Académique Documents

Professionnel Documents

Culture Documents

Boiler Pressure Parts

Transféré par

LTE002Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Boiler Pressure Parts

Transféré par

LTE002Droits d'auteur :

Formats disponibles

Product Preview

Page 1 of 2

Boilers - Pressure Parts

The Babcock Power Services Group includes numerous companies within the Babcock Power Inc. family,

focusing on the power generation and waste-to-energy markets. Included within this Group are the OEM

Riley Power Inc., Boiler Tube Company of America, and Babcock Power Services Inc. Combining the

strengths and experience of each of these companies under one Group allows us to provide replacement

pressure parts for any OEMs unit, whether for in-kind replacement, improved performance, or lifeextension enhancement. It also provides us with the choice of several manufacturing facilities to assist us

in optimizing the shop selected to ensure compliance with your specification and delivery requirements.

We also have one of the largest inventories of Straight tubing in the USA, available 24/7/365.

Pressure parts Offered:

Drums

Superheaters

Headers

Reheaters

Generating Tubes

Economizers

Waterwalls

DRUMS

Steam and water drums can be provided for any OEMs natural

circulation boiler design, or capacity. Drums up to 84 diameter

are available, including those requiring single thickness tube

and wrapper sheets, or different thickness tube and wrapper

sheets. In-house stress relieving capability is available, as is all

required NDE to ASME and ASNT requirements.

HEADERS

Replacement headers are available for any application,

including superheaters, reheaters, economizers, and

waterwalls. We have extensive experience with the latest

materials currently required for all operating units, including

natural circulation and supercritical designs. During fabrication,

the headers are produced under the strictest surveillance of

our Quality Control Department to insure complete compliance

with all necessary codes.

GENERATING TUBES

Generating tubes for all OEM boiler designs are available and are typically

tubes extending between the mud/water and steam drums that convert a

large volume of water into steam. Generating tubes are normally

manufactured from various grades of carbon steel, including SA-178 Gr.

A, SA-178 Gr. C, SA-192, and SA-210 A1. Where designs require that the

generating tubes be swaged to a smaller diameter at each end, our shops

can comply and will insure that acceptable levels of hardness are

maintained through specific annealing processes so that the tubes can be rolled properly into the drums.

Each tube row configuration is matched to insure that the new tubes will be properly aligned with the

existing tubes in each row. This is particularly important if your existing arrangement has baffles,

vibration restraints, or other attachments.

WATERWALLS

Waterwall configurations, materials, and designs vary greatly for each boiler

design. Most waterwalls today are of the membrane type construction,

although we can also offer waterwalls utilizing tangent tube construction.

http://www.babcockpower.com/popups/productswindow.php?id=87&print=print

6/8/2006

Product Preview

Page 2 of 2

We have numerous panel welding machines at our manufacturing facilities capable of producing

membrane-type waterwalls from a variety of tube sizes, materials, and fin widths. Where bent panels are

required to insure correct alignment of all tubes, a panel gang bender is utilized. Weld overlay can be

applied where operating conditions justify it.

SUPERHEATERS

Replacement superheaters for in-kind replacement, as well as improved

performance and/or extended life, can be furnished for any OEMs unit.

Procedures necessary to insure acceptable bend geometry and material

mechanical characteristics, as well as those required to manufacture any

design with any of the materials needed to meet todays performance

and code requirements, are available. When appropriate, weld overlay

can also be provided.

REHEATERS

Reheaters are often exposed to very

high temperatures during start-up.

Premature failure in reheaters can

often be attributed to poorly designed

support and alignment systems, as

well as inadequate tube material

selection for the high temperatures to

which they are exposed. Replacement

reheaters can be designed to meet

your operating requirements utilizing

the centuries of experience available within the Babcock Power Services Group. Revised designs, utilizing

the correct materials and the latest manufacturing techniques, can be offered to help insure that your unit

will operate reliably and efficiently. Where appropriate, weld overlay can also be applied.

ECONOMIZERS

Complete design capabilities are available within the Babcock Power

Services Group to produce any type of economizer for any type of boiler,

including bare tube, bar-fin tube, spiral wound and H-fin. After consulting

with our client about the operating conditions of a specific unit, and the

desired performance and operating enhancements, a complete

evaluation is conducted, and a final solution proposed. Consideration is

given to the type of fuel being fired, flue gas characteristics, potential for

plugging, gas velocity and temperature, sootblower requirements,

operating hours, load variation, and unit history. After complete

evaluation, a solution is offered, selecting the appropriate tube size and

material, as well as the correct finning surface, if appropriate, including BTAs H-fin surface for dirty flue

gas applications.

New Economizer

Manufacturing H-Fin Surface

Close

http://www.babcockpower.com/popups/productswindow.php?id=87&print=print

6/8/2006

Vous aimerez peut-être aussi

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingD'EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsD'EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsÉvaluation : 4 sur 5 étoiles4/5 (6)

- Sikagrout 214-11 PdsDocument2 pagesSikagrout 214-11 PdscharlessimoPas encore d'évaluation

- E101 3240 Industrial Water Tube Package Boilers Babcock WilcoxDocument12 pagesE101 3240 Industrial Water Tube Package Boilers Babcock Wilcoxa_parratPas encore d'évaluation

- Sharpen Steam System Best Practices EbookDocument26 pagesSharpen Steam System Best Practices EbookswaminathanPas encore d'évaluation

- FW Utility Boiler PDFDocument12 pagesFW Utility Boiler PDFChandan AulakhPas encore d'évaluation

- CondenserDocument4 pagesCondensermaneeshjha9368100% (1)

- Coil Catalog Version 09 - 01ADocument28 pagesCoil Catalog Version 09 - 01AblindjaxxPas encore d'évaluation

- AIR COOLED HEAT EXCHANGER DESIGN AND MANUFACTURINGDocument16 pagesAIR COOLED HEAT EXCHANGER DESIGN AND MANUFACTURINGModesty100% (1)

- Industrial Plants Power Steam GeneratorsDocument20 pagesIndustrial Plants Power Steam GeneratorslosmoscasbrPas encore d'évaluation

- Basco Engineered ProductsDocument12 pagesBasco Engineered ProductsavazcPas encore d'évaluation

- STF Industrial BoilersDocument20 pagesSTF Industrial BoilersDaniellzhangPas encore d'évaluation

- Ashrae Handbook 2000 CHDocument8 pagesAshrae Handbook 2000 CHKazuto NakazatoPas encore d'évaluation

- Description & SpecificationDocument3 pagesDescription & SpecificationJAY PARIKHPas encore d'évaluation

- Fired HeatersDocument20 pagesFired HeatersCal100% (5)

- Boiler Project FundamentalsDocument7 pagesBoiler Project FundamentalsAlejandro AlvarengaPas encore d'évaluation

- Boiler Project Fundamentals: Back To BasicsDocument7 pagesBoiler Project Fundamentals: Back To BasicsChemical.AliPas encore d'évaluation

- Babcox BoilerDocument14 pagesBabcox BoilertoanbtdPas encore d'évaluation

- Boiler Tube Repair ProcedureDocument7 pagesBoiler Tube Repair ProcedurejoelandrewpintoPas encore d'évaluation

- Shell-and-tube Heat Exchangers SolutionsDocument24 pagesShell-and-tube Heat Exchangers SolutionsSubrata DasPas encore d'évaluation

- Jacketed Piping & Fittings1Document3 pagesJacketed Piping & Fittings1Melele MuPas encore d'évaluation

- Shell and Tube Heat ExchangersDocument4 pagesShell and Tube Heat ExchangersMohamed Ashraf0% (1)

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 pageseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xPas encore d'évaluation

- Integral Low Fin TubeDocument16 pagesIntegral Low Fin TubePeter_Phee_341Pas encore d'évaluation

- Heat Ex Changer CatalogDocument16 pagesHeat Ex Changer Catalogareqeem0713100% (1)

- Brazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsDocument31 pagesBrazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsHitesh Panchal100% (1)

- Shell and tube heat exchangers constructionDocument8 pagesShell and tube heat exchangers constructionZeeshan SajidPas encore d'évaluation

- GE Heavy-Wall Reactors 011811Document7 pagesGE Heavy-Wall Reactors 011811gpskumar22Pas encore d'évaluation

- Sluice Gates - Slide Gates - PenstocksDocument28 pagesSluice Gates - Slide Gates - Penstocksnazar750100% (2)

- Rehau Everloc Sales Brochure 890700 UkDocument8 pagesRehau Everloc Sales Brochure 890700 UkFlorin StanciuPas encore d'évaluation

- Reliable Process Piping ProjectsDocument5 pagesReliable Process Piping Projectsabchavhan20Pas encore d'évaluation

- Shell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsDocument24 pagesShell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsZewdu TsegayePas encore d'évaluation

- Basco Type 500Document12 pagesBasco Type 500Sebastian OviedoPas encore d'évaluation

- Basic Construction of Shell & Tube Heat ExchangersDocument12 pagesBasic Construction of Shell & Tube Heat ExchangerslatsharePas encore d'évaluation

- CalorifierDocument12 pagesCalorifierNay Myo OoPas encore d'évaluation

- Coiled Tubing StringDocument10 pagesCoiled Tubing StringVirnando NainggolanPas encore d'évaluation

- Advantages and Limitations: Engineered Heat Transfer SolutionsDocument2 pagesAdvantages and Limitations: Engineered Heat Transfer SolutionsMarco CarrieriPas encore d'évaluation

- Boiler TubeDocument12 pagesBoiler Tuberudi setiawanPas encore d'évaluation

- CALVERTDuctos Barra Fase No Segregada NSPBInglesDocument16 pagesCALVERTDuctos Barra Fase No Segregada NSPBInglesmartinpellsPas encore d'évaluation

- SEC Spiral Heat Exchangers BrochureDocument4 pagesSEC Spiral Heat Exchangers BrochureShrikant Nimbalkar100% (1)

- Water Transmission PipelinesDocument16 pagesWater Transmission Pipelinesdownloadused33% (3)

- Turflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochureDocument8 pagesTurflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochurePablo Angel ToiaPas encore d'évaluation

- Types of Boilers Classification and Hydrostatic Test OverviewDocument10 pagesTypes of Boilers Classification and Hydrostatic Test OverviewIbrahim MustafaPas encore d'évaluation

- Industrial Watertube BrochureDocument12 pagesIndustrial Watertube Brochuregonzaracing84Pas encore d'évaluation

- Api 600 Cast Steel Valves 1: Service FeaturesDocument5 pagesApi 600 Cast Steel Valves 1: Service FeaturesRevanPas encore d'évaluation

- Onload Boiler Cleaning SystemDocument11 pagesOnload Boiler Cleaning SystemidigitiPas encore d'évaluation

- Braithwaite Hot Pressed Steel Tank HistoryDocument8 pagesBraithwaite Hot Pressed Steel Tank Historysegunoyes0% (1)

- Aosmith HeatersDocument48 pagesAosmith HeatersAli Kamel AkilPas encore d'évaluation

- Boiler Part - Pin TubeDocument7 pagesBoiler Part - Pin TubeoktemPas encore d'évaluation

- Fulton - BroDocument4 pagesFulton - BroCarlos André MuñozPas encore d'évaluation

- HRSG 2011 BrochureDocument12 pagesHRSG 2011 BrochureAndry SetiawanPas encore d'évaluation

- Bubble Cap Tray Design and ManufacturingDocument4 pagesBubble Cap Tray Design and ManufacturingPujo PurwantoPas encore d'évaluation

- Hot Topping Split TeeDocument4 pagesHot Topping Split Teelili100% (1)

- Basco Type ESDocument8 pagesBasco Type ESkawag51241Pas encore d'évaluation

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesD'EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesPas encore d'évaluation

- Gasoline and Oil Stoves, "New Process" and "Standard." 1901D'EverandGasoline and Oil Stoves, "New Process" and "Standard." 1901Pas encore d'évaluation

- Machines, Tools and Methods of Automobile ManufactureD'EverandMachines, Tools and Methods of Automobile ManufactureÉvaluation : 4 sur 5 étoiles4/5 (1)

- YZ - 10 Intumescent CoatingDocument26 pagesYZ - 10 Intumescent CoatingLTE002Pas encore d'évaluation

- MethaneDocument24 pagesMethaneLTE002Pas encore d'évaluation

- ZH - 09 Steel ConnectionDocument65 pagesZH - 09 Steel ConnectionLTE002Pas encore d'évaluation

- YYJ - Stiff - 2003 Caternary Action - Steel BeamDocument29 pagesYYJ - Stiff - 2003 Caternary Action - Steel BeamLTE002Pas encore d'évaluation

- Centrifugal PumpDocument42 pagesCentrifugal Pumprumabiswas853100% (2)

- Pump Affinity Laws GuideDocument3 pagesPump Affinity Laws Guidesubramanyanvenkat6185Pas encore d'évaluation

- ZH - 09 Steel ConnectionDocument65 pagesZH - 09 Steel ConnectionLTE002Pas encore d'évaluation

- YZ - 11 Intumescent Coating ModellingDocument39 pagesYZ - 11 Intumescent Coating ModellingLTE002Pas encore d'évaluation

- ZH - 2005 RCDocument99 pagesZH - 2005 RCLTE002Pas encore d'évaluation

- Oxygen RequirementsDocument22 pagesOxygen RequirementsLTE002Pas encore d'évaluation

- Bio Gas Burner 1Document21 pagesBio Gas Burner 1saadullah_siddiqui6076Pas encore d'évaluation

- Fire Sprinklers PDFDocument28 pagesFire Sprinklers PDFChristopher BrownPas encore d'évaluation

- Bridges - Asia-22-25 02 10Document84 pagesBridges - Asia-22-25 02 10LTE002100% (1)

- Building Digest 20Document4 pagesBuilding Digest 20LTE002Pas encore d'évaluation

- Soil WashingDocument19 pagesSoil WashingLTE002Pas encore d'évaluation

- Gas ChromatographDocument21 pagesGas ChromatographLTE002Pas encore d'évaluation

- 32438Document154 pages32438vasakaPas encore d'évaluation

- PH MeasurementsDocument12 pagesPH MeasurementsLTE002Pas encore d'évaluation

- Simulation of High-Speed FillingDocument13 pagesSimulation of High-Speed FillingLTE002Pas encore d'évaluation

- Biomass To Ethanol ProcessDocument132 pagesBiomass To Ethanol ProcessLTE002Pas encore d'évaluation

- High PerformanceDocument3 pagesHigh PerformanceLTE002Pas encore d'évaluation

- Otis About ElevatorsDocument14 pagesOtis About ElevatorsRajeshkragarwalPas encore d'évaluation

- Cal Methodology - Energy Saving - Electrical - HouseholdDocument15 pagesCal Methodology - Energy Saving - Electrical - HouseholdLTE002Pas encore d'évaluation

- Trigger Sprayer Dynamic Systems ModelDocument5 pagesTrigger Sprayer Dynamic Systems ModelLTE002Pas encore d'évaluation

- Toxicity of BiodieselDocument53 pagesToxicity of BiodieselLTE002Pas encore d'évaluation

- Heat Exchanger VibrationDocument3 pagesHeat Exchanger VibrationTim KuPas encore d'évaluation

- I. Introduction, Purpose, and Study LayoutDocument17 pagesI. Introduction, Purpose, and Study LayoutLTE002Pas encore d'évaluation

- Ettv - BcaDocument56 pagesEttv - BcaHo Chee YongPas encore d'évaluation

- EarthingDocument40 pagesEarthingmamoun_hammad7917Pas encore d'évaluation

- 833 Anaerobic Digestion ParametersDocument4 pages833 Anaerobic Digestion ParametersLTE002Pas encore d'évaluation

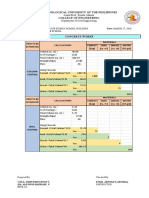

- Daily Overtime & Night Shift Permit SummaryDocument23 pagesDaily Overtime & Night Shift Permit SummaryDwi Agung AriyonoPas encore d'évaluation

- Chemical Process Calculations - Anna UnivDocument10 pagesChemical Process Calculations - Anna UnivGoutham R100% (1)

- Investment Casting Process and ApplicationsDocument28 pagesInvestment Casting Process and ApplicationsKristin Louise Agbulos100% (1)

- Environmental Health and Vessel Sanitation Preventive Procedure Instruction #11Document1 pageEnvironmental Health and Vessel Sanitation Preventive Procedure Instruction #11VizitiuAnisoaraPas encore d'évaluation

- bizurado-silvaco-PIN Detector Thesis PDFDocument143 pagesbizurado-silvaco-PIN Detector Thesis PDFombraga1896Pas encore d'évaluation

- CV of Dr. Janakarajan RamkumarDocument20 pagesCV of Dr. Janakarajan RamkumarAnonymous fgrTyKxxsLPas encore d'évaluation

- Loctite 577™: Technical Data SheetDocument5 pagesLoctite 577™: Technical Data SheetAditya DarmawanPas encore d'évaluation

- Advances in The Chemistry, Physics and Technology of Polysaccharides and LigninDocument2 pagesAdvances in The Chemistry, Physics and Technology of Polysaccharides and LigninSya'roni ImamPas encore d'évaluation

- Elementary Solid State Physics Omar PDF Free Halaman 15 46Document32 pagesElementary Solid State Physics Omar PDF Free Halaman 15 46Ihsania Ikrima KinantiPas encore d'évaluation

- MQ SP M 4002 PDFDocument28 pagesMQ SP M 4002 PDFjaseelPas encore d'évaluation

- Vane Pump Article WearDocument7 pagesVane Pump Article WearDirk DreesPas encore d'évaluation

- 2 Concrete Works CompuDocument14 pages2 Concrete Works CompuALFONSO RAPHAEL SIAPas encore d'évaluation

- Methods For Improving The Microstructure of Recycled Concrete Aggregate - A ReviewDocument18 pagesMethods For Improving The Microstructure of Recycled Concrete Aggregate - A ReviewMO AbdulkareemPas encore d'évaluation

- Microstructure-Property Correlations For Hard, Superhard, and Ultrahard MaterialsDocument244 pagesMicrostructure-Property Correlations For Hard, Superhard, and Ultrahard MaterialsJH ShinPas encore d'évaluation

- Robust Prediction of Full Creep Curves From Minimal Data and Time To Rupture ModelDocument9 pagesRobust Prediction of Full Creep Curves From Minimal Data and Time To Rupture ModelFarzad SadrPas encore d'évaluation

- Diode Operation IntroductionDocument3 pagesDiode Operation IntroductionAnonymous FKMfvCbPas encore d'évaluation

- Tube Fitting Hoke Gyrolok CatalogueDocument56 pagesTube Fitting Hoke Gyrolok CatalogueGorbyPas encore d'évaluation

- Monolithic DomeDocument38 pagesMonolithic Domerichuricha100% (1)

- Plastic Surgeon Rob Mouser ProfileDocument3 pagesPlastic Surgeon Rob Mouser ProfileKatie BrownPas encore d'évaluation

- Consolidation - Odoemeter TestDocument30 pagesConsolidation - Odoemeter TestLuqman YusofPas encore d'évaluation

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiPas encore d'évaluation

- Module 6 (Chemistry)Document152 pagesModule 6 (Chemistry)Adabala Durgarao NaiduPas encore d'évaluation

- The optimal solution for your projects in damp and corrosive environmentsDocument24 pagesThe optimal solution for your projects in damp and corrosive environmentsDavidPas encore d'évaluation

- Low-Bias Transport in Graphene:an IntroductionDocument57 pagesLow-Bias Transport in Graphene:an IntroductionLIAKMANPas encore d'évaluation

- Prof. Dr. Zainul Huda: Resume ofDocument31 pagesProf. Dr. Zainul Huda: Resume ofMuhammed ThanzeelPas encore d'évaluation

- Abaa1985 The Structure and Petrography of Alkaline Rocks of The MadaDocument7 pagesAbaa1985 The Structure and Petrography of Alkaline Rocks of The MadaSanda MoustaphaPas encore d'évaluation

- Polyurethanes From Renewable ResourcesDocument46 pagesPolyurethanes From Renewable ResourcesMohammad R ChandanPas encore d'évaluation

- Assignment On Soil PollutionDocument18 pagesAssignment On Soil PollutionImran Hussain100% (1)

- IB MYP Chemistry Term End AssessmentDocument2 pagesIB MYP Chemistry Term End AssessmentKrishna Teja67% (3)