Académique Documents

Professionnel Documents

Culture Documents

ASME

Transféré par

muhammad chilmiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ASME

Transféré par

muhammad chilmiDroits d'auteur :

Formats disponibles

2011a SECTION VIII DIVISION 1

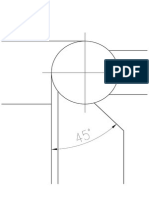

FIG. UW-9 BUTT WELDING OF PLATES OF UNEQUAL THICKNESS

(2) For materials not identiable in accordance with

UG-10, UG-11, UG-15, or UG-93, but identiable as to

nominal chemical analysis and mechanical properties,

S-Number under Section IX, QW/QB-422, or to a material

specication not permitted in this Division, satisfactory

qualication of the welding procedure under Section IX

is considered as proof of weldable quality. For materials

identied by S-Numbers, the provisions of Section IX,

QW/QB-422 may be followed for welding procedure qualication. The welding procedure need only be qualied

once for a given nominal chemical analysis and mechanical

properties or material specication not permitted in this

Division.

(3) Material which cannot be identied may be

proved to be of weldable quality by preparing a butt-joint

test coupon from each piece of nonidentied material to

be used. Guided bend test specimens made from the test

coupon shall pass the tests specied in QW-451 of Section IX.

(c) Two materials of different specications may be

joined by welding provided the requirements of Section

IX, QW-250, are met.

(d) Materials joined by the electroslag and electrogas

welding processes shall be limited to ferritic steels and the

following austenitic steels which are welded to produce a

ferrite containing weld metal: SA-240 Types 304, 304L,

316, and 316L; SA-182 F304, F304L, F316, and F316L;

SA-351 CF3, CF3A, CF3M, CF8, CF8A, and CF8M.

(e) Welding of SA-841 by the electroslag or electrogas

welding process is prohibited.

(f) Materials joined by the inertia and continuous drive

friction welding processes shall be limited to materials

assigned P-Numbers in Section IX and shall not include

rimmed or semikilled steel.

DESIGN

UW-8

GENERAL

The rules in the following paragraphs apply specically

to the design of pressure vessels and vessel parts that are

fabricated by welding and shall be used in conjunction

with the general requirements for Design in Subsection A,

and with the specic requirements for Design in Subsection

C that pertain to the class of material used.

UW-9

DESIGN OF WELDED JOINTS

(a) Permissible Types. The types of welded joints permitted in arc and gas welding processes are listed in Table

UW-12, together with the limiting plate thickness permitted

for each type. Butt type joints only are permitted with

pressure welding processes [see UW-27(b)].

(b) Welding Grooves. The dimensions and shape of the

edges to be joined shall be such as to permit complete

fusion and complete joint penetration. Qualication of the

welding procedure, as required in UW-28, is acceptable

as proof that the welding groove is satisfactory.

(c) Tapered Transitions. A tapered transition having a

length not less than three times the offset between the

adjacent surfaces of abutting sections, as shown in Fig.

UW-9, shall be provided at joints between sections that

differ in thickness by more than one-fourth of the thickness

of the thinner section, or by more than 18 in. (3 mm),

whichever is less. The transition may be formed by any

process that will provide a uniform taper. When the transition is formed by removing material from the thicker section, the minimum thickness of that section, after the

material is removed, shall not be less than that required

by UG-23(c). When the transition is formed by adding

115

Vous aimerez peut-être aussi

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Module 1: Code Basics: Part QW WeldingDocument12 pagesModule 1: Code Basics: Part QW WeldingaliPas encore d'évaluation

- Asme Viii Div 1 2013 Cri-1Document4 pagesAsme Viii Div 1 2013 Cri-1vivicastedoPas encore d'évaluation

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyPas encore d'évaluation

- ASME Code Case 2247Document2 pagesASME Code Case 2247Rana Mubbashir IqbalPas encore d'évaluation

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshPas encore d'évaluation

- IX Exercise Rev 02 PDFDocument11 pagesIX Exercise Rev 02 PDFweerasinghekPas encore d'évaluation

- BKI Rules For Classification and ConstructionDocument4 pagesBKI Rules For Classification and ConstructionwongyuliongPas encore d'évaluation

- ASME Sec IX Groove To Fillet WeldDocument3 pagesASME Sec IX Groove To Fillet WeldAzhar Ali0% (1)

- Basic of Asme Sec IxDocument116 pagesBasic of Asme Sec IxHamid Mansouri100% (2)

- Asme Section Ix 2019Document116 pagesAsme Section Ix 2019mostafa nabil100% (3)

- ASME IX ExerciseDocument11 pagesASME IX ExerciseRanaweera Ariyamanjula100% (1)

- Field Welding Field Welding Field Welding Field Welding Manual Manual Manual ManualDocument14 pagesField Welding Field Welding Field Welding Field Welding Manual Manual Manual Manualjaheer1Pas encore d'évaluation

- 11Document5 pages11MOHAMEDPas encore d'évaluation

- API - STD - 650 - 2020 - 13 TH Ed - WELDING PROCEDUREDocument3 pagesAPI - STD - 650 - 2020 - 13 TH Ed - WELDING PROCEDUREsarlsnmplastPas encore d'évaluation

- 2007 Section ViiiDocument3 pages2007 Section ViiiMiriam LopezPas encore d'évaluation

- ASME Sec IXDocument5 pagesASME Sec IXkirubha_karan2000Pas encore d'évaluation

- 01 Samss 035 API LinepipeDocument28 pages01 Samss 035 API Linepipemdsazidalam100% (2)

- Asme IxDocument10 pagesAsme IxMohammed YoussefPas encore d'évaluation

- Extracted Pages From ASME BPVC 2021 Section IX-2Document2 pagesExtracted Pages From ASME BPVC 2021 Section IX-2Roberto Carlos Arana ChumpitazPas encore d'évaluation

- Split Tee Specifications and Drawings - 20130906 - 191217Document17 pagesSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLIPas encore d'évaluation

- Enbridge Pipeline Repair Workplan WeldingDocument23 pagesEnbridge Pipeline Repair Workplan WeldingJesus MaestrePas encore d'évaluation

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynidePas encore d'évaluation

- 4 Asme Sec Ix Wps PQR Slide 71 To 105Document35 pages4 Asme Sec Ix Wps PQR Slide 71 To 105dhasdj100% (1)

- Q210 Welding of Power PipingDocument7 pagesQ210 Welding of Power Pipingpragmatix100% (2)

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarPas encore d'évaluation

- Split Tee Specifications and DrawingsDocument7 pagesSplit Tee Specifications and DrawingsFareha AbdelkaderPas encore d'évaluation

- Welding Procedure SpecificationDocument30 pagesWelding Procedure Specificationrahman196011100% (1)

- Solved Paper On Section IxDocument25 pagesSolved Paper On Section IxNasir Javed90% (20)

- Tube-To-Tube Sheet Joint RequirementsDocument2 pagesTube-To-Tube Sheet Joint RequirementsWaqas WaqasPas encore d'évaluation

- Asme IX BQ Art 11Document5 pagesAsme IX BQ Art 11Maria Alexandra Lange LenzPas encore d'évaluation

- ASME in BriefDocument25 pagesASME in BriefshankerPas encore d'évaluation

- MpiDocument2 pagesMpimusaismail8863Pas encore d'évaluation

- Extracted Pages From Section IX-2015Document78 pagesExtracted Pages From Section IX-2015Jhony ValenciaPas encore d'évaluation

- A 928 - A 928M - 04 Qtkyoc9boti4tqDocument6 pagesA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdPas encore d'évaluation

- Work Sheet 3Document16 pagesWork Sheet 3raghbirPas encore d'évaluation

- 7-Material ASME VIIIDocument23 pages7-Material ASME VIIIel_sharkawy2011Pas encore d'évaluation

- Specification For Statically Cast Chilled White Iron-Gray Iron Dual Metal Rolls For Pressure Vessel UseDocument2 pagesSpecification For Statically Cast Chilled White Iron-Gray Iron Dual Metal Rolls For Pressure Vessel UseBinay K SrivastawaPas encore d'évaluation

- AISC - 2022 - Qualidade e InspeçãoDocument13 pagesAISC - 2022 - Qualidade e InspeçãoBruno ornellasPas encore d'évaluation

- Welder Qualification Radiography Acceptance CriteriaDocument2 pagesWelder Qualification Radiography Acceptance CriteriaKamalnath KpPas encore d'évaluation

- Appendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryDocument2 pagesAppendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryTarif Aziz MarufPas encore d'évaluation

- Welder Qualifications and The ASME CodeDocument2 pagesWelder Qualifications and The ASME CodeWaqas WaqasPas encore d'évaluation

- ItpDocument64 pagesItpomda4wady100% (1)

- ASME IX Temper Bead WeldingDocument4 pagesASME IX Temper Bead WeldingAhmadiBinAhmadPas encore d'évaluation

- 2b. The Impact Testing 1Document4 pages2b. The Impact Testing 1zahidnedPas encore d'évaluation

- Chapter N - Quality Control and Quality AssuranceDocument13 pagesChapter N - Quality Control and Quality AssuranceGirl Who LivedPas encore d'évaluation

- M-1002 Appendix W: Brazing, and Nondestructive ExaminationDocument89 pagesM-1002 Appendix W: Brazing, and Nondestructive ExaminationCentre For Total Quality ManagementPas encore d'évaluation

- Weld Overlay Procedure For InconelDocument3 pagesWeld Overlay Procedure For InconelArash Mohamadi100% (2)

- Summary of ASME BPVC Section VIII Div 1 (Part 1) - Welding & NDTDocument11 pagesSummary of ASME BPVC Section VIII Div 1 (Part 1) - Welding & NDTTin Aung KyiPas encore d'évaluation

- ASTM A842 - Corpo de Prova OmegaDocument4 pagesASTM A842 - Corpo de Prova OmegaFabiano MonteiroPas encore d'évaluation

- Note 7 - Welder Test - Mechanical Test and X-RayDocument29 pagesNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiPas encore d'évaluation

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiPas encore d'évaluation

- Section 6 - Manholes, Frames, Covers and Cleanouts 6-01. General RequirementsDocument3 pagesSection 6 - Manholes, Frames, Covers and Cleanouts 6-01. General RequirementsThupten Gedun Kelvin Ong100% (1)

- Nyse125 - Nickel Aluminium Bronze Castings For Water Service PDFDocument5 pagesNyse125 - Nickel Aluminium Bronze Castings For Water Service PDF이선엽0% (1)

- ANSI AWS Writing and Qualifying Welding Procedures - Technical BulletinsDocument4 pagesANSI AWS Writing and Qualifying Welding Procedures - Technical Bulletinscleiton.wtecPas encore d'évaluation

- Asme Section II A-2 Sa-476 Sa-476mDocument6 pagesAsme Section II A-2 Sa-476 Sa-476mAnonymous GhPzn1xPas encore d'évaluation

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaPas encore d'évaluation

- ASME Section Materials ViiiDocument41 pagesASME Section Materials ViiiSatria 'igin' Girindra NugrahaPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 Studsmuhammad chilmiPas encore d'évaluation

- BRT CP GD 001 Cutting Plan GirderDocument1 pageBRT CP GD 001 Cutting Plan Girdermuhammad chilmiPas encore d'évaluation

- Greenhill Model (Balok)Document1 pageGreenhill Model (Balok)muhammad chilmiPas encore d'évaluation

- Pib STDDocument1 pagePib STDmuhammad chilmiPas encore d'évaluation

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 Studsmuhammad chilmiPas encore d'évaluation

- En 10029 (Detail)Document3 pagesEn 10029 (Detail)muhammad chilmiPas encore d'évaluation

- BRT HPH004 DW 002Document1 pageBRT HPH004 DW 002muhammad chilmiPas encore d'évaluation

- HandrailDocument1 pageHandrailmuhammad chilmiPas encore d'évaluation

- Pib STDDocument1 pagePib STDmuhammad chilmiPas encore d'évaluation

- 595 C +/-10 C Diagram Holding Temperatur 1" THK / HourDocument1 page595 C +/-10 C Diagram Holding Temperatur 1" THK / Hourmuhammad chilmiPas encore d'évaluation

- 595 C +/-10 C Diagram Holding Temperatur 1" THK / HourDocument1 page595 C +/-10 C Diagram Holding Temperatur 1" THK / Hourmuhammad chilmiPas encore d'évaluation

- Assembly 14V108Document1 pageAssembly 14V108muhammad chilmiPas encore d'évaluation

- Detail of Pipe DavitDocument1 pageDetail of Pipe Davitmuhammad chilmiPas encore d'évaluation

- General ArrangementDocument1 pageGeneral Arrangementmuhammad chilmiPas encore d'évaluation

- Ladder Rung - 1Document1 pageLadder Rung - 1muhammad chilmiPas encore d'évaluation

- Top Ladder Detail Rev.0Document2 pagesTop Ladder Detail Rev.0muhammad chilmiPas encore d'évaluation

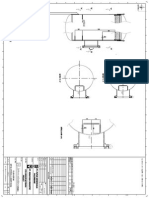

- General Arrangement Platform Fa - 604: (Liquid Ammonia Flash Drum)Document2 pagesGeneral Arrangement Platform Fa - 604: (Liquid Ammonia Flash Drum)muhammad chilmiPas encore d'évaluation

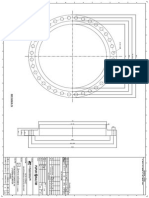

- Body Flange Fa 602Document1 pageBody Flange Fa 602muhammad chilmiPas encore d'évaluation

- Lenovo t400 Service Manual PDFDocument386 pagesLenovo t400 Service Manual PDFJosé Fabio Lou100% (1)

- Dramix 3d 8060bl-8060blDocument1 pageDramix 3d 8060bl-8060blcsillag janosPas encore d'évaluation

- MECH3502 Lab-2Document11 pagesMECH3502 Lab-2mateiPas encore d'évaluation

- Three Saddle Supports For Horizontal VesselDocument7 pagesThree Saddle Supports For Horizontal VesselhuangjlPas encore d'évaluation

- Whirlpool Arg 773 Service ManualDocument9 pagesWhirlpool Arg 773 Service ManualkrisgoPas encore d'évaluation

- Ii Food PackagingDocument2 pagesIi Food PackagingLeila Bert Marie GamboaPas encore d'évaluation

- CE155 Estimating Lecture 3 PDFDocument71 pagesCE155 Estimating Lecture 3 PDFArly Tolentino100% (1)

- Seminar On Steam EngineDocument26 pagesSeminar On Steam EngineEr Akhilesh Singh100% (1)

- End Sem Q PaperDocument2 pagesEnd Sem Q PapersantkabirPas encore d'évaluation

- Tpi 28 - Pkir - Pkis - en - 201411Document24 pagesTpi 28 - Pkir - Pkis - en - 201411KundzoPas encore d'évaluation

- Thermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eDocument3 pagesThermostability of PVC and Related Chlorinated Polymers: Application Bulletin 205/2 eAnas ImdadPas encore d'évaluation

- Naphtha Catalytic Cracking For Propylene ProudctionDocument5 pagesNaphtha Catalytic Cracking For Propylene ProudctionWong Yee SunPas encore d'évaluation

- A Banjo BuildingDocument20 pagesA Banjo BuildingRégis MoewiusPas encore d'évaluation

- Low-Carbon Carbon-Bonded Alumina Refractories For Functional Components in Steel TechnologyDocument10 pagesLow-Carbon Carbon-Bonded Alumina Refractories For Functional Components in Steel TechnologyRyanto SitanggangPas encore d'évaluation

- Ground Improvement PPT ISquareRDocument19 pagesGround Improvement PPT ISquareRsamPas encore d'évaluation

- EFI BasicsDocument168 pagesEFI BasicsBryanMaes100% (1)

- Consolidated Undrained Triaxial Compression Test For Cohesive SoilsDocument11 pagesConsolidated Undrained Triaxial Compression Test For Cohesive SoilsNikhilPas encore d'évaluation

- Plazmax Servicio PDFDocument109 pagesPlazmax Servicio PDFLeonel Losada Cardozo0% (1)

- GCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBODocument2 pagesGCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBOKickingEdgarAllenPoePas encore d'évaluation

- Dazio Beyer Bachmann - 2009 PDFDocument16 pagesDazio Beyer Bachmann - 2009 PDFErick LópezPas encore d'évaluation

- Internal Sizing of Paper - AKD - ASADocument71 pagesInternal Sizing of Paper - AKD - ASAelgendawyPas encore d'évaluation

- Topdek PIR Installation Guide A5 Sept 2020Document12 pagesTopdek PIR Installation Guide A5 Sept 2020fahim007Pas encore d'évaluation

- Carl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiDocument1 pageCarl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiA GHAILANE EL HASSANI RABII SOUMAYAPas encore d'évaluation

- Gates: Conventional Flap GateDocument8 pagesGates: Conventional Flap GateprasenjitsayantanPas encore d'évaluation

- Research ReviewDocument8 pagesResearch ReviewJOSEPH OLUWABUKOLAPas encore d'évaluation

- W7 Smith CapacitorsDocument31 pagesW7 Smith CapacitorsyjandePas encore d'évaluation

- Bo Ride Nozzle CatalogDocument46 pagesBo Ride Nozzle CatalogsossiePas encore d'évaluation

- Commissioning ProceduresDocument152 pagesCommissioning Proceduresmabrarahmed100% (1)

- Wisner Case 13Document8 pagesWisner Case 13Nabaneeta SahanaPas encore d'évaluation

- Skin Depth EquationDocument3 pagesSkin Depth EquationSrijit MukherjeePas encore d'évaluation