Académique Documents

Professionnel Documents

Culture Documents

Lesson 1 - Basics of Arc Welding10

Transféré par

thindmanmohanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lesson 1 - Basics of Arc Welding10

Transféré par

thindmanmohanDroits d'auteur :

Formats disponibles

Lesson1

TheBasicsofArc

Welding

LESSONI,PARTB

1.8.5.2

Thetransformerinaweldingmachineperformsmuchthesameasalargepower

Current

Chapter

Tableof

Contents

planttransformer.Theprimaryvoltagecomingintothemachineistoohighforsafe

Lesson2

CommonElectric

ArcWelding

Processes

Lesson3

CoveredElectrodes

forWelding

MildSteels

welding.Therefore,itissteppeddowntoauseablevoltage.Thisisbestillustratedwithan

explanationofhowasingletransformerworks.

1.8.5.3

Intheprecedingparagraphs,wehavefoundthananelectricalcurrentcanbe

GoToTest

inducedintoaconductorwhenthatconductorismovedthroughamagneticfieldto

producealternatingcurrent.Ifthisalternatingcurrentispassedthroughaconductor,a

pulsatingmagneticfieldwillsurroundtheexteriorofthatconductor,thatisthemagnetic

fieldwillbuildinintensitythroughthefirst90electricaldegrees,orthefirstcycle.Fromthat

point,themagneticfieldwilldecayduringthenextquartercycleuntilthevoltageorcurrent

Lesson4

CoveredElectrodes

forWeldingLowAlloy

Steels

reacheszeroat180electricaldegrees.Immediately,thecurrentdirectionreversesandthe

Glossary

magneticfieldwillbegintobuildagainuntilitreachesamaximumat270electricaldegrees

inthecycle.Fromthatpointthecurrentandthemagneticfieldagainbegintodecayuntil

theyreachzeroat360electricaldegrees,wherethecyclebeginsagain.

Lesson5

WeldingFillerMetals

forStainlessSteels

1.8.5.4

Ifthatconductoriswoundaroundamaterialwithhighmagneticpermeability

(magneticpermeabilityistheabilitytoacceptlargeamountsofmagneticlinesofforce)

suchassteel,themagneticfieldpermeatesthatcore.See

STEELCORE

Figure14.Thisconductoriscalledtheprimarycoil,andif

Lesson6

Carbon&LowAlloy

SteelFillerMetals

GMAW,GTAW,SAW

voltageisappliedtooneofitsterminalsandthecircuitis

completed,currentwillflow.Whenasecondcoiliswound

TurnPages

SECONDARY

COIL

460V

80V

aroundthatsamesteelcore,theenergythatisstoredin

thisfluctuatingmagneticfieldinthecoreisinducedinto

Lesson7

FluxCoredArc

ElectrodesCarbon

LowAlloySteels

PRIMARY

COIL

80

TURNS

460

TURNS

thissecondarycoil.

BASICTRANSFORMER

1.8.5.5

Itisthebuildupandcollapseofthismagnetic

fieldthatexcitetheelectronsinthesecondarycoilofthe

FIGURE14

transformer.Thiscausesanelectricalcurrentofthesamefrequencyastheprimarycoilto

Lesson8

Hardsurfacing

Electrodes

flowwhenthesecondarycircuitiscompletedbystrikingtheweldingarc.Rememberthat

alltransformersoperateonlyonalternatingcurrent.

1.8.5.6

AsimplifiedversionofaweldingtransformerisschematicallyshowninFigure15.

Thiswelderwouldoperateon230voltsinputpowerandtheprimarywindinghas230turns

Lesson9

Estimating&

ComparingWeld

MetalCosts

Search

Chapter

(Faster

Download)

ofwireonthecore.Weneed80voltsforinitiatingthearcinthesecondaryorwelding

circuit,thuswehave80turnsofwireinthesecondarywindingofthecore.Beforethearc

isstruck,thevoltagebetweentheelectrodeandtheworkpieceis80volts.Rememberthat

nocurrent(amperage)flowsuntiltheweldingcircuitiscompletedbystrikingthearc.

Lesson10

ReliabilityofWelding

FillerMetals

COPYRIGHT1999THEESABGROUP,INC.

Search

Document

(Slower

Download)

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Face Bend Test ReportDocument1 pageFace Bend Test ReportthindmanmohanPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Process Validation RecordDocument11 pagesProcess Validation Recordthindmanmohan50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Proper Use of Weld Gages - Welding AnswersDocument13 pagesProper Use of Weld Gages - Welding AnswersthindmanmohanPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Acctstmt HDFC MFDocument1 pageAcctstmt HDFC MFthindmanmohanPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Parveen SAWDocument5 pagesParveen SAWthindmanmohanPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Face Bend Test ReportDocument1 pageFace Bend Test ReportthindmanmohanPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Duty CycleDocument3 pagesDuty CyclethindmanmohanPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Weld DistortionDocument4 pagesWeld DistortionthindmanmohanPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Amtek Railcar Industries Private Limited: Check SheetDocument2 pagesAmtek Railcar Industries Private Limited: Check SheetthindmanmohanPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Appreciation Letter To BossDocument7 pagesAppreciation Letter To BossthindmanmohanPas encore d'évaluation

- Lesson 1 - Basics of Arc Welding6Document1 pageLesson 1 - Basics of Arc Welding6thindmanmohanPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- PSF 250 PSF 510wDocument24 pagesPSF 250 PSF 510wthindmanmohanPas encore d'évaluation

- Lesson 1 - Basics of Arc WeldingDocument1 pageLesson 1 - Basics of Arc WeldingthindmanmohanPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Ohs 583974Document1 pageOhs 583974thindmanmohanPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- ER90SD2Document3 pagesER90SD2thindmanmohanPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- WPS 22 MMDocument2 pagesWPS 22 MMthindmanmohanPas encore d'évaluation

- Cert IWT Manmohan SinghDocument1 pageCert IWT Manmohan SinghthindmanmohanPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Before You StartDocument5 pagesBefore You StartthindmanmohanPas encore d'évaluation

- Process Mapping For TS 16949Document8 pagesProcess Mapping For TS 16949thindmanmohanPas encore d'évaluation

- Counselling Schedule 2015-16Document1 pageCounselling Schedule 2015-16thindmanmohanPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 22 Accident - Near Miss ReportDocument1 page22 Accident - Near Miss ReportthindmanmohanPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Dhanowali Enclave Back of DPSDocument2 pagesDhanowali Enclave Back of DPSthindmanmohanPas encore d'évaluation

- Brochure PudaDocument24 pagesBrochure PudathindmanmohanPas encore d'évaluation

- Deviation FormDocument4 pagesDeviation FormthindmanmohanPas encore d'évaluation

- 11 - Lathe-A4Document3 pages11 - Lathe-A4thindmanmohanPas encore d'évaluation

- Energy Meter UsedDocument21 pagesEnergy Meter UsedthindmanmohanPas encore d'évaluation

- Energy Meter UsedDocument21 pagesEnergy Meter UsedthindmanmohanPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Welding OptionsDocument7 pagesWelding Optionsmaro151Pas encore d'évaluation

- Area RCC Flooring Tile FlooringDocument2 pagesArea RCC Flooring Tile FlooringthindmanmohanPas encore d'évaluation

- Laptop Lenovo Foxcon-TPC01Document39 pagesLaptop Lenovo Foxcon-TPC01حسن علي نوفلPas encore d'évaluation

- Unit2 Electrical and Electronic Technology Past PapersDocument17 pagesUnit2 Electrical and Electronic Technology Past Papersalbertvalerie742Pas encore d'évaluation

- TBS299Document2 pagesTBS299harmonoPas encore d'évaluation

- Item No. Picture Name Colors QTY Product Size Material ModalDocument3 pagesItem No. Picture Name Colors QTY Product Size Material Modalgeorgius daniPas encore d'évaluation

- MRN4296Document1 pageMRN4296jazztonickxPas encore d'évaluation

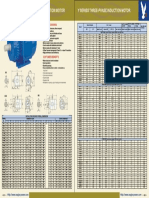

- Y Series Three-Phase Induction Motor Y Series Three-Phase Induction Motor Y Series Three-Phase Induction Motor Y Series Three-Phase Induction MotorDocument1 pageY Series Three-Phase Induction Motor Y Series Three-Phase Induction Motor Y Series Three-Phase Induction Motor Y Series Three-Phase Induction MotorBudi Utomo86Pas encore d'évaluation

- Ina 125Document18 pagesIna 125Prasad SasidharanPas encore d'évaluation

- Brochure Medium Voltage AssembliesDocument98 pagesBrochure Medium Voltage AssembliesfranPas encore d'évaluation

- Bare Copper Conductor: Standards / Testing SpecificationsDocument4 pagesBare Copper Conductor: Standards / Testing SpecificationskjkljkljlkjljlkPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- A - Measurement Systems - Week - 4 - 20200225Document32 pagesA - Measurement Systems - Week - 4 - 20200225Musah NgcobohPas encore d'évaluation

- Semikron SKIIP 11NAB126V1 DatasheetDocument4 pagesSemikron SKIIP 11NAB126V1 DatasheetGabriel EscamillaPas encore d'évaluation

- APN-003 Arc Flash ProtectionDocument14 pagesAPN-003 Arc Flash ProtectionIvoPas encore d'évaluation

- BXE - Unit 1Document191 pagesBXE - Unit 1HardikPas encore d'évaluation

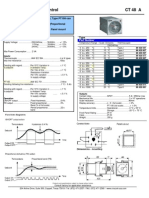

- Analog Temperature ControlDocument1 pageAnalog Temperature Controlangeljavier9Pas encore d'évaluation

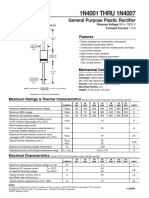

- 1N4001 THRU 1N4007: General Purpose Plastic RectifierDocument2 pages1N4001 THRU 1N4007: General Purpose Plastic RectifierroekanPas encore d'évaluation

- Central Battery System Euro Zb.1: SKU CG 1x6 - 1/3Document5 pagesCentral Battery System Euro Zb.1: SKU CG 1x6 - 1/3Muthuvel GaneshPas encore d'évaluation

- Thunderstruck VCU Troubleshooting - August 2021: Me thw1 and Record Voltage RangeDocument1 pageThunderstruck VCU Troubleshooting - August 2021: Me thw1 and Record Voltage RangeJohnPas encore d'évaluation

- Instalación Krk3011a0600h - 01Document2 pagesInstalación Krk3011a0600h - 01Ranses RomanPas encore d'évaluation

- Class 12th Physics Lab Manual Activity 5Document2 pagesClass 12th Physics Lab Manual Activity 5CoolBoyPas encore d'évaluation

- ANSI C82.6 For Lamp Ballasts. Ballasts For High-Intensity Discharge Lamps - Methods of MeasurementDocument29 pagesANSI C82.6 For Lamp Ballasts. Ballasts For High-Intensity Discharge Lamps - Methods of MeasurementJose Luis Perez RodriguezPas encore d'évaluation

- bq25606 PDFDocument46 pagesbq25606 PDFAdityaPas encore d'évaluation

- Rly3-Ossd2: Safety RelaysDocument6 pagesRly3-Ossd2: Safety RelaysTapir ConstantinoPas encore d'évaluation

- ComPacT NSX - New Generation - C40N32D400Document3 pagesComPacT NSX - New Generation - C40N32D400Ban Juan OoiPas encore d'évaluation

- WH Magnetic Door ContactDocument4 pagesWH Magnetic Door ContactUsman ZouquePas encore d'évaluation

- Red/High Leg Delta Configuration: Technical NoteDocument10 pagesRed/High Leg Delta Configuration: Technical NoteJosé MéndezPas encore d'évaluation

- Servomotor Belimo LM230A - PDFDocument4 pagesServomotor Belimo LM230A - PDFSoficu DanielPas encore d'évaluation

- Siemens Polydoros LX 30-50 X-Ray - AdjustmentDocument82 pagesSiemens Polydoros LX 30-50 X-Ray - Adjustmenthaseeb100% (1)

- V"AJH13: Nunber of Swilchmg Are TrippmgDocument2 pagesV"AJH13: Nunber of Swilchmg Are TrippmgrizwanPas encore d'évaluation

- Electronic Products & Components in PUNEDocument4 pagesElectronic Products & Components in PUNESenthil Kumar MuraliPas encore d'évaluation

- X360Run SLIM GlitcherBoard20131118-english PDFDocument9 pagesX360Run SLIM GlitcherBoard20131118-english PDFAntonio Henrique100% (1)

- The Cyanide Canary: A True Story of InjusticeD'EverandThe Cyanide Canary: A True Story of InjusticeÉvaluation : 4 sur 5 étoiles4/5 (52)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontD'EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontÉvaluation : 4.5 sur 5 étoiles4.5/5 (18)

- Slow Violence and the Environmentalism of the PoorD'EverandSlow Violence and the Environmentalism of the PoorÉvaluation : 4 sur 5 étoiles4/5 (5)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionD'EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionÉvaluation : 3 sur 5 étoiles3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretD'EverandWaste: One Woman’s Fight Against America’s Dirty SecretÉvaluation : 5 sur 5 étoiles5/5 (1)

- Introduction to Ecology and Environmental Laws in IndiaD'EverandIntroduction to Ecology and Environmental Laws in IndiaPas encore d'évaluation

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionD'Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionPas encore d'évaluation