Académique Documents

Professionnel Documents

Culture Documents

Wall Climbing Robot

Transféré par

tarasasankaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Wall Climbing Robot

Transféré par

tarasasankaDroits d'auteur :

Formats disponibles

Recent Advances in Circuits, Systems, Signal and Telecommunications

Wall Climbing Robot: Mechanical Design and

Implementation

A. Albagul1, A. Asseni1, O. Khalifa2,

Control Engineering Department The Higher Institute of Electronics, Baniwalid, Libya

Faculty of Engineering, International Islamic University Malaysia Kuala Lumpur, Malaysia

albagoul@yahoo.com

AbstractA wall climbing robot is a robot with the capability

of climbing vertical surfaces. This paper describes the design

and fabrication of a quadruped climbing robot. We are

required to design and create a wall climbing robot which

uses suction as a means of sticking to the wall. The robot will

be controlled using Basic Stamp and the movement of its legs

will generated by two servo motors. Each servo motor will

control legs which are located on the left and right side of the

robot. The leg rotations mimic stepping motions through the

use of a slider and crank. The suction force will be supplied

by two vacuum pumps that will turn on intermittently. The

main body of the robot will carry all the components except

for the compressor thus making it mobile. Currently the robot

is only designed for linear movement. However plans to

incorporate maneuverability and other functions can be

implemented after the first stage of the development achieves

success.

Keywords-component; wall robots; basic stamp; suction

cups; slider-crank.

I.

INTRODUCTION

Robots have been created to assist or replace humans in

various dangerous and difficult tasks. Robots have been

used in construction, manufacturing, security and etc. This

is because they are able to adapt to different environments

and situations. They have conquered nearly all

environments that humans have put them through.

Climbing robots can be used on artificial surfaces like a

wall, or on natural surfaces like trees or cave walls. They

are desirable for several applications such as search and

rescue. This phenomena is still a challenge to be achieved

using robotic devices. Climbing robots should have some

practical utility to deal with different surfaces and

geometries. This can be achieved by the use of special

purpose attachment devices such as magnets or suction. At

the same time, the machines need to be power autonomous,

to avoid the hazard and the limitations of a tether.

Climbing robots need unprecedented reliability: even one

misstep in a thousand can lead to a catastrophic fall.

Previously designed climbing robots have successfully

climbed a number of hard, real world terrains. In general

however these robots have been designed with a specific

subset of terrain geometries or surface types in mind. A

wall climbing robot can be used for numerous functions

such as surveillance, construction, maintenance, search and

rescue [1, 2, 3]. In 2003 a gecko like climbing robot called

Rhex was developed for Pentagon to be used as a

surveillance tool in their counter-terrorism program [4].

However Rhex is still years from completion. Current

existing robots are limited in their usefulness due to their

design complexity. Most climbing robots are still in their

prototype stage and require much more research in order to

be applicable in real life. Most wall climbing robots can

either climb smooth surfaces or non-smooth surfaces. Not

ISBN: 978-960-474-271-4

28

many robots can climb both types of surfaces. The majority

of the robots in existence can only climb smooth surfaces.

Researchers use nature as inspiration in designing their

robots. They try to mimic natures surface climbers such as

insects, reptiles and worms. Most researchers try to mimic

spiders who they believe to be one of the most versatile

wall climbers [5]. Six legs give great maneuvering

capabilities but limit the speed of the robot and make the

design very complicated. A quadruped robot though

possessing less maneuvering capabilities is theoretically

faster and less difficult to build. Most quadruped climbing

robots mimic lizards. However we decided to make a

climbing robot that is similar to walking robots. By adding

suction cups to the end of the legs we will make the robot

literally walk up a wall. After going through more than

four different designs we came up with a design that is

simple but efficient.

II.

SYSTEM DESIGN

A. Mechanical design

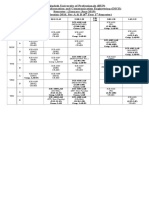

Figure 1 shows different views of the general structure of

the slider-crank mechanism of the leg. The purpose of this

design to make sure that the all of sucking cups are vertical

to the wall surface. By using 2 servo motors for controlling

the movement of legs, each of leg will control by servo

motor to generate the rotational motion. 2 of legs will be

synchronized movement to generate the forward and

backward movement of robot. The slider-crank

mechanism, as shown in figure 2, is design to maintain the

position of leg perpendicular to the surface of wall. The

main body of the robot is able to carry the basic stamp

controller, servo motors, pneumatic valves, and pneumatic

pumps. At a certain time only 2 legs will touch the surface

of wall, so a base support will support the body of robot

during movement to maintain the stability of robot.

Recent Advances in Circuits, Systems, Signal and Telecommunications

will move synchronized. These positions depend on a

movement of robot whether it move forward or

backward.

5. For the forward movement:

Two rotation legs will touch the first switch at position 2

then it will stop. At this state all 4 suction cups will stick

on the surface of wall. After a few seconds, the suction

cups of 2 non-rotational legs will release it contact to the

surface of wall.2 rotation legs will rotate until it touching

to the second switch at position 4 then it will stop. At this

state the suction cups of 2 rotation legs will stick on the

surface of wall. At this state all 4 suction cups will stick

on the surface of wall. After a few seconds, the suction

cups of 2 non-rotational legs will stick to the surface of

wall while the 2 legs will rotate continuously until it

touching the first switch without any contact of suction

cup to the surface. This process will repeat continuously

to generate movement of robot.

6. For the backward movement:

Two rotation legs will touch the first switch at position 4

then it will stop. At this state all 4 suction cups will stick

on the surface of wall. After a few seconds, the suction

cups of 2 non-rotational legs will release it contact to the

surface of wall. Two rotation legs will rotate until it

touching to the second switch at position 2 then it will

stop. At this state the suction cups of 2 rotation legs will

stick on the surface of wall. At this state all 4 suction cups

will stick on the surface of wall. After a few seconds, the

suction cups of 2 non-rotational legs will stick to the

surface of wall while the 2 legs will rotate continuously

until it touching the first switch without any contact of

suction cup to the surface. This process will repeat

continuously to generate movement of robot.

Figure 1: The lay out of the robot

Figure 2: The slider-crank mechanism for the robot legs

B. Robot Mechanism

The mechanism of the robot includes the followings:

1. The robot consists of 2 servo motors and 4 legs, in

which the functions of 2 motors are to generate rotary

motion of 2 legs only (leg contains suction cup 1 & 4).

These 2 legs motion will operate synchronized. The

remaining 2 legs are to support a body of robot during a

movement.

2. To make the body of robot move forward and backward.

The slider-crank mechanism consists of the links as

shown in figure 3. For the link 1 it joint with the servo

motor and link 2, while for the link 2 which include with

suction cup joint with the link 3, lastly the link 3 is joint

with slider. A joint is a non-fixed connection between

two or more links that allows certain relative motion

between these links.

3. Each of the 4 cranks is connected with the slider part and

sucking cup. Only the motion of the slider-crank

mechanism of legs consist suction cup 1 & 4 will cause

the robot to move. The remaining of legs consist suction

cup 2 & 3 will be fixed at a certain position as shown in

figure 3.

4. All of these position (1,2,3 & 4) will occur during

rotational motion of 2 legs only. The 2 movement legs

ISBN: 978-960-474-271-4

29

C. Degree Of Freedom (DOF) of the slider-crank

mechanism

Each of the 4 cranks is connected with the slider part and

sucking cup. Only 2 legs will generate motion of the slidercrank mechanism while 2 legs remain fixed at a certain

position see figure 3. The numbers of DOF are the number

of components of motion that are required in order to

generate the motion. The formula of DOF of any planar

mechanism through number of moving links (n), number

and types of joints (f1 and f2) can be expressed as:

F = 3*n 2*f1 f2

where, f1 is the number of one DOF joint and f2 is the

number of two DOF joint. The DOF for the slider-crank

mechanism of the robot leg can be calculated.

No. of links = 3

No. of one DOF = 4 (3 joints and 1 slider)

F = 3*3 2*4 0

=1

Therefore, the suction cups will remain vertical to the wall

surface.

D. Suction Mechanism

The factors that have been considered in the development

of the suction system for the robot are:

1. Make sure that all of sucking cups are vertical to

the wall surface during the rotational motion of

legs.

2. By using the vacuum pumps of high vacuum level

application so that the suction cups adhere on the

surface of ordinary wall building.

Recent Advances in Circuits, Systems, Signal and Telecommunications

E. Electronic Designs

The electronic design of the robot consists of integrating

circuits of different functions with the basic stamp. The

Basic Stamp controls all of the robots actions. The Basic

Stamp BS2 module is chosen for this project. BASIC

Stamp modules are microcontrollers (tiny computers) that

are designed for use in a wide array of applications. Many

projects that require an embedded system with some level

of intelligence can use a BASIC Stamp module as the

controller. Each BASIC Stamp comes with a BASIC

Interpreter chip, internal memory (RAM and EEPROM), a

5-volt regulator, a number of general-purpose I/O pins

(TTL-level, 0-5 volts), and a set of built-in commands for

math and I/O pin operations. BASIC Stamp modules are

capable of running a few thousand instructions per second

and are programmed with a simplified, but customized

form of the BASIC programming language, called

PBASIC. The Basic Stamp BS2 modules can be connected

either by using serial ports or USB. The programs are

transferred through these ports and stored in the basic

stamp.

Figure 3: Legs position for different movements

III.

Figure 4: Suction cups mechanism

Figure 4 shows the connection mechanism of suction cup.

Spot welding is used for joining the link with suction cup.

For the suction process, firstly air will flow through black

tubing from the compressor to the 2 valves. It operates with

the ON and OFF function to control flow of air from the

compressor. Each valve will connect to the vacuum pump,

which 1 vacuum pump will connect to 2 suction cups. The

reason using 2 valves, at a certain time all suction cups will

stick on the surface of wall. When the valve turns ON, air

will flow to the vacuum and suction cups. Straight fitting

are used for joining the black tubing with the valves,

vacuum pumps, and suction cups. Suction cup is a type of

rubber elastic which can make flexible movement when

touching on surface of wall. Figure 5 shows the flowchart

of suction process.

Figure 5: The flow chart of suction process

ISBN: 978-960-474-271-4

30

PROGRAM FLOW AND ROBOT MOVEMENT

The program allows the robot to move forward and

backward. It follows a strict sequence in order to ensure the

robots stability. The walbot program contains several subprograms that control the overall motion of the robot. The

program can be divided into two large sub-programs for

controlling forward and backward movement.

a) Forward Motion

This is the main program for controlling the forward

motion of the robot. The function of this program is to

initialize the inputs, outputs and variables. After initializing

the variables, the SEQ1 program will then turn ON both

pneumatic valves thus making all four legs stick to the wall

for 4 seconds. This program is responsible for controlling

the first step of forward motion. The program will turn on

OFF one of the pneumatic valve while the other is

maintained at the ON state. The motors then rotate until

variables representing inputs 4 and 7 are no longer 0. The

program will then activate the CH1 sub-program. This

program checks the state of the variables representing the

inputs and tells the motor to stop or to continue rotating.

After ensuring that each variable is equal to 1 the subprogram PARITY1 will then activate sub-program

SEQ2 which will then turn both pneumatic valves ON

for five seconds and then the entire process is repeated with

the pneumatic valve formerly ON in the first process in

the OFF state and the pneumatic valve formerly OFF in

the ON state. The SEQ2 sub-program is similar to the

SEQ1 sub-program with a different valve ON. After the

second sequence is complete the sub-program called

JCHECK will check the state of the variable X which

represents IN3. If the condition is 1 then the sub-program

JUNCTION will be activated. If condition is 0 then the

program MAIN1 will be activated and the entire process

is repeated from the first sequence.

b) Reverse Motion

The reverse motion main program is similar to the

forward motion main program. It resets all the conditions

of the variables to its initial state. It will than activate the

RSEQ1 sub-program. The RSEQ1 sub-program is

responsible for controlling the first step of reverse motion.

The program will turn on OFF one of the pneumatic

Recent Advances in Circuits, Systems, Signal and Telecommunications

valve while the other is maintained at the ON state. The

motors then rotate until variables representing inputs 5 and

6 are no longer 0. The program will then activate the

RCH1 sub-program. The RCH1 program checks the state

of the variables representing the inputs and tells the motor

to stop or to continue rotating. After ensuring that each

variable is equal to 1 the sub-program RPARITY1 will

then activate sub-program RSEQ2 which will then turn

both pneumatic valves ON for five seconds and then the

entire process is repeated with the pneumatic valve

formerly ON in the first process in the OFF state and

the pneumatic valve formerly OFF in the ON state.

c) Junction Sub-program

The JUNCTION sub-program functions as a junction

between forward motion and reverse motion. Whenever the

pause button is pressed the JUNCTION sub-program will

be activated. This sub-program will continue looping until

a selection between forward and reverse motion is selected.

The flowchart of the main program is shown in figure 6.

CONCLUSIONS

The design and fabrication of the Wall Climbing Robot has

been successfully achieved and is shown in figure 7. The

components required are simple enough and the

programming required is basic. However the material used

to hold the suction cup is made out of light aluminum thus

making it hard to weld the fitting together. Only by using

spot welding can the fitting be attached. This is to ensure

that the chasis of The power distribution of the electronic

components should be planned more carefully because it is

discovered that the basic stamp draws a lot of power when

connected to multiple circuits. Only when using the

Energizer 9V battery can the servos run. However these

batteries deplete very quickly and are costly. It is

recommended that another more powerful rechargeable

battery be used as a supply. The battery should also be

lightweight so that the torque on the servos is small. The

12V battery used for remote control aircraft has the

characteristics required. However the batteries are

expensive and last for a very short time. Finally, this robot

should be further developed so that it can be assigned to do

tasks that would be difficult for humans to do.

REFERENCES

[1] Maki K. Habib, Omni Directional Robot That Can

Climb A Wall, 6th Intl Conf. on Mechatronic

Technology, Kitakyushu, Japan, 2002.

[2] M. Murphy, M. Sitti, Waalbot: An Agile SemiAutonomous Wall Climbing Robot

[3] Chun- Hung Chen, Vijay Kumar, Motion Planning of

Walking Robots in Environment with Uncertainty

[4] C. Menon, M. Murphy, M. Sitti, Gecko Inspired

Surface Climbing Robots IEEE Intl Conf. on

Robotics and Biomimetics (ROBIO), Shenyang,

China, 2004.

[5] Tomoshisa OHMORI, Peng Chen, Walking Control

method for Quadruped Robot by Genetic Algorithms,

6th Intl Conf. on Mechatronic Technology, Kitakyushu,

Japan, 2002.

[6] L. Briones, P. Bustamante, and M. Serna (1994)

ROBICEN: A wall-climbing pneumatic robot for

inspection in nuclear power plants. Robotics and

Computer-Integrated Manufacturing 11, 287-292.

[7] Z. Yanzeng, S. Hao, and W. Yan (1999) Wall-climbing

robot with negative pressure sucker used for cleaning

work. High Technology Letters 5, 85-88

[8] L. Shuliang, Z. Yanzheng, G. Xueshan, X. Dianguo,

Wang Yan (2000) A wall-climbing robot with

magnetic crawlers for sand-blasting. Spray-painting

[9] T. Bretl, S. Rock, J. C. Latombe, B. Kennedy, and H.

Aghazarian, Free-Climbing with a Multi-Use Robot,

Proceedings of the International Symposium on

Experimental Robotics (ISER), Singapore, Jun. 2004.

[10] L. Guo, K. Rogers, and R. Kirkham, A Climbing

Robot with Continuous Motion, Proceedings of the

IEEE International Conference on Robotics and

Automation (ICRA 94), 813 May 1994.

[11] S. Hirose, and K. Kawabe, Ceiling Walk of

Quadruped Wall Climbing Robot NINJA-II,

Proceedings of the 1st International Conference on

Walking and Climbing Robots (CLAWAR 98),

Brussels, Belgium, 1998.

[12] T. Yano, T. Suwa, M. Murakami, and T. Yamamoto,

Development of a Semi Self-Contained Wall

Figure 6: The flow chart of the main program.

Figure 7: Wall Climbing Robot.

ISBN: 978-960-474-271-4

IV.

31

Recent Advances in Circuits, Systems, Signal and Telecommunications

Climbing Robot with Scanning Type Suction Cups,

Proceedings of the IEEE International Conference on

Intelligent Robots and Systems (IROS 97), Grenoble,

France, 711 September, 1997.

[13] R. Lal Tummala, R. Mukherjee, N. Xi, D. Aslam, H.

Dulimarta, J. Xiao, M. Minor, and G. Dang, Climbing

The Walls, IEEE Robotics and Automation Magazine,

vol. 9, no. 4, pp. 1019, Dec. 2002.

[14] S.F. Frazier, G.S Larsen, D. Neff, L. Quimby, M.

Carney, R.A. DiCaprio, S.N. Zill, Elasticity and

Movements of the Cockroach Tarsus in Walking,

Journal of Comparative Physiology A, vol. 185, pp.

157-172, 1999.

[15] S. Hirose, A. Nagabuko, and R. Toyama, Machine

That Can Walk And Climb on Floors, Walls and

Ceiling, Proc. International Conference on Advanced

Robotics and Automation, France, 1992.

[16] M. Minor, M., H. Dulimarta, G. Danghi, R.

Mukherjee, R. Lal Tummala, and D. Aslam, Design,

implementation, and evaluation of an under-actuated

miniature biped climbing robot, Proc. IEEE/RSJ

International Conference on Intelligent Robots and

Systems, 2000.

[17] K. Yoneda, Y. Ota, K. Hirano, and S. Hirose,

Development of a Light-Weight Wall Climbing

Quadruped with Reduced Degrees of Freedom, Proc.

4th International Conference on Climbing and

Walking Robots, 2001.

[18] K.A. Daltorio, S. Gorb, A. Peressadko, A.D. Horchler,

R.E. Ritzmann, and R.D. Quinn, A Robot that Climbs

Walls using Micro-structured Polymer Feet, Proc.

International Conference on Climbing and Walking

Robots, London, UK, 2005.

[19] K.A. Daltorio, A.D. Horchler, S. Gorb, R.E.

Ritzmann, and R.D. Quinn, A Small Wall-Walking

Robot with Compliant, Adhesive Feet, Proc. IEEE

International Conference on Intelligent Robots and

Systems, Alberta, Canada, 2005.

[20] M. Spenko, M. Cutkosky, C. Majidi, R. Fearing, R.

Groff, and K. Autumn, Foot design and integration for

bioinspired

climbing

robots,

Proc.

SPIE

Defense&Security Symposium, Unmanned Systems

Technology, Orlando, FL, 2006.

[21] W.P. Provancher, J.E. Clark, B. Geisler, and M.R.

Cutkosky, Towards Penetration-based Clawed

Climbing, Int. Conf. on Climbing and Walking

Robots, Madrid, Spain, 2004.

ISBN: 978-960-474-271-4

32

Vous aimerez peut-être aussi

- Design and Implementation of Microcontroller Based Controller For Direction and Speed of A RobotDocument65 pagesDesign and Implementation of Microcontroller Based Controller For Direction and Speed of A Robotkhechibakamel100% (1)

- Automatic Pneumatic Punching and Riveting MachineDocument4 pagesAutomatic Pneumatic Punching and Riveting MachineElakkiya Karthic100% (1)

- Project PPT 1Document17 pagesProject PPT 1Dishant PrasadPas encore d'évaluation

- Smart Child Borewell System 3Document44 pagesSmart Child Borewell System 3Venkat nagulapatiPas encore d'évaluation

- Final Four WayDocument35 pagesFinal Four WayRohitsingh JadaunPas encore d'évaluation

- Design of Walking Mechanism With Straight and Parallel Leg MotionDocument28 pagesDesign of Walking Mechanism With Straight and Parallel Leg MotionKashif MobinPas encore d'évaluation

- 4 Way Hacksaw Machinex (Read-Only)Document34 pages4 Way Hacksaw Machinex (Read-Only)harrysinghPas encore d'évaluation

- Wireless Robot and Robotic Arm Control With Accelerometer Sensor ProjectDocument41 pagesWireless Robot and Robotic Arm Control With Accelerometer Sensor ProjectAmandeep Singh KheraPas encore d'évaluation

- Fabrication of Automatic Side Stand Braking Mechanism For Two WheelerDocument37 pagesFabrication of Automatic Side Stand Braking Mechanism For Two Wheelergnana muruganPas encore d'évaluation

- Wall Climbing Robot by KartikDocument50 pagesWall Climbing Robot by KartikVishal Sharma100% (1)

- Productivity Improvement I N MM540 Steering BoxDocument42 pagesProductivity Improvement I N MM540 Steering BoxVijay JPas encore d'évaluation

- Literature Survey On Variable Frequency Drive: Anuradha Tomar Devesh SinghDocument8 pagesLiterature Survey On Variable Frequency Drive: Anuradha Tomar Devesh SinghAjay DSElectrical100% (1)

- Box Transport MechanismDocument41 pagesBox Transport MechanismsaijanPas encore d'évaluation

- An Empirical Study On Corporate Governance, Special ReferenceDocument52 pagesAn Empirical Study On Corporate Governance, Special ReferenceAsm Saiful IslamPas encore d'évaluation

- Study On US TAXATIONDocument9 pagesStudy On US TAXATIONManish BhurePas encore d'évaluation

- Remote Controlled Screw Jack 2014 AcDocument58 pagesRemote Controlled Screw Jack 2014 AcChockalingam AthilingamPas encore d'évaluation

- Nfo ProjectDocument75 pagesNfo Projectankitverma9716Pas encore d'évaluation

- Pneumatic Riveting and Punching MachineDocument43 pagesPneumatic Riveting and Punching MachineAnil AnukulaPas encore d'évaluation

- Clutch Inplant Training ReportDocument31 pagesClutch Inplant Training ReportMrityunjay Pathak100% (1)

- Vijay Halilole.: Fabrication of Vertical Axis Wind TurbineDocument45 pagesVijay Halilole.: Fabrication of Vertical Axis Wind TurbineThaha Refaye0% (2)

- Intelligent Braking System - SynopsisDocument6 pagesIntelligent Braking System - SynopsisTanviPas encore d'évaluation

- A Micro-Project Report On ": Metal Detector Circuit"Document34 pagesA Micro-Project Report On ": Metal Detector Circuit"Om PawarPas encore d'évaluation

- A Project Report OnDocument26 pagesA Project Report OnPrashant JhurawatPas encore d'évaluation

- Pneumatic Sheet Cutting MachineDocument55 pagesPneumatic Sheet Cutting MachineBhushan HadalagiPas encore d'évaluation

- 81.automatic Pneumatic Riveting MachineDocument4 pages81.automatic Pneumatic Riveting MachineIyappan100% (3)

- Automatic Mechanical Garage Door Opener: ComponentsDocument2 pagesAutomatic Mechanical Garage Door Opener: Componentspramo_dassPas encore d'évaluation

- Project Report On Pedal Operated Hack Saw MachineDocument42 pagesProject Report On Pedal Operated Hack Saw MachineNishithPas encore d'évaluation

- Wall Climbing RobotDocument79 pagesWall Climbing Robotneha gupta100% (3)

- Internship Report (IIP)Document53 pagesInternship Report (IIP)Mehtab AlamPas encore d'évaluation

- 2 Wheel Drive Hybrid MotorcycleDocument36 pages2 Wheel Drive Hybrid MotorcycleJOHN JOSEPHPas encore d'évaluation

- Over Speed Fuel CutoffDocument3 pagesOver Speed Fuel Cutoffselvaganapathy1992Pas encore d'évaluation

- Automatic Screw JackDocument46 pagesAutomatic Screw JackAnonymous YfpcmA100% (1)

- Rocker Bogie MechanismDocument6 pagesRocker Bogie MechanismjishnuPas encore d'évaluation

- Baudrate GeneratorDocument88 pagesBaudrate GeneratorT.snehaPas encore d'évaluation

- Research On Automatic Bike Starter KitDocument38 pagesResearch On Automatic Bike Starter KitGokul RajaPas encore d'évaluation

- Push Button Operated Gear Shifting Mechanism For Two WheelerDocument19 pagesPush Button Operated Gear Shifting Mechanism For Two Wheelersabareesh91mechPas encore d'évaluation

- Major Synopsis On Hydraulic ArmDocument7 pagesMajor Synopsis On Hydraulic ArmPrashant Balhara0% (2)

- Coin Based Water Controlling SystemDocument34 pagesCoin Based Water Controlling SystemSanthosh Guduru75% (4)

- Presentation On: Design and Development of Sugarecane Bud Cutting Machine Guided By-Dr. S.S.KULKARNIDocument16 pagesPresentation On: Design and Development of Sugarecane Bud Cutting Machine Guided By-Dr. S.S.KULKARNIVenPas encore d'évaluation

- Project ReportDocument65 pagesProject ReportMusical world100% (1)

- Sand Slinger MC Pneumatic 2016 VeltechDocument47 pagesSand Slinger MC Pneumatic 2016 VeltechChockalingam AthilingamPas encore d'évaluation

- Design of Jig and Fixture For Milling Machine, Case Study: Cylindrical PartsDocument24 pagesDesign of Jig and Fixture For Milling Machine, Case Study: Cylindrical PartsRoby MauliansyahPas encore d'évaluation

- Fabrication of Hydraulic Dual Brake Single Lever System: SynopsisDocument4 pagesFabrication of Hydraulic Dual Brake Single Lever System: SynopsissiddharthPas encore d'évaluation

- Development of Wall Painting RobotDocument5 pagesDevelopment of Wall Painting RobotPrakash Kumar SenPas encore d'évaluation

- Potentiometer PDFDocument7 pagesPotentiometer PDFstevenspillkumar67% (3)

- A Project Report: Design and Fabrication of Multi Process Machining Using Scotch Yoke MechanismDocument44 pagesA Project Report: Design and Fabrication of Multi Process Machining Using Scotch Yoke MechanismKali DasPas encore d'évaluation

- Automatic Side Stand With Breaking Locking SystemDocument44 pagesAutomatic Side Stand With Breaking Locking SystemSaravanan Viswakarma100% (2)

- Alcohol Detection System in Vehicle Using Arduino PDFDocument5 pagesAlcohol Detection System in Vehicle Using Arduino PDFMuniyandi LakshmananPas encore d'évaluation

- Magnetic GearDocument28 pagesMagnetic GearGeetha Lekshmi KPas encore d'évaluation

- Automatic Brake Failure IndicatorDocument1 pageAutomatic Brake Failure Indicatorbalabooks100% (1)

- Automatic Side Stand Retreiving SystemDocument49 pagesAutomatic Side Stand Retreiving SystemEtgsPas encore d'évaluation

- Project Report ON Credit RatingDocument76 pagesProject Report ON Credit RatingMunish Pathania0% (1)

- Major Project Report FormatDocument9 pagesMajor Project Report FormatdjaidkaPas encore d'évaluation

- A Design of 360 Degree Flexible Drilling MachineDocument26 pagesA Design of 360 Degree Flexible Drilling MachineSai RamPas encore d'évaluation

- Automatic Garrage SystemDocument11 pagesAutomatic Garrage SystemTalha NayyarPas encore d'évaluation

- A Project Submitted in Partial Fulfilment of The Requirement For The Awards ofDocument36 pagesA Project Submitted in Partial Fulfilment of The Requirement For The Awards ofHari Arts100% (1)

- IDocument6 pagesIRohitSinghBishtPas encore d'évaluation

- A Mini Project ON Study and Development of Robotic Arm Using Arduino UnoDocument39 pagesA Mini Project ON Study and Development of Robotic Arm Using Arduino UnoRahul DhadbanjanPas encore d'évaluation

- Wall Climbing Robot: Mechanical Design and Implementation: January 2011Document6 pagesWall Climbing Robot: Mechanical Design and Implementation: January 2011rkPas encore d'évaluation

- Wall Climbing Robot: Mechanical Design and Implementation: January 2011Document6 pagesWall Climbing Robot: Mechanical Design and Implementation: January 2011Parth PandeyPas encore d'évaluation

- 2017 July IJIRSETDocument9 pages2017 July IJIRSETtarasasankaPas encore d'évaluation

- 2019 June IJRARDocument8 pages2019 June IJRARtarasasankaPas encore d'évaluation

- Analysis and Characterization of Tensile Property of MG MMC Using ANSYSDocument5 pagesAnalysis and Characterization of Tensile Property of MG MMC Using ANSYStarasasankaPas encore d'évaluation

- Lesson Plan ME410A (R16)Document2 pagesLesson Plan ME410A (R16)tarasasankaPas encore d'évaluation

- Topics No - of Classes Unit - I: Lesson PlanDocument2 pagesTopics No - of Classes Unit - I: Lesson PlantarasasankaPas encore d'évaluation

- Finite Element MethodsDocument20 pagesFinite Element MethodstarasasankaPas encore d'évaluation

- 7B AnswerDocument6 pages7B AnswertarasasankaPas encore d'évaluation

- Manufacturing Operations: 1 Processing and Assembly OperationsDocument4 pagesManufacturing Operations: 1 Processing and Assembly OperationstarasasankaPas encore d'évaluation

- Cutter Compensation ExampleDocument8 pagesCutter Compensation ExampletarasasankaPas encore d'évaluation

- List of Suggested Books Aicte - UgDocument25 pagesList of Suggested Books Aicte - UgtarasasankaPas encore d'évaluation

- Industrial Control and Automation Unit-3 Computer Numerical ControlDocument49 pagesIndustrial Control and Automation Unit-3 Computer Numerical ControltarasasankaPas encore d'évaluation

- Scilab CodeDocument4 pagesScilab CodetarasasankaPas encore d'évaluation

- Wear Behavior of Magnesium Alloy AZ91 Hybrid Composite MaterialsDocument10 pagesWear Behavior of Magnesium Alloy AZ91 Hybrid Composite MaterialstarasasankaPas encore d'évaluation

- Robot End EffectorDocument25 pagesRobot End EffectortarasasankaPas encore d'évaluation

- UNIT-IVDocument5 pagesUNIT-IVtarasasankaPas encore d'évaluation

- Unit2&3 HRDocument60 pagesUnit2&3 HRtarasasankaPas encore d'évaluation

- Static Dynamic Thermal Analysis AnsysDocument5 pagesStatic Dynamic Thermal Analysis AnsystarasasankaPas encore d'évaluation

- Class Routine Final 13.12.18Document7 pagesClass Routine Final 13.12.18RakibPas encore d'évaluation

- Module 1 Supply Chain Management in Hospitality IndustryDocument39 pagesModule 1 Supply Chain Management in Hospitality IndustryHazelyn BiagPas encore d'évaluation

- Design of Footing R1Document8 pagesDesign of Footing R1URVESHKUMAR PATELPas encore d'évaluation

- Topic 3 Intellectual RevolutionDocument20 pagesTopic 3 Intellectual RevolutionOlive April TampipiPas encore d'évaluation

- Zgouras Catherine Team Together 1 Teachers BookDocument257 pagesZgouras Catherine Team Together 1 Teachers Booknata86% (7)

- MidsemDocument6 pagesMidsemAravind SomasundaramPas encore d'évaluation

- Use The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficeDocument5 pagesUse The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficedakingPas encore d'évaluation

- I.A.-1 Question Bank EM-3 (Answers)Document11 pagesI.A.-1 Question Bank EM-3 (Answers)UmmPas encore d'évaluation

- Research Project Presentation of Jobairul Karim ArmanDocument17 pagesResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanPas encore d'évaluation

- Hypothesis Testing Random MotorsDocument8 pagesHypothesis Testing Random MotorsLinn ArshadPas encore d'évaluation

- Unit 7 ActivitiesDocument8 pagesUnit 7 ActivitiesleongeladoPas encore d'évaluation

- Namagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishDocument10 pagesNamagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishMonydit santinoPas encore d'évaluation

- International Supply Chain ManagementDocument2 pagesInternational Supply Chain ManagementPRASANT KUMAR SAMALPas encore d'évaluation

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạPas encore d'évaluation

- Green ThumbDocument2 pagesGreen ThumbScarlet Sofia Colmenares VargasPas encore d'évaluation

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- Afa Coursework ExamplesDocument6 pagesAfa Coursework Examplesiuhvgsvcf100% (2)

- Classroom Management PlanDocument14 pagesClassroom Management PlancowlesmathPas encore d'évaluation

- Managing Markets Strategically: Professor Noel CaponDocument49 pagesManaging Markets Strategically: Professor Noel CaponChristiandeuxPas encore d'évaluation

- Unit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Document147 pagesUnit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Madhan MPas encore d'évaluation

- Headlight Washer System: Current Flow DiagramDocument3 pagesHeadlight Washer System: Current Flow DiagramLtBesimPas encore d'évaluation

- ResumeDocument3 pagesResumeAstig Kuging63% (8)

- Progressive Muscle Relaxation ExerciseDocument2 pagesProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- CTRLX Automation BrochureDocument60 pagesCTRLX Automation BrochureNinja do SofáPas encore d'évaluation

- Pamphlet 89 Chlorine Scrubbing SystemsDocument36 pagesPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- Sustainable Development Precautionary PR 2Document12 pagesSustainable Development Precautionary PR 2PramodPas encore d'évaluation

- Concept of Lokmitra Kendra in Himachal PradeshDocument2 pagesConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaPas encore d'évaluation

- SQL and Hand BookDocument4 pagesSQL and Hand BookNaveen VuppalaPas encore d'évaluation

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDocument2 pagesElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiPas encore d'évaluation

- Skirmishes Graham Harman PDFDocument383 pagesSkirmishes Graham Harman PDFparaiaPas encore d'évaluation

- Algorithms to Live By: The Computer Science of Human DecisionsD'EverandAlgorithms to Live By: The Computer Science of Human DecisionsÉvaluation : 4.5 sur 5 étoiles4.5/5 (722)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyD'EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyÉvaluation : 4 sur 5 étoiles4/5 (51)

- The Future of Geography: How the Competition in Space Will Change Our WorldD'EverandThe Future of Geography: How the Competition in Space Will Change Our WorldÉvaluation : 4 sur 5 étoiles4/5 (6)

- Cyber War: The Next Threat to National Security and What to Do About ItD'EverandCyber War: The Next Threat to National Security and What to Do About ItÉvaluation : 3.5 sur 5 étoiles3.5/5 (66)

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldD'EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (55)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveD'EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurvePas encore d'évaluation

- Generative AI: The Insights You Need from Harvard Business ReviewD'EverandGenerative AI: The Insights You Need from Harvard Business ReviewÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyD'EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyÉvaluation : 3.5 sur 5 étoiles3.5/5 (111)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindD'EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindPas encore d'évaluation

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumD'EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumÉvaluation : 3 sur 5 étoiles3/5 (12)

- Solutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesD'EverandSolutions Architect's Handbook: Kick-start your career as a solutions architect by learning architecture design principles and strategiesPas encore d'évaluation

- AI Superpowers: China, Silicon Valley, and the New World OrderD'EverandAI Superpowers: China, Silicon Valley, and the New World OrderÉvaluation : 4.5 sur 5 étoiles4.5/5 (398)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andD'EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andÉvaluation : 4.5 sur 5 étoiles4.5/5 (709)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceD'EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceÉvaluation : 5 sur 5 étoiles5/5 (5)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessD'EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessPas encore d'évaluation

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeD'EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeÉvaluation : 4.5 sur 5 étoiles4.5/5 (99)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyD'EverandChip War: The Quest to Dominate the World's Most Critical TechnologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (228)

- Mini Farming: Self-Sufficiency on 1/4 AcreD'EverandMini Farming: Self-Sufficiency on 1/4 AcreÉvaluation : 4 sur 5 étoiles4/5 (76)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldD'EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (107)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)D'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Pas encore d'évaluation

- Restoration Agriculture: Real-World Permaculture for FarmersD'EverandRestoration Agriculture: Real-World Permaculture for FarmersÉvaluation : 4.5 sur 5 étoiles4.5/5 (86)