Académique Documents

Professionnel Documents

Culture Documents

NCR Repair

Transféré par

Panruti S SathiyavendhanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

NCR Repair

Transféré par

Panruti S SathiyavendhanDroits d'auteur :

Formats disponibles

PALM MALL MUSCAT

NCR-Corrective Action

Client:

Tamani Global Development &

Investment LLC(TGDT)

Project

Management:

Project Management

Consultancy(PMC)

Consultant:

Engineering Innovation Design &

Consulting LLC (EIDC)

Main

Contractor:

SMC INFRA LLC

LOCATION:

1) NCR NO:005 & 006

SMC INFRA LLC

PROJECT: PALM MALL MUSCAT

NCR-Corrective Action

2) Over wall of lift at Grid C/38,39 And staircase at Grid D/38,39.

3) Over Columns at Grid E/F -34 to 39.

4) Cracks over footing Grid K/14 to16& Grid N/10 to 12.

METHODOLOGY OF REPAIRING

Treatment of segregation area:

Surface preparation:

Water jet and wire brush the honey combed areas to remove

loose particles, deposits, rust, oil, grease, fungus, ect on the

surface of the honey combed areas and allow the surface to

dry.

The loosely bond concrete of the honey combed area shall be

chipped out using chisel & hammer / concrete cutting machine

and the debris is remove.

Where ever completed finishing work without approval area

again chipped out and carryout the repair work using

approved material and As per EIDC Engineer Instructed

method.

Treatment of surface cracks (shrinkage)

We absorbed crack area not developed more and here Informed to you we

applied using approved material below the methods.

a) Surface Preparation

The cracks to be sealed shall be saw cut or chiseled to form a V groove of

approximately of 6mmX 6mm. The grooves shall be cleaned to remove all the

loose particles, dust ect.

The groove shall be sprinkled with clean water before applying the sealing mortar.

Application

The mixed approved material past is filled into the grooved by gloved hand and

the surface finished using a putty blade. This is continued till the full length of

crack is sealed.

SMC INFRA LLC

PROJECT: PALM MALL MUSCAT

NCR-Corrective Action

Material preparation:

1.

The repaired are to be saturated & the surface is to dry

condition prior to application of the approved repairing

material.

The approved repairing material should be mixed manual.

The required amount of gauging water should be placed in

the mixing bucket and the mixing should the specified amount

of water to obtain the desired consistency maximum of 3.5

litres per 25kg beg.

Should be placed in a single continuous operation.

Poured material should be introduced slowly to prevent

entrapment of air.

It is essential to place the mixed material the mixed material

within 30minutes of batching.

All cementations material curing is of vital importance to

ensure that optimum properties are obtained.

Cure the repair mortar for a minimum duration of 7days.

MANPOWER REQUIREMENT

1)

Site engineer

2)

Site supervisors

3)

4)

Safety assistant

EQUIPMENT REQUIREMENT

Foreman

5)

Charge hand

6)

Masons

7)

Labor

2.

1)

Approved repairing mortar

2)

Potable Water

3)

Tray

SMC INFRA LLC

PROJECT: PALM MALL MUSCAT

NCR-Corrective Action

4)

Chisel

5)

Hammer

6)

Scaffold (if required)

7)

Trowel

8) Steel float

3.

HEALTH AND SAFETY PROVISION

All the personal involved in the application should wear the safety

masks.

Avoid breathing spray and contact with skin when in use

Must wear protection clothing, gloves.

Wash contaminated skin and clothing after use.

While using scaffolding working at height above 1.5metres ,safety

harness to be worn wherever necessary.

Vous aimerez peut-être aussi

- Quality Assurance ManualDocument6 pagesQuality Assurance ManualEdgarDavidDiazCamposPas encore d'évaluation

- How Are Cracked Sections Analyzed in SAFE. CSI SAFEDocument3 pagesHow Are Cracked Sections Analyzed in SAFE. CSI SAFEJaime Manalili LandinginPas encore d'évaluation

- Epoxy Painting MethodDocument3 pagesEpoxy Painting MethodKaram MoatasemPas encore d'évaluation

- Method Statement of Steel Structures (TS TRUSS SDN BHD)Document21 pagesMethod Statement of Steel Structures (TS TRUSS SDN BHD)Calvin OhPas encore d'évaluation

- Cem Tec White PuDocument2 pagesCem Tec White Pupravi3434Pas encore d'évaluation

- Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentDocument3 pagesMastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentFrancois-Pas encore d'évaluation

- INTERN REPORT PrivaccyDocument50 pagesINTERN REPORT PrivaccyAmeera TashaPas encore d'évaluation

- S. I. 268 of 2018 Environmental Management Hazardous SubDocument78 pagesS. I. 268 of 2018 Environmental Management Hazardous SubMoleki NgendaPas encore d'évaluation

- PMPT Itp 010Document3 pagesPMPT Itp 010hz135874Pas encore d'évaluation

- Apron Concrete Repair Method R01Document19 pagesApron Concrete Repair Method R01ayhanarmanPas encore d'évaluation

- Masterprotect 1855 TdsDocument2 pagesMasterprotect 1855 TdsShahsoor Shah Majeed100% (1)

- Method Statements 20 % Week 08-09Document10 pagesMethod Statements 20 % Week 08-09Sujani MaarasinghePas encore d'évaluation

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 pagesMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidPas encore d'évaluation

- Majestic True Beauty Matt: Technical Data SheetDocument3 pagesMajestic True Beauty Matt: Technical Data SheetBilher SihombingPas encore d'évaluation

- Guidelines To Follow at Temporary Fabrication YardDocument1 pageGuidelines To Follow at Temporary Fabrication Yardkapileswar pradhanPas encore d'évaluation

- Rev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectDocument11 pagesRev-2 Method Statement For Access Road Construction Works Puma Energy Daulatpur ProjectM Waqas HabibPas encore d'évaluation

- Anti TermiteDocument19 pagesAnti TermiteAjoy McPas encore d'évaluation

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pages03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankPas encore d'évaluation

- MS - MasterTop 135PGDocument4 pagesMS - MasterTop 135PGAzhar Shaikh100% (1)

- MSDS Bostik 2402 PDFDocument6 pagesMSDS Bostik 2402 PDFJunior Gabriel Cusi HuillcaPas encore d'évaluation

- Section 03 Site Clearance N Demolition PDFDocument11 pagesSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- Methodology - AntitermiteDocument3 pagesMethodology - Antitermiteseshadri buttappaPas encore d'évaluation

- Method Statement For Excavation and Back Filling WorksDocument4 pagesMethod Statement For Excavation and Back Filling WorksLAM COPas encore d'évaluation

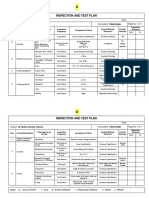

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yPas encore d'évaluation

- Jotun Resist 86 Data SheetDocument7 pagesJotun Resist 86 Data SheetKunal AjgaonkarPas encore d'évaluation

- QCS 2010 Section 5 Part 2 AggregatesDocument9 pagesQCS 2010 Section 5 Part 2 Aggregatesbryanpastor106Pas encore d'évaluation

- TEC-031100A-MET-DoR-002 (Method Statement For Deshuttering of RCC Elements)Document8 pagesTEC-031100A-MET-DoR-002 (Method Statement For Deshuttering of RCC Elements)Ahmet ÖzdenPas encore d'évaluation

- TEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Document8 pagesTEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Tomi Wiryandi SaputraPas encore d'évaluation

- Test Report FOR Compacted Density of Mix Aggregate Astm D-1559Document9 pagesTest Report FOR Compacted Density of Mix Aggregate Astm D-1559Jovanni RodriguezPas encore d'évaluation

- Polyseal 1PU: One Part Polyurethane Joint SealantDocument2 pagesPolyseal 1PU: One Part Polyurethane Joint SealantVaittianathan MahavapillaiPas encore d'évaluation

- Method Statement ProcedureDocument4 pagesMethod Statement ProcedureVictor Thembinkosi MakhubelePas encore d'évaluation

- Health and Safety Compliance: Form HDocument1 pageHealth and Safety Compliance: Form HStanley Ng100% (1)

- Method Statement For Sign Board InstallationDocument45 pagesMethod Statement For Sign Board InstallationEngr Primus ChinonyePas encore d'évaluation

- Bedding & Back Filling SpecificationDocument3 pagesBedding & Back Filling SpecificationMohammed Asimuddin Farooqui100% (1)

- Ms Block WorksDocument3 pagesMs Block WorksjaladeepPas encore d'évaluation

- QCS 2010 Section 26 Part 3 Primers, Paints and CoatingsDocument4 pagesQCS 2010 Section 26 Part 3 Primers, Paints and Coatingsbryanpastor106Pas encore d'évaluation

- Method Statement For LPG DismantlingDocument8 pagesMethod Statement For LPG DismantlingHusain abidiPas encore d'évaluation

- Method Statement Striking FormworkDocument3 pagesMethod Statement Striking FormworkSurya HeriwijayaPas encore d'évaluation

- MOS Change Road Kerb and SurfaceDocument6 pagesMOS Change Road Kerb and SurfacePrince Car-changPas encore d'évaluation

- TDS Renderoc RGM IndiaDocument4 pagesTDS Renderoc RGM IndiaKishore Nayak kPas encore d'évaluation

- Manpower DeploymentDocument18 pagesManpower DeploymentKrm ChariPas encore d'évaluation

- P028 Aso 090000 Mat 000024 - 02 BHC AjnDocument101 pagesP028 Aso 090000 Mat 000024 - 02 BHC AjnnagarajankumaranPas encore d'évaluation

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerDocument2 pagesPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebPas encore d'évaluation

- Henscha Phils. Inc.: Concrete Pouring ChecklistDocument4 pagesHenscha Phils. Inc.: Concrete Pouring Checklistchester carpioPas encore d'évaluation

- Masteremaco S 422Document3 pagesMasteremaco S 422shahidPas encore d'évaluation

- Const - of Water TankDocument6 pagesConst - of Water TankHiren ThakkarPas encore d'évaluation

- Method Statement For Installation of Fire Hydrant Pipes and FittingDocument51 pagesMethod Statement For Installation of Fire Hydrant Pipes and FittingHafiz M WaqasPas encore d'évaluation

- NOVEC System - Commissioning and TestingDocument5 pagesNOVEC System - Commissioning and TestingSalim Bakhsh100% (1)

- Method Statement For 1st Construction Years Weir Foundation ExcavationDocument19 pagesMethod Statement For 1st Construction Years Weir Foundation ExcavationJoseph NguyenPas encore d'évaluation

- Method Statement For Temporary Access Road (Towayya) - (Rev.)Document14 pagesMethod Statement For Temporary Access Road (Towayya) - (Rev.)skystar100% (1)

- Reynaldo Mamacos BPO SupervisorDocument3 pagesReynaldo Mamacos BPO SupervisormarckePas encore d'évaluation

- Method Statement For Installation of Steam RoomDocument10 pagesMethod Statement For Installation of Steam RoomSanto E0% (1)

- MasterSeal 550Document38 pagesMasterSeal 550Ahmad ElghazolyPas encore d'évaluation

- Durosan Action Matt (OM)Document3 pagesDurosan Action Matt (OM)محمد عزتPas encore d'évaluation

- APPENDIX 1 Issues For Method Statements in Industrial Roof WorkDocument3 pagesAPPENDIX 1 Issues For Method Statements in Industrial Roof WorkJulianna BakerPas encore d'évaluation

- Kure Kote 75Document1 pageKure Kote 75pravi3434100% (2)

- Details Required For ESIADocument2 pagesDetails Required For ESIAbhaskarPas encore d'évaluation

- 3.7 Method StatementDocument3 pages3.7 Method StatementHenryPas encore d'évaluation

- BCB Solutions Business ProfileDocument9 pagesBCB Solutions Business ProfileJacaranda FM NewsPas encore d'évaluation

- RWTP-DD-FC0010 DTIC... - PDO Codes: Document Transmittal Issue CodesDocument1 pageRWTP-DD-FC0010 DTIC... - PDO Codes: Document Transmittal Issue CodesPanruti S SathiyavendhanPas encore d'évaluation

- Gulfdam Master RFI Log 02-09-21Document2 pagesGulfdam Master RFI Log 02-09-21Panruti S SathiyavendhanPas encore d'évaluation

- Abbreviations For Memos (Not File Names) : RWTP-DD-FC0009... - AgreementsDocument1 pageAbbreviations For Memos (Not File Names) : RWTP-DD-FC0009... - AgreementsPanruti S SathiyavendhanPas encore d'évaluation

- RWTP-DD-FC0011 DSCD... - PDO Codes: Document Status Codes and DescriptionDocument1 pageRWTP-DD-FC0011 DSCD... - PDO Codes: Document Status Codes and DescriptionPanruti S SathiyavendhanPas encore d'évaluation

- Rigging Diagram For PrecastDocument1 pageRigging Diagram For PrecastPanruti S SathiyavendhanPas encore d'évaluation

- Gulfdam Master RFI Log 02-09-21Document2 pagesGulfdam Master RFI Log 02-09-21Panruti S SathiyavendhanPas encore d'évaluation

- RWTP DD FC0012R08 210622 SusTeco Staff ListDocument1 pageRWTP DD FC0012R08 210622 SusTeco Staff ListPanruti S SathiyavendhanPas encore d'évaluation

- GD 102 SB SD Eff 013.1Document1 pageGD 102 SB SD Eff 013.1Panruti S SathiyavendhanPas encore d'évaluation

- Routine Lift Plan For All crane-ZOOMLION QY 70KDocument1 pageRoutine Lift Plan For All crane-ZOOMLION QY 70KPanruti S SathiyavendhanPas encore d'évaluation

- TN 083Document4 pagesTN 083Panruti S SathiyavendhanPas encore d'évaluation

- Gulfdam Master RFI Log 02-09-21Document2 pagesGulfdam Master RFI Log 02-09-21Panruti S SathiyavendhanPas encore d'évaluation

- Gulfdam Master RFI Log 02-09-21Document2 pagesGulfdam Master RFI Log 02-09-21Panruti S SathiyavendhanPas encore d'évaluation

- MANPOWER REPORT SEPTEMBER 17TH 2019Document4 pagesMANPOWER REPORT SEPTEMBER 17TH 2019Panruti S SathiyavendhanPas encore d'évaluation

- MANPOWER REPORT October 15th 2019Document6 pagesMANPOWER REPORT October 15th 2019Panruti S SathiyavendhanPas encore d'évaluation

- List of Absent Workers: Sr. No B# Name Trade CompanyDocument2 pagesList of Absent Workers: Sr. No B# Name Trade CompanyPanruti S SathiyavendhanPas encore d'évaluation

- De WateringDocument1 pageDe WateringPanruti S SathiyavendhanPas encore d'évaluation

- BBS For Culvert - FormatDocument3 pagesBBS For Culvert - FormatPanruti S SathiyavendhanPas encore d'évaluation

- Al Riyan: Direct Indirect No. Name Designation Induction DateDocument2 pagesAl Riyan: Direct Indirect No. Name Designation Induction DatePanruti S SathiyavendhanPas encore d'évaluation

- UG Piping Works - Service Water System SummaryDocument7 pagesUG Piping Works - Service Water System SummaryPanruti S SathiyavendhanPas encore d'évaluation

- BBS For Culvert - FormatDocument3 pagesBBS For Culvert - FormatPanruti S SathiyavendhanPas encore d'évaluation

- 01 C0102XDocument1 page01 C0102XPanruti S SathiyavendhanPas encore d'évaluation

- SL# Badge # Name Trade Foreman Company RemarkDocument4 pagesSL# Badge # Name Trade Foreman Company RemarkPanruti S SathiyavendhanPas encore d'évaluation

- Document Transmittal Note: PIL QC Group Target QC Group CCDocument1 pageDocument Transmittal Note: PIL QC Group Target QC Group CCPanruti S SathiyavendhanPas encore d'évaluation

- Area 60 Sanitary Manholes ListDocument1 pageArea 60 Sanitary Manholes ListPanruti S SathiyavendhanPas encore d'évaluation

- Area 60 RCC Pipe DetailsDocument1 pageArea 60 RCC Pipe DetailsPanruti S SathiyavendhanPas encore d'évaluation

- NOTICE Document Verification RevisedDocument1 pageNOTICE Document Verification RevisedPanruti S SathiyavendhanPas encore d'évaluation

- Area 60 Valve Pit StatusDocument2 pagesArea 60 Valve Pit StatusPanruti S SathiyavendhanPas encore d'évaluation

- Area 60 U Ditch Details 04.01.2020Document5 pagesArea 60 U Ditch Details 04.01.2020Panruti S SathiyavendhanPas encore d'évaluation

- Area 60 Ows Manholes ScheduleDocument1 pageArea 60 Ows Manholes SchedulePanruti S SathiyavendhanPas encore d'évaluation

- Kernels - Special Characteristics PDFDocument3 pagesKernels - Special Characteristics PDFPanruti S SathiyavendhanPas encore d'évaluation

- Comparison and Contrast Essay FormatDocument5 pagesComparison and Contrast Essay Formattxmvblaeg100% (2)

- CXC - Past - Paper - 2022 Solutions PDFDocument17 pagesCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- API 510 Practise Question Nov 07 Rev1Document200 pagesAPI 510 Practise Question Nov 07 Rev1TRAN THONG SINH100% (3)

- Bhert - EoDocument2 pagesBhert - EoRose Mae LambanecioPas encore d'évaluation

- CBEU Service ConditionsDocument623 pagesCBEU Service ConditionsAtul ModiPas encore d'évaluation

- Chemical Quick Guide PDFDocument1 pageChemical Quick Guide PDFAndrejs ZundaPas encore d'évaluation

- AFMAN91-201 NewDocument458 pagesAFMAN91-201 NewbombtechPas encore d'évaluation

- Nta855 C400 D6 PDFDocument110 pagesNta855 C400 D6 PDFIsmael Grünhäuser100% (4)

- Multi-Wing Engineering GuideDocument7 pagesMulti-Wing Engineering Guidea_salehiPas encore d'évaluation

- G1 Series User Manual Ver. 1.2Document101 pagesG1 Series User Manual Ver. 1.2unedo parhusip100% (1)

- Penilaian Akhir TahunDocument4 pagesPenilaian Akhir TahunRestu Suci UtamiPas encore d'évaluation

- 001 RuminatingpacketDocument12 pages001 Ruminatingpacketكسلان اكتب اسميPas encore d'évaluation

- Covid-19 Mitigation PlanDocument8 pagesCovid-19 Mitigation PlanEkum EdunghuPas encore d'évaluation

- Ventricular Septal DefectDocument8 pagesVentricular Septal DefectWidelmark FarrelPas encore d'évaluation

- 2020 ROTH IRA 229664667 Form 5498Document2 pages2020 ROTH IRA 229664667 Form 5498hk100% (1)

- Sop For Enlistment of Engineering ConsultantsDocument1 pageSop For Enlistment of Engineering Consultantssatheb319429Pas encore d'évaluation

- S ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do OntarioDocument15 pagesS ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do Ontariocarlos menaPas encore d'évaluation

- The Case - Lijjat PapadDocument16 pagesThe Case - Lijjat Papadganesh572Pas encore d'évaluation

- Congenital Flexural Deformity in CalfDocument6 pagesCongenital Flexural Deformity in CalfBibek SutradharPas encore d'évaluation

- Reading Practice 6Document5 pagesReading Practice 6Âu DươngPas encore d'évaluation

- Soil Biotechnology (SBT) - Brochure of Life LinkDocument2 pagesSoil Biotechnology (SBT) - Brochure of Life Linkiyer_lakshmananPas encore d'évaluation

- G103 Remov Waste Dust Extraction UnitDocument2 pagesG103 Remov Waste Dust Extraction UnitJoseCRomeroPas encore d'évaluation

- QA-QC TPL of Ecube LabDocument1 pageQA-QC TPL of Ecube LabManash Protim GogoiPas encore d'évaluation

- Inverter 1 KW ManualDocument44 pagesInverter 1 KW ManualLeonardoPas encore d'évaluation

- Analysis of Pure Copper - A Comparison of Analytical MethodsDocument12 pagesAnalysis of Pure Copper - A Comparison of Analytical Methodsban bekasPas encore d'évaluation

- 'Bubble Kid' Success Puts Gene Therapy Back On TrackDocument5 pages'Bubble Kid' Success Puts Gene Therapy Back On TrackAbby Grey Lopez100% (1)

- Itrogen: by Deborah A. KramerDocument18 pagesItrogen: by Deborah A. KramernycPas encore d'évaluation

- Null 6 PDFDocument1 pageNull 6 PDFSimbarashe ChikariPas encore d'évaluation

- Basic Electrical Engineering NotesDocument25 pagesBasic Electrical Engineering NotesAnas AnsariPas encore d'évaluation

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazPas encore d'évaluation

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation