Académique Documents

Professionnel Documents

Culture Documents

DuPont Easycompact 55-72 SM

Transféré par

repropDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DuPont Easycompact 55-72 SM

Transféré par

repropDroits d'auteur :

Formats disponibles

DuPont

Easycompact 55/72

1st Edition October 1992

This manual has Article No 6796 CES/US Part No 671197300-9

Easycompact 55/72

GENERAL INFORMATION

This manual is valid for:

DuPont Easycompact 55 from serial No 9224-51 and

DuPont Easycompact 72 from serial No 9225-40.

The serial No is specified on the processor nameplate located on the backside of the machine next to the film

basket.

The manual was written and illustrated using the best possible information available at the time of publication.

Any differences between the manual and the equipment reflect improvements introduced after the publication

of the manual.

Changes, technical inaccuracies, and typographic errors will be corrected in subsequent editions.

As a part of our policy of continuous improvement, we reserve the right to alter design and specifications

without further notice.

APPROVALS

DIN VDE 0805/05.90

DIN 1988 (DVGW) Part 4

EN 60950 German Edition

IEC 950 (1986 - 1st edition, modified)

DIN VDE 0871/b, EN 50081 (FTZ)

FCC Part 15 (US-Norm - RFI)

EN 55011 (EMC Emission)

EN 50082-1 (EMC Immunity)

EN 55022

CAN/CSA - C22.2, No. 950-M89

UL 122 (US-Models only)

IMPORTANT!

It is the responsibility of the owner and operator/s of this machine, that the installation is made in accordance

with local regulations, and by engineers authorized to carry out plumbing and electrical installations.

The manufacturer cannot be held responsible for any damage caused by incorrect installation of this machine.

The installation procedure is described in chapter 2 "INSTALLATION".

SILVER RECOVERY

To avoid any damage (ex. corrosion of the fixer tank heater element) only the DuPont EasyFix 10 recovery

unit must be connected to the processor!

0/2

9450

Easycompact 55/72

WARNINGS, CAUTIONS AND NOTES!

Throughout the manual warnings, cautions, and notes are written in italics on a grey background like the

example below:

CAUTION! Fuses should only be changed by authorized personnel.

Explanation:

NOTE!

The operator should observe and/or act according to the information in order to obtain the best possible

function of the equipment.

CAUTION!

The operator must observe and/or act according to the information in order to avoid any mechanical or

electrical damage to the equipment.

WARNING!

The operator must observe/and or act according to the information in order to avoid any personnel injury.

AUTHORIZED PERSONNEL

Some notes, cautions and warnings refer to Authorized personnel or Service Technician like the example

below:

NOTE! Authorized personnel only.

NOTE! Call service technician.

Explanation:

Authorized personnel:

Persons inside your company who are familiar with all the processors functions, change in programs and

maintenance.

Service Technician:

Service personnel from your local DuPont dealer, who is trained in servicing the DuPont Easycompact

processors.

9450

0/3

Easycompact 55/72

0/4

9450

Easycompact 55/72

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

GENERAL INFORMATION

0/2

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0/2

WARNINGS, CAUTIONS AND NOTES! . . . . . . . . . . . . . . . . . . . . . . . . 0/3

AUTHORIZED PERSONNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0/3

SAFETY INSTRUCTIONS

GENERAL . .

ELECTRICAL .

MECHANICAL

CHEMICAL . .

0/11

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ENVIRONMENTAL PROTECTION

. 0/11

. 0/11

. 0/11

. 0/11

0/12

DISPOSAL OF CHEMICALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0/12

TECHNICAL SPECIFICATIONS

1/1

PROCESSING MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/1

INSTALLATION

PREPARATIONS BEFORE INSTALLATION . . . . . . . . . .

ENVIRONMENTAL REQUIREMENTS . . . . . . . . . . . . . .

SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . .

WATER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . .

DRAIN OUTLETS . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING FACILITIES . . . . . . . . . . . . . . . . . . . . .

POWER CONNECTIONS . . . . . . . . . . . . . . . . . . . .

MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . .

UNPACKING . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION KIT . . . . . . . . . . . . . . . . . . . .

ASSEMBLING THE STAND . . . . . . . . . . . . . . . .

LEVELLING OF THE MACHINE . . . . . . . . . . . . .

FEED TABLE/DAYLIGHT CASSETTE . . . . . . . . . .

"THROUGH-THE-WALL" INSTALLATION . . . . . . . .

WATER CONNECTION . . . . . . . . . . . . . . . . . .

DRAIN CONNECTIONS . . . . . . . . . . . . . . . . . .

REPLENISHMENT HOSES . . . . . . . . . . . . . . . .

EXHAUST INSTALLATION FOR CHEMICAL VAPOURS

9501

2/1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2/1

2/1

2/1

2/1

2/1

2/1

2/1

2/3

2/3

2/3

2/3

2/3

2/4

2/5

2/6

2/6

2/7

2/8

0/5

Easycompact 55/72

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

ELECTRICAL INSTALLATION . . . . . . . . . . . .

MAIN POWER OUTLET . . . . . . . . . . . .

MOUNTING A PLUG . . . . . . . . . . . . .

MODIFICATION FOR TRANSFORMER . . .

MAIN POWER CONNECTION, US-MODELS

TIMER . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

FUNCTIONAL DESCRIPTION

GENERAL . . . . . . . . . . . .

DEVELOPER/FIXER SECTIONS

WASH SECTION . . . . . . . . .

DRYER SECTION . . . . . . . .

ECOLOGICAL UNITS . . . . . .

REPLENISHMENT SYSTEM . .

TRANSPORT SYSTEM . . . . .

MAIN COMPONENTS . . . . . .

ELECTRONIC CONTROL . . . .

MAINBOARD PCB GCB .

FUSES . . . . . . . . . . .

DRAWER LOCK . . . . . .

STAND-BY MODE . . . . . . . .

PROCESSING MODES . . . . .

FUSES . . . . . . . . . . . . . .

ELECTRICAL DIAGRAM . . . . .

3/1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

OPERATING PROCEDURES

INITIAL START-UP . . . . . . . . . . . . . . . . . . . . . . . . .

SETTING OF THE PROGRAMS . . . . . . . . . . . . . . . . . .

ADJUSTING THE REPLENISHMENT PUMPS . . . . . . . . . .

DAILY START-UP . . . . . . . . . . . . . . . . . . . . . . . . .

PROCESSING FROM THE FEED TABLE . . . . . . . . . . . .

PROCESSING CASSETTES FROM THE DAYLIGHT CASSETTE

SHELF/FEED TABLE . . . . . . . . . . . . . . . . . . . . . . .

PROCESSING FROM THE DAYLIGHT SLOT . . . . . . . . . .

USING THE REWASH SLOT . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . .

MAKING ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . .

SHUT-DOWN PROCEDURE . . . . . . . . . . . . . . . . . . .

0/6

. 2/9

. 2/9

. 2/9

. 2/9

. 2/10

. 2/11

. 3/1

. 3/2

. 3/2

. 3/2

. 3/3

. 3/3

. 3/3

. 3/5

. 3/11

. 3/11

. 3/11

. 3/11

. 3/12

. 3/12

. 3/13

. . .

4/1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 4/3

. 4/3

. 4/5

. 4/7

. 4/9

. 4/9

. 4/9

. 4/11

. 4/11

. 4/13

. 4/13

. 4/15

9501

Easycompact 55/72

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

OPERATORS CONTROLS AND INDICATORS

GENERAL . . . . . . . . . . . . .

DIMENSIONS . . . . . . . . . . .

FEATURES . . . . . . . . . . . . .

THE CONTROL BOX . . . . . . .

DAYLIGHT AND REWASH LAMPS

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5/1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

CLEANING AND MAINTENANCE

6/1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIP TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOVING THE WET RACKS . . . . . . . . . . . . . . . . . . .

REMOVING THE DRYER RACK . . . . . . . . . . . . . . . . . .

ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAYLIGHT GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . .

ANTI-OXIDATION LIDS . . . . . . . . . . . . . . . . . . . . . . .

REMOVING THE DRIVE SHAFT . . . . . . . . . . . . . . . . . .

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING . . . . . . . . . . . . . . . . . . . . . . .

WEEKLY CLEANING . . . . . . . . . . . . . . . . . . . . .

MONTHLY CLEANING . . . . . . . . . . . . . . . . . . . .

CLEANING OF VALVES IN THE REPLENISHMENT PUMPS

CLEANING OF CIRCULATION PUMPS . . . . . . . . . . .

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLACING AN INPUT SENSOR . . . . . . . . . . . . . .

REPLACING A HEATER SAFETY FUSE . . . . . . . . . . .

REPLACING A DAYLIGHT OR REWASH SENSOR . . . . .

REPLACING A FUSE . . . . . . . . . . . . . . . . . . . . .

REPLACING A RELAY . . . . . . . . . . . . . . . . . . . .

CHECK OF DEVELOPER REPLENISHMENT . . . . . . . .

CHECK OF FIXER REPLENISHMENT . . . . . . . . . . . .

CHECK OF OXIDATION REPLENISHMENT . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 6/1

. 6/1

. 6/2

. 6/3

. 6/5

. 6/5

. 6/6

. 6/7

. 6/8

. 6/8

. 6/8

. 6/8

. 6/9

. 6/9

. 6/10

. 6/11

. 6/11

. 6/12

. 6/13

. 6/14

. 6/14

. 6/15

. 6/15

. 6/15

TROUBLE SHOOTING

GENERAL . . . . . . . . . . . . . . . . . . .

CONDITIONS BEFORE STARTING TROUBLE

PROBLEMS WITH THE PROCESSOR . . . .

PROBLEMS WITH PROCESSED MATERIAL .

9501

5/1

5/1

5/1

5/3

5/4

7/1

. . . . . . .

SHOOTING

. . . . . . .

. . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7/1

7/1

7/2

7/6

0/7

Easycompact 55/72

TABLE OF CONTENTS

PAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING SPAREPARTS FOR EASYCOMPACT 55

PARTS DELIVERED . . . . . . . . . . . . . .

INSTALLATION KIT . . . . . . . . . . . . . .

SPAREPARTS KIT . . . . . . . . . . . . . . .

ACCESSORIES . . . . . . . . . . . . . . . .

ISOMETRIC DRAWINGS AND SPAREPARTS

.

.

.

.

.

8/1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ORDERING SPAREPARTS FOR EASYCOMPACT 72

PARTS DELIVERED . . . . . . . . . . . . . .

INSTALLATION KIT . . . . . . . . . . . . . .

SPAREPARTS KIT . . . . . . . . . . . . . . .

ACCESSORIES . . . . . . . . . . . . . . . .

ISOMETRIC DRAWINGS AND SPAREPARTS

.

.

.

.

.

9/1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

SERVICE INFORMATION

PARAMETER LEVELS, PCB GCB . . . .

PARAMETERS (EUR) . . . . . . . . . . .

PARAMETERS (USA) . . . . . . . . . . .

EXPLANATION, PARAMETERS . . . . . .

DISPLAY FORMAT IN NORMAL MODE .

DISPLAY OF REPLENISHMENT VALUES

TEST-PROGRAM . . . . . . . . . . . . .

ENTERING TEST-MODE . . . . . .

DISPLAY FORMAT IN TEST-MODE

LEAVING TEST MODE . . . . . . .

SERVICE PARAMETERS . . . . . . . . .

ADJUSTING OF THE PCB GCB . . . . . .

LED DESCRIPTION . . . . . . . . . . . .

CURL TEST . . . . . . . . . . . . . . . .

(NOT IN USE)

0/8

8/1

8/1

8/3

8/3

8/6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

9/1

9/1

9/3

9/3

9/6

APPENDIX A

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A/1

A/2

A/4

A/6

A/8

A/8

A/10

A/10

A/10

A/10

A/11

A/13

A/14

A/15

APPENDIX B

9501

Easycompact 55/72

TABLE OF CONTENTS

PAGE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POLYESTER PROCESSOR

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . .

TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . .

IMPORTANT BY INSTALLATION . . . . . . . . . . . . . . .

PLACEMENT OF ROLLERS IN POLYESTER PROCESSOR

SPAREPARTS . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING SPAREPARTS . . . . . . . . . . . . . . . . . .

APPENDIX C

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

C/1

C/1

C/1

C/2

C/3

C/3

ELECTRICAL DIAGRAM

9501

0/9

Easycompact 55/72

0/10

9501

Easycompact 55/72

SAFETY INSTRUCTIONS

Personnel operating and maintaining the machine

must be familiar with all aspects of its operation and

be proficient in maintenance. Such personnel should

review the following precautions to promote safety

awareness.

GENERAL

Observe all NOTES, CAUTIONS and WARNINGS

(see page 0/3).

Wear safety glasses and gloves when maintaining

or servicing the equipment.

Do not wear a necktie, jewelry, or loose-fitting

clothing while operating the machine.

ELECTRICAL

Disconnect all electrical power before servicing.

If electrical power must be applied for servicing or

trouble shooting, wear insulated gloves and use

extreme caution to prevent injury.

MECHANICAL

Keep hands, fingers and tools clear of moving

parts.

When removing a wet transport rack, a drip tray

under the rack helps to avoid wet, slippery floors.

Install all panels and covers after servicing.

CHEMICAL

Always refer to first aid recommendations

provided by the chemical manufacturer.

Wear eye protection and special clothing such as

an apron and gloves when handling chemicals.

In case of chemical contact with eyes or skin,

immediately flush affected area with plenty of

fresh water for 15 minutes. Wash affected clothing.

In case of ingestion, contact a physician

immediately.

Do not mix chemicals.

Disconnect the power cable to prevent anyone

from restoring electrical power mistakenly.

Shut off water supply and reduce system pressure

before disconnecting plumbing fixtures.

Do not defeat or by-pass built-in equipment safety

features.

Provide adequate ventilation; avoid prolonged

breathing of solution vapours.

Avoid splashing and spilling.

Wipe up spills immediately.

9241

0/11

Easycompact 55/72

ENVIRONMENTAL PROTECTION

DISPOSAL OF CHEMICALS

Most chemicals used in film processors are strong

pollutants and do not belong in the public sewer

system.

Therefore chemicals must be led to waste containers

in order to protect the environment.

Many countries have strong regulations on chemical

disposal, and disposal of containers with waste

chemicals must be made according to these

regulations. Refer to local authorities for information

regarding disposal of waste chemicals.

Contact your supplier of chemicals if you need

more information about safety and disposal.

DO NOT LEAD CHEMICALS DOWN THE

DRAIN!

0/12

9241

Easycompact 55/72

CHAPTER 1

TECHNICAL SPECIFICATIONS

PROCESSING MATERIAL

DRY-TO-DRY TIME

60 - 240 sec.

Rali materials.

Imagesetting paper and film.

Camera line exposures on rapid access film.

Contact work on contact film/paper, rapid access

film and daylight film/paper.

CONVERSION TABLE

Dev. time

in sec.

Film speed

cm/min.

(in/min.)

Dry-to-dry

in sec.

Halftones on rapid access film.

60

33 (13.0)

240

Paper contact work.

55

36 (14.2)

220

50

40 (15.7)

200

45

44 (17,3)

180

40

50 (19,7)

160

35

57 (22.4)

140

30

66 (26,0)

120

(2.8" - 21.7")

(2.8" - 28.5")

25

79 (31.1)

100

20

100 (39.4)

80

(4" - 21.7")

(4" - 28.5")

15

132 (52.0)

60

Laser scanner positives on rapid access film.

SPECIFICATIONS

FILM WIDTH

SHEET-MATERIAL:

ECP 55

7.0 - 55.0 cm

ECP 72

7.0 - 72.5 cm

ROLL-MATERIAL:

ECP 55

10.0 - 55.0 cm

ECP 72

10.0 - 72.5 cm

TEMPERATURES

FILM LENGTH

12.0 cm - 30.0 m

(4.7" - 1181.1")

Dev :

Fix :

Dryer :

20 - 50C

20 - 50C

20 - 70C

(68 - 122 F)

(68 - 122 F)

(68 - 158 F)

FILM THICKNESS

0.0762 - 0.1905 mm(0.003" - 0.0075")

TANK CAPACITIES

ECP 55

DEV. TIME

15 - 60 sec.

ECP 72

Dev:

Fix:

Wash:

Dev:

Fix:

Wash:

16.0

15.0

15.0

21.0

20.0

20.0

l

l

l

l

l

l

(4.2

(4.0

(4.0

(5.5

(5.3

(5.3

US

US

US

US

US

US

gal.)

gal.)

gal.)

gal.)

gal.)

gal.)

TRANSPORT SPEED

33.0 - 132.0 cm/min.

9437

(13 - 52 in/min.)

1/1

Easycompact 55/72

HOSE CONNECTIONS

Water supply:

POWER SUPPLY

12 mm reinforced hose

(3/4" or 1/2" male thread)

Drains:

Dev:

25 mm

(1")

Fix:

25 mm

(1")

Wash:

25 mm

(1")

(Water hose and drain fittings are delivered with

the machine).

Dryer air exhaust: 100 mm

(4")

230V AC, single phase + PE, 50-60 Hz

fused by 25 A, or

230V AC, 3 phases + PE, 50-60 Hz,

fused by 20 A, or

3 x 230/400V AC + N + PE, 50-60 Hz,

fused by 16 A.

VOLTAGE TOLERANCES

230V +10% / -14%

WATER SUPPLY

Consumption:

In operate:

In stand-by:

Pressure:

Temperature:

1/2

1.5 l/min. or

3.0 l/min

0.0 l/min

1.5 - 4 bar

5 - 40C

(0.4 gal./min.)

(0.8 gal./min.)

(0.0 gal./min.)

(22 - 60 psi)

(41F - 104F)

POWER CONSUMPTION

Max:

5.0 kW

NOISE LEVEL

In operate:

In stand-by:

<70 dB (A)

<70 dB (A)

9437

Easycompact 55/72

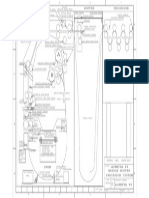

DIMENSIONS, PROCESSOR

(See fig. 1/1)

ECP 55:

Width (W):

Depth (D1):

83.0 cm

122.0 cm

incl. film basket

100.0 cm

excl. film basket

Depth (D2): Feed table 20.0 cm

Daylight cassette 23.0 cm

Height (H1): 28.0 cm

Height (H2): 77.0 - 79.0 cm

(30.3

incl. adjustable legs

Height (H3): 96.0 - 98.0 cm

(37.8

incl. adjustable legs

ECP 72:

Width (W):

Depth (D1):

100.5 cm

122.0 cm

incl. film basket

100.0 cm

excl. film basket

Depth (D2): Feed table 20.0 cm

Daylight cassette 23.0 cm

Height (H1): 28.0 cm

Height (H2): 77.0 - 79.0 cm

(30.3

incl. adjustable legs

Height (H3): 96.0 - 98.0 cm

(37.8

incl. adjustable legs

(32.7")

(48.0")

(39.4")

(7.9")

(9.1")

(11.0")

- 31.1")

- 38.6")

(39.6")

(48.0")

(39.4")

(7.9")

(9.1")

(11.0")

- 31.1")

- 38.6")

Fig. 1/1 Dimensions, Processor

DIMENSIONS, PTS/IMAGESETTING

CASSETTES

The max. dimensions of the PTS/Imagesetting

cassettes that fit into the daylight cassette (option)

are:

Width:

625 mm

(24.6")

Depth:

195 mm

( 7.7")

Height:

195 mm

( 7.7")

WEIGHT*

ECP 55:

ECP 72:

Empty:

Shipping:

Empty:

Shipping:

108

158

125

183

kg

kg

kg

kg

(238

(348

(275

(403

lbs)

lbs)

lbs)

lbs)

*) Standard version with closed stand and feed

table.

9437

1/3

Easycompact 55/72

1/4

9437

Easycompact 55/72

CHAPTER 2

INSTALLATION

PREPARATIONS BEFORE

INSTALLATION

To avoid waste of your production time as well as

the time it will take for the engineer to install the

machine, make sure that the requirements listed

below are fulfilled before you make the installation.

Installation procedure is described from page 2/3.

ENVIRONMENTAL REQUIREMENTS

Provide a heating and ventilating system capable of

maintaining room temperature between 15 and 25 C

(59 - 77 F) and relative humidity (RH) on max. 80%.

DRAIN OUTLETS

The drain outlet should have a funnel shape to allow

for proper drain line routing.

The recommended distance from the machine to the

drain is 0.5 m - max. 2 m (2 - max. 6 ft).

CAUTION! Copper or brass should not be used

in the drainage system as fixer containing silver

might attack it. Therefore plastic or rubber is

recommended.

(See also "DRAIN CONNECTIONS").

NOTE! If silver recovery is desired the 25 mm

(1") drain hose from the fixer can be led to a

silver recovery unit.

SPACE REQUIREMENTS

Make sure that free space around the machine at

the installation site will be approx. 1 m (3-4 ft) This

makes servicing possible, and allows you to pull out

the electronics drawer and the trolley.

CLEANING FACILITIES

WATER SUPPLY

POWER CONNECTIONS

A water tap should be installed in the darkroom

close to the installation site. Max. distance to the

machine should be 2 - 3 m (6 - 10 ft). The water tap

must be 1/2" or 3/4" male threaded. The water hose

is included with the installation kit.

(See also "WATER CONNECTION").

For cleaning purposes it would be convenient to

have easy access to a water tap and a suitable sink,

where racks, rollers and guides can be washed and

chemicals mixed.

If not already there, a main power outlet should be

installed in the room, where the machine will be

situated. Max. recommended distance to the

machine is 2 m (6 ft). The requirements are as

follows:

230V AC, 1 phase + PE, 50-60 Hz,

fused by 25 A, or

230V AC, 3 phases + PE, 50-60 Hz,

fused by 20 A, or

3 x 230/400V AC + N + PE, 50-60 Hz,

fused by 16 A.

Voltage tolerance at 230V:

9501

2/1

Easycompact 55/72

2/2

9501

Easycompact 55/72

MECHANICAL INSTALLATION

UNPACKING

Carefully unpack the machine and check that all

parts are present and in good condition.

The parts are listed in chapter 8 for Easycompact

55, and in chapter 9 for Easycompact 72.

ASSEMBLING THE STAND

The machine is delivered with a closed stand.

The stand consists of a frame with 4 legs and 4

panels.

Assemble the stand as described in the following.

(See illustration opposite)

INSTALLATION KIT

An installation kit is included with the processor.

It comprises the different parts that are necessary to

make the installation.

See chapter 8 and 9 for further information.

Insert the bushings (1) into the horizontal

panels (2) and (3).

Screw the bolts (4) into the bushings but do not

tighten the bolts yet.

When the right panel (2) and left panel (3) are

fitted with bolts they can be assembled with the

legs (5) on the front (6) and rear (7) frame parts.

Tighten the bolts from above (inside the legs) and

through the oval holes (8) by means of a wrench.

Screw the adjustable legs (9) into the frame and

level out.

Mount the four locking magnets (10) on the legs.

Insert the right (11) and left (12) side panels.

Place the processor on top of the stand, and

make sure that it fits inside the panels of the

stand.

WARNING! Do not remove any part of the stand

while the processor is placed on top of it.

LEVELLING OF THE MACHINE

NOTE! The machine must be placed on a steady

surface, so that it does not shake and the

chemicals cannot splash from one section to

the other.

Place the machine in its final position. Usa a wrench

to adjust the four legs (9) underneath the stand. Use

a level to make a final level-out of the machine. Do

not rely on the floor being absolutely in level.

9501

2/3

Easycompact 55/72

FEED TABLE/DAYLIGHT CASSETTE

The machine is delivered with either a feed table, a

daylight cassette for processing from

PTS/Imagesetting cassettes, or both. Either one of

them now should be fixed onto the processor.

Fig. 2/1 and 2/2 show how to fix the feed table and

the daylight cassette by means of the 4 screws

enclosed in the installation kit.

Fig. 2/1 Mounting of the Feed Table

2/4

Fig. 2/2 Mounting of the Daylight Cassette

9501

Easycompact 55/72

"THROUGH-THE-WALL"

INSTALLATION

(See Fig. 2/3).

If the processor has to be installed in a

"through-the-wall" installation, a hole has to be cut in

the wall, through which the machine is going to be

installed.

The hole should be cut min. 100 mm (4") wider

than the max width of the machine (see chapter 1)

and min. 200 mm (8") higher than the feed table

surface. Walls thicker than 50 mm (2") should be

cut with a slope (approx. 45 ) above the feed table.

When the machine has been placed in position, the

hole in the wall should be reduced to the exact size

of the machine by means of a light-tight material

(thickness 7 - 7.5 mm).

For this purpose a special "THROUGH-THE-WALL

KIT" is available (see chapter 8 and 9,

"ACCESSORIES").

With this kind of installation it should be taken into

consideration that it must be possible, without any

difficulties, to use the daylight feeding slot and to

remove the top cover and the racks for cleaning and

servicing purposes.

Fig. 2/3 "Through-the-wall" Installation

9501

2/5

Easycompact 55/72

WATER CONNECTION

DRAIN CONNECTIONS

The water supply connection should be made by

means of the plastic hose, fitting and gaskets

delivered with the machine.

As shown in Fig. 2/4 the hose must be connected

between the water tap and the water inlet solenoid

valve located to the left underneath the dryer section.

The hose can be connected to a water tap with 1/2"

or 3/4" WRG male thread (3/4" NPT for

USA-models). When connecting to 3/4", the

reduction nipple shall not be used.

Drain connections are made underneath the

machine (see Fig. 2/5). The drains from the DEV

and FIX baths are on the lefthand side and the drain

from the wash tank is on the righthand side. Drain

hoses are included with the machine. The water

drain should be connected to a 25 mm (1") hose and

led to a drain placed 0.5 - max. 2 m (2 - max. 6 ft)

from the machine. Make sure there is a positive fall

from the machine to the drain, and that the hoses do

not sag or form water traps.

CAUTION! Do not lead chemicals down the

drain. Lead the drains from the chemical baths

to waste chemical containers (see chapter 0).

Fig. 2/4 Water Connection

2/6

Fig. 2/5 Drain Connections

9501

Easycompact 55/72

REPLENISHMENT HOSES

The replenishment hoses are located underneath the

machine as well. Connect the replenishment hoses

to the replenishment containers as shown in Fig. 2/6:

BLUE HOSE TO DEVELOPER.

RED HOSE TO FIXER.

Fig. 2/6 Replenishment Hoses

9501

2/7

Easycompact 55/72

EXHAUST INSTALLATION

FOR CHEMICAL VAPOURS

The processor is equipped with a scavenger fan to

remove chemical vapours from the processor and

the room. The fan is located to the left of the dryer

section and leads the exhaust to a flange placed

underneath the dryer section. The processor can be

connected to an external exhaust system by means

of a 80 mm (3.15") exhaust hose (see Fig. 2/7 and

chapter 8 and 9, "ACCESSORIES")

Fig. 2/7 Exhaust Connection, Chemical Vapours

NOTE! When connecting the processor to an

external exhaust system, an adjusting valve

should be fitted between the processor and the

exhaust system to adjust the exhaust rate to

approx. 15 m3/h (530 ft3/h).

If the exhaust capacity is too high you might get

problems with keeping the correct temperature

in the baths of the processor and the

consumption of chemicals will increase

unnecessarily.

2/8

9501

Easycompact 55/72

ELECTRICAL INSTALLATION

MAIN POWER OUTLET

MODIFICATION FOR TRANSFORMER

WARNING! Service technicians only

If not already there, a main power outlet should be

installed next to the machine. The requirements are

as follows:

WARNING! Service technicians only

If the machine is installed in countries where the

voltage is above 230V the following modification has

to be made for transformer M1:

(See fig. 2/9).

230V AC, 1 phase + PE, 50-60 Hz,

fused by 25 A, or

Turn the power off and unplug the unit.

230V AC, 3 phases + PE, 50-60 Hz,

fused by 20 A, or

Disconnect and isolate the white wire.

NOTE! Make sure that the 2 leads in the white

wire have still contact when isolating them.

Otherwise the processor will not work.

3 x 230/400V AC + N + PE, 50-60 Hz,

fused by 16 A.

Voltage tolerance at 230V is +10% / -14%.

Locate terminal block X510 on the GCB.

In the same cable locate the yellow wire, remove

the isolation and insert the wire into the terminal

block.

MOUNTING A PLUG

WARNING! Service technicians only

When mounting a plug, the wires in the main cable

have to be connected as follows:

Yellow/green:

Blue:

Black:

Black:

Brown:

Earth

Neutral

L1

L2

L3

Fig. 2/8

9501

2/9

Easycompact 55/72

MAIN POWER CONNECTION,

US-MODELS

The processors for USA are shipped wired for single

phase 208/220 volt operation and can be easily

converted to a three phase power configuration.

All plugs and receptacles for this single phase

connection should be the standard National

Electrical Manufacturers Association (NEMA)

polarized configuration L6-30 and be Underwriters

Laboratory (UL) listed.

Processors for USA are provided with a 10 AWG 4

conductor power supply cord with a NEMA

configuration L6-30 U.L. listed 30 amp single phase

250V + PE twist-lock power plug Harvey Hubbell

Inc. type Insulgrip 2621. One conductor will be

unused in the single phase connection.

For the proper receptacle please refer to your local

electrician.

For three phase 208/220 volt + PE connections all

plugs and receptacles should be the standard

(NEMA) polarized configuration L15-20 and be

Underwriters Laboratory (UL) listed.

To convert to a three phase connection make

following modifications:

See Fig. 2/10.

Change the main power plug to a NEMA

configuration L15-20 U.L. listed 20 amp three

phase 250 volt + PE twist lock power plug such

as Harvey Hubbell Inc. type Insulgrip 2421.

Connect red, black and white wires to the gold

terminals and the green wire to the silver or green

terminal.

Connect the red insulated unused wire at the

terminal block TB1, position L3.

Place the jumpers on terminal block TB1 as

shown in Fig. 2/10.

For the proper receptacle please refer to your

local electrician.

2/10

Fig. 2/9

9501

Easycompact 55/72

TIMER

If you wish to connect the processor to an external

timer it is possible to do so by means of the special

cable delivered with the installation kit (see chapter

8).

The purpose of the timer is to start up the processor

e.g. half an hour before start of working hours. This

way the processor has reached the correct working

temperatures when production starts.

The operator must be able to stop the processor

manually but can only do so if the timer relay is

"OFF". Therefore the "ON"-time of the timer relay

should be set to the shortest possible time.

Connect the processor to the timer as shown on Fig.

2/11.

Fig. 2/10 Timer-connection

9501

2/11

Easycompact 55/72

2/12

9501

Easycompact 55/72

CHAPTER 3

FUNCTIONAL DESCRIPTION

GENERAL

The processor contains 4 major sections (see fig.

3/1): Developer (A), fixer (B), wash (C), and dryer

section (D). Each section performs a basic function

to change the exposed film into a fully developed

and dry film, ready for handling.

The operation of the processor is handled by the

control box (E).

The film material (F) is fed into the machine from the

feed-table (G).

If the machine is equipped with a daylight cassette

(H) both film sheets and film rolls from

PTS/Imagesetting cassettes (I) can be processed.

The processor is also equipped with a daylight slot

(J) and a rewash slot (K) which make it possible to

use the processor outside the darkroom when

installed in a "through-the-wall" installation.

At the processor entrance the transport roller system

takes over and leads the film safely through each of

the four sections at a uniform speed and special

guides make sure that it passes smoothly from one

section to another.

When the film leaves the machine, it lands in the

film basket (L).

Fig. 3/1

9437

3/1

Easycompact 55/72

DEVELOPER/FIXER SECTIONS

WASH SECTION

In the developer (DEV) section (A) the latent image

created during exposure is developed and in the

fixer (FIX) section (B) the developing process is

stopped and unexposed silver halide is dissolved.

The DEV and FIX sections are identical (except for

racks), containing a processing tank with a heater

and a thermostate to keep the temperature constant.

A level detector circuit in each tank prevents

operation of the processor with insufficient amount of

chemicals.

In both sections a pump recirculates the solution to

maintain a uniform temperature of the chemicals and

both tanks overflow into waste chemical containers

(M) through combined overflow and drain tubes.

Each tank is covered with a floating lid preventing

condensation underneath the top cover and

oxidation of chemicals.

In the wash section (C) residual chemicals are

removed from the film material.

In the wash tank the flow of the wash water is

controlled by a solenoid valve (N) and the

overflow/drain tube is accessible through the top

cover (see description later in this chapter).

DEV and FIX rack configurations are described in

chapter 6 "CLEANING AND MAINTENANCE".

DRYER rack configuration is described in chapter 6

"CLEANING AND MAINTENANCE".

WASH rack configuration is described in chapter 6

"CLEANING AND MAINTENANCE".

DRYER SECTION

In the dryer section (D) the moisture is removed

from the film to allow for handling immediately after

processing. The dryer section consists of a

centrifugal fan (O) with an integrated heater and two

air distributing-boxes, one above and one

underneath the dryer rack.

Fig. 3/1

3/2

9437

Easycompact 55/72

ECOLOGICAL UNITS

TRANSPORT SYSTEM

The processor is prepared for connections to

ecological units for DEV, FIX and WASH. Ask your

local dealer for more information about the

ecological units.

The transport system consists of a main drive-motor

connected to a worm gear drive system. The drive

system turns the rollers in each rack which, in

conjunction with the film guides and crossovers,

directs the film through the processor (see Fig. 3/2).

In the wet sections the bottom rollers of each rack

are light, which allow them to float. This results in

good contact on the film providing proper film

transport. Squeegee rollers at the entrance of the

dryer section remove surface moisture from the film

and divert water to the wash section.

REPLENISHMENT SYSTEM

Two oscillating pumps (P) connected to two external

replenishment containers (Q) automatically add

developer and fixer to the tanks to compensate for

chemicals used during actual film processing.

The system also supplies additional developer to

compensate for lost activity caused by normal

oxidation.

It is possible to operate the replenishment pumps

manually (to "top up" the tank levels) on the Control

Box (E) (see also chapter 5).

Film sensors at the entrance of the processor start

the replenishment control circuit when film is

entered. The replenishment control circuit also starts

when daylight slot is opened, but not when rewash

slot is opened.

1 FILM PATH

2 DAYLIGHT/ENTRANCE

GUIDE

3 CROSSOVER GUIDE

DEV/FIX

4 REWASH/CROSSOVER

GUIDE FIX/WASH

5 CROSSOVER GUIDE

WASH/DRY

6 SQUEEGEE ROLLERS

7 DRYER RACK

8 FILM GUIDE

9 BOTTOM GUIDE

10 LIGHT ROLLER

Fig. 3/2 Transport System

9437

3/3

Easycompact 55/72

3/4

9437

Easycompact 55/72

MAIN COMPONENTS

(See illustration opposite)

MAIN SWITCH (1)

Switches the power to the machine ON/OFF.

The MAIN-switch is also a lock, and cannot be

turned on without the key delivered with the

processor.

ELECTRONICS DRAWER (2)

The electronics drawer holds the main control

electronics and the fuses for all functions (see

description later in this chapter). The drawer is fitted

with a cover inside to protect the electronics

CONTROL BOX (3)

The processor is operated by the Control Box.

(See description in Chapter 5.)

FEED TABLE (4)

As standard the machine is equipped with a feed

table. Alternatively the machine can be ordered with

a daylight cassette (option, see chapter 8 and 9,

"ACCESSORIES").

As shown in Fig. 3/3 the cassette is equipped with a

specially designed shelf that makes it easy to handle

different sizes of PTS/Imagesetting cassettes. The

shelf can also be used as a feed table.

See max. dimensions of PTS cassettes in chapter 1

"DIMENSIONS, PTS/IMAGESETTING CASSETTES".

INPUT SENSORS (5)

2 input sensors are placed at the processor

entrance. When film is inserted, the input sensors

automatically starts the machine provided that the

machine is switched on by the MAIN-swtich (1) and

the ON-button on the Control Box (3).

9437

Fig. 3/3 Daylight Cassette

DEVELOPER SECTION (6)

See description earlier in this chapter.

NOTE! The developer rack is different from the

fixer and wash racks regarding roller

configuration, entrance-roller bearings and

daylight guide.

FIXER SECTION (7)

See description earlier in this chapter.

The fixer rack roller configuration is identical to the

wash rack.

3/5

Easycompact 55/72

3/6

9437

Easycompact 55/72

WASH SECTION (8)

SCAVENGER FAN (14)

See description earlier in this chapter.

The wash rack roller configuration is identical to the

fixer rack.

NOTE! The wash rack is different from the fixer

rack regarding rewash guide.

Removes chemical vapours from inside the wet

section.

See also description in chapter 2, "EXHAUST

INSTALLATION".

OVERFLOW/DRAIN TUBE (15)

DRYER SECTION (9)

See description earlier in this chapter.

ANTI-OXIDATION LIDS (10)

Each rack in the wet section is equipped with an

anti-oxidation lid. The anti-oxidation lids reduce the

oxidation from the chemical baths as well as it

prevents build-up of condensate underneath the

top-cover (12).

Each bath is equipped with a combined overflow and

drain tube. In the developer section and in the fixer

section the tubes are placed underneath the top

cover on the lefthand side. The tube for the wash

water is placed through the top cover on the

righthand side of the processor.

To empty the baths the tubes must be turned 90

counterclockwise.

Fig. 3/4 illustrates the open and closed position of

the wash tank drain-tube.

CONDENSATION LID (11)

Underneath the top cover the processor is equipped

with a condensation lid to prevent fixer condensation

to drip into the developer section and opposite.

The condensation lid is also designed as a drip tray

on which racks can be carried away for cleaning

without spilling of chemicals.

TOP COVER WITH DAYLIGHT AND

REWASH SLOTS (12)

The processor is designed for "through-the-wall"

installation (see chapter 2) and the daylight and

rewash slots make it possible to use the processor

outside the darkroom.

INTERLOCK SWITCHES (13) & (16)

Fig. 3/4 Drain Tube, Wash Section

The processor is equipped with 2 interlock switches.

Switch (13) is activated by the dryer cover (17) and

switch (16) by the top cover (12). If either of the

covers is lifted off, the related switch will turn off the

machine.

9437

3/7

Easycompact 55/72

3/8

9437

Easycompact 55/72

DRYER COVER (17)

REPLENISHMENT CONTAINERS ON

TROLLEY (20)

The lamps are lit when daylight or rewash slots are

opened.

See detailed description in chapter 5 "DAYLIGHT

AND REWASH LAMPS".

The machine is delivered with 2 containers for

replenishment chemicals (one for developer and one

for fixer). The containers are placed on a trolley. The

trolley fits inside the closed stand (21) and makes it

easy to handle the replenishment containers when

changing, emptying, refilling etc.

FILM BASKET (19)

STAND (21)

When leaving the machine the film material lands in

the film basket.

The processor is delivered with a closed stand (see

chapter 2 "INSTALLATION"). Inside the stand there

is room for the replenishment containers on trolley

(20).

DAYLIGHT AND REWASH LAMPS (18)

9437

3/9

Easycompact 55/72

3/10

9437

Easycompact 55/72

ELECTRONIC CONTROL

MAINBOARD PCB GCB

The processor is electronically controlled by the

Mainboard PCB GCB placed in the electronics

drawer underneath a cover (see Illustration opposite).

The PCB holds all the controls, the adjustment

potentiometers for the thermostates and the

replenish pumps as well as the max. and min. speed

potentiometers for the motor control. Furthermore

the PCB is fitted with two cooling fin brackets where

some triac relays are located (1). The triac relays

control the high voltage output. Another small relay

issue low voltage to the electronics when the

ON-button is activated. Also the fuses for heaters,

pumps etc. are placed on the PCB.

The PCB also communicates with the Control Box

(see description in chapter 5).

The PCB has a display (2) and two set of buttons

(3) for making adjustments. The procedure of

making adjustments on the GCB is described in

chapter 4.

The PCB GCB comprises the following circuits:

1 Power supply for the electronics.

3 Low-level detectors.

1 Heater thermostat for the developer.

FUSES

All fuses (4) for the heaters, pumps and motors etc.

are placed on the PCB GCB through the drawer

cover.

The dryer heater fuses F4 and F5 (5) are placed

through the bottom panel in the left side of the

drawer.

The fuses F1, F2 and F3 (6) are only used for

installations without neutral wire (in USA) and

therefore placed underneath a cover.

The fuses are listed in "FUSES" later in this chapter.

CAUTION! Disconnect all power to the machine

before changing a fuse.

DRAWER LOCK

The electronics drawer is fitted with a small notch in

each side (7). These notches lock the drawer when

pulled half way out. In order to close the drawer, lift

up a little to release the notches and push in.

If it becomes necessary to change a fuse, pull the

drawer halfway out untill it locks, then lift up a little

and pull the drawer all the way out.

CAUTION! Never leave the drawer open. This is

to protect the electronics from chemicals, if

spilled.

1 Heater thermostat for the dryer.

1 Heater thermostat for the fixer.

1 Motor speed control for the main motor.

Change of fuses is described in chapter 6

"CLEANING AND MAINTENANCE".

1 Power supply for the main motor control.

2 Replenishment circuits, one for developer, one

for fixer

2 Oxidation replenishment circuits. One for

developer and one for fixer.

2 Input detector circuits.

1 Timing circuit for the start and stop of process

time.

9437

3/11

Easycompact 55/72

STAND-BY MODE

This manual will often refer to stand-by mode of the

processor. This is when the processor is started as

described in chapter 4 "DAILY START-UP" and

when no program has been activated.

In stand-by mode the processor operates as follow:

The transport mechanism operates at min. speed,

app. 33 cm/min. (13 in/min.) in order to avoid

crystallization of chemicals on rollers and guides.

The wash water solenoid valve is closed.

The dryer heater works to keep the temperature

whitin a fixed range (see APPENDIX, PAR 12 and

13).

The processor automatically goes into stand-by

mode 15-30 seconds after the film has left the dryer

section when in Automatic mode (see

"PROCESSING MODES").

PROCESSING MODES

Processing is made in one of two modes:

Automatic or Continuous.

The processor is running in Automatic mode unless

otherwise is chosen. (To switch from Automatic

mode to Continuous mode, change parameter 07

from 00 to 01, see APPENDIX).

Automatic mode: When film is fed, the input

sensors start the machine and:

The transport mechanism resumes the operating

speed specified in the selected program.

The wash water solenoid valve opens to let in

water.

The temperature in the dryer is controlled and

regulated by the dryer temperature control.

When the film has left the dryer section, the

machine returns to stand-by mode after 15-30

seconds. (This depends on film speed).

Continuous mode: The processor functions exactly

as in Automatic mode except that it never enters

the stand-by mode.

3/12

9437

Easycompact 55/72

FUSES

The fuses below are located on the Mainboard PCB BGCB

Fuse

Fuse for...

Part No

Heater, fixer bath

5A, 6.3 x 32 mm, fast

675534001 / 67 84 644

Heater, developer bath

5A, 6.3 x 32 mm, fast

675534001 / 67 84 644

Blowers, dryer section

1A, 6.3 x 32 mm, fast

675671001 / 67 84 DJD

Circulation pumps

1A, 6.3 x 32 mm, fast

675671001 / 67 84 DJD

Replenishment pump, FIX

0.5A, 6.3 x 32 mm, fast

675535001 /

Replenishment pump,

DEV

0.5A, 6.3 x 32 mm, fast

675535001 /

Transformer

Low voltage power supply

for the control electronics.

9437

Type/Dimension

0.8A, 6.4 x 31.8mm, slow 671634000 /

18 V AC supply for

the control electronics.

1.5A, 6.3 x 32 mm, slow

671602900 / 66 84 BGN

24 V AC for level

detectors

0.25A, 6.3 x 32 mm, fast

675530001 /

Power supply for the

main motor speed control.

3A, 6.3 x 32 mm, slow

671601400 / 66 84 BGM

3/13

Easycompact 55/72

The fuses below are located in the bottom panel and connected to the mainboard PCB BGCB. The fuses

F4 and F5 are for the dryer heaters. The fuses F1 - F3 are used for USA only (for installations without

neutral wire) and covered with a small plate.

Fuse

3/14

Fuse for...

Type/Dimension

Part No

Heater, dryer

10A, 6.3 x 32 mm, fast

671607900 / 67 84 DYG

Heater, dryer

10A, 6.3 x 32 mm, fast

671607900 / 67 84 DYG

Only used for

installations

without neutral wire

10A, 6.3 x 32 mm, fast

671607900 / 67 84 DYG

Only used for

installations

without neutral wire

10A, 6.3 x 32 mm, fast

671607900 / 67 84 DYG

Only used for i

nstallations

without neutral wire

12A, 6.3 x 32 mm, fast

671609900 / 67 84 EGV

9437

Easycompact 55/72

ELECTRICAL DIAGRAM

The electrical diagram for the processors is on the

fold-out page behind the appendix.

9437

3/15

Easycompact 55/72

3/16

9437

Easycompact 55/72

CHAPTER 4

OPERATING PROCEDURES

After the installation is finished, (see chapter 2 in

this book), the initial start-up, described on the

following pages, can be carried out.

9314

Turn power off and unplug the unit before

commencing the initial start-up procedure.

4/1

Easycompact 55/72

4/2

9314

Easycompact 55/72

INITIAL START-UP

Remove top cover, condensation lid and dryer

cover.

Remove the racks (see chapter 6) and inspect all

rollers and film guides for impurities etc.

Open all tank drain-tubes by turning them 90

counterclockwise. The drain-tubes for the DEV

and FIX baths are at the lefthand side of the tank

and the drain-tube (E) for the wash tank is at the

righthand side.

Place the top cover, condensation lid and dryer

cover and make sure that they are placed

correctly in order to activate the interlock

safety-switches. Otherwise you will not be able to

start the processor.

Fill the replenishment containers (K) and make

sure that the hoses are installed correctly:

BLUE HOSE TO DEVELOPER

RED HOSE TO FIXER

Insert power plug into wall socket.

Open external water supply valve (H).

Vacuum clean all tanks if required.

Turn the MAIN-switch (J) on.

Carefully rinse all tanks, rollers and film guides

with water (use a hose) to get all impurities out of

the tanks.

Push the ON-button (1). The indicator lamp for

latest employed program (8) will light up. The

solenoid valve will open to fill the wash tank with

water.

If the ON-button is pushed immediatly after the

machine is turned on by the MAIN-switch, it takes

approx. 10 seconds before the machine starts.

Let the tanks run dry then close the drain-tubes.

Fill the developer and fixer tanks (fixer first) with

ready made solution. The tanks are filled correctly

when level is as specified in Fig. 4/1. Be careful

not to get fixer into the developer section and

opposite.

Reinstall the racks. Be careful to insert the correct

racks in the correct baths.

If the WAIT-lamp (6) flashes, the developer, fixer

or dryer temperature is either too high or too low.

Wait until the WAIT-lamp turns off. Normal

warm-up time will be approx. 30 min.

Run some sheets of film through the machine to

clear the rollers of impurities.

The machine is now ready for processing.

SETTING OF THE PROGRAMS

The electronics holds 4 programs (A, B, C and D) in

which you can set 4 different developing speeds for

different types of processing jobs.

Setting of the program values is described later in

this chapter and in APPENDIX.

Fig. 4/1

9314

4/3

Easycompact 55/72

4/4

9314

Easycompact 55/72

ADJUSTING THE

REPLENISHMENT PUMPS

Calibrate both replenishment pumps (one at the

time) as described below.

Remove the replenishment hose from the

replenishment container (K). Keep the hose

elevated.

Fill a graduate with chemicals.

Place the replenishment hose into the graduate.

Push the replenishment button (3) for DEV or (4)

for FIX and pump until no more air is in the

replenishment system. Keep the hose end under

the chemical surface.

Refill the graduate, so that it contains:

for ECP 55

min. 300 ml.

for ECP 72

min. 400 ml.

Fig. 4/2 Replenishment Adjustment Valves

Push the replenishment button again for 30 sec.

The approximate volume of liquid pumped out

of the graduate should be:

275 ml (550 ml/min.)

for ECP 55

350 ml (700 ml/min.).

for ECP 72

If not, calibrate the pump using the replenish

adjustment valves (see Fig. 4/2).

NOTE! It is very important that the pumps are

calibrated very accurately. Otherwise the values

set in the replenishment parameters (see

APPENDIX) are not correctly obtained.

9314

4/5

Easycompact 55/72

4/6

9314

Easycompact 55/72

DAILY START-UP

(See illustration opposite)

Check that the replenishment containers (K) are

sufficiently filled and that the containers for waste

chemicals (C) are empty.

Remove the top cover and condensation lid and

check the level of the developer and fixer baths.

Add chemicals if required.

Before starting the machine, wipe clean all top

rollers and crossover guides.

Open external water supply valve (H).

NOTE! Make certain that the wash tank drain

tube (E) is closed (see fig. 4/3). Do not operate

the processor with an empty wash tank.

Turn MAIN-switch (J) on. The exhaust blower will

start, and the replenishment pumps may also run

for a few moments.

Push the ON-button (1) and verify that the built-in

lamp is lit.

If the ON-button is pushed immediatly after the

machine is turned on by the MAIN-switch, it takes

approx. 10 seconds before the machine starts.

When switched on, the processor automatically

fills the water tank.

The processor is programmed for Automatic

mode from the factory. If you want to use

Continuous mode, please refer to the APPENDIX.

Press the PROGRAM SELECTION-button (7) until

the lamp (8) for the desired program number is lit.

If WAIT-lamp (6) is lit and one ore more of the

LOW LEVEL- lamps (5) flashes, low level is

detected in the respective section(s). For fixer or

developer press one of the buttons (3) or (4) and

hold it. The respective replenishment pump will

start to top up the level in the section until the

lamps turn off. While the pump runs the LOW

LEVEL-lamp (5) is lit constantly. Wait until the

lamp turns off.

If automatic regeneration has been selected (PAR

01, see APPENDIX) the respective replenishment

pump starts automatically when low level is

detected. When the pump runs the LOW

LEVEL-lamp (5) flashes and if correct level has

not been reestablished within 5 minutes, the

replenishment pump stops while the lamp

continues to flash.

In case of low level in wash tank, check that

solenoid valve is open and that drain tube (E) is

closed. Wait until correct level is reestablished

and the LOW LEVEL-lamp turns off.

If the WAIT-lamp (6) flashes, the temperature in

either the developer, fixer or dryer section is too

low or too high.

Wait until the lamp turns off.

Fig. 4/3

Allow the processor to reach normal operating

conditions. Normal warm-up time will be app. 30

minutes.

Feed some sheets of film/paper through the

machine to clean it.

The machine is now ready for processing.

9314

4/7

Easycompact 55/72

4/8

9314

Easycompact 55/72

PROCESSING FROM

THE FEED TABLE

PROCESSING CASSETTES

FROM THE DAYLIGHT CASSETTE

(See illustration opposite).

(See also fig. 4/4).

Select the program suitable for the processing

material by means of the PROGRAM

SELECTION- button (7). The lamp (8) shows

which program is active at any time.

Verify that the processor is not busy (WAIT-lamp

(6) not lit).

Slowly enter the film (preferably with the emulsion

side upwards) into the processor using the film

feed guide (B) until it engages the drive system.

The input sensors are activated and the machine

starts at the speed specified in the selected

program.

Verify that the WAIT-lamp (6) is lit indicating that

film is being fed into the machine.

Wait until the WAIT-lamp turns off before you

insert another film.

When the film exits, verify that the processor goes

into stand-by mode after 15 - 30 seconds. (See

chapter 3, "STAND-BY MODE").

Open the cassette cover (9).

Adjust the shelf (10) to fit the cassette size or

remove it, whatever is necessary.

Select processing program by means of the

PROGRAM SELECTION-button (7). The lamp (8)

shows which program is active at any time.

Place the cassette (11) in the daylight cassette

and enter the film/paper (12) into the processor

until it engages the drive system. The input roller

(13) ensures that the material enters the machine

without scratches. When the input sensors are

activated, the processor starts and the WAIT-lamp

(6) is lit.

Close the cassette cover (9) and do not open

until the WAIT-lamp (6) turns off!

When the WAIT-lamp turns off, the machine is

ready to process another cassette.

SHELF/FEED TABLE

The shelf can also be used as feed table. In that

case adjust the shelf to upper position and follow the

procedure described in "PROCESSING FROM THE

FEED TABLE". Feed paper between the white

marks on the shelf.

Fig. 4/4 Processing PTS Cassettes

9314

4/9

Easycompact 55/72

4/10

9314

Easycompact 55/72

PROCESSING FROM

THE DAYLIGHT SLOT

USING THE REWASH SLOT

(See illustration opposite).

(See illustration opposite).

Verify that the processor is not busy (DAYLIGHT(F) and REWASH-lamps (G) not lit).

Verify that the processor is not busy (DAYLIGHT(F) and REWASH-lamps (G) not lit).

Select processing program by means of the

PROGRAM SELECTION button (7). The lamp (8)

for the selected program is lit.

Open the REWASH slot (D). The processor starts,

the WAIT-lamp (6), the DAYLIGHT-lamp (F) and

the REWASH-lamp (G) are lit.

Open the DAYLIGHT slot (A). The processor

starts, the WAIT-lamp (6), the DAYLIGHT-lamp

(F) and the REWASH-lamp (G) are lit. (The

replenishment control circuit starts).

Feed film/paper into the processor and close the

REWASH slot (D). (WAIT-lamp and

DAYLIGHT-lamp turn off).

Feed film/paper into the processor and close the

DAYLIGHT slot (A). (WAIT-lamp turns off).

When the DAYLIGHT lamp (F) turns off, the

processor is ready to receive another film through

the DAYLIGHT slot (A).

When the REWASH-lamp (G) turns off, the