2220

1900-L

4.1-6.2

400

500

680

66598002

7/8"X710

M30X600

2

2

9.1

6659820

M30X600

7.1-13.6

1144

760, 910, 1060, 1110/

1220, 1250/1320, 1460,

900-T/1020-T, 1110-T/

66618105

6882120

M30X1050

M30X850

M30X950

4

2

M30X850

M30X950

M30X1050

2

4

32.5-37

1220-T

3450/7620

24.9-27.3

2500/2820

NOTE:

Hardened washers (Washer-Flat M30 Hardened FZV) added to type D mounting kits effective 8/05.

Place washers between nut and plate at both top and bottom of mount. Refer to mounting kit drawings

in 25-28 tm Parts Manual (99903217) and 34-37 tm Parts Manual (99903242) for details.

E

68812203

M30X600

M30X710

1

3

13.8-17.8

1560

1680/1820

1580-L

1580-T/1720-T

INSTALL-MHS/LG: 99901230:

19990707

MOUNTING BOLT LOCATIONS

PARTS-5

INSTALL-MHS/LG: 99901230: 20050801

PARTS-6

MOUNTING FITTINGS

0.7" (20 mm)

217 ft-lb (30 kg/m)

MOUNTING FITTINGS, TYPE A

FIGURE 5

(NOT RECOMMENDED)

2"

(50 mm)

M14 (Kval 8.8)

1.18" (30 mm) 360 ft-lb (50 kg/m)

.875" (22 mm) 253 ft-lb (35 kg/m)

87 ft-lb

(12 kg/m)

MOUNTING FITTINGS, TYPE C

FIGURE 7

FIGURE 6

0.2" (5 mm)

2"

(50 mm)

M14 (Kval. 8.8)

87 ft-lb

(12 kg/m)

FIGURE 8

MOUNTING FITTINGS,

TYPE B & D

NOTE: NO

WELDING ON

CHASSIS

FRAME!

H

R5

1.18" (30

(50ft-lb

kg/m)

30 mm)

mm: 360

450ft-lb

+/- 45

.875" (22 mm) (610

253 ft-lb

(35Nm)

kg/m)

+/- 60

INSTALL-MHS/LG: 99901230:

20040930

PARTS-7

MOUNTING FITTINGS (CONT)

Figure 9

M14: 115 Nm (12 kg/m)

M16: 196 Nm (20 kg/m)

Min. 2" (50 mm)

M30x2 500 Nm (51 kg/m)

INSTALL-MHS/LG: 99901230:

20050801

PARTS-8

MOUNTING BOLTS INFORMATION

MOUNTING FITTINGS-TYPE A

Use 20mm mounting bolts, bracketed to the frame

with M14 bolts, 4 places. See Fig. 5.

The mounting bolts are manufactured from heat

treated steel of high quality. They MUST NOT be bent

or heated. The threads have been rolled and must not

be lengthened by means of cutting. Doing so will

weaken the bolt. Nuts must never be secured by

means of tack welding.

MOUNTING FITTINGS-TYPE B

A combination of types C and D. The single bolt fitting

is fastened using M14 bolts, 6 places. The twin bolt

fitting has a cross bar under the chassis. The single

bolt fitting is not raised above the frame as mentioned

below, but the crane must rest on the frame.

The mounting fittings are bolted onto the chassis

frame via driven bolt connections. Special mounting

bolts, on which the smooth part of the shaft is able to

reach almost through the mounting fitting and the

chassis, must be used. Drilling diameter is 13.8mm.

Place a hard washer (HB 200) under the head of the

bolt and the nut.

MOUNTING FITTINGS-TYPE C

See Fig. 6 and 7. Use 7/8" or 30mm mounting bolts,

fastened using M14 bolts, 6 places. The mounting

fitting is raised until there is a distance of

approximately 0.2" (5mm) between the loader and the

frame. See Fig. 7.

MOUNTING FITTINGS-TYPE D

See Fig. 8. Use 7/8" or 30mm mounting bolts, 2

places, and a cross bar under the chassis.

The height of the spacer inside the side member of

the chassis must be carefully adjusted to fit between

the flanges, and the four corners rounded 0.2"R (R5).

You must prevent the spacer from turning by locking

it to the subframe using a piece of flat iron. The flat

iron must not be welded onto the chassis. The edges

of the cross bar towards the chassis are rounded 0.2"

(R5) to prevent wear and tear on the chassis.

Fastening must take place in stages in order for the

cross bars to press evenly against the lower side of

the side member.

LENGTH "

7/8"UNF X 14

15.75(400)

19.69(500)

66 58 974

66 61 624

M30X2.0

M20X2.5

12 61 304

23.62(600)

27.95(710)

66 61 614

68 86 684

68 86 874

33.46(850)

37.40(950)

66 557 614

66 58 684

68 86 884

68 86 894

41.34(1050)

47.24 (1200)

TORQUE

68 86 904

68 86 914

340 Nm (35 kg-m) 450 +/- 45 ft-lb

(610 +/- 60Nm)

BOLT SIZE X L PART NO.

A

Washer HB200

M14X35 (1.38)

M14X40 (1.57)

31 980

31 497

13mm (.51")

18mm (.71")

M14X45 (1.77)

M14X50 (1.97)

31 981

31 498

23mm (.91")

25mm (.98")

M14X60 (2.36)

M16X35 (1.38)

31 499

31 982

35mm (1.38")

13mm (.51")

M16X40 (1.57)

28/15X2

31 496

31 111

16mm (.63")

30/17X3

31 103

M14

M16

30 863

30 864

Torque

Nut

87 ft-lbs (12 kg-m)

145 ft-lbs (20 kg-m)

INSTALL-MHS/LG: 99901230:

20030522

WELDING OF STOP

To prevent the loader from moving on the chassis,

stops (1) are welded on, when the loader has been

mounted on the chassis. The position of the stops are

shown in Fig. 10 and 11.

When the mounting bolts have been tightened, the

square washers are tack welded to the suspension

traverse and the mounting pockets of the base, not to

the base itself.

PARTS-9

INSTALL-MHS/LG: 99901230:

19990707

PARTS-10

CHASSIS REINFORCEMENT

In most cases it is necessary to reinforce the chassis

so that it can sustain the strain applied by the crane.

The strain from the crane represents a bending

moment on the chassis approximately corresponding

to the load moment of the crane, plus 15%. Thus, a

necessary reinforcement is calculated on that basis.

The dimensions of the chassis frame being taken into

consideration.

It is a general rule for all subframes that if the crane

is fastened against the frame, you must place a wear

plate as shown in Fig. 13. If the crane is raised until it

is free of the frame, as shown in Fig. 7, the wear plate

is not needed.

Fig. 12

To maintain the flexibility of the chassis, the

subframe should be fastened to one end only, other

fastenings must be flexible. Where great demands are

made to the strength, the subframe and the chassis

could be bolted together with fixed strap-plates in the

total length of the frame.

The subframe for crane, body hoist, tipping gear, and

for coupling for semi-trailer, etc., must always be in

one piece, and preferably with the same crosssection in the whole length.

If the cross-sections of the subframe are different,

the crossing must be smooth, see Fig. 12, and the

welding must be done very carefully, and all the way

through.

INSTALL-MHS/LG: 99901230:

19990707

PARTS-11

INSTALL-MHS/LG: 99901230:

19990707

INSTALLATION WITHOUT CHASSIS

REINFORCEMENT

If no reinforcement of the chassis is necessary, the

crane may be mounted as shown in Fig. 13, 14 and

15.

Fig. 13.

The crane must never rest directly on the chassis

frame, but should be placed on a wear plate of .39"

(10mm) flat iron. The length (L) should be 7.87"

(200mm) longer than the distance between the

crane's mounting bolts. The width (B) equals the width

of the side member less .59" (15mm). When welding,

avoid damage to the edges of the side member.

This mounting method is only recommended for small

cranes, and you must be sure that welding on the

chassis frame is accepted by the authorities and the

truck manufacturer.

PARTS-12

Fig. 14.

If welding is not allowed, wear plate can be made as

shown. The length (L) equals the distance between

the mounting bolts, plus 7.87" (200mm). For cranes

up to 7 ton-meters, an .31" (8mm) plate is used. For

larger cranes the plate should be .39" (10mm) thick. It

is often necessary to make cutouts in the plate to

accomodate bolts, struts, etc., on the chassis.

Fig. 15.

If the crane has to be raised above the chassis

because of gear box, etc., the crane is mounted on a

short subframe as shown in Fig. 15. For cranes up to

10 ton-meters, a box section of .31" (8mm) thick

material is used. For cranes of 10 ton-meters or more,

the thickness of material must be .39" (10mm). The

sections are tapered 30 at both ends, and two Usections - a bit lower than the box section and of .24"

(6mm) thick material - are welded between them. The

lower edges of the subframe should be rounded .2"R

(R5) to prevent wear and tear on the chassis.

INSTALL-MHS/LG: 99901230:

19990707

PARTS-13

INSTALLATION BEHIND CAB

The drawing below shows mounting of subframe

fastened to the chassis by means of strap-plates in

front and flexible fastenings at the rear. The subframe

is made of U-sections, and between these, traverse

U-sectons, which are placed a bit lower and have a

thickness of material of .24" (6mm), are welded. A Usection is placed as close as possible to each

mounting bolt. From the crane and to the rear, the Usections are placed at a distance of 78.7" (2m)

maximum. From the rear mounting bolt and to the

rear, the subframe is fastened by means of a strapplate (see Fig. 16) at a distance of approximately

31.5" (0.8m), and then by means of a flexible

fastening (see Fig. 17) at a distance of 47.24" (1.2m)

maximum to the rear, as shown on the drawing. If the

distance from the front mounting bolt to the front edge

of the subframe is maore than 7.87" (200mm), you

should mount a strap-plate.

INSTALL-MHS/LG: 99901230:

19990707

PARTS-14

FRONT MOUNTED CRANE PLUS

TIPPING GEAR

The subframe of the tipping gear must be safely

fastened to the chassis around the rear bearing.

Therefore, the subframe must be fastened from the

rear to the spring suspension of the rear axle by

means of strap-plates (See Fig. 16) and further on by

means of flexible fastenings.

The mounting fittings of the crane must not be welded

onto the subframe. If large demands are made of the

reinforcement of the chassis, and the truck is mainly

used on even ground, strap-plates can be used along

the entire length, and mounting fittings can be welded

onto the subframe.

INSTALL-MHS/LG: 99901230:

20030522

PARTS-15

REAR MOUNTED CRANE

The subframe should be made of box sections to

ensure maximum stability when driving, and should

be made as described in the previous paragraph.

Traverse U-sections are welded between the box

sections at a mutual distance of 78.74" (2m)

maximum, though there must be a U-section by each

mounting bolt. If the loader is rear mounted the

stabilizer legs must face backwards. To the front

spring suspension of the rear axle the subframe must

be fastened to the frame by means of fixed strapplates. In front of this section flexible fastenings

should be used.

0.24"

(6 mm)

0.24"

(6 mm)

M14 (Kval. 8.8)

87 ft-lb

(12 kg/m)

253 ft-lb

(35 kg/m)

FIGURE 18

INSTALL-MHS/LG: 99901230:

19990707

FLAT IRON REINFORCEMENT

The drawing below shows reinforcement, mainly for

smaller cranes, and must only be used where welding

on the chassis is accepted by the authorities and the

truck manufacturer.

The drawing shows side member with flat iron

reinforcement welded on. In front the flat iron is

carried as far ahead as possible and tapered 30. On

the upper side of the side member the flat iron is

carried as far back as possible and on the lower side

to the rear spring suspension. The flat iron should be

about .59" (15mm) narrower than the side member

and is placed .39" (10mm) from the inner edge of the

side member. The welding is made as shown displaced on the inner side - and damage to the inner

edges of the side member should be avoided. On top

of the flat iron strip, a wear plate of .31" (8mm) flat

iron is placed as shown.

PARTS-16

INSTALL-MHS/LG: 99901230:

19990707

STABILITY CALCULATION

When a crane is mounted on a truck, it is necessary

to check the stability against overturning.

Note that the rules concerning installation of truck

mounted cranes may vary from one country to

another, and that this installation manual should be

regarded as a guide only. You should check the local

rules and take those into consideration. The truck

manufacturers often have special instructions for

mounting of extra equipment which must be complied

with, if the guarantee is to apply.

CRANE MOUNTED BEHIND CAB

Fig. 1 shows a truck with crane on which the outrigger

legs are extended. The supporting area is now formed

by the letters Q-R-S-T-U-V. If the load (PL) is swung

outside this area, the truck will be in danger of tilting.

Normally, this risk will be greatest when the boom is

in the shown position, at a right angle to line m

The stabilizing moment (MS)

can be determined as follows if the center of gravity

(G2) of the crane lies within the tilting line m:

MS = (PF x LF) + (PR x LR) + )G1 x LC) + (G2 (LC - H2))

If G2 lies outside the tilting line the last term of the

above equation is negative.

The tilting moment (MT) is determined as follows:

(MT) = PL x a

The safety factor against overturning must be:

MS

= > 1.25

MT

Crane and chassis are drawn on a suitable scale

(1:20). The dimensions are taken from drawings of the

chassis and the crane.

PARTS-17

INSTALL-MHS/LG: 99901230:

19990707

PARTS-18

If G lies within the tilting line m, following fomula is

used:

MS

(PF x LF) + (PR x LR) + (G1 x LC) + (G2 (LC - H2))

___ = ___________________________________________ = > 1.25

MT

PL x a

If G2 lies outside the tilting line the last term of the

above equation is negative.

If the chassis is short, the stability must be checked

with the boom pointing straight forward. The procedure

is the same as described above, and the tilting line

will equal the placing of the front axle PF

MS

(PR x A) + (G1 x Lc) + (G2 x (LC - H2))

___ = ___________________________________________ = > 1.25

MT

PL x a

Often, it will be impossible to obtain sufficient

stability in this boom position. Consequently, the best

solution would be to reduce the crane's slewing angle

to 200 covering the truck body.

INSTALL-MHS/LG: 99901230:

19990707

When the crane is mounted at the rear of the truck,

the supporting area will be a triangle. In consequence

of the flexibility of the chassis you cannot utilize PF.

The tilting lines are drawn through PF as shown.

The stabilizing moment (MS)

is determined as follows when G lies within tilting line

m:

MS = (PR x LB) + (G1 x LC) + (G2 x (LC - H2))

If G2 lies outside the tilting line the last term of the

above equation is negative.

The tilting moment (MT) is determined as follows:

M = PL x a

MS

___ => 1.4

MT

PARTS-19

INSTALL-MHS/LG: 99901230:

19990707

PARTS-20

If the chassis is short the stability should be checked

with the boom pointing straight backwards. Here we

get:

A number of countries now require a theoretical

safety factor in accordance with DIN 15019 and FEM

5.007:

MS

PF x (A + B) + (PR x B)

___ = _____________________ => 1.25

MT

(PL x L) + (G2 x H2)

Front mounted crane S = 1.25

Rear mounted crane S = 1.40

The dimensions H2 - G2 - G1 - f are shown in Technical

Information 313501 and 317902.

The dimensions PL - L - S are shown in the brochure.

SUPPLEMENT TO STABILITY

CALCULATIONS

The increasing demands from the authorities

regarding stabilty and the tendency to mount

proportionally larger cranes on vehicles of standard

gross weight mean that it is necessary to check the

theoretical stability before mounting the crane.

Fig. 3 Front mounted crane

MS

Stability moment

S = ___ = ________________

MV

Tilting moment

In such cases, the stability test is required to be

carried out with a stability load of 1.25 x PL + 0.1 x

G2, which applies to both front and rear mounted

cranes. (G2 is the weight of the boom).

If the stability requirement cannot be complied with

by means of the crane's outrigger legs, it may be

necessary to mount an extra outrigger beam. See Fig.

3 and 4.

INSTALL-MHS/LG: 99901230:

19990707

REAR MOUNTED CRANE

The stabilizing moment MS:

MS = (PF x LF) + (PR x LR) + (G1 x LC) + (G2 x (LC - H2))

The tilting moment:

MT = P L x a

PF and PR, the weight of the truck must be inclusive

of platform and permanent equipment.

PARTS-21

If four outrigger legs are used, it is necessary to

make the chassis torsion resistant in order for the

extra outrigger legs to transfer the moment. This is

done by making a subframe of RHS (Rectagular

Hollow Section) tubes supported by a transverse

bracing of corresponding profiles.

This is against the truck manufacturer's general

requirement for flexible chassis, and therefore, we

have to refer to the recommendations of the truck

manufacturer.

INSTALL-MHS/LG: 99901230:

19990707

PUMP & HYDRAULIC SYSTEM

It is important that the correct pump be chosen, and

that it is installed properly, in order for the crane to

work to full satisfaction.

If the pump chosen is too small, the crane will

operate slowly. If the pump is too large, the working

speed, and thus the shock factor on the crane is too

high, and the life expectancy of the unit will be

reduced. Furthermore, the generation of heat is

increased, and in some cases it may be difficult to

get enough torque from the carrier vehicle's engine.

PUMP SELECTION CHECKLIST

Determine the requirements of the pump

performance. The performance stated in the

Instruction Manual is effective performance at

working pressure of the crane.

Choose number of engine revolutions.

Choose gear ratio of PTO.

Choose the pump size according to the following

table.

If a suitable pump size is not found, choose the one

nearest your requirements, and change the number of

engine revolutions accordingly.

Check that the engine can perform the necessary

torque.

Check that the PTO and the drive shaft can transfer

the necessary torque.

Check that the regulator of the fuel pump operates at

the chosen number of revolutions

PARTS-22

WARNING

THE INSTALLER OF THE DRIVELINE MUST INSPECT

THE FINAL POSITION OF THE DRIVELINE TO

DETERMINE WHETHER ITS LOCATION PROVIDES

SUFFICIENT PROTECTION TO AN OPERATOR, OR

OTHER PERSONNEL, FROM HAZARDS ASSOCIATED

WITH A ROTATING DRIVELINE. IF PROTECTION IS

INSUFFICIENT, THE INSTALLATION OF A GUARD IS

REQUIRED. IF YOU ARE UNSURE OF METHODS TO

GUARD A ROTATING DRIVELINE, CALL IOWA MOLD

TOOLING CO., INC. FOR INSTRUCTIONS. FAILURE TO

DO SO MAY RESULT IN SERIOUS INJURY OR DEATH.

INSTALL-MHS/LG: 99901230: 20040930

PARTS-23

Volvo F1 - Determine the direction of rotation. If necessary, modify the rotation of the pump according

to Volvo instructions.

*)

CASAPPA CPL - Dual rotation pump

Normally 12/24V DC electric driven pump unit

INSTALL-MHS/LG: 99901230:

19990707

PUMP MOUNTING

Direct mounting of the pump on the PTO is the

simplest and most reliable solution.

PARTS-24

By mounting of double pumps on divider gearbox, the

gear ratio must be taken into consideration, as it

changes the speed of the pump and applies more

stress to the drive shaft. Before mounting of pump,

remove the seal of the drive shaft and plug the leakoil hole. Fill the gear housing with oil. Refer to the

pump manufacturer's instructions.

If the pump is mounted with drive shaft, the universal

joint yokes must be parallel, as shown.

PUMP HYDRAULIC LINES

By mounting of drive shaft the two angles B1 and B2

must be the same. The axle of the PTO and the axle

of the pump must be parallel.

This also means that if the engine tilts backward in

the chassis, the pump must be mounted with the

same slope.

SUCTION LINE

The suction line must be synthetic rubber hose with

steel coil insert, to prevent collapse of the hose when

bent. Dimension according to table.

MIN D

1-1/4" (32mm)

1-1/2" (38mm)

2" (50mm)

MAX FLOW Q gal(l)/MIN

6.6 (25)

9.2 (35)

17.2 (65)

PRESSURE PIPE

The pressure pipe is made of high-pressure hose of

dimension and quality according to the table below, or

of pipes indicated in the table. Pipe material must be

seamless steel, ST35.4 NBK annealed (DIN2391.2/

C).

Before starting, the pump housing must be filled with

hydraulic oil.

MIN D

HOSE

3/8"SAE 100 R2 AT

1/2"SAE 100 R2 AT

3/4"DIN 20023-4SP

PIPE

15X1.5

18X2

22X2.5

MAX FLOW

Q gal(l)/MIN

MAX FLOW

6.6 (25)

11.9 (45)

17.2 (65)

INSTALL-MHS/LG: 99901230:

19990707

NORMALLY MOUNTED CRANE

Pipe and hose connections must be made as short

as possible, and be placed with as few bends as

possible. Angular connections must be avoided on

the pressure pipe and banjo connections must not be

used. The suction line must fall down towards the

pump without upward bends, which may create air

pockets. The suction hose must be mounted

carefully, in order to avoid air being sucked into the

pump.

REAR MOUNTED CRANE

A separate tank with a capacity of approximately 1.5

to 2 times the pump performance must be mounted

close to the pump. The base of the crane cannot be

used, as the suction line will become too long and

create cavitation in the pump. The pressure pipe and

return pipe should be one dimension larger than

indicated in the table.

NOTE

THE BASE OF THE CRANE MUST ALWAYS BE

FILLED WITH HYDRAULIC OIL TO ENSURE

LUBRICATION AND TO AVOID CORROSION OF THE

ROTATION SYSTEM.

REAR MOUNTED DETACHABLE CRANE

The rear mounted detachable crane is connected

using quick-release couplings turned opposite each

other to prevent incorrect connection.

A safety valve (part no. 60 357) is mounted between

the pump and return pipe, close to the pump, to

protect the pump in the event that the quick-release

coupling is not connected. Opening pressure should

be 435 psi (30 bar) higher than the working pressure

of the crane.

A blow-off valve of 725 psi (50 bar) (part no. 12 43

614) is mounted in the return line of the crane

between the valve block and the quick-release

coupling to protect the system in the event the return

quick-release coupling is not connected.

CRANE MOUNTED 2-CIRCUIT HYDRAULIC

SYSTEM (TYPE TS)

Due to the larger volume of circulating oil, the crane's

standard oil tank and return filter will not be adequate,

therefore a separate oil tank should be mounted. The

capacity of the oil tank should be approximately 1.5

times larger than pump performance. See chart

below.

PARTS-25

SYSTEM CHECK

After the crane has been installed, check the

following:

1. Check that the oil tank is full and the crane is

lubricated. If a separate tank is installed, check that

the base of the crane has been filled with hydraulic

fluid.

2. Check that all functions of the crane are bled.

3. Check that the Serial Number placard is correct.

4. Check the pressure setting with a pressure gauge,

and that it corresponds to the crane's requirements.

5. Check that all pressure setting adjustment screws

are sealed.

6. Check all connections for tightness. Tighten if

necessary. Also check that hoses are free of

obstructions and not twisted. Check adjustment of

lateral play in the outrigger beams.

7. Load and function test.

8. Top up the hydraulic oil.

9. Remove unnecessary protective paper from hoses

and labels.

When the crane is delivered, the following should be

demonstrated:

1. Use of outrigger legs.

2. Operation of the crane.

3. Crane maintenance.

An explanation of these points is provided in the

Instruction Manual.

A linking of standard tank and separate tank is not

recommended. Remember to fill the tank in the base.

Oil tank with

suspension &

return filter

REF NO.

OIL CAPACITY

AVAIL. OIL VOLUME

HXWXL

0014270

GALLONS (LITERS)

23.8 (90)

GALLONS (LITERS)

16.4 (62)

INCHES (MM)

15.0X16.9X24.6 (380X430X625)

0014260

0014260

26.4 (100)

42.3 (160)

20.3 (77)

33.3 (126)

19.7X23.6X15.0 (500X600X380)

19.7X23.6X23.6 (500X600X600)

INSTALL-MHS/LG: 99901230:

20000707

PARTS-26

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

641-923-3711

TECHNICAL SUPPORT FAX: 641-923-2424

MANUAL PART NUMBER: 99901230

Vous aimerez peut-être aussi

- Bobcat Technical Information BulletinDocument2 pagesBobcat Technical Information BulletinheruPas encore d'évaluation

- Ansi Asabe Ad8759-1-1998 (R2013-01)Document7 pagesAnsi Asabe Ad8759-1-1998 (R2013-01)StephanPas encore d'évaluation

- Cylinder Liner ProjectionDocument4 pagesCylinder Liner ProjectionFernando Daniel Saez VillarrealPas encore d'évaluation

- Trailblazer 302 DieselDocument68 pagesTrailblazer 302 DieselAnonymous NzvN4PjPas encore d'évaluation

- New Holland L160, L170 Skid Steer Loader Service Repair ManualDocument21 pagesNew Holland L160, L170 Skid Steer Loader Service Repair ManualggjjjjotonesPas encore d'évaluation

- 1 Mbe4000 06aDocument38 pages1 Mbe4000 06azahar222Pas encore d'évaluation

- Series D: Product GuideDocument8 pagesSeries D: Product GuideFrank Felipe Cruz ChavezPas encore d'évaluation

- Maxitorq t308 ServiceDocument199 pagesMaxitorq t308 ServicePlanta Damiana2Pas encore d'évaluation

- Modelo 680A & BDocument20 pagesModelo 680A & BCarlos Enrique Vega OrtegaPas encore d'évaluation

- Caterpillar: Procedure To Repair Cylinder Block Pump Mounting Pad On 3406B, 3406C, 3406E, C15, and C-15 EnginesDocument3 pagesCaterpillar: Procedure To Repair Cylinder Block Pump Mounting Pad On 3406B, 3406C, 3406E, C15, and C-15 EnginesJavier Hector CayaPas encore d'évaluation

- (Parts Manual Magnum 325 4x4) PDFDocument72 pages(Parts Manual Magnum 325 4x4) PDFjose100% (2)

- Adjustment of The Compression BrakeDocument2 pagesAdjustment of The Compression BrakeCarlos Juarez ChungaPas encore d'évaluation

- 008-014 Coolant Thermostat HousingDocument3 pages008-014 Coolant Thermostat HousingYè WințPas encore d'évaluation

- TM55 2320 209-15-1 Transportability Guid 2.5to M35 SeriesDocument96 pagesTM55 2320 209-15-1 Transportability Guid 2.5to M35 SeriesdieudecafePas encore d'évaluation

- Ep 30ag 08 PDFDocument412 pagesEp 30ag 08 PDFRichardReveloPas encore d'évaluation

- Recommended Procedure For Cutting Brake Chamber Push-Rod: Service BulletinDocument2 pagesRecommended Procedure For Cutting Brake Chamber Push-Rod: Service BulletinFernando PadillaPas encore d'évaluation

- Ansi Asabe S207.12 - 2004-02Document11 pagesAnsi Asabe S207.12 - 2004-02Stephan100% (1)

- Jacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040BDocument4 pagesJacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040Bvasanth kumar100% (1)

- Axilok InstallatTuercasDocument1 pageAxilok InstallatTuercasalxsscabal100% (1)

- Inspeccion Visual de CojinetesDocument50 pagesInspeccion Visual de CojinetesMIGUEL EDUARDO HUAMAN POLARPas encore d'évaluation

- Pilgrims Rest: An Historical Novel Of A Pioneering Family's Struggle In 1870s South AfricaD'EverandPilgrims Rest: An Historical Novel Of A Pioneering Family's Struggle In 1870s South AfricaÉvaluation : 3 sur 5 étoiles3/5 (1)

- Fuel Injection Pump - Install - With Electronic GovernorDocument5 pagesFuel Injection Pump - Install - With Electronic Governoreshopmanual limaPas encore d'évaluation

- Heavyduty Kits Catalog 2017Document8 pagesHeavyduty Kits Catalog 2017panamapuro100% (1)

- Diagnostic Code Cross Reference: SMCS - 1900Document4 pagesDiagnostic Code Cross Reference: SMCS - 1900Handrean Yudya PratamaPas encore d'évaluation

- Alliance - Filter CatalogDocument82 pagesAlliance - Filter CatalogSamPas encore d'évaluation

- Wiring ComunicacionDocument4 pagesWiring ComunicacionHamilton MirandaPas encore d'évaluation

- Palfinger ETI 29/33/37Document2 pagesPalfinger ETI 29/33/37DarthCain0% (1)

- 6-55 Hydraulic Equipment Pump & Adapting PartsDocument4 pages6-55 Hydraulic Equipment Pump & Adapting PartsPaull SalasPas encore d'évaluation

- GM 3.0 LDocument36 pagesGM 3.0 Lmeyyiti01Pas encore d'évaluation

- Rainbird Isa 406Document44 pagesRainbird Isa 406RhianonCatillazPas encore d'évaluation

- mDRIVE - SPECIFICATIONSDocument7 pagesmDRIVE - SPECIFICATIONSvicente456Pas encore d'évaluation

- SB 214062Document2 pagesSB 214062api-19785517Pas encore d'évaluation

- LX279 With 48C Deck: Lawn Tractor 48" Convertible DeckDocument1 pageLX279 With 48C Deck: Lawn Tractor 48" Convertible DeckManuel Fernandez Mora0% (1)

- 2011 Mad PogDocument81 pages2011 Mad PogBruno Pilieci100% (1)

- Engine Compression Brake Actuator, Replacement, CXU, GU, MP7 2007, 2010Document6 pagesEngine Compression Brake Actuator, Replacement, CXU, GU, MP7 2007, 2010Christian FloresPas encore d'évaluation

- Catalogue Produits OnanDocument6 pagesCatalogue Produits OnanJohn LarsonPas encore d'évaluation

- Tuning The TBIDocument21 pagesTuning The TBINacer MezghichePas encore d'évaluation

- Caterpillar XQ30 Towable Diesel Generator SetDocument5 pagesCaterpillar XQ30 Towable Diesel Generator SetMacAllister Machinery100% (1)

- Illustrated Parts List: 13500 Starting WattsDocument6 pagesIllustrated Parts List: 13500 Starting WattsTeresa ArguelloPas encore d'évaluation

- Single Phase P11000 (Yanmar)Document2 pagesSingle Phase P11000 (Yanmar)gigo_dreamPas encore d'évaluation

- Labrie - Heavy Duty Right-Hand Arm - Parts Manual - 90418Document42 pagesLabrie - Heavy Duty Right-Hand Arm - Parts Manual - 90418stainless31620039126Pas encore d'évaluation

- Hydro-Ax Wiring Diagram PDFDocument1 pageHydro-Ax Wiring Diagram PDFJohnny BranamPas encore d'évaluation

- Dana Spicer Steer Axles: Service Manual AXSM-0038 September 2005Document44 pagesDana Spicer Steer Axles: Service Manual AXSM-0038 September 2005wadalla100100% (1)

- MRAPs: Main Resistant Ambush Protected VehiclesD'EverandMRAPs: Main Resistant Ambush Protected VehiclesÉvaluation : 5 sur 5 étoiles5/5 (1)

- SK 26139Document1 pageSK 26139eefutestPas encore d'évaluation

- Little Tripper: Technical DrawingsDocument30 pagesLittle Tripper: Technical DrawingsosvaldoPas encore d'évaluation

- 1-60-04 JacobsDocument2 pages1-60-04 JacobsRuben Antonio Huaranca CruzPas encore d'évaluation

- 2007 250SXFDocument43 pages2007 250SXFMartin ValderramaPas encore d'évaluation

- VorlandiDocument24 pagesVorlandiKieran RyanPas encore d'évaluation

- 2014 - 65SX KTM Part Manual BookDocument44 pages2014 - 65SX KTM Part Manual BookAndevha WygaPas encore d'évaluation

- Valve Adjustment E7Document16 pagesValve Adjustment E7malcolm stewartPas encore d'évaluation

- DOBDSM1501Document186 pagesDOBDSM1501Sorin CiuculanPas encore d'évaluation

- Metro-Liner: Specifications Mid Axle Forward 6x4 8x4 10x4Document2 pagesMetro-Liner: Specifications Mid Axle Forward 6x4 8x4 10x4Ricardo CastroPas encore d'évaluation

- Alpha LPW LPWS LPWX Engines Operators HandbookDocument48 pagesAlpha LPW LPWS LPWX Engines Operators Handbookchristiam tevesPas encore d'évaluation

- Massey Ferguson MF 263 T TRACTOR Service Parts Catalogue Manual (Part Number 3310692)Document16 pagesMassey Ferguson MF 263 T TRACTOR Service Parts Catalogue Manual (Part Number 3310692)qlb898316Pas encore d'évaluation

- Powerhouse: PH3100RI Digital Inverter Generator Shop ManualDocument69 pagesPowerhouse: PH3100RI Digital Inverter Generator Shop ManualRene Bourgoin100% (1)

- Camshaft Gear - Remove and InstallDocument4 pagesCamshaft Gear - Remove and InstallAndy PircaPas encore d'évaluation

- Powerstroke 6L Wire Chafing - TSB 041806Document4 pagesPowerstroke 6L Wire Chafing - TSB 041806Manuel AlboPas encore d'évaluation

- PartsBook - DT25c (89 99) DT30c (88 97)Document65 pagesPartsBook - DT25c (89 99) DT30c (88 97)JOSE EMILIO VAZQUEZ GONZALEZPas encore d'évaluation

- Crane Installation Manual: Model 4/29 Model 5/35 Model 6/45Document20 pagesCrane Installation Manual: Model 4/29 Model 5/35 Model 6/45Bui Hoang DucPas encore d'évaluation

- Evo Design S.R.L.: Calculation SheetDocument1 pageEvo Design S.R.L.: Calculation SheetkhantoPas encore d'évaluation

- Geoff's Woodwork: Using Timber StructurallyDocument5 pagesGeoff's Woodwork: Using Timber StructurallykhantoPas encore d'évaluation

- 2 - Mike Stress and StrengthDocument18 pages2 - Mike Stress and StrengthkhantoPas encore d'évaluation

- Washing MachineDocument17 pagesWashing MachinekhantoPas encore d'évaluation

- 5826 Multicad BP WP En4Document7 pages5826 Multicad BP WP En4khantoPas encore d'évaluation

- A 10 VoDocument44 pagesA 10 VoEliasd100% (7)

- Anales28 001Document7 pagesAnales28 001khantoPas encore d'évaluation

- Dow 3504Document2 pagesDow 3504khantoPas encore d'évaluation

- OAK Ridge National Laboratory: Basic Properties of Reference Crossply Carbon-Fiber CompositeDocument60 pagesOAK Ridge National Laboratory: Basic Properties of Reference Crossply Carbon-Fiber CompositekhantoPas encore d'évaluation

- Bolted JointsDocument3 pagesBolted JointsGiuseppe GiuseppePas encore d'évaluation

- Electric Submersible Pumps (ESP) PDFDocument31 pagesElectric Submersible Pumps (ESP) PDFFernandoEnriqueCalveteGonzález100% (2)

- ABB - PCS 6000 STATCOM - Reference ListDocument8 pagesABB - PCS 6000 STATCOM - Reference ListProyectos IPC S.A.S - Manuel CadenaPas encore d'évaluation

- Fuel System: Fuel Tank / Fuel Cock 4-1 Fuel Pump 4 - 2 Carburetor 4 - 3Document10 pagesFuel System: Fuel Tank / Fuel Cock 4-1 Fuel Pump 4 - 2 Carburetor 4 - 3Fabrizio FloresPas encore d'évaluation

- Digital Filter DesignDocument102 pagesDigital Filter Designjaun danielPas encore d'évaluation

- LCD Interfacing With Microcontroller 8051Document50 pagesLCD Interfacing With Microcontroller 8051Darshan Vala100% (2)

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaPas encore d'évaluation

- Report.... 555ic and Stepper MotorDocument73 pagesReport.... 555ic and Stepper MotorJenielyn IparbaPas encore d'évaluation

- 378 and 378 HT SeriesDocument2 pages378 and 378 HT SeriesTim Stubbs100% (2)

- GS-1930 GS-1530 Service Manual: Technical PublicationsDocument137 pagesGS-1930 GS-1530 Service Manual: Technical PublicationshabibullaPas encore d'évaluation

- Boston Matrix of CokeDocument11 pagesBoston Matrix of CokeIrvin A. OsnayaPas encore d'évaluation

- 8 PCO Training Invitation Letter December 2018Document2 pages8 PCO Training Invitation Letter December 2018sayo goraPas encore d'évaluation

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- 49 CFR 195Document3 pages49 CFR 195danigna77Pas encore d'évaluation

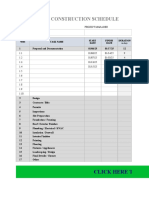

- Residential Construction Schedule: Click Here To Create in SmartsheetDocument14 pagesResidential Construction Schedule: Click Here To Create in SmartsheetVinayak VaghePas encore d'évaluation

- Silent Sound Technology Seminar ReportDocument42 pagesSilent Sound Technology Seminar ReportSrinivas B India79% (14)

- 3g 4g Call FlowDocument16 pages3g 4g Call Flowpoiuytreza26Pas encore d'évaluation

- 50Hz Curves Series 912Document38 pages50Hz Curves Series 912Vero ColladoPas encore d'évaluation

- Sba 2017 To 2018Document12 pagesSba 2017 To 2018api-383788708Pas encore d'évaluation

- Mahesh Chand CVDocument4 pagesMahesh Chand CVMahesh NiralaPas encore d'évaluation

- A Research Instrument Is A SurveyDocument1 pageA Research Instrument Is A SurveyHasan YusuvPas encore d'évaluation

- Y y Y Y Y: Design of Machinery 86Document1 pageY y Y Y Y: Design of Machinery 86Star GlacierPas encore d'évaluation

- ETL Vs ELT White PaperDocument12 pagesETL Vs ELT White PaperDeepak RawatPas encore d'évaluation

- RF1510EN00Document56 pagesRF1510EN00Vijay Kumar NandagiriPas encore d'évaluation

- The Giza Power PlantDocument10 pagesThe Giza Power Plantinterstar100% (1)

- SCW PQSDocument67 pagesSCW PQStabathadennis100% (1)

- Binary and Decimal Number Systems: Addressing The Network - Ipv4Document3 pagesBinary and Decimal Number Systems: Addressing The Network - Ipv4Mase Astrid C. BarayugaPas encore d'évaluation

- Preliminary Pages FinallyDocument9 pagesPreliminary Pages FinallyMark Kian ProfogoPas encore d'évaluation

- Global Trends 2030 Preview: Interactive Le MenuDocument5 pagesGlobal Trends 2030 Preview: Interactive Le MenuOffice of the Director of National Intelligence100% (1)

- Iso 21969 2009 en PDFDocument8 pagesIso 21969 2009 en PDFAnonymous P7J7V4Pas encore d'évaluation

- Summer SLS 1103 SyllabusDocument22 pagesSummer SLS 1103 SyllabusJay100% (1)