Académique Documents

Professionnel Documents

Culture Documents

Concrete Weight Coating

Transféré par

bonnicoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Concrete Weight Coating

Transféré par

bonnicoDroits d'auteur :

Formats disponibles

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

TABLEOFCONTENT

1

PROJECTINTRODUCTION............................................................................................................5

1.1

SCOPEOFDOCUMENT.......................................................................................................................7

1.2

DEFINITION.........................................................................................................................................7

1.3

ABBREVIATION...................................................................................................................................7

REFERENCES................................................................................................................................8

2.1

PROJECTDOCUMENTS.......................................................................................................................8

2.2

COMPANYSTANDARDS......................................................................................................................8

2.3

CODESANDSTANDARDS....................................................................................................................8

2.4

SYSTEMOFUNITS...............................................................................................................................9

GENERALREQUIREMENTS.........................................................................................................10

CONCRETECOATINGMATERIALS..............................................................................................11

4.1

CEMENT............................................................................................................................................11

4.2

AGGREGATES....................................................................................................................................11

4.3

WATER..............................................................................................................................................12

4.4

ADDITIVES.........................................................................................................................................12

4.5

REINFORCINGSTEEL.........................................................................................................................12

4.6

WELDEDSTEELWIREMESH..............................................................................................................13

4.7

STEELCAGETYPE..............................................................................................................................13

RECEIPT,HANDLINGANDSTORAGEOFBAREPIPES...................................................................14

CONCRETECOATINGAPPLICATION...........................................................................................15

6.1

VISUALANDHOLIDAYINSPECTIONOF3LAYERPECOATEDPIPES.................................................15

6.2

PLACEMENTOFREINFORCEMENTSTEEL.........................................................................................15

APPLICATIONOFCOATINGMATERIALS.....................................................................................16

7.1

PREPARATIONOFTHECUTBACKAREA............................................................................................16

7.2

FINISHINGOPERATIONSWITHINCONCRETECOATINGPLANT........................................................16

7.3

CURING.............................................................................................................................................17

7.3.1

WATERCURING...............................................................................................................................17

7.3.2

STEAMCURING................................................................................................................................18

7.3.3

CURINGBYSEALINGCOMPOUNDS.................................................................................................18

Page2of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

7.3.4

CURINGUNDERPOLYETHYLENEWRAPPING...................................................................................18

7.3.5

FOGCURING....................................................................................................................................19

INSPECTIONANDTESTING........................................................................................................20

8.1

STACKINGOF3LAYERPECOATEDPIPES.........................................................................................21

8.2

CONTROL,IDENTIFICATIONANDSEGREGATIONOF3LAYERPECOATEDPIPES.............................22

8.3

DELIVERYANDSTORAGEOFCONCRETECOATINGRAWMATERIALS..............................................22

8.4

TESTTOBEPERFORMEDONCONCRETECOATINGMATERIALUPONRECEIPT...............................23

8.4.1

SIEVEANALYSISANDCLEANLINESSCONTROLOFAGGREGATES....................................................23

8.4.2

STEELREINFORCEMENTWIRESDIMENSIONALCONTROL..............................................................23

8.4.3

MIXINGWATERCHEMICALANALYSIS.............................................................................................23

8.5

VERIFICATIONOFCALIBRATIONOFTHETESTINSTRUMENTS.........................................................24

8.5.1

HOLIDAYDETECTOR........................................................................................................................24

8.5.2

PIPEWEIGHINGSCALES...................................................................................................................24

8.6

VISUALANDHOLIDAYINSPECTIONOFTHE3LAYERPECOATEDPIPES..........................................24

8.7

CONCRETECOATINGMIXCONTROL................................................................................................25

8.8

CONCRETECOATINGMIXTEMPERATUREMEASUREMENT.............................................................25

8.9

WATERCEMENTRATIOCHECK........................................................................................................25

8.10

REINFORCINGWIREPOSITIONCONTROL.........................................................................................26

8.11

CONCRETECOATINGAPPLICATIONCONTROL.................................................................................26

8.12

MEASUREMENTOFEXTERNALDIAMETEROFAPPLIEDCONCRETE.................................................26

8.13

CUTBACKCONTROL..........................................................................................................................27

8.14

WEIGHINGOFFRESHLYCONCRETECOATEDPIPE............................................................................27

8.15

CALCULATIONOFNEGATIVEBUOYANCY.........................................................................................27

8.16

VISUALINSPECTIONOFAPPLIEDCONCRETE....................................................................................28

8.16.1

SURFACEFALLOUTS(SPALLING)OFFRESHLYCONCRETECOATEDPIPES......................................29

8.16.2

CONCRETECOATINGDAMAGESONFRESHANDHARDENEDCONCRETE.......................................29

8.16.3

CRACKS............................................................................................................................................29

8.17

ELECTRICALRESISTANCEBETWEENSTEELREINFORCEMENTANDTHEPIPE...................................30

8.18

CONTROLOFCURINGPROCESS.......................................................................................................30

8.19

CONTROLOFSTACKINGOFPIPESDURINGTHECURINGPROCESS..................................................30

Page3of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

8.20

CONTROLOFMARKINGONCONCRETECOATEDPIPES...................................................................30

8.21

CONTROLOFMARKINGONCONCRETECOATINGREPAIR...............................................................31

8.22

DETERMINATION OF FACTOR ALPHA IN THE FORMULA FOR CALCULATION OF NEGATIVE

BUOYANCY.......................................................................................................................................31

8.23

COMPRESSIONSTRENGTHTESTCUBES...........................................................................................31

8.24

COMPRESSIONSTRENGTHCORESAMPLES......................................................................................32

8.25

DETERMINATIONOFTHETIMEFORSTACKINGOFPIPESINMORETHANONELAYER...................33

8.26

WATERABSORBTIONTEST...............................................................................................................34

8.27

ADHESIONBETWEENTHE3LAYERPECOATINGANDCONCRETECOATING...................................34

8.28

IMPACTTESTING..............................................................................................................................35

8.29

STACKINGOFCUREDCONCRETECOATEDPIPES..............................................................................36

8.30

LOADOUTINSPECTIONS..................................................................................................................37

3LAYERPECOATINGREPAIR....................................................................................................38

10

CONCRETECOATINGREPAIRANDSTRIPPINGOFCONCRETECOATEDPIPES..............................40

11

PIPEMARKING..........................................................................................................................42

12

STORAGE,HANDLINGANDTRANSPORTATIONOFCONCRETECOATEDPIPES............................43

13

DOCUMENTATION....................................................................................................................45

13.1

GENERALREQUIREMENTS................................................................................................................45

13.2

TECHNICALDOCUMENTATIONTOBESUBMITTEDDURINGTHEBIDDINGPHASE..........................45

13.3

TECHNICAL DOCUMENTS TO BE SUBMITTED AFTER AWARD OF THE CONTRACT TO

SUBCONTRACTOR............................................................................................................................46

13.4

FINALTECHNICALDOCUMENTATION..............................................................................................47

13.5

CONTENTOFPARTICULARTECHNICALDOCUMENTS......................................................................48

13.5.1

CONCRETECOATINGAPPLICATIONPROCEDURE............................................................................48

13.5.2

INSPECTIONANDTESTPLAN...........................................................................................................49

13.5.3

DAILYPRODUCTIONREPORT...........................................................................................................49

Page4of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

PROJECTINTRODUCTION

NC3andNC8aregasfieldslocatedinBlockSK316,approximately180kmNorthofBintulu,Sarawakwith

waterdepthrangingapprox.between70m105m.NC8fieldislocatedapproximately7kmSouthEaston

NC3field.ThenearbyriserfacilityE11RCislocatedapproximately80kmSouthWestofNC3.Theexisting

trunklineconnectingE11RCtoshoreTL6isavailableandprovisionedforinthisgasfielddevelopment.The

locationsofNC3,NC8andnearbyfacilitiesareillustratedinFigure11below.

Figure11LocationofProject

GasfromNC3andNC8fieldsarethemainfeedgassupplierintothePETRONASLNGComplexTrain9near

Bintulu which is expected to be ready for startup in December 2015.The scope demarcation between

upstreamanddownstreamfacilitiesisasdescribedbelowinFigure12.

Figure12UpstreamandDownstreamScopeDemarcation

Page5of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

ThedevelopmentofNC3andNC8fieldsisenvisagedtobeincomplextypeconfiguration.NC3willbecome

ahubcomprisingofaCentralProcessingPlatform(CPP)withlivingquartersandabridgelinkedWellhead

Platform(WHP).AnotherWHPistobeinstalledatNC8;itwillbetiedbacktoNC3viaaninterfieldsubsea

pipeline. Though compression may not be required at the beginning of production, the need for gas

compressionisanticipatedafterapproximatelyfour(4)years.Hencetheprovisionforfuturecompression

facilitiesandmercuryremovalfacilitiesshallbeconsideredaspartofthisFEEDworkfortheNC3CPP.

Figure13OverallDevelopmentConcept

A new subsea pipeline connecting NC3 and E11RC will be installed to deliver the processed gas and the

spikeddehydratedcondensate.Duetoincompatibilityofthisgasqualitywiththeexistinggassupplyatthe

riser,adedicatedmanifoldatE11RCmayberequiredtoaccommodatethistiein.Thisistoensurethatthe

gasfromNC3andNC8fieldsdonotcontaminatetheentirenetworktoshore.Assuch,modificationwillbe

requiredtoconverttheexistingTL6tobededicatedforgasfromNC3andNC8.

Thefuturetrunkline(TL7)mayberequiredinthefutureshouldTL6nolongerbefitforservice.

The processed gas and dehydrated condensate will be separated at onshore receiving facilities prior to

beingintroducedintoLNGPlantTrain9.

Page6of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

1.1 SCOPEOFDOCUMENT

Thepurposeofthisdocumentistodefinetheminimumrequirementsforconcreteweightcoatingtobe

usedforthefollowingoffshorerigidpipelineintheSK316DevelopmentProject:

32OffshorepipelinefromNC3WHPtoE11RCPlatform

32OffshorepipelinefromE11RCPlatformtoOnshoreBeachValveLocation

20OffshorepipelinefromNC8WHPtoNC3WHP(Diametertobeconfirmed)

1.2 DEFINITION

COMPANY

PETRONASCarigaliSdnBhd

CONTRACTOR

SAIPEM

SUBCONTRACTOR

PartyselectedbyCOMPANY/CONTRACTORresponsiblefor

application of the concrete weight coating on PROJECT

pipes in accordance with this specification and other

contractualdocuments

MANUFACTURER

Supplier of the raw materials or inspection and testing

equipmentrequiredtoperformthework

PROJECT

FEED for SK316 Facilities Development of the NC3 and

NC8GasFields

1.3

ABBREVIATION

FBE

FusionBondedEpoxy

N/A

NotApplicable

No.

Number

OD

Outsidediameter(externalpipediameter)

PQT

PreQualificationTest

3LPE

3LayerPolyethylene

3LPP

3LayerPolypropylene

CWC

ConcreteWeightCoating

Page7of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

REFERENCES

Unlessotherwisestated,thelatestissueofthebelowlistedPTSCOMPANYSpecifications,Codes,Standards

andRegulationsshallapply.Equivalentalternativesmaybeoffered;theseshallbeidentifiedandmutually

agreedon.

2.1

PROJECTDOCUMENTS

DOCUMENT

NAME

/1/ 05SSPLBODU0001

PipelineAndRiserDesignBasis

/2/ TBC

InputforPipelineStudy

/3/ 05GENBODB0001

ProcessDesignBasis

/4/ 05SSPLREPU0001

SteadyStatePipelineSimulationReport

/5/ 05GENBODZ0002

CorrosionStudyMemorandum

/6/ 05SSPLREPU0002

PipelineTransientAnalysisReport

/7/ 05SSPLREPU0003

PipelineRouteSelectionReport

2.2

COMPANYSTANDARDS

DOCUMENT

NAME

/8/ 31.40.00.20

Pipeline&RiserEngineering

/9/ 31.40.30.30

Concretecoatingoflinepipe

2.3

CODESANDSTANDARDS

DOCUMENT

NAME

/10/ ISO218091

Petroleum and Natural Gas Industries External

CoatingsforBuriedorSubmergedPipelinesUsedin

PipelineTransportationSystemsPart1:Polyolefin

Coatings(3LayerPEand3LayerPP).

/11/ BSEN10288

Steel Tubes and Fittings for Onshore and Offshore

Pipelines External Two Layer Extruded

PolyethyleneBasedCoatings

/12/ ASTMC150

StandardSpecificationforPortlandcement

/13/ ASTMC33

StandardSpecificationforConcreteAggregates

/14/ ASTMA81001

Standard Specification for ZincCoated (Galvanized)

SteelPipeWindingMesh

Page8of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

/15/ ASTMA615M

Standard Specification for Deformed and Plain

CarbonSteelBarsforConcreteReinforcement

/16/ ASTM18501

Standard Specification for Steel Welded Wire

Reinforcement,Plain,forConcrete

/17/ ASTMA8201

Standard Specification for Steel Wire, Plain, for

ConcreteReinforcement

/18/ ASTMC30998A

Standard Specification for Liquid Membrane

FormingCompoundsforCuringConcrete

/19/ ASTMC171

Standard Specification for Sheet Materials for

CuringConcrete

/20/ ASTMC39/C39M01

Standard Test Method for Compressive Strength of

CylindricalConcreteSpecimens

/21/ ASTMC61798

Standard Practice for Capping Cylindrical Concrete

Specimens

/22/ BSEN1971

Cement Part 1: Composition, Specifications and

ConformityCriteriaforCommonCements

/23/ BSEN1008

Mixing Water for Concrete Specification for

Sampling, Testing and Assessing the Suitability of

Water, Including Water Recovered from Processes

in the Concrete Industry, as Mixing Water for

Concrete

/24/ BS4482

Cold Reduced Steel Wire for the Reinforcement of

ConcreteProductsSpecification

/25/ BS4483

Steel Fabric for the Reinforcement of Concrete

Specification

/26/ BSEN123902

Testing Hardened Concrete Part 2: Making and

CuringSpecimensforStrengthTests

/27/ BSEN123903

Testing Hardened Concrete Part 3: Compressive

StrengthoftestSpecimens

2.4

SYSTEMOFUNITS

The International Unit System (SI) shall be utilized throughout the project, unless otherwise highlighted.

Anyconversionshallbeprovidedinparenthesiswhereapplicable.

Page9of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

GENERALREQUIREMENTS

FortestingpurposesspecifiedinthisSpecification,theproductionshiftshallbeconsideredofmaximum12

hours depending on the SUBCONTRACTORs internal organization. In case SUBCONTRACTOR intends to

workmorethan12hoursperday,COMPANY/CONTRACTORshallconsiderthattheworkisperformedin

morethanoneshiftandtherelevanttestingfrequencyshallberespectedasperthisSpecification.

AllSUBCONTRACTORsdocumentsshallcomplywiththelimitationsofthisSpecification.SUBCONTRACTOR

shallpromptlyinformCOMPANY/CONTRACTORofanyneedtomakechangestothesedocuments,which

shallhavetobespecificallyacceptedbyCOMPANY,whohastherighttorequireadditionaltestingwithout

additionalcosts.

Any technical deviations to this Specification shall be obtained by SUBCONTRACTOR only through a

concessionrequestformat.InanycaseitisnotallowedtoinsertanydeviationfromthisSpecificationin

anySUBCONTRACTORsdocumentpriorthatthisdeviationhasnotbeenpreviouslypresentedseparately

toCOMPANY/CONTRACTORandapprovedinwrittenbyCOMPANY/CONTRACTOR.

Concession requests require COMPANYs review and approval prior to implementation of the proposed

changes. Pipes coated by implementing the technical changes prior to the COMPANYs approval shall be

rejected.

Priortothecommencementoftheproductionandduringtheproduction,COMPANYshallreservetheright

toperformauditsintheSUBCONTRACTORsfacilities.

COMPANYandCOMPANYsrepresentativesshallbepermittedbySUBCONTRACTORtheunlimitedaccess

to all SUBCONTRACTORs facilities related to the SUBCONTRACTORs scope of work for the PROJECT

startingfromthemomenttheworkhasbeenawardedtoSUBCONTRACTORuntilSUBCONTRACTORhas

completedalloftheobligationsrelatedtohisscopeofworkinthePROJECT.

It is mandatory requirement for SUBCONTRACTORs coating facilities that all of the inspection activities

accordingtotheactionpointsspecifiedininspectionandtestplanscanbeperformedbyinspectorsfrom

all involved Parties in safe manner for all personnel involved in these activities. In case the inspection

activities cannot be safely performed for all persons involved in inspection (CONTRACTOR,

SUBCONTRACTORs, COMPANYs and Third Partys personnel), SUBCONTRACTOR shall stop all of the

activitiesatthatparticularinspectionpointandshallorganizetheworkspaceinamannerthatallactivities

canbeperformedinsafemanner.AllcostsduetosuchstoppagesshallbeborneonlybySUBCONTRACTOR.

Page10of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

CONCRETECOATINGMATERIALS

Theconcretecoatingappliedonlinepipesshallhavethefollowingnominaldryandcuredconcretedensity

of3044kg/m3.

4.1 CEMENT

UnlessotherwisespecifiedinthePurchaseOrder,allcementusedforthepreparationoftheconcreteshall

bePortlandCementconformingtotherequirementsofoneofthefollowingstandardsdependingonthe

availabilityatthelocationwheretheconcretecoatingapplicationshallbecarriedout:

ASTMC150TypeIIandV;

MS522standard;

BSEN1971standard.

All batches of cement shall be supplied to SUBCONTRACTOR with test certificate stating the compliance

either with the ASTM C 150 (Type II and V) or BS 12 or EN 1971 standard which shall then

SUBCONTRACTORsubmittoCOMPANYforreviewpriortoitsuse.

The certificates must be presented to COMPANYs review to verify that also the following mandatory

requirementsaremet:

thatthecontentofalkaliis<0.6%;

thatthecontentoftricalciumaluminateC3Ais<8%.

Cementthathashardened,partiallysetorlumpywillberejectedandshallberemovedfromtheworksite.

Regroundandgradedcementshallnotbeused.

CementnotmeetinganysingleofabovementionedrequirementsshallnotbeusedinthePROJECT.

Cementshallbestoredincoveredareasorcoveredbyplasticsheeting.

4.2

AGGREGATES

Thesandshallbeofthesilicatype.Clayeyandschistosesandsshallnotbeused.

Sandshallbestoredinamannertoavoidcontaminationfromsoilorotherforeignmatter.

Heavy aggregates shall be made of crushed granite, or any other aggregate approved by the

COMPANY/CONTRACTOR. Aggregates shall not be made from chalky or decomposed stone. In case high

densityconcreteisrequired,SUBCONTRACTORmayaddironoretotheconcretecoatingmix.

AllaggregatesshallbecertifiedaccordingtoASTMC33standardwithexceptionofgrading.

SUBCONTRACTOR shall propose the grading of aggregates in the concrete mix which shall be confirmed

duringthePreQualificationTest.Howeveritismandatorythatallaggregatesshallbeofthesizethat100%

oftheirquantitywillbeabletopass10mmsieves.

Allaggregatesshallbewashedandshallbefreefrominjuriousamountsofsalts,alkali,organicimpurities

or deleterious substances such as oxides of lead and zinc that may affect the strength of the concrete.

Page11of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

Samplingandtestingforcleanlinessofaggregatesshallbecarriedoutforeachdeliveryofeachaggregate

inaccordancewithASTMC33standardandotherstandardsreferredintheASTMC33standard.

Duringproductionthegradingandcleanlinessshallbecheckedatleastonceeverythreedaysfromeach

stockpileandeachnewconsignmentforcleanlinessandgrading.Thegradingshallbeasperthenominal

valuesandtolerancesspecifiedbySUBCONTRACTORandverifiedduringthePQT.Thetestforcleanliness

shall mean visual inspection for presence of any foreign material in tested sample beside the tested

aggregateitself(wood,shells,oranyothersimilarcontaminant).SUBCONTRACTORshallberesponsiblefor

properstorageofaggregatesandallcostsrelatedtotheCOMPANYsrejectionofcontaminatedaggregate

shallbebornebySUBCONTRACTOR.

Differenttypesofaggregatesshallbestoredseparatelyinbinsorwellpreparedareas,i.e.cobbled,paved

orwellcompactedareasallowingadequatedrainageofmaterials.

4.3 WATER

WaterusedinconcretecoatingmixshallbefreshandshallcomplywithAppendixAofBSEN1008.

Water shall be of potable quality and obtained from a public supply where possible. Water shall not be

takenfromaspring,well,lakeorsimilarsourceunlesstestindicateitssuitability.

DuringthebiddingstageofthePROJECTtheSUBCONTRACTORshallpresentthecertificateforthemixing

waterusedinthecoatingplantandtheSUBCONTRACTORshallprovidetheguarantythatthesamewater

shallbeusedduringentireSUBCONTRACTORsworkinthePROJECT.

4.4 ADDITIVES

Additivescontainingchloridesshallnotbeusedintheconcretemix.Thetotalquantityofchlorideswithin

theconcretemix,calculatedasfreeCaCl2,shallnotexceed0.4%oftheweightofthecement.

Waterreducingagentsforconcretemaybeusedintheconcretemix.

Airentrainingagentsshallnotbeusedintheconcretemix.

4.5 REINFORCINGSTEEL

Thereinforcingsteelmaybeusedinthefollowingforms:

weldedsteelwiremesh(typeWWCortypeWWNaspertheASTMA81001standard);

steelcagetype.

Chickenwiremeshandsteelpoultrynettingarenotallowedasthereinforcementmaterial.

Thediameterofthereinforcingsteelshallbeselectedinamannerthatallofthefollowingrequirements

aremet:

theminimumcircumferentialreinforcementshallbe0.5%ofthelongitudinalcrosssectionalareaof

theconcretecoating;

theminimumlongitudinalreinforcementshallbe0.08%ofthetransversecrosssectionalareaofthe

concretecoating;

Page12of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

minimumdiameterofthereinforcingwirefortheweldedsteelwiremeshshallbe1.6mm;

minimumdiameterforthereinforcingwireinthecagetypeshallbe3mm.

4.6 WELDEDSTEELWIREMESH

Theweldedsteelwiremeshshallbegalvanized.Theonlyapprovedtypeofthereinforcingsteelwiremesh

areTypeWWCandTypeWWNaspertheASTMA81001standard.

ThephysicalandchemicalpropertiesofthewireandwiremeshshallbeinaccordancewiththeASTMA

641andASTMA81001standard.

4.7 STEELCAGETYPE

The reinforcement shall be in the form of spirally wound cages having a continuous hoop wire with a

numberofstraightlongitudinalbarsevenlyspacedaroundthespiralandweldedateachwireintersection.

Alternatively, the continuous hoop wire may be replaced by single circumferential hoops. The material

usedshallbenharddrawnwiretoBS4482orASTMA615M(deformed),ortoCOMPANY/CONTRACTOR

approvedequivalentstandard.TheweldingofmaterialsshallresultinasteelfabricinaccordancewithBS

4483orASTMA185.

Thediameterofthecircumferentialandlongitudinalbarsshallbecalculatedfromtherequiredpercentage

ofreinforcing,withaminimumdiameterof3mm.

Thespacingofthelongitudinalbarsshallbebetween50and250mmbutnotlessthanfourlongitudinal

barsatapproximatelyequalspacingshallbeprovided.Thecircumferentialhoopspacingshallnotbemore

than100mm.Cagesshallhavetwohoopsspaced50mmapartateachpipeend.

Thephysicalandchemicalpropertiesofthereinforcingwireandofthewiremeshshallbeinaccordance

withtheASTMA8201(orASTMA615M)andASTMA18501standard.

Page13of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

RECEIPT,HANDLINGANDSTORAGEOFBAREPIPES

Pipescoatedonlywith3layerpolyethyleneshallbehandled,storedandtransportedinamannerthatthe

pipesteelandpipecoatingshallnotbedamaged.

Allforeignsubstancessuchasexcessivedirt,debrisofcoatingmaterialsoranyotherforeignobjectsshall

beremovedfrominternalpipesurfacebeforestackingofpipesorapplicationofconcretecoating.

Coated pipes can be handled using slings, lifting hooks padded with soft material with suitable spreader

bars, forklifts having lifting forks padded with soft material, front loaders padded with soft material and

vacuumlifting.Chainsorwireropesoranyotherdevicethatmaydamagethepipesteelorpipecoating

shallnotbeused.

Whenmorethanonepipeislifted,separateslingsorhooksshallbeusedforeachpipe.

Pipesshallbepickedupfromthestackingpointandatnotimeshallbedraggedorrolled.

Coatedlinepipeshallnotbesubjectedtojarorimpactandallpipesupportsshallbepadded.

Pipesupportsshallbespacedtoavoidbendingoflinepipes.

Thecoatedlinepipesshallalwaysbestackedtoavoidsurfacecontactwiththeground.Thepipesshallbe

stacked on approved supports which shall be free of any material that could potentially damage the

appliedcoating.

The stacking height of 3LPE/3LPP coated line pipes shall be limited to avoid damage of the coated line

pipesduetotheweightofotherones.Themaximumnumberofstackinglayersforthecoatedlinepipes

shallbecalculatedbySUBCONTRACTORandrelevantcalculationshowingcalculationstepsandresultsshall

be submitted to COMPANY/CONTRACTOR for review and approval however, for safety reasons the

maximumheightofanystackshallbe3m.IncaseSUBCONTRACTORdoesnotprovideanycalculationnote

related to stacking of coated pipes acceptable for COMPANY/CONTRACTOR, the coated pipes shall be

stackedinmaximum4rows.

Thestacksofcoatedpipesshallbeseparatedforeachofthefollowingcombinations:

pipenominalODxpipenominalwallthickness.

Thelinepipesshallbestackedataslightangletoallowdrainageofanyrainwater.

The coated pipes shall not be stacked below and near electrical lines or near any facility which may

increase residual magnetism in the pipes (at all times it shall be kept the minimum distance of 30 m

betweenthestoredpipesandanyelectricalcablemeasuredfromtheverticalprojectiontothegroundof

thenearestelectricalcable).

Incaseitisdetecteddisbondmentofthe3layerPEcoatingfromthepipeatthecoatingedgeswhenthe

coated pipes are stacked either before or during the load out operation, that particular pipe shall be

rejectedandthe3layerPEshallbestrippedandreappliedatSUBCONTRACTORscost.

Page14of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

6

6.1

CONCRETECOATINGAPPLICATION

VISUALANDHOLIDAYINSPECTIONOF3LAYERPECOATEDPIPES

Prior to placement of the steel reinforcement and/or application of concrete coating, the entire factory

appliedanticorrosioncoatingofthepipeshallbevisuallyinspected.

Any foreign matter shall be removed from the surface of the anticorrosion coating and each detected

coatingdamageshallberepairedaccordingtotheapprovedprocedurepriortothecommencementofthe

concretecoatingapplication.

Then, the entire coated surface of the pipes shall be inspected using a holiday detector at a voltage of

minimum 25 kV. The holiday detector shall be equipped with a visual and an acoustic signalling device

clearlyaudibleintheprevailingworkingconditions.Alldamagesdetectedbytheholidaydetectorshallbe

repaired.

6.2

PLACEMENTOFREINFORCEMENTSTEEL

Forconcretethicknessupto50mm,onewrapofreinforcingshallbeused.Forthicknessesofmorethan50

mm, two layers should be considered. Additional layers may be necessary for concrete thicknesses in

excessof120mm,butthiswouldthenrequirefurtherCOMPANY/CONTRACTORsapproval,sothenumber

ofsteelreinforcinglayersshallbeasfollows:

concretecoatingthicknessupto50mm1layer;

concretecoatingthicknessfrom51mmupto100mm2layers;

concretecoatingthicknessfrom101mmupto140mm3layers.

According to SUBCONTRACTORs discretion, SUBCONTRACTOR may apply also the combination of the

reinforcing steel cage and reinforcing steel welded wire mesh but the above mentioned number of

reinforcinglayersvs.concretecoatingthicknessandtherequirementsforpercentageofreinforcingsteelin

concretecoatingcrosssectionalareasmustberespected.

Duringtheapplicationofthereinforcingsteel,atalltimes,thefollowingrequirementsmustbemet:

minimum15mmdistancebetweenthereinforcingsteelandthefactoryappliedanticorrosionpipe

coating;

minimum10mmdistancebetweenthereinforcingsteelandtheoutersurfaceofappliedconcrete

coating;

minimum10mmdistancebetweentwolayersofreinforcingsteel.

Incasethereinforcingsteelweldedwiremeshisused,thelongitudinaloverlapofthewiremeshshallbe

minimum25mm.

Incasethecagetypeofreinforcementisused,thesteelreinforcementshallterminate:

10mm30mmfromtheendofconcretecoating.

Page15of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

APPLICATIONOFCOATINGMATERIALS

It will be the SUBCONTRACTORs decision to apply the concrete coating using impingement method or

compressioncoatmethod(extrusion),howeveronlytheapplicationmethodusedduringthesuccessfully

passedandcompletedprequalificationtestshallbeused.

Prior to the application of the concrete coating, the temperature of the concrete coating mix shall be

withintherangebetween+5Cand+35C.

In case the temperature of the concrete coating mix is less than +5C, the concrete coating shall not be

performeduntilSUBCONTRACTORmanagestoheattheentireconcretemixupto+5C.

Incasethetemperatureoftheconcretecoatingmixishigherthan+35C,themixingwatershallbecooled

withiceorasuitablecoolingsystemshallbeprovidedforthemixingwaterinordertoobtaintheconcrete

mixtemperatureofmaximum+35C.

Thefreewater/cementrationshallnotexceed0.45byweight.

Theconcretecoatingapplicationmethodshallbesuchthatthecoatingtimeforeachpipedoesnotexceed

30 minutes (starting from the moment that the water was added to the concrete mix and the concrete

coatingapplicationstartedonthatparticularpipeuptothecompletionofapplicationofconcretecoating

onthesamepipe)otherwisetheconcretecoatingonthatpipeshallberejected.

Useofreclaimed/reboundmaterialmightbeallowedprovidingitisdemonstratedthatitdoesnothaveany

detrimentaleffectonthefinalconcreteproduct.

Secondary mixing of the reclaimed material with freshly batched concrete must follow immediately and

must produce a homogeneous cohesive mixture. The amount of recycled material used shall not exceed

10%ofthetotalmixbyweight.Ifabreakofthisoperation,forwhateverreason,exceeds30minutesany

reclaimedmaterialnotpreviouslyaddedtothemixshallbediscardedandremovedfromthecoatingarea.

7.1

PREPARATIONOFTHECUTBACKAREA

Theconcretecoatingshallberemovedatbothpipeendstakingcarenottodamagepipesteelorfactory

appliedanticorrosioncoating.Thelengthofsuchpreparedconcretecoatingcutbackshallbe380mm(0

mm/+20mm).Thecutbackshallbesquarewithrespecttopipeaxis.

7.2

FINISHINGOPERATIONSWITHINCONCRETECOATINGPLANT

Surfacefallouts(spalling) shallbefilledbyguniting. Therepair mixshallbesimilarincompositiontothe

originalmix.Therepairshallbecarriedoutinaccordancewithapprovedprocedurewithin30minutesafter

applicationoftheoriginalconcretecoatingmix.

Surfacedamageonconcretecoatingshallnotbeconsideredasadefectifallofthefollowingconditions

havebeenmet:

damageisnotexposingreinforcingsteel;

Page16of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

damageisnotextendedtomorethan20%ofthenominalconcretecoatingthickness;

damagedareaislessthan1000cm2(0.1m2).

Incasethetotalareaoffallouts(spalling)ismorethan20%oftheconcretesurface,theconcretecoating

shallberemovedfromthatparticularpipe.

The cutback area and internal pipe surface shall be completely free from any residual concrete coating

materialandfromanymaterialsdetrimentaltothewelding,NDTandfieldjointcoatingoperationswhich

shallbeperformedbypipelayingCONTRACTORduringthepipelayingoperations.

Finally,eachpipeendshallbeprotectedwithendcapandtheexposedsteelandthefirst100mmof3

layerPEcoatingshallbewrappedwithpolyethylenesheetthatdoesnotcontainanyadhesiveandwhich

shallbefirmlytightenedaroundthispipelocation.

7.3

CURING

Immediatelyaftercompletionoftheapplicationofconcretecoatingoperations,theconcretecoatedpipe

passingallonlineinspectionsandtestsshallbetransferredtothecuringarea.

Duringthecuringperiod,thepipesshallbestackedinasinglelayer.

Curingshallbeperformedeitherbyusingwatercuring,steamcuring,curingbysealingcompoundsorby

polyethylenewrapping.Theexposedsurfacesoftheconcretecoatingshallbeprotectedduringthecuring

periodfromanyadverseeffectsofsunshine,dryingwinds,rainorrunningwater.

The curing process shall continue until a minimum compressive strength of 14 MPa has been achieved

whenthecompressionstrength testisperformedoncoresamplesafterwhichthe concretecoated pipe

can be lifted, transported and stacked in more than one layer up to the maximum allowed number of

stacking layers. In case the period when the pipe reaches minimum 14 MPa of compression strength on

coresampleshasnotbeendeterminedbypracticaltests,thepipesshallremainstackedinasinglelayerfor

minimumsevendays.

Locations where the core samples shall be taken from the pipe for this purpose shall be selected by

COMPANY/CONTRACTOR.

7.3.1

WATERCURING

Watercuringshallconsistofwettingandmoisteningtheconcretecoating,startingnotlaterthan6hours

aftercompletionofconcretecoatingapplication.

The concrete coating shall be kept continuously moist by intermittent spraying for a period of at least 7

days.Theintervalbetweensprayingshallnotbemorethan24hours.Attheambienttemperaturesbelow

+4C,suitableprecautionsshallbetakentopreventdamageduetofreezing.

Page17of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

7.3.2

STEAMCURING

If the curing process involves steam or warm highhumidity air, then it shall be demonstrated that the

process will have no deleterious effects on the concrete. Under no circumstances shall the pipe wall be

allowedtoreachatemperaturethatwouldcauseanydamagetotheanticorrosioncoating.

Curingbysteamshallnotstartsoonerthan3hoursaftercompletionoftheconcretecoatingapplication

completion.

Concretecoatedpipesshallbeenclosedinplasticorsimilarcoversuitabletomaintainsteamcirculation.

Steam circulation shall start at the ambient temperature and shall be controlled to give a temperature

gradientofapproximately10C/houruptothemaximumsteelorcoatingtemperatureof+60C.

The pipes shall be held under steam curing for at least 6 hours and then allowed to cool for a similar

period.SUBCONTRACTORshalldemonstrateduringtheprequalificationtestthatthecuringtimeusedis

sufficienttomeetthespecifiedconcretestrengthlevels.

7.3.3

CURINGBYSEALINGCOMPOUNDS

SealingcompoundsshallmeetrequirementsofASTMC30998Astandard.Thematerialshallbestored,

prepared and applied in accordance with instructions supplied by the MANUFACTURER of sealing

compounds.

The compound shall be nontoxic and nonflammable and shall not react with any constituent of the

concrete,reinforcement,protectivecoatingorpipesteel.

Unless otherwise specified by the compound MANUFACTURERs instructions, membrane sealing

compounds shall be sprayed over the complete concrete surface within 6 hours after completion of the

concrete application and shall remain for a minimum of 7 days. The materials shall not be applied at

temperatureslessthan+4C.

7.3.4

CURINGUNDERPOLYETHYLENEWRAPPING

Wrapping in polyethylene film shall be done during the application of concrete coating. A light spray of

water shall be applied before applying the plastic film. The polyethylene film shall have a minimum

thicknessof0.2mmandtheoverlapofthesheetshallnotbelessthan25%ofthesheetwidth.

ThepolyethylenefilmshallbeinaccordancewithASTMC171standard.

Theinterfacebetweentheconcreteandthebaresteelatthepipeendsshallalsobeprotectedinorderto

achieveanairtightseal.

Thepolyethylenewrappingshallremainonthepipeforminimumsevendaysbutitshallberemovedprior

tofinalloadoutofthepipe.

Page18of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

7.3.5

FOGCURING

Fresh concrete coating is continuously moistened by mist released from fogging tips and covered with

tarpaulinsheetstoprovideaclosedenvironmentforcuring.

Atomizedmist,withhighwetabilityisintroducedgraduallybuildingtoaclosedhighhumidity,near

saturation ambience to facilitate proper curing environment. The continuous introduction of atomized

fog/mist into tarpaulin shall be continued for one shift before the pipe is removed/subject to further

handling.

Page19of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

INSPECTIONANDTESTING

ThePreQualificationTestshallbeperformedonfivefullyconcretecoatedpipesandshallbecompleted

beforethestartofactualproductioninthePROJECT.Thecombinationofpipematerialvs.pipeexternal

diametervs.pipewallthicknessvs.concretecoatingthicknessselectedforPreQualificationTestshallbe

agreedbetweenSUBCONTRACTORandCOMPANY/CONTRACTOR.

Itismandatorythatallfiveconcretecoatedpipesareconcretecoatedinasequencewithoutanystoppage

of the concrete coating plant in order to allow performance of the offline PQT tests. In case this

requirementisnotmet,thePQTshallberepeated.

Alloftheinspectionsandtestslistedinthisdocumentshallbeaddressedintheinspectionandtestplan.

Defects or anomalies detected during coating process shall start immediate corrective actions from the

SUBCONTRACTOR.

All line pipes to be submitted to the inspections and tests shall be selected in agreement with the

COMPANY/CONTRACTORsInspector.

Intheeventthataproductionlinepipefailstomeettheacceptancecriteriaforthetestslistedinthetable

thetestcanberepeatedonlyshouldthefailurebecausedeitherbyimproperuseofthetestingequipment

orbyerrorinthetestingprocedure.

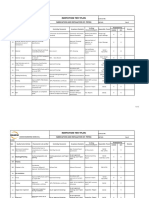

Thefollowinginspectionsandtestsshallbecarriedout:

Inspection/Test

Inspectionofthe3layerPEcoatedpipesduring

thereceipt

Visual inspection of the stacking of the 3layer

PEcoatedpipes

Inspections of the concrete coating materials

duringtheirreceipt

Reference

Section6

Section8.2

Section8.1

BeforethestartofthePQT.

Production

Beforethestartof

production.

Periodically.

BeforethestartofthePQT.

Mixing water certificate to

bedeliveredbeforethestart

ofthePQT.

BeforethestartofthePQT.

Onceperday.

EachPQTpipe.

Eachpipe.

Section8.7

BeforethestartofthePQT.

Onceperweek.

Concretecoatingmixtemperaturecheck

Section8.8

Once.

Watercementratiocheck

Section8.9

Once.

Whentheambienttemperatureiswithinthe

rangefrom+10C upto+25C,thetestshall

notbecarriedout.

In case the ambient temperature is outside

the above mentioned range the concrete

coatingmix

temperature shall be measured at the

beginning of each working shift and then

every4hours.

Firstworkingshiftof

eachworkingday.

Verification of calibration of the holiday

detector and the concrete coated pipes

weighingscale

Visual and holiday inspection of 3layer PE

coated pipes immediately before application of

concretecoating

Concrete coating mix control (verification of

calibrationoftheconcretecoatingmixingplant)

Section8.3

Section8.4.1

Section8.4.2

Section8.4.3

Section8.5

Section8.5.1

Section8.5.2

Section8.6

PQT

BeforethestartofthePQT.

Page20of50

Area

05

File

Each package of received concrete coating

material.

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

Inspection/Test

Verification of the correct positioning of the

concretecoatingsteelreinforcement

Reference

Section8.10

PQT

FirsttwoPQTpipes.

Concretecoatingapplicationcontrol

Measurement of external diameter of applied

concretecoating

Cutbackcontrol

Weighingoffreshlyconcretecoatedpipe

Calculationofnegativebuoyancy

Visualinspectionofappliedconcrete

Measurement of the electrical resistance

betweenthesteelreinforcementandthepipe

Section8.11

Section8.12

EachPQTpipe.

EachPQTpipe.

Section8.13

Section8.14

Section8.15

Section8.16

Section8.17

Eachpipe.

Eachpipe.

Eachpipe.

Eachpipe.

Reinforcingsteelwiremesh:eachPQTpipe.

Steelcage:

On the pipes where the test for verification

of the correct positioning of the concrete

coating steel reinforcement has been

performed.

Control of the curing process and control of

stacking of concrete coated pipes during the

curingprocess

Controlofmarkingonconcretecoatedpipes

Section8.18

Section8.19

EachPQTpipe.

EachPQTpipe.

EachPQTpipe.

EachPQTpipe.

Reinforcingsteelwiremesh:

eachPQTpipe.

Steelcage:

On the pipes where the test

forverificationofthecorrect

positioning of the concrete

coating steel reinforcement

hasbeenperformed.

EachPQTpipe.

Section8.20

EachPQTpipe.

Eachpipe.

Controloftheconcretecoatingrepair

Controloftheconcretecoatingrepair

Section8.20

Section8.21

EachPQTpipe.

EachPQTpipe.

Determination of factor in the formula for

calculation of negative buoyancy (performance

ofthistestisnotmandatory)

Compressionstrengthtestcubes

Section8.22

Two PQT pipes not

submitted to the water

absorptiontest.

EachPQTpipe.

Eachpipe.

Eachpipeonwhichtheconcretecoating has

beenrepaired.

N/A.

Compressionstrengthtestoncoresamples

Section8.24

Determinationofthetimeforstackingofpipes

inmorethanonelayer(performanceofthistest

isnotmandatory)

Waterabsorptiontest

Section8.25

ThreePQTpipes.

Section8.26

TwoPQTpipes.

Section8.27

Onetest.

One pipe coated each day during the first

threeproductiondays.

In case all tests had acceptable results the

testshallbeperformedoncepershift.week

N/A.

Section8.28

Section8.29

Section8.30

WhenRequested

N/A

N/A

WhenRequestedoneperweek

Eachpipe.

Eachpipe.

Adhesion between the 3layer PE coating and

concretecoating

Impacttesting

StackingofcuredCWCpipes

Loadoutinspections

8.1

Section8.23

EachPQTpipe.

Production

One pipe concrete coated at the beginning

and on one pipe concrete coated in the

middleofeachworkingshift.

Eachpipe.

Eachpipe.

Periodically.

4 cubes from first pipe at the beginning of

eachworkingshiftandthenevery25pipes.

2x3coresfromfirstpipeatthebeginningof

eachworkingshiftandthenevery15pipes.

N/A.

STACKINGOF3LAYERPECOATEDPIPES

Periodicalvisualinspectionshallbeperformedintheareadedicatedforstackingofthepipescoatedwith

3layer PE awaiting the application of concrete coating in order to verify that these pipes have been

stackedinamaximumallowednumberoflayersandthattheyhavebeenstackedonapprovedsupports.

In case of nonconformance with relevant requirements SUBCONTRACTOR shall inform

COMPANY/CONTRACTORwhowillbringfurtherdecisionsandCOMPANY/CONTRACTORsdecisionshallbe

binding.

Page21of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

8.2

CONTROL,IDENTIFICATIONANDSEGREGATIONOF3LAYERPECOATEDPIPES

The 3layer PE coated pipes shall be visually inspected for bevel damages, dents, gauges, flat ends and

coatingdamages.Alsothecontentofagreedpipemarkingrequiredatthisstageofworkshallbeverified

onthepipe.

Incasebeveldamages,significantcorrosion,dents,gouges,laminationorflatendshavebeendetectedon

barepipeportionatthecutbackarea,thepipeshallbemarkedwithcolouredtape,segregatedifpractical

to do so, and brought to COMPANY/CONTRACTORs attention who will instruct SUBCONTRACTOR about

actionstobetakenonthispipe.

Incasethecoatingdamagehasbeendetected,damagedareashallbemarkedandcolouredtapeshallbe

put around that pipe which shall remain on the pipe until the coating repair has been completed and

approvedbyCOMPANY/CONTRACTOR.

Incaseoil,greaseoranysimilarcontaminationhasbeendetectedatthecutbackarea,thecontamination

shallberemovedwithfreshwateranddetergent,solventoranyothersuitablemethod.

Incasethemissingorincorrectpipemarkinghasbeendetected,thepipeshallbemarkedwithcoloured

tape, segregated if practical to do so and brought to the COMPANY/CONTRACTORs attention who will

instructSUBCONTRACTORabouttheactionstobetakenonthatpipe.

8.3

DELIVERYANDSTORAGEOFCONCRETECOATINGRAWMATERIALS

Ateach deliveryofthecoatingrawmaterials,thereceived documentationshallbereviewedagainstthe

receivedmaterialpackagesandagainstthePurchaseOrderdocumentsinordertoverifythatthereceived

documentsandmaterialsconformtotherequirementsspecifiedinthepurchaseorder.

Incaseofanynonconformance,itshallbetheSUBCONTRACTORsresponsibilitytoresolvethisissuewith

the supplier of the nonconforming material. However, the batch of the material delivered in

SUBCONTRACTORspremisesnonconformingtotherequirementsofthisspecification,shallnotbeusedin

thePROJECT.

Periodically,avisualinspectionshallbeperformedinordertoverifythatthecoatingmaterialshavebeen

storedinconditionsasrecommendedbythematerialMANUFACTURER.

Thecementshallbestoredinproperwaterproofsilos.

The aggregates can be stacked in stockpiles at the open on clean site, free from the possibility of

contamination.

Thegalvanizedwiremeshmaybestoredattheopencleansitefreefrompossibilityofcontaminationbut

thewiresusedformanufacturingofsteelcagemustbestoredinclosedstoragefacilityindryplace.

Thepolyethylenewrappingthatshallbeusedforcuringofconcretecoatedpipesmaybestoredoutsidein

cleansitebutitmustbecoveredwithappropriatesheetingtoavoidexposuretotherainandraisedfrom

thegroundtoavoidflooding.

Page22of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

COMPANY/CONTRACTORreservestherighttorejecttheuseofimproperlystoredmaterialinthePROJECT.

8.4

8.4.1

TESTTOBEPERFORMEDONCONCRETECOATINGMATERIALUPONRECEIPT

SIEVEANALYSISANDCLEANLINESSCONTROLOFAGGREGATES

Thegradingandcleanlinessofaggregatesshallbecheckedfromeachstockpileforcleanlinessandgrading.

ThegradingshallbeasperthenominalvaluesandtolerancesspecifiedbySUBCONTRACTORandverified

duringthePQT.Thetestforcleanlinessshallmeanvisualinspectionforpresenceofanyforeignmaterialin

testedsamplebesidethetestedaggregateitself(wood,shells,oranyothersimilarcontaminant).

In case of test failure, the test shall be repeated on doubled number of samples taken from the same

batch.Incaseofrepeatedfailure,theaffectedbatchofsuppliedmaterialshallnotbeusedinthePROJECT

oritshallbecleanedfromallcontaminationasperCOMPANY/CONTRACTORssatisfaction.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,testedmaterial,materialsupplier,materialbatch

numberifapplicable,acceptancecriteria,testresults,remarks.

8.4.2

STEELREINFORCEMENTWIRESDIMENSIONALCONTROL

Foreachbatchofreceivedreinforcingsteelsomeofthereceivedrollsofwiremeshand/orthewiresfor

cagetypereinforcementshallbecheckedbymeasuringthediameteroflongitudinalandstaywireswitha

calliper.

The measured value shall correspond to the minimum value provided by the reinforcing steel

MANUFACTURER required to meet the requirements for reinforcing steel in concrete coating in this

specification(minimumtolerancespecifiedfirstbyrelevantstandardandifthisvaluecannotbefoundin

thestandardthentheminimumtolerancevaluecanbespecifiedbytheMANUFACTURER).

In case of test failure, the test shall be repeated on doubled number of samples taken from the same

batch.Incaseofrepeatedfailure,theaffectedbatchofsuppliedmaterialshallnotbeusedinthePROJECT.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,testedmaterial,materialsupplier,materialbatch

numberifapplicable,acceptancecriteria,testresults,remarks.

8.4.3

MIXINGWATERCHEMICALANALYSIS

WaterusedinconcretecoatingmixshallbefreshandshallcomplywithAppendixAofBSEN1008.During

thebiddingstageofthePROJECTtheSUBCONTRACTORshallpresentthecertificateforthemixingwater

usedinthecoatingplantandtheSUBCONTRACTORshallprovidethewrittenguarantythatthesamewater

shallbeusedduringentireSUBCONTRACTORsworkinthePROJECT.

Page23of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

In case the above mentioned requirement is not met, the chemical analysis of mixing water shall be

completed and the certificate submitted to COMPANY/CONTRACTOR two weeks before the

commencementofthePreQualificationTestotherwiseSUBCONTRACTORshallnotbeallowedtostartthe

performance of the prequalification test. In case the quality of mixing water does not meet the

requirementsofthisspecification,theconcretecoatingplantshallnotbequalifiedforthework.

8.5

VERIFICATIONOFCALIBRATIONOFTHETESTINSTRUMENTS

The verification of calibration shall be verified for the holiday detector and pipe weighing scales each

working day while the calibration of other testing equipment shall not be verified but the Third Partys

calibrationcertificatesshallbeused.

The instruments whose accuracy is not meeting the relevant acceptance criteria for each particular

instrument shall not be used in the PROJECT until the instruments accuracy is brought back within

acceptablelimits.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

The report shall contain the following items: date, shift, testing equipment, testing equipment serial

number,acceptancecriteria,testresults,remarks.

8.5.1

HOLIDAYDETECTOR

The voltage of the holiday detector shall be compared with the voltage of the certified calibration high

voltage instrument recommended by the MANUFACTURER of the holiday inspection equipment for this

purpose. The holiday detector shall be considered acceptable when the voltage of the holiday detector

when checked with the high voltage calibration instrument set at 25.0 kV shows the values within the

rangefrom25.0kVto25.5kV.

8.5.2

PIPEWEIGHINGSCALES

Theverificationofcalibrationoftheweighingscaleswhichshallbeusedfordeterminationoftheweightof

freshlyconcretecoatedpipesshallbeperformedbyweighingoftheminimum11.5mlongminimum10

diameterpipehavingknownandcertifiedweight.Theweighingbridgeshallbeconsideredacceptablefor

usewhenthemeasuredvalueoftheknownweightiswithintherange:

Nominalweightofthepipehavingknownandcertifiedweight0.3%.shift.

8.6

VISUALANDHOLIDAYINSPECTIONOFTHE3LAYERPECOATEDPIPES

Prior to the commencement of application of the concrete coating, the 3layer PE coated pipes shall be

submittedtothevisualinspectionandholidayinspectionat25kV.

Thepipesshallhavenomajorsteeldefectsandthepipecoatingshallbewithoutvisibledefects.

Thereshallbenoholidaysdetectedafterholidayinspectionat25kV.

Page24of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

The 3layer PE coating shall be repaired in accordance with the SUBCONTRACTORs coating repair

procedureapprovedbyCOMPANY/CONTRACTOR.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivityonlyin

caseanynotconformanceoccurred.

8.7

CONCRETECOATINGMIXCONTROL

Prior to the commencement of the prequalification test and during the production once per week,

SUBCONTRACTORshallperformtheverificationthattheirbatchingplantprovidesthecompositionofthe

concretecoatingmixwithinthetolerancesselectedbytheSUBCONTRACTORhimself.Productionshallnot

startifthebatchingplantisnotproperlycalibrated.

Within the concrete coating application procedure, SUBCONTRACTOR shall describe in details the

verification of calibration of batching plant for determination of percentage of each component in the

concretecoatingmix.

8.8

CONCRETECOATINGMIXTEMPERATUREMEASUREMENT

Whentheambientairtemperatureislessthan+10Canditishigherthan+25C,SUBCONTRACTORshall

measure the temperature of the concrete coating mix at the beginning of each working shift and then

every4hours.

Approximately310kgofconcretemixshallbetakenattheendofthebeltlocatedafterexitofthemixer

andputintothebucketoranyothersuitablecontainer.

Then,theimmersionprobeofthedigitalthermometershallbeimmersedinthefreshconcretemixandthe

temperatureshallbereadfromthedisplayoftheinstrument.

In case the temperature of the concrete coating mix is less than +5C, the concrete coating shall not be

performeduntilSUBCONTRACTORmanagetoheattheentireconcretemixupto+5C.

Incasethetemperatureoftheconcretecoatingmixishigherthan+35C,themixingwatershallbecooled

withiceorasuitablecoolingsystemshallbeprovidedforthemixingwaterinordertoobtaintheconcrete

mixtemperatureofmaximum+35C.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,acceptancecriteria,testresults,remarks.

8.9

WATERCEMENTRATIOCHECK

Thefreewater/cementratioshallbecheckedatthebeginningofthefirstworkingshiftofeachworking

day.

Thewatertocementratioshallnotexceed0.45byweight.

In case the acceptance criterion is not met, the concrete coating operations shall not start it has been

verifiedthatthewater/cementratioiswithinacceptablelimits.

Page25of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,acceptancecriteria,testresults,remarks.

8.10 REINFORCINGWIREPOSITIONCONTROL

On one pipe concrete coated at the beginning and on one pipe concrete coated in the middle of each

working shift, the proper positioning of the reinforcing steel wire mesh shall be verified by opening a

windowofapproximatedimensions200mmx75mmpenetratingdowntotheanticorrosionpipecoating

whiletheconcretecoatingisstillfresh.

During this visual inspection it shall be verified that the requirements specified in Section 8.2 of this

specificationhavebeenmet.

Only in case the cage type steel reinforcement is used by SUBCONTRACTOR, during this test it shall be

tested also the electrical resistance between the bottom layer of the reinforcing steel and the pipe end.

Oneelectrodeoftheohmmetershallbeinthecontactwiththebottomlayerofthereinforcingsteelofthe

cageandanotherelectrodeshallbeinthecontactwithbarepipeendatthecutbackarea.Theminimum

measuredresistanceshallbe1000Ohm.

Incasetheacceptancecriteriahavenotbeenmet,thetestingshallcontinueuntilitisdeterminedontwo

consecutive pipes concrete coated before and on two consecutive pipes concrete coated after the test

failure,thatthesetestsaresuccessfullypassed.Thepipesnotpassinganysingleofthesetestsshallhave

theconcretecoatingremoved.

8.11 CONCRETECOATINGAPPLICATIONCONTROL

Duringtheapplicationoftheconcretecoatingthefollowingverificationsshallbecarriedoutoneachpipe:

thattheconcretehasbeenappliedreasonablyuniformlythroughouttheentirepipelengthandthat

ithasbeenappliedwithoutanymajorirregularities;

thatthespallingisrepairedonthefreshlyconcretecoatingpipemaximum30minutesafteradding

thewaterintheconcretecoatingmixintheconcretebatchingplant;

whenthereinforcingsteelintheformofwiremeshisusedthatthepolyethylenewrappinghasbeen

applied immediately after the concrete application with minimum overlap of 25 % of the sheet

width.

Pipesnotmeetingacceptancecriteriashallhavetheconcretecoatingremoved.

8.12 MEASUREMENTOFEXTERNALDIAMETEROFAPPLIEDCONCRETE

Theexternalcircumference/diameterofappliedconcreteshallbemeasuredoneachconcretecoatedpipe

usingaflexiblemeasuringtapeatfiveequidistantpointsalongthepipelength.

The measurements shall not be taken at first 400 mm from the ends of applied concrete coating. The

average of five measurements for external diameter of applied coating shall than be inserted in the

formulaforcalculationofnegativebuoyancy.

Page26of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,pipesequencenumber,pipenumber,pipeexternal

diameter,pipewallthickness,pipenominalconcretecoatingthickness,testresults,remarks.

8.13 CUTBACKCONTROL

The cutback length shall be measured on each concrete coated pipe end. The average of two

measurementsshallbeinsertedintheformulaforcalculationofnegativebuoyancy.

Theedgesofconcretecoatingatthecutbackareashallbeperpendicularwithrespecttothepipeaxisand

entire concrete coating cutback area shall be free of residual concrete coating and from any materials

detrimentaltothewelding,NDTandfieldjointcoatingoperationswhichshallbeperformedbythepipe

layingCONTRACTORduringthepipelayingoperations.

Theconcretecoatingcutbacklengthshallbe380(0mm/+20mm).

Incasetheacceptancecriteriahavenotbeenmet,thepipeshallbequarantineduntiltheremedialworkis

takenwhichshallresultinacceptableconcretecoatingcutback.

Relevant inspection report specifying cutback lengths shall be prepared by SUBCONTRACTOR related to

thisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,pipesequencenumber,pipenumber,pipeexternal

diameter,pipewallthickness,pipenominalconcretecoatingthickness,acceptancecriteria,resultofeach

cutbacklengthmeasurement,remarks.

8.14 WEIGHINGOFFRESHLYCONCRETECOATEDPIPE

Eachfreshlyconcretecoatedpipeshallbeplacedonaweighingscalewhereitsweightshallbemeasured.

Theresultshallbedisplayedandwhenthepipeweighthasstabilized.Theresultofmeasurementshallbe

insertedintheformulaforcalculationofnegativebuoyancy.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,pipesequencenumber,pipenumber,pipeexternal

diameter,pipewallthickness,pipenominalconcretecoatingthickness,testresults,remarks.

8.15 CALCULATIONOFNEGATIVEBUOYANCY

Thenegativebuoyancyshallbecalculatedoneachpipeasfollows:

NB

= negativebuoyancy[kg/m];

Wbp

= weightofbarepipe,informationsuppliedfromthepipeMANUFACTURER[kg];

W3LPE/3LPP

= weight of applied 3layer PE/3layer PP not including mass of bare pipe, calculated using either

nominaloraverage3layerPEorotherexternalanticorrosioncoatingthickness[kg];

Page27of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

= lengthofthelinepipetakenthedatafrompipeMANUFACTURER[m];

CB3LPE/3LPP

= averageoftwomeasurementsofthe3layerHDPE/3layerPPcutbacklength;

theoreticalaverageisalsoallowedforthispurpose[m];

CBCWC

= averageoftwoactuallytakenmeasurementsoftheconcretecoatingcutbacklengthonwhichthe

lengthhasbeenmeasured[m];

= factor of change in the weight of concrete coating from wet and fresh to dry and cured; unless

otherwisedemonstratedduringthePQT,thefactor=0.99[nondimensionalvalue];

WCWC

= weightofthepipecoatedwithfreshconcrete,measurementtakenimmediatelyafterapplicationof

concretecoating[kg];

DCWC

= external diameter of the concrete coated pipe obtained by average of five measurements of the

concretecoatingcircumferenceasperthisspecificationdividedby[m];

= densityofseawater.

Theacceptancecriteriafornegativebuoyancyforeachcombinationofpipeexternaldiametervs.pipewall

thicknessvs.concretecoatingthicknessshallbeprovidedbyCOMPANY/CONTRACTORinduetime.

OnlyunlessotherwisecommunicatedbyCOMPANY/CONTRACTORthefollowingtolerancesshallapply:

perworkingshift:nominalvalueofnegativebuoyancy(0%/+4.5%);

persingleconcretecoatedpipe:nominalvalueofnegativebuoyancy(0%/+10%).

Eachpipenotmeetingacceptancecriteriahavetheconcretecoatingremoved.

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Thereportshallcontainthefollowingitems:date,shift,pipesequencenumber,pipenumber,pipeexternal

diameter, pipe wall thickness, pipe nominal concrete coating thickness, acceptance criteria, test results,

remarks.

8.16 VISUALINSPECTIONOFAPPLIEDCONCRETE

Eachfreshlyconcretecoatedpipeshallbevisuallyinspectedfordefects.

Surfacedamageonconcretecoatingshallnotbeconsideredasadefectifallofthefollowingconditions

havebeenmet:

damageisnotexposingreinforcingsteel;

damageisnotextendedtomorethan20%ofthenominalconcretecoatingthickness;

damagedareaislessthan1000cm2(0.1m2).

RelevantinspectionreportshallbepreparedbySUBCONTRACTORrelatedtothisinspectionactivity.

Page28of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)

Thereportshallcontainthefollowingitems:date,shift,pipesequencenumber,pipenumber,pipeexternal

diameter,pipewallthickness,pipenominalconcretecoatingthickness,testresults,remarks.

Thefollowingshallbeconsideredduringvisualinspectionofconcretecoatedpipes.

8.16.1 SURFACEFALLOUTS(SPALLING)OFFRESHLYCONCRETECOATEDPIPES

Incasethespallingoccurs,itshallberepairedonlyifthemaximum20%oftheconcretecoatingsurfaceis

affectedbyit.Thespallingshallberepairedinproductionlinewithin30minutesafterapplicationofthe

originalconcretecoatingmixorincasethistimeisexceededbygunitingusingtheconcretecomposition

similartotheoriginalconcretecoatingmixappliedonthepipe.Afterrepairthepipeshallbereweighedfor

calculationofnegativebuoyancy.

8.16.2 CONCRETECOATINGDAMAGESONFRESHANDHARDENEDCONCRETE

Damages caused by taking of core samples for compression strength test shall be repaired unless the

anticorrosionpipecoatinghasbeendamaged.Incasetheanticorrosioncoatinghasbeendamagedduring

thecoresamplingprocess,theconcretecoatingshallberemovedfromthatpipe.

In case reinforcing steel has been only cut but not removed from the pipe, the concrete coating can be

repairedandthereinforcingsteelshallbepositionedproperlyduringtherepair.

However,ifanyportionofreinforcingsteelhasbeenremovedfromthepipe,theconcretecoatingshallbe

removedfromthatpipe.

Concrete coating damages resulting also in damage of the 3layer PE coating shall have the concrete

coatingremoved.

Considering above mentioned limitations, repair of concrete coating damages is allowed when the

concrete coating has been damaged or it has been removed from the pipe for repair purposes up to

maximum20%oftheconcretecoatingsurface(notoftheconcretecoatingvolume.

8.16.3 CRACKS

Circumferential surface cracking of the concrete not exposing reinforcing steel having a crack width less

than5mmshallnotbeconsideredasadefect.

Circumferentialannularcrackingvisibleatpipeendsisgenerallynotacceptableandallpipeshavingsuch

cracksintotalcircumferentiallengthgreaterthan200mmshallhavetheconcretecoatingremoved.

Allcrackspenetratingdowntothe3layerPEcoatingshallnotbeacceptableandsuchpipeshallhavethe

concretecoatingremoved.

Longitudinal surface cracks less than 250 mm in length and having a width of 8 mm or less shall not be

consideredasadefectbutholesof10mmnominaldiametershallbedrilledatthecracktipstoprevent

propagationofthecrack.Thebottomoftheseholesshallbe710mmfromtheanticorrosioncoating.

Longitudinal cracks having a length from 250 mm up to 1000 mm shall be repaired by chiselling out the

cracktoawidthofatleast25mmthroughoutitslengthtakingcarenottodamageanticorrosioncoating.

Page29of50

Area

05

File

Loc.

SSPL

Typ.

SPC

Disc.

U

05SSPLSPCU00050.doc

No.

0005

Rev.

0

PETRONASCARIGALISDNBHD

PROVISIONOFFRONTENDENGINEERINGDESIGN(FEED)AND

ENGINEERING,PROCUREMENT,CONSTRUCTION,INSTALLATION&

COMMISSIONING(EPCIC)OFSK316DEVELOPMENTPROJECT

(CONTRACTNO.CHO/2012/D316/1000)