Académique Documents

Professionnel Documents

Culture Documents

Summary of Cutting Data For Axial Grooving: Material Details

Transféré par

unmilionlei931Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Summary of Cutting Data For Axial Grooving: Material Details

Transféré par

unmilionlei931Droits d'auteur :

Formats disponibles

Summary of cutting data for Axial grooving

To:

Contact:

Marian

Marian

unmilionlei@yahoo.com

n/a

5/18/2015 9:22 AM

Subject: scula

Summary of cutting data for Axial grooving

Material details

Werkstoffnummer DIN, 1.0116, Hardness: 124 HB, Material group:P1.1.Z.AN

Task details

Axial grooving

Depth of machining feature (DEPTHMF)

8.5

mm

84.75

mm

2.5

mm

Width tolerance lower (LWTOLL)

-0.1

mm

Width tolerance upper (LWTOLU)

0.1

mm

General radius parameter (RADIUS)

0.4

mm

Radius tolerance lower (RTOLL)

-0.4

mm

Radius tolerance upper (RTOLU)

0.4

mm

Minimum machined diameter (DMN)

General width parameter (WIDTH)

Cutting edge condition code (CUTCC)

Continuous cut

Machine

Multitask 01 - Medium (8-12" chuck), stability of fixturing: Good stability

CoroPak 15.1, CoroGuide 2.0 (14.3.1.315)

1 of 4

5/18/2015

Summary of cutting data for Axial grooving

Recommended solution

570-32R123F15B068A

N123F1-0250-0002-CM 1125

Tool

Insert

Tool (TOOL)

570-32R123F15B068A

N123F1-0250-0002-CM 1125

No. of pieces (#)

Type (ASMTYPE)

Indexable

Operation (SUBOPSEQ)

Grooving Axial

Grade (GRADE)

1125

Type of cooling (COOLSTL)

Internal

Coolant (COOLT)

Emulsion 10%

Machining time (TMF)

mm:ss,f

00:07.200

No. of features (TLIFEC)

58.4

No. of passes (NAP)

Adaption type (ADINTMS)

SL head (screw mounted) -size

32

ECONOMY

Cutting time total (TCCT)

00:07.200 mm:ss,f

Non cutting time total (TNCT)

00:00.016 mm:ss,f

Machining time (TMF)

00:07.200 mm:ss,f

No of grooves (TLIFEC)

58.4 Grooves

Cost per insert (COST)

35.66 %

Tool costs (COST)

6.14 %

Cost machine tool (COST)

58.22 %

Cost per feature (COST)

100 %

Cutting data

PASS

DIOUT

mm

1

AP

mm

89.75

FN

mm

2.5

N

1/min

0.08

VC

m/min

887

250

PPC

kW

MMC

Nm

1.96

21.1

TCC

mm:ss,f

00:07.200

TNC

mm:ss,f

00:00.016

Product information

CoroPak 15.1, CoroGuide 2.0 (14.3.1.315)

2 of 4

5/18/2015

Summary of cutting data for Axial grooving

Description

CoroCut 1-2 head for face grooving

Ordering code

ISO

570-32R123F15B068A

ANSI

570-32R123F15B068A

EDP

Bar code

12007026

SSCM

insert seat size code

SSCN

insert seat size code

ADINTMS

adaptive interface machine direction

SL head (screw mounted) -size 32

CZC

connection size code

32

CDX

cutting depth maximum

15 mm

DAXIN

axial groove inside diameter minimum

68 mm

DAXX

maximum axial groove outside diameter

98 mm

OHX

maximum overhang

12.75 mm

CNSC

coolant entry style code

1: axial concentric entry

DCON

connection diameter

32 mm

LF

functional length

14 mm

WF

functional width

37.4 mm

HF

functional height

0.1 mm

CP

coolant pressure

10 bar

WT

weight of item

0.65 kg

MIIDM

master insert identification

N123F2-0250-0002-CM

MIIDN

master insert identification

N123F2-0250-0002-CM

TQ

torque

2 Nm

TSYC

tool style code

570-xxR/L123..B..A

KAPR

tool cutting edge angle

90 deg

HAND

hand

GAMO

orthogonal rake angle

0 deg

LAMS

inclination angle

0 deg

AXGSUP

axial groove support direction

BAWS

workpiece side body angle

90 deg

BMC

body material code

CXSC

coolant exit style code

2: radial exit

DAXN

minimum axial groove outside diameter

73 mm

ITEMTYPE

item type

Tool Item

LFCIRP

length to cutting item reference point

12.75 mm

OAL

overall length

17.8 mm

RELEASEPACK

release pack id

5.2

WFCIRP

width to cutting item reference point

37.4 mm

CoroPak 15.1, CoroGuide 2.0 (14.3.1.315)

3 of 4

5/18/2015

Summary of cutting data for Axial grooving

Description

CoroCut 1-2 insert for parting

Ordering code

ISO

N123F1-0250-0002-CM 1125

ANSI

N123F1-0250-0002-CM 1125

EDP

Bar code

12290423

SSCM

insert seat size code

SSCN

insert seat size code

CW

cutting width

2.5 mm

HAND

hand

CTPT

operation type

Medium

AN

clearance angle major

7 deg

REL

Corner radius left

0.2 mm

RER

Corner radius right

0.2 mm

INSL

insert length

19.75 mm

TSYC

tool style code

N123x1-CM

insert thickness

4.3 mm

GRADE

grade

1125

WT

weight of item

0.003 kg

CUTINT_CLAMPSU

RF

insert clamping interface

INSCLPINT_7

CUTINT_SIZESHAP

E

insert size and shape

MCOR_CCF1_1

SUBOP

suboperation

Grooving Axial

SUBOP

suboperation

Parting Off

SUBOP

suboperation

Grooving Internal

SUBOP

suboperation

Grooving External

COATING

coating

PVD

BAMS

machine side body angle

0 deg

CBMD

chip breaker manufacturer's designation

CM

CECC

cutting edge condition code

CWTOLL

cutting width lower tolerance

0 mm

CWTOLU

cutting width upper tolerance

0.1 mm

IFS

insert mounting style code

ITEMTYPE

item type

Insert

MAINFUNC

main functionality

MAINFUNC

main functionality

NSIDE

number of sides of a tool item or cutting item

PFS

profile style code

RELEASEPACK

release pack id

7.2

RETOLL

corner radius lower tolerance

-0.1 mm

RETOLU

corner radius upper tolerance

0.1 mm

SUBSTRATE

Substrate

HM

TCE

tipped cutting edge code

Legal Notice

The data provided may be used at your own risk. AB Sandvik Coromant does not guarantee the applicability and functionality of the program, particularly the accuracy of the calculations. AB Sandvik Coromant will not accept any liability for trouble-free and

faultless use of the program. The user bears the entire risk of use.

In no event are Sandvik Coromant and its staff liable to the user for any damages, disadvantages and expenses, including any pecuniary damages, loss of data, etc., arising for the user or a third party out of, or in connection with, the use of, or inability to

use, the program. This exclusion of liability does not apply when and in as such as damages, disadvantages and expenses are caused intentionally or by gross negligence on the part of the staff of AB Sandvik Coromant.

Vous aimerez peut-être aussi

- Summary of Cutting Data For Hole in Rotation Component: Material DetailsDocument6 pagesSummary of Cutting Data For Hole in Rotation Component: Material DetailsdullecncPas encore d'évaluation

- Coroguide Report 2016-05-26Document4 pagesCoroguide Report 2016-05-26Irwing MontenegroPas encore d'évaluation

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument6 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialIorga AlexandruPas encore d'évaluation

- Summary of Cutting Data For Plain Surface: Material DetailsDocument5 pagesSummary of Cutting Data For Plain Surface: Material DetailsIorga AlexandruPas encore d'évaluation

- Summary of Cutting Data For Plain Surface: Material DetailsDocument5 pagesSummary of Cutting Data For Plain Surface: Material DetailsIorga AlexandruPas encore d'évaluation

- Summary of Cutting Data For Ext. Cylindrical Surface: Material DetailsDocument4 pagesSummary of Cutting Data For Ext. Cylindrical Surface: Material DetailsAndrei MihaiPas encore d'évaluation

- CoroPlusToolGuide Report 2023-01-25Document7 pagesCoroPlusToolGuide Report 2023-01-25FEL EmpiresPas encore d'évaluation

- Summary of Cutting Data For Facing of Bar: Material DetailsDocument1 pageSummary of Cutting Data For Facing of Bar: Material DetailsPaul BuenañoPas encore d'évaluation

- Summary of Cutting Data For Facing of Bar: Material DetailsDocument1 pageSummary of Cutting Data For Facing of Bar: Material DetailsPaul BuenañoPas encore d'évaluation

- CoroPlusToolGuide Report 2022-01-12Document3 pagesCoroPlusToolGuide Report 2022-01-12Catalin AirineiPas encore d'évaluation

- Summary of Cutting Data For Ext. Cylindrical Surface: Material DetailsDocument4 pagesSummary of Cutting Data For Ext. Cylindrical Surface: Material DetailsAndrei MihaiPas encore d'évaluation

- CoroPlusToolGuide Report 2019-12-01 PDFDocument5 pagesCoroPlusToolGuide Report 2019-12-01 PDFIorga AlexandruPas encore d'évaluation

- Summary of Cutting Data For Hole On Solid MaterialDocument5 pagesSummary of Cutting Data For Hole On Solid MaterialMarko ZmejPas encore d'évaluation

- Summary of Cutting Data For Widening and Finishing of Hole (No Demand On Shoulder)Document5 pagesSummary of Cutting Data For Widening and Finishing of Hole (No Demand On Shoulder)Iorga AlexandruPas encore d'évaluation

- Summary of Cutting Data For Cylindrical Hole in Solid MaterialDocument5 pagesSummary of Cutting Data For Cylindrical Hole in Solid MaterialIorga AlexandruPas encore d'évaluation

- Summary of Cutting Data For Cylindrical Surface With ShoulderDocument1 pageSummary of Cutting Data For Cylindrical Surface With ShoulderPaul BuenañoPas encore d'évaluation

- U01471 - 6.125-MS1366Document1 pageU01471 - 6.125-MS1366deepblue07Pas encore d'évaluation

- Thermal Printer Head ftp-642mcl001Document7 pagesThermal Printer Head ftp-642mcl001Sveto SlPas encore d'évaluation

- Summary of Cutting Data For Profile Surface - Ball Nose: Material DetailsDocument5 pagesSummary of Cutting Data For Profile Surface - Ball Nose: Material DetailsPalade LucianPas encore d'évaluation

- CoroPlusToolGuide Report 2021-05-31Document4 pagesCoroPlusToolGuide Report 2021-05-31Dorin MacaruPas encore d'évaluation

- I Grades enDocument230 pagesI Grades enDougPabitonPas encore d'évaluation

- Gerwah Servo ADS RDocument1 pageGerwah Servo ADS RxavicojmPas encore d'évaluation

- Smart JR Fanuc Mate TD SpecDocument4 pagesSmart JR Fanuc Mate TD SpecNandha GopalPas encore d'évaluation

- Summary of Cutting Data For Cylindrical Surface With Relief: Material DetailsDocument2 pagesSummary of Cutting Data For Cylindrical Surface With Relief: Material DetailsPaul BuenañoPas encore d'évaluation

- Surface TesterDocument12 pagesSurface TesterAditya DhikaPas encore d'évaluation

- I XmillDocument8 pagesI XmillVladimir Pereira MacielPas encore d'évaluation

- Datasheet: TVH 335-01/01Z-M20Document6 pagesDatasheet: TVH 335-01/01Z-M20Abu Haydar Amin MustanginPas encore d'évaluation

- Cabos IHMs DeltaDocument10 pagesCabos IHMs DeltaAlex Amaral DiasPas encore d'évaluation

- Notch Cutting MachineDocument2 pagesNotch Cutting MachineAbraham RaygozaPas encore d'évaluation

- H8 f7 ToleranceDocument3 pagesH8 f7 ToleranceSIPNETPas encore d'évaluation

- Atlas Transducer - enDocument4 pagesAtlas Transducer - enk_sakpolachet_heartPas encore d'évaluation

- Dial Gauge DigitalDocument21 pagesDial Gauge DigitalSheikh ZakirPas encore d'évaluation

- Summary of Cutting Data For Plain Surface: DegrosareDocument4 pagesSummary of Cutting Data For Plain Surface: DegrosareAndrei MihaiPas encore d'évaluation

- Data Sheet Renishaw TS27R Toolsetting ProbeDocument2 pagesData Sheet Renishaw TS27R Toolsetting ProbePham LongPas encore d'évaluation

- Data Sheet Renishaw TS27R Toolsetting Probe PDFDocument2 pagesData Sheet Renishaw TS27R Toolsetting Probe PDFPham LongPas encore d'évaluation

- 12mm Size Insulated Shaft TypeDocument5 pages12mm Size Insulated Shaft TypeshyhuPas encore d'évaluation

- Tesfa0 2024 01 25 00 05Document6 pagesTesfa0 2024 01 25 00 05Ivan NikodijevicPas encore d'évaluation

- CoroPlusToolGuide Report 2023-01-12Document5 pagesCoroPlusToolGuide Report 2023-01-12FEL EmpiresPas encore d'évaluation

- Calculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDocument10 pagesCalculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationM036Pas encore d'évaluation

- Резьбонарезка IscarDocument208 pagesРезьбонарезка IscarstctoolPas encore d'évaluation

- CP P26 16 2S p2616Document8 pagesCP P26 16 2S p2616blueword66Pas encore d'évaluation

- Trojan T15: Universal Tongue Operated Safety Interlock SwitchDocument4 pagesTrojan T15: Universal Tongue Operated Safety Interlock SwitchGabriel VerdugoPas encore d'évaluation

- Acceptence Criteria IMTEDocument12 pagesAcceptence Criteria IMTEdanaka007100% (1)

- CT375 Technical Document (100216)Document20 pagesCT375 Technical Document (100216)Vitor JVA MáquinasPas encore d'évaluation

- 20100716172219667Document6 pages20100716172219667김두리Pas encore d'évaluation

- ANEXEDocument16 pagesANEXERaul PopPas encore d'évaluation

- ToolsDocument21 pagesToolsKirubakaran AnnaduraiPas encore d'évaluation

- Modulos LutzeDocument11 pagesModulos Lutzesrp1987Pas encore d'évaluation

- SSSS7Document5 pagesSSSS7shyhuPas encore d'évaluation

- Raport Cutit9797Document4 pagesRaport Cutit9797Catalin AirineiPas encore d'évaluation

- Deh P3000RDocument68 pagesDeh P3000Rpite3Pas encore d'évaluation

- Odt-N 50: Modular Driven Tool Device For Axial System Din 1809 CouplingDocument24 pagesOdt-N 50: Modular Driven Tool Device For Axial System Din 1809 CouplingPaulo SoaresPas encore d'évaluation

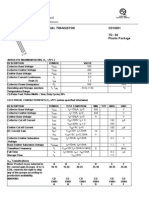

- Continental Device India Limited: NPN Silicon Planar Epitaxial Transistor CD13001 TO - 92 Plastic PackageDocument3 pagesContinental Device India Limited: NPN Silicon Planar Epitaxial Transistor CD13001 TO - 92 Plastic PackageRaj SharmaPas encore d'évaluation

- ETD Cores and Accessories ETD29: 1 e 3 e e 2 Min 2 11 0.3 15.8 0.2Document3 pagesETD Cores and Accessories ETD29: 1 e 3 e e 2 Min 2 11 0.3 15.8 0.2Marcel BlinduPas encore d'évaluation

- El817 1471182106Document14 pagesEl817 1471182106RăzvanPas encore d'évaluation

- Tehnicki Vodic PDFDocument273 pagesTehnicki Vodic PDFSlaven Dadan-NanoPas encore d'évaluation

- LMR 400 PDFDocument4 pagesLMR 400 PDFviktor220378Pas encore d'évaluation

- NPN CD 13001Document3 pagesNPN CD 13001huvillamilPas encore d'évaluation

- Adiba Final Activity CousellingDocument29 pagesAdiba Final Activity Cousellingadiba KhanPas encore d'évaluation

- International Journal of Agricultural ExtensionDocument6 pagesInternational Journal of Agricultural Extensionacasushi ginzagaPas encore d'évaluation

- Approaches To Curriculum DesigningDocument20 pagesApproaches To Curriculum DesigningCristel CatapangPas encore d'évaluation

- Flotech Corporate FlyerDocument6 pagesFlotech Corporate FlyerPrasetyo PNPPas encore d'évaluation

- KrautKramer DM4E DM4DL - ManualDocument38 pagesKrautKramer DM4E DM4DL - ManualfdsgfdgPas encore d'évaluation

- Nature'S Numbers: - BasicbooksDocument39 pagesNature'S Numbers: - Basicbooksyeol pacisPas encore d'évaluation

- Language Focus. Past Simple or Past ContinuousDocument3 pagesLanguage Focus. Past Simple or Past ContinuoustotydnrPas encore d'évaluation

- Module - 5Document92 pagesModule - 5Anand APas encore d'évaluation

- Refraction Experiment-PekaDocument8 pagesRefraction Experiment-PekaA. Suhaimi100% (3)

- ISO 27001 Gap Analysis ChecklistDocument6 pagesISO 27001 Gap Analysis Checklistlijo jacob70% (10)

- Morphometric Characterization of Jatropha Curcas Germplasm of North-East IndiaDocument9 pagesMorphometric Characterization of Jatropha Curcas Germplasm of North-East IndiafanusPas encore d'évaluation

- De Thi Khao Sat HSG 12 Mon Tieng AnhDocument8 pagesDe Thi Khao Sat HSG 12 Mon Tieng AnhbuitinhPas encore d'évaluation

- No 1 Method ValidationDocument2 pagesNo 1 Method ValidationdanaciortanPas encore d'évaluation

- Legislation Statutory Inspection ChecklistDocument2 pagesLegislation Statutory Inspection ChecklistAry PutraPas encore d'évaluation

- GRADE 8 3rd Quarter DLP in EnglishDocument484 pagesGRADE 8 3rd Quarter DLP in EnglishJulius Salas100% (4)

- Manual of Armacad v9 PDFDocument102 pagesManual of Armacad v9 PDFCristiana FelicianoPas encore d'évaluation

- Press Releases Are Not A PR Strategy An Executive Annas ArchiveDocument200 pagesPress Releases Are Not A PR Strategy An Executive Annas Archivehelenajosemacuacua31Pas encore d'évaluation

- Modul MarketingDocument5 pagesModul MarketingDeni IrvandaPas encore d'évaluation

- Conversation Class - Video GamesDocument4 pagesConversation Class - Video GamesMaíra MouraPas encore d'évaluation

- Merged DocumentDocument28 pagesMerged DocumentJamirah Maha ShahinurPas encore d'évaluation

- Saudi Arabia Companies Contact DetailsDocument64 pagesSaudi Arabia Companies Contact DetailsYAGHMOURE ABDALRAHMAN86% (69)

- ENG-116: Branches of Linguistics: Books) .Farmer, A. K Demers, R. A. A Linguistics WorkbookDocument6 pagesENG-116: Branches of Linguistics: Books) .Farmer, A. K Demers, R. A. A Linguistics WorkbookBILAL ZAFARPas encore d'évaluation

- Ai R16 - Unit-6Document36 pagesAi R16 - Unit-6RakeshPas encore d'évaluation

- AOC TFT-LCD Color Monitor 931Fwz Service ManualDocument54 pagesAOC TFT-LCD Color Monitor 931Fwz Service ManualtecnosomPas encore d'évaluation

- Ipcrf Core Values 2019 - FinalDocument23 pagesIpcrf Core Values 2019 - FinalFrendelyn p. Gador100% (4)

- Alpha 20 TDS (EN) 100063006 1Document5 pagesAlpha 20 TDS (EN) 100063006 1Ariel Gallardo Galaz100% (1)

- FOCGB5 Rtest 1-6BDocument3 pagesFOCGB5 Rtest 1-6BM-DPas encore d'évaluation

- Operator'S Manual AND Set-Up Instructions For The: WDL-2070-FADocument49 pagesOperator'S Manual AND Set-Up Instructions For The: WDL-2070-FAМаксим ЛитвинPas encore d'évaluation

- Prose 2 - Lost Spring - Important QADocument5 pagesProse 2 - Lost Spring - Important QADangerous GamingPas encore d'évaluation

- 120-21 TM RF HandbookDocument164 pages120-21 TM RF HandbookbaymanPas encore d'évaluation