Académique Documents

Professionnel Documents

Culture Documents

Uat 1

Transféré par

Erwin SambasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Uat 1

Transféré par

Erwin SambasDroits d'auteur :

Formats disponibles

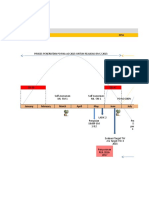

Protection Relay Test

Equipment

Unit Aux. Transformer Differential Protection Relay RET670

Feeder

UAT #1

1.

2.

Reference Drawing

Schematic Diagram

KPP-00-TPS-W-141

Transformer Bay

11kV 6.3kV UAT #1

General Data

ABB

Manufacture :

Type

3.

RET670

F87T

Designation :

Sereal No.

Commissioning Tests

3.1 Visual Check

a)

Physically Good ?

b)

Relay Healthy ?

c)

Mounting and wiring completed ?

3.2 Verifying the connections and the analog inputs

Apply input signals as needed and verify that signals are measured correctly

Injected Values

Measured

Secondary

Values Primary

No.

Procedure

Inject current phase R A101

Inject current phase S A102

Inject current phase T A103

Inject current phase R A104

Inject current phase S A105

Inject current phase T A106

Inject current Neutral A107

Contractor

Remarks

3.3 Deferential Protection Test

(1) Check on HV side

No.

Secondary Injection

Procedure

Items to be verified.

Remarks

1 Make sure that REF and OC / EF

function are set to off.

2 Connect the test set for injection of 3

phase current to the current terminals

of RET670 which are connected to the

CT's on HV side of transformer

3 Increase the current in phase L1 until

the protection operates and check

L1

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

4 Increase the current in phase L2 until

the protection operates and check

L2

For stable condition,

Trip not operated

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

5 Increase the current in phase L3 until

the protection operates and check

For stable condition,

Trip not operated

L3

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

Contractor

(2) Check on LV side

Secondary Injection

No.

Procedure

Connect the test set for injection of 3

phase current to the current terminals

of RET670 which are connected to the

CT's on LV side of transformer

2 Increase the current in phase L1 until

the protection operates and check

Items to be verified.

L1

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

3 Increase the current in phase L2 until

the protection operates and check

L2

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

4 Increase the current in phase L3 until

the protection operates and check

L3

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

Contractor

Remarks

3.4 6.3kV Restricted EF Protection Test

(1) Secondary Injection

Procedure

No.

Items to be verified.

1 Make sure that Differential protection

and OC/EF function are set to off.

2 Connect the test set for injection of

neutral current to the current terminals

of RET670 to which the NCT 20kV is

connected

3 Increase the current in until the

protection operates and check

L1

a) the operating current (Iop)

a) Iop :

b) Trip contacts operation

b) Trip contact :

Operate / Not operate

c) Alarm contact operation

c) Alarm contact :

Operate / Not operate

4.

Remarks :

Contractor

Remarks

Protection Relay Test

Equipment

Backup OC & EF Protection Relay REF615

Feeder

UAT #1

1.

2.

Reference Drawing

Schematic Diagram

KPP-00-TPS-W-141

Transformer Bay

11kV 6.3kV UAT

General Data

ABB

Manufacture :

Type

3.

RET615

F5051

Designation :

Sereal No.

1VHR91059397

Commissioning Tests

3.1 Visual Check

a)

Physically Good ?

b)

Relay Healthy ?

c)

Mounting and wiring completed ?

3.2 Verifying the connections and the analog inputs

Apply input signals as needed and verify that signals are measured correctly

Injected Values

Measured

Secondary

Values Primary

No.

Procedure

Inject current phase R

Inject current phase S

Inject current phase T

Inject current phase N

Contractor

Remarks

3.3 Testing of the phase overcurrent protection

The test is performed as a secondary test, by injecting current to the current energizing

inputs with the setting values used during normal operation

Procedure

No.

1

Items to be verified.

Inject the current (Ii) in phase L1

Ii = 2.5 * I > * rated current input

I > setting :

* In

t > setting :

s

Inject the current (Ii) in phase L2

Ii = 2.5 * I > * rated current input

I > setting :

* In

t > setting :

s

Inject the current (Ii) in phase L3

Ii = 2.5 * I > * rated current input

I > setting :

* In

t > setting :

s

Inject the current (Ii) in phase L1

Ii = 8 * I >>> * rated current input

I >>> setting :

* In

t >>> setting :

s

Inject the current (Ii) in phase L2

Ii = 8 * I >>> * rated current input

I >>> setting :

* In

t >>> setting :

s

Inject the current (Ii) in phase L3

Ii = 8 * I >>> * rated current input

I >>> setting :

* In

t >>> setting :

s

Contractor

Start of stage I > :

.

Trip of stage I > :

.

Operation time :

s

Start of stage I > :

.

Trip of stage I > :

.

Operation time :

s

Start of stage I > :

.

Trip of stage I > :

.

Operation time :

s

Start of stage I >>> :

.

Trip of stage I >>> :

.

Operation time :

s

Start of stage I >>> :

.

Trip of stage I >>> :

.

Operation time :

s

Start of stage I >>> :

.

Trip of stage I >>> :

.

Operation time :

s

Remarks

3.4 Testing of the earth fault protection

The test is performed as a secondary test, by injecting current to the current energizing

inputs with the setting values used during normal operation

Procedure

No.

1

Items to be verified.

Inject the current (Ii) in the earth fault

energizing input :

Ii = 2.5 * I0 > * rated current input

I0 > setting :

* In

t0 > setting :

Inject the current (Ii) in the earth fault

Start of stage I > :

.

Trip of stage I > :

.

Operation time :

s

energizing input :

Ii = 2.5 * I0 >> * rated current input

4.

I0 >> setting :

* In

t0 >> setting :

Remarks :

Contractor

Start of stage I >> :

.

Trip of stage I >> :

.

Operation time :

s

Remarks

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Small Switch Mode Power Supplies Modification Secrets PDFDocument41 pagesSmall Switch Mode Power Supplies Modification Secrets PDFpedram92% (12)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Celda Melin Gerin F400 CatalogueDocument56 pagesCelda Melin Gerin F400 CatalogueCarlos Hernández ValenzuelaPas encore d'évaluation

- UAT No.1 & No.2 Protection Relay Setting & TestingDocument39 pagesUAT No.1 & No.2 Protection Relay Setting & TestingErwin SambasPas encore d'évaluation

- FAULT CURRENT CALCULATIONS AND RELAY CO-ORDINATION TRAINING COURSEDocument118 pagesFAULT CURRENT CALCULATIONS AND RELAY CO-ORDINATION TRAINING COURSElankesh_dbPas encore d'évaluation

- MuaraKarang CCPP - Drawing List 220618Document172 pagesMuaraKarang CCPP - Drawing List 220618putra2503Pas encore d'évaluation

- Master Station SCADADocument32 pagesMaster Station SCADAKrisna Adi100% (2)

- Itp MechanicalDocument840 pagesItp MechanicalErwin SambasPas encore d'évaluation

- Remote Station SCADA PrintDocument36 pagesRemote Station SCADA PrintErwin SambasPas encore d'évaluation

- Electrical Engineer's 10+ Years ExperienceDocument4 pagesElectrical Engineer's 10+ Years Experienceaman vaidyaPas encore d'évaluation

- Book IiDocument4 pagesBook IiErwin SambasPas encore d'évaluation

- Comm Procedure For Genset Installlation in Govt Building HongkongDocument23 pagesComm Procedure For Genset Installlation in Govt Building Hongkongbhen08Pas encore d'évaluation

- API STD Summeries For Instr & CSDocument2 pagesAPI STD Summeries For Instr & CSAndres Fitria FarrelPas encore d'évaluation

- Z076.60.10-1, Drain Piping 疏水管路Document1 pageZ076.60.10-1, Drain Piping 疏水管路Erwin SambasPas encore d'évaluation

- Delivering Projects with Demag CranesDocument1 pageDelivering Projects with Demag CranesErwin SambasPas encore d'évaluation

- Proses Penerbitan PO RKA AO 2015-2017Document6 pagesProses Penerbitan PO RKA AO 2015-2017Erwin SambasPas encore d'évaluation

- Sample Material Approval - Concrete BlockDocument1 pageSample Material Approval - Concrete BlockErwin SambasPas encore d'évaluation

- Z51704.36.70-1, Instrument panel on the spot 就地开机仪表盘 PDFDocument1 pageZ51704.36.70-1, Instrument panel on the spot 就地开机仪表盘 PDFErwin SambasPas encore d'évaluation

- Realibity Run FormDocument2 pagesRealibity Run FormErwin SambasPas encore d'évaluation

- 24 Pages From Condition Monitoring of Electrical MotorDocument24 pages24 Pages From Condition Monitoring of Electrical MotorMuhd Muhd HasifPas encore d'évaluation

- DVR-UserGuide-en4 0 1Document113 pagesDVR-UserGuide-en4 0 1Erwin SambasPas encore d'évaluation

- No.2 Unit Turbine Ups GroupDocument2 pagesNo.2 Unit Turbine Ups GroupErwin SambasPas encore d'évaluation

- What's Up With Bump Testing ?: By: Jack D. PetersDocument47 pagesWhat's Up With Bump Testing ?: By: Jack D. PetersArhab Abdillah Yusuf Rizal100% (1)

- No.2 Unit Turbine Ups GroupDocument2 pagesNo.2 Unit Turbine Ups GroupErwin SambasPas encore d'évaluation

- Uat 1Document7 pagesUat 1Erwin SambasPas encore d'évaluation

- 45cbuniv PDFDocument74 pages45cbuniv PDFErwin SambasPas encore d'évaluation

- Roots Blower ADocument1 pageRoots Blower AErwin SambasPas encore d'évaluation

- Regeneration Water Pump ADocument1 pageRegeneration Water Pump AErwin SambasPas encore d'évaluation

- Regeneration Water Pump ADocument1 pageRegeneration Water Pump AErwin SambasPas encore d'évaluation

- R0 Washing PumpDocument1 pageR0 Washing PumpErwin SambasPas encore d'évaluation

- Primary Seawater Desalination High Pressure Pump ADocument1 pagePrimary Seawater Desalination High Pressure Pump AErwin SambasPas encore d'évaluation

- Neutralizing Water Pump ADocument1 pageNeutralizing Water Pump AErwin SambasPas encore d'évaluation

- Primary Seawater Desalination High Pressure Pump ADocument1 pagePrimary Seawater Desalination High Pressure Pump AErwin SambasPas encore d'évaluation

- Aman Seminar ReportDocument38 pagesAman Seminar ReportAman Yadav0% (2)

- Synchronous RectifiersDocument19 pagesSynchronous RectifierslogdapinPas encore d'évaluation

- Protecciones California State U EEE145 SyllabusDocument7 pagesProtecciones California State U EEE145 Syllabusjorge gonzalezPas encore d'évaluation

- G09075661 PDFDocument6 pagesG09075661 PDFVoundai MahamatPas encore d'évaluation

- PSC Sub Engineer in KSEB Question Paper Solved 2015Document11 pagesPSC Sub Engineer in KSEB Question Paper Solved 2015Vineesh M MadathodiPas encore d'évaluation

- Product Catalog 2020: Integrated AmplifiersDocument16 pagesProduct Catalog 2020: Integrated AmplifiersEnrique RangelPas encore d'évaluation

- SCADA Reference PaperDocument9 pagesSCADA Reference PapermalleswarararaoPas encore d'évaluation

- Frequency Conversion Series Resonance Technology Enables 220kV Cable Withstand Voltage TestingDocument5 pagesFrequency Conversion Series Resonance Technology Enables 220kV Cable Withstand Voltage TestingjosePas encore d'évaluation

- D04 BuscouplerDocument65 pagesD04 BuscouplerபாரதிPas encore d'évaluation

- R 4360c 36 Series Gas Valve Cross Reference en 5239824Document28 pagesR 4360c 36 Series Gas Valve Cross Reference en 5239824pandahiuPas encore d'évaluation

- 500kVA UAT Technical SpecificationDocument11 pages500kVA UAT Technical SpecificationDy. Chief Engineer PHE SNRPas encore d'évaluation

- PS Basic ConceptDocument22 pagesPS Basic ConceptORBIZ ORBIZPas encore d'évaluation

- Load Test On Scharge MotorDocument4 pagesLoad Test On Scharge MotorRamakrishna SagarPas encore d'évaluation

- PDFDocument31 pagesPDFJesus SalazarPas encore d'évaluation

- BEng 21 EE ME ETE Dec 2022 Discussion QsDocument2 pagesBEng 21 EE ME ETE Dec 2022 Discussion QsJOH 112Pas encore d'évaluation

- PROFILE Jashubhai Patel's Electrical Business ProfileDocument167 pagesPROFILE Jashubhai Patel's Electrical Business ProfileAnkur ShahPas encore d'évaluation

- Electrical Machine DesignDocument194 pagesElectrical Machine Designatul mishra100% (4)

- Lecture 8Document107 pagesLecture 8sampath bandaraPas encore d'évaluation

- Handbook On Overhead Line ConstructionDocument848 pagesHandbook On Overhead Line ConstructionSunil SinghPas encore d'évaluation

- E16406Document11 pagesE16406HOFFERPas encore d'évaluation

- METREL Variable TransformersDocument12 pagesMETREL Variable Transformershassham.altmashPas encore d'évaluation

- Electrician PDFDocument53 pagesElectrician PDFAbujaid KahnPas encore d'évaluation

- EMS-GC10 - Genset Controller Unit - Operator S Manual - 00-02-0878 - March 2013 - FW MURPHY PDFDocument183 pagesEMS-GC10 - Genset Controller Unit - Operator S Manual - 00-02-0878 - March 2013 - FW MURPHY PDFpevarePas encore d'évaluation

- Presentation 1Document11 pagesPresentation 1anshumanPas encore d'évaluation