Académique Documents

Professionnel Documents

Culture Documents

Zqa 25

Transféré par

harde2lahTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Zqa 25

Transféré par

harde2lahDroits d'auteur :

Formats disponibles

where cf is the rock compressibility.

This equation assumes that the fractional

change in PV is small. Physically, the rock expansivity represents the fractiona

l change in PV while, in contrast, the rock compressibility represents the rate

of change in fractional PV with pressure. While the former is more pertinent to

material-balance calculation, experimental data are often reported in terms of t

he latter. Table 1 includes rock-compressibility measurements. If cf is known as

a function of pressure, then the integral on the right side of Eq.1 can be eval

uated numerically to determine Ef(p). If cf is relatively independent of pressur

e, then Eq.1 can be simplified to

RTENOTITLE....................(2)

This method of estimating Ef is not usually preferable because cf is rarely cons

tant. Fig.1 illustrates a case and plots the rock compressibility as a function

of pressure from the data in Table 1. Several features are worth noting, and man

y of these features are characteristic of compaction drives.

?Rock compressibility ranges between 4 to 21 10 6 psi 1, which is a greater-than-nor

mal range.

?Rock compressibility clearly is not independent of pressure.

?Compressibility declines sharply as the pressure first declines below the initi

al pressure. This phenomenon is largely attributed to grain rearrangement.

?Rock compressibility increases at pressures below 4,000 psia. This phenomenon i

s attributed to pore collapse.

Fig. 1

.

Rock compressibility as a function of pressure for a Gulf Coast reservoir

Once Ef(p) is estimated, the material-balance methods in the related pages below

can be applied to estimate the OOIP and confirm the producing mechanism.

Nomenclature

cf = rock compressibility, Lt2/m, 1/psi

Ef = rock (formation) expansivity

p = pressure, m/Lt2, psi

References

1.? 1.0 1.1 Cook, C.C. and Jewell, S. 1996. Reservoir Simulation in a North Sea

Reservoir Experiencing Significant Compaction Drive. SPE Res Eng 11 (1): 48-53.

SPE-29132-PA. http://dx.doi.org/10.2118/29132-PA

2.? 2.0 2.1 Sulak, R.M. 1991. Ekofisk Field: The First 20 Years. J Pet Technol 4

3 (10): 1265-1271. SPE-20773-PA. http://dx.doi.org/10.2118/20773-PA

3.? 3.0 3.1 Sulak, R.M., Thomas, L.K., and Boade, R.R. 1991. 3D Reservoir Simula

tion of Ekofisk Compaction Drive (includes associated papers 24317 and 24400 ).

J Pet Technol 43 (10): 1272-1278. SPE-19802-PA. http://dx.doi.org/10.2118/19802PA

4.? Fetkovich, M.J., Reese, D.E., and Whitson, C.H. 1998. Application of a Gener

al Material Balance for High-Pressure Gas Reservoirs (includes associated paper

51360). SPE J. 3 (1): 3-13. SPE-22921-PA. http://dx.doi.org/10.2118/22921-PA

Noteworthy papers in OnePetro

Use this section to list papers in OnePetro that a reader who wants to learn mor

e should definitely read

External links

Use this section to provide links to relevant material on websites other than Pe

troWiki and OnePetro

See also

Material balance in oil reservoirs

Solution gas drive reservoirs

Gas cap drive reservoirs

Water drive reservoirs

Oil fluid characteristics

PEH:Oil_Reservoir_Primary_Drive_Mechanisms

Category: 5.2.4 Compaction

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Engine Construction and OperationDocument31 pagesEngine Construction and OperationRohit NewarPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Electrical Plan SampleDocument1 pageElectrical Plan SampleKit67% (3)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Chemical Engineering Unit Operations Syn PDFDocument13 pagesChemical Engineering Unit Operations Syn PDFsamerPas encore d'évaluation

- Spe 131758 Ms - GL and EspDocument11 pagesSpe 131758 Ms - GL and EspSamuel VmPas encore d'évaluation

- Contractor instrument pressure piping hook-up documentDocument35 pagesContractor instrument pressure piping hook-up documentTahir100% (1)

- 7.MMCR JuliDocument5 281 pages7.MMCR JuliAngga StwnPas encore d'évaluation

- PIPENET VISION SPRAY MODULE TRAINING MANUALDocument48 pagesPIPENET VISION SPRAY MODULE TRAINING MANUALElton Situmeang50% (2)

- Conservation of Energy Worksheet #1 Answers - 1Document3 pagesConservation of Energy Worksheet #1 Answers - 1Fitz Baniqued67% (3)

- Screw Compressors: Models: VEDocument42 pagesScrew Compressors: Models: VEVoştinar IoanPas encore d'évaluation

- Safety Guide for Coal Stockpiles and Reclaim TunnelsDocument46 pagesSafety Guide for Coal Stockpiles and Reclaim TunnelsFarah SafrinaPas encore d'évaluation

- Wuhuan - MR Pi JinlinDocument34 pagesWuhuan - MR Pi JinlinAmanPas encore d'évaluation

- Reception Class Easter Holiday Homework Pack 2023Document12 pagesReception Class Easter Holiday Homework Pack 2023harde2lahPas encore d'évaluation

- Name: - DateDocument8 pagesName: - Dateharde2lahPas encore d'évaluation

- Improve 12Document1 pageImprove 12harde2lahPas encore d'évaluation

- ZQZ 3321Document2 pagesZQZ 3321harde2lahPas encore d'évaluation

- Blue WordsDocument1 pageBlue Wordsharde2lahPas encore d'évaluation

- ZQZ 331Document2 pagesZQZ 331harde2lahPas encore d'évaluation

- Broiler Vaccination GuideDocument1 pageBroiler Vaccination Guideharde2lahPas encore d'évaluation

- (Poultry Diseases Diagnosis and Aquaculture Lab) Ogere-Remo, Ogun State The M.D Nutridel Farms, Ogdl/0322/052/Ast AsipaDocument1 page(Poultry Diseases Diagnosis and Aquaculture Lab) Ogere-Remo, Ogun State The M.D Nutridel Farms, Ogdl/0322/052/Ast Asipaharde2lahPas encore d'évaluation

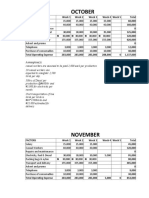

- Poultry Farm Monthly ExpensesDocument28 pagesPoultry Farm Monthly Expensesharde2lahPas encore d'évaluation

- New Hope Agric and Tech Nig LTD - 20227283131579Document1 pageNew Hope Agric and Tech Nig LTD - 20227283131579harde2lahPas encore d'évaluation

- Jovan Petronic: 2012 FIDE World Youth Chess Champions in ActionDocument8 pagesJovan Petronic: 2012 FIDE World Youth Chess Champions in ActionKasparicoPas encore d'évaluation

- DL Conversion TableDocument10 pagesDL Conversion Tableharde2lahPas encore d'évaluation

- ZQZ 33Document1 pageZQZ 33harde2lahPas encore d'évaluation

- Careful planning when involving packers and tubing in well completion stepsDocument1 pageCareful planning when involving packers and tubing in well completion stepsharde2lahPas encore d'évaluation

- Reservoir Fluids and Flow Course InformationDocument4 pagesReservoir Fluids and Flow Course Informationharde2lahPas encore d'évaluation

- ZQZ 31Document1 pageZQZ 31harde2lahPas encore d'évaluation

- 600.0 Straight-Line (HCPV Const) Pot Aquifer: Cumulative Gas Recovery, GP/G, %Document3 pages600.0 Straight-Line (HCPV Const) Pot Aquifer: Cumulative Gas Recovery, GP/G, %harde2lahPas encore d'évaluation

- ZQZ 32Document1 pageZQZ 32harde2lahPas encore d'évaluation

- ZQZ 3Document1 pageZQZ 3harde2lahPas encore d'évaluation

- Linear Programming OptimizationDocument49 pagesLinear Programming Optimizationh_badgujarPas encore d'évaluation

- Zqer 124 WDocument1 pageZqer 124 Wharde2lahPas encore d'évaluation

- ZQZ 2Document1 pageZQZ 2harde2lahPas encore d'évaluation

- Zqer 1 D 2Document1 pageZqer 1 D 2harde2lahPas encore d'évaluation

- ZQZ 1Document2 pagesZQZ 1harde2lahPas encore d'évaluation

- Zqer 124Document1 pageZqer 124harde2lahPas encore d'évaluation

- ZQD 7211 GDocument2 pagesZQD 7211 Gharde2lahPas encore d'évaluation

- Zqer 124 W 1Document1 pageZqer 124 W 1harde2lahPas encore d'évaluation

- Zqer 12Document1 pageZqer 12harde2lahPas encore d'évaluation

- Zqer 1 DDocument2 pagesZqer 1 Dharde2lahPas encore d'évaluation

- Zqer 1Document1 pageZqer 1harde2lahPas encore d'évaluation

- Effect of Water Absorption in Polymers at Low and High TemperaturesDocument9 pagesEffect of Water Absorption in Polymers at Low and High TemperaturesGeotamPas encore d'évaluation

- Catalytic LEL SensorsDocument9 pagesCatalytic LEL Sensorsvibhor_748408347Pas encore d'évaluation

- PanasonicDocument15 pagesPanasonicMohd HaniffPas encore d'évaluation

- Diesel Engine Technical SpecificationsDocument3 pagesDiesel Engine Technical SpecificationsFahad MohammedPas encore d'évaluation

- Solar Water HeaterDocument27 pagesSolar Water HeaterSantosh ThapaPas encore d'évaluation

- rr320801 Mass Transfer Operations IIDocument7 pagesrr320801 Mass Transfer Operations IISRINIVASA RAO GANTAPas encore d'évaluation

- Wave Nature of The Motor Cable and Voltage Stress of The Motor in Inverter DriveDocument9 pagesWave Nature of The Motor Cable and Voltage Stress of The Motor in Inverter DrivealbertofgvPas encore d'évaluation

- 46 0M 090209pr V Navy FSIV SpecificationDocument32 pages46 0M 090209pr V Navy FSIV SpecificationCapitan PetacaPas encore d'évaluation

- Kings Motorbikes 80cc Bicycle Engine Kit Installation ManualDocument11 pagesKings Motorbikes 80cc Bicycle Engine Kit Installation ManualnwobastardsPas encore d'évaluation

- Documents - MX - Absorption Exercises Treybal PDFDocument6 pagesDocuments - MX - Absorption Exercises Treybal PDFJvson Vens Sance100% (1)

- Electrical Machines DemystifiedDocument6 pagesElectrical Machines DemystifiedRishiSunariya50% (2)

- Gates em Ingles 2010Document76 pagesGates em Ingles 2010felipeintegraPas encore d'évaluation

- ABB String Inverters: PVS-50/60-TLDocument4 pagesABB String Inverters: PVS-50/60-TLBianca OlaruPas encore d'évaluation

- 1 s2.0 S0165237019300294 Main PDFDocument11 pages1 s2.0 S0165237019300294 Main PDFNatashaA.CuencaSchillingPas encore d'évaluation

- X9 User Manual: ImportantDocument28 pagesX9 User Manual: ImportantWolleo LW100% (1)

- Lista Precios Ahu Mas Accesorios Sinclair 2020Document80 pagesLista Precios Ahu Mas Accesorios Sinclair 2020Jonathan ArboledaPas encore d'évaluation

- Zenit Compact Setup Manual En3Document26 pagesZenit Compact Setup Manual En3Garage Lifestyle BVGPas encore d'évaluation

- Home Automation and Surveillance: A ReviewDocument4 pagesHome Automation and Surveillance: A ReviewATSPas encore d'évaluation

- Anomaly Events GuideDocument33 pagesAnomaly Events GuideRichard LittlesPas encore d'évaluation