Académique Documents

Professionnel Documents

Culture Documents

1 PB

Transféré par

Matthew SmithTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 PB

Transféré par

Matthew SmithDroits d'auteur :

Formats disponibles

2948

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

Shift Control System of Heavy-duty Vehicle

Automatic Transmission

Yan Zhang and Wenxing Ma

College of Mechanical Science and Engineering, Jilin University, Changchun, China

Email: zhangyan19870515@163.com, mawx@jlu.edu.cn

Xuesong Li

State Key Laboratory of Automobile Simulation and Control, Jilin University, Changchun, China

Corresponding author, Email: lixuesong@jlu.edu.cn

AbstractHeavy-duty vehicle hydrodynamic mechanical

automatic transmission shifting operation system was

designed, mathematical model of its simplified hydraulic

system was established and simulation model of shifting

operation system was established with AMESim, the

simulation experiment was carried out, then oil pressure

curves of each clutch hydraulic cylinder were obtained when

giving forward gear or reverse gear signals. The simulation

results show that shifting operating system meets the design

requirements, and verify the correctness of the model. The

shift timing is correct, and there is no power interruption or

gear overlap during the shift transition process. Joint oil

pressure of designed system is stable, and shifting shock is

small. The research results are providing the basis for

further study of shifting operation system and a reasonable

platform for the studying of shift schedule and quality. The

theoretical design method and dynamic simulation

experiment will be feasible for the real industrial

applications. The research results can be used in design and

optimization of hydraulic system.

Index TermsHydrodynamic Mechanical Automatic

Transmission; Shifting Operation System; Dynamic

Simulation Experiment; Joint Oil Pressure

I.

INTRODUCTION

The rapid development of computer technology

promotes the application of simulation technology in

social production and life [1-2]. The application of

computer simulation technology is also becoming more

and more popular in the development, design,

manufacture, assembly, testing and other aspects with

vehicles as the most common forms of transport [3-4].

Automatic transmission as important automotive power

train components, its advantages and disadvantages of

power transmission performance directly affect the

quality of the vehicle. In AT research and develop

process, the use of computer simulation technology for

virtual development can be achieved in parallel

development of products, which effectively shortens the

development cycle and reduces the cost of production,

therefore, virtual design for the automatic transmission

has gradually become the mainstream [5]. Hydrodynamic

mechanical automatic transmission (AT) is currently the

2013 ACADEMY PUBLISHER

doi:10.4304/jnw.8.12.2948-2955

most widely used type of automatic transmission, and it

becomes the first choice of heavy-duty vehicle automatic

transmission with its advantages of simple operation and

saving effort, improving the traffic safety, reducing the

labor intensity, improving the ride comfort, extending the

service life of the mechanical parts, improving the

dynamic performance of the vehicle, reducing air

pollution, and having a good self-adaptability [6-7].

Shift operation system is an important part of

automatic transmission mainly used to ensure normal

work of transmission system and realize changing shift.

Rational design shift operation system not only can

extend the service life of the shift clutch and brake, but

also improve the reliability of the automatic transmission,

and can reduce the power loss in shifting process, reduce

shift shock, improve shift quality [8]. In previous studies,

the mathematical model of shift operation system

established often ignored the influence of friction, oil

characteristics, environmental temperature and other

factors, so that it cannot truly reflect shifting

characteristics of shift operation system [9-11].

Literatures [12-13] are modeling and simulation for one

valve of automatic transmission hydraulic system.

Literatures [14-15] are modeling and simulation research

for a clutch of shifting hydraulic system. Until now, there

are few references about the research for the modeling

and simulating of AT hydraulic system. Taking into

account the automatic transmission of heavy vehicles

gradually developing in the direction toward multi-shift,

this paper designed eight-speed automatic transmission

shift operation system of some heavy-duty, established

the simulation model of the system, analyzed oil pressure

changing curves of each clutch and brake during shifting

process [16]. Kinematics and dynamics changing process

of each manipulation member in shifting hydraulic

system was mastered, the separation and integration of

the clutch when shifting was observed visually.

II.

SYSTEM MODEL

A. The Principle of Shifting Control System

Fig. 1 is shown that the shifting operation system

working schematic and hydraulic components of

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

designed

a

heavy-duty

eight-speed

automatic

transmission. Shifting valve uses priority interlock circuit,

in order to prevent two of clutches jointed at the same

time effectively [17]. The function of stationary

combination valve 9 is adjusting boost characteristic of

clutch cylinder in the shifting instant, reducing shift

shock, improving shift quality. High speed brake 23, low

speed clutch 24 and reverse gear brake 25 are directional

control joint element, middle gear brake 20, high gear

clutch 21 and low gear brake 22 are shifting control joint

element. The working condition of electromagnetic valve

can achieve six forward gears and one reverse gear

operation as shown in Table I.

2949

(1) Response capability of the valve is ideal that is the

valve port is response to fully open, then the spool

displacement and the flow rate change of pressure drop

can occur instantaneously.

(2) The internal and external leakage of hydraulic

cylinder is laminar flow.

(3) The oil supply pressure is constant, and the oil

return pressure is zero.

(4) The internal friction loss and the dynamic

characteristics of the pipeline are ignored.

(5) The oil temperature is constant.

Figure 2. Simplified model of hydraulic system

Figure 1. The shifting operation system working schematic

After linear processing to steady-state working points

on the system, linear flow equation of the two-position

three way valve for fluid control is obtained

QL Kq XV KC PC .

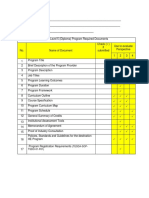

TABLE I.

THE WORKING OF EACH ELECTROMAGNETIC VALVE

Electromagnetic valve

M1

M2

Reverse

Neutral

I

II

III

IV

VI

Gears

M3

M4

B. The Mathematical Modeling of Shifting Operation

System

Mathematical modeling of shifting operation system is

beneficial for selecting simulation parameters and

analyzing dynamic characteristics of operation system,

though simulation analysis software based on graphical

modeling approach of physical models. The mathematical

model of the clutch pressure control is established with

oil passed gear valve to clutch as an example. The

clutch is equivalent to spring damping system,

considering that viscous damping coefficient between

clutch piston and the external load is small, which can be

ignored. Fig. 2 is shown simplified model of hydraulic

operation system. Making following assumptions when

the system is analyzed:

2013 ACADEMY PUBLISHER

(1)

where QLflow of load, m3/s,

Kqflow gain of slide valve, m2/s,

KCflow pressure coefficient of slide valve, m5/Ns,

XVspool displacement of slide valve, m,

PCthe control pressure of the hydraulic cylinder

control chamber, Pa.

The Laplace transformation of formula (1) is

QL Kq XV KC PC

(2)

Considering internal and external leakage of the

hydraulic cylinder and hydraulic oil compressibility in

cylinder, the flow continuity equation of hydraulic

cylinder is got

QL A

dVC

V dP

Cip PC C C

dt

e dt

(3)

VC V0 AX P

(4)

where Awork area of hydraulic cylinder, m2,

Cipinternal leakage coefficient of hydraulic

cylinder, m5/Ns,

VCcontrol cavity volume of hydraulic cylinder, m3,

V0control cavity initial volume of hydraulic

cylinder, m3,

eeffective bulk elasticity modulus of oil, Pa,

2950

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

XPpiston displacement of hydraulic cylinder, m.

Combined formula (3) and (4) is

QL A

V dP

dX P

Cip PC C C

dt

e dt

If the ratio of load spring stiffness and hydraulic spring

(5)

K M K

stiffness is K/Kh<<1, and satisfied C 2 t

the formula (10) can be further simplified to

The Laplace transformation of formula (5) is

QL AsX P Cip PC

VC

Kq

G( s)

(6)

sPC

Combined formula (2) and (6) is

K q X V KC PC AsX P Cip PC

VC

(7)

sPC

PC A M t

dt

KX P FL

(8)

PC A M t s 2 X P KX P FL

Kq M t s2 K

(9)

(10)

VC M t 3

V K

s KC Cip M t s 2 KC Cip A2 C s KC Cip K

e

e

XV

Kq

QL

1

AS

Xp

Cip

Vc

1

M r s2 K

A

natural

(11)

frequency,

Kh

e A

, rad/s,

Mt

VC M t

2

hdamping ratio, h

KC Cip

2A

e M t

VC

rinertia corner frequency, r

Cip K

A2

Pc

Figure 3. Transfer function block diagram of hydraulic control system

e A2

, N/m.

VC

Hydraulic system natural frequency h is an important

parameter of measuring system dynamic characteristics.

It can get a better stability by appropriately increasing the

natural frequency of the system, so improving working

area of hydraulic cylinder is conducive to the stability of

the system. Additionally, the smaller the 1/r is, the

faster system reflects. Therefore, increasing working area

of hydraulic cylinder and reducing spring stiffness of load

appropriately can effectively avoid the clutch pressure

rising too fast, which is conducive to improve shifting

performance.

Then analyzed dynamics and kinematics of shifting

process, and got the maximum friction clutch torque Mm

from relevant information [18]

M m M PRd zk0

(12)

where Mtransmission torque, Nm,

reserve coefficient,

coefficient of friction,

Rdequivalent radius of frictional force, m,

Pclamping force, MPa,

zthe number of friction pair,

k0loss coefficient of compression force.

The clamping force P is calculated as

P

Kc

2013 ACADEMY PUBLISHER

hhydraulic

Khhydraulic spring stiffness, K h

Transfer function of hydraulic control system can get

by combining formula (7) and (9) then eliminating XP

Fig. 3 is transfer function block diagram of hydraulic

cylinder system controlled by valve with input spool

displacement XV and output the clutch pressure PC

depicted by formula (10).

The form of the transfer function only depends on the

parameters of the system itself, and has nothing to do

with input function of external, which means it does not

consider the influence of FL. G(s) describes the inherent

dynamic characteristics of system, which reflects the

dynamic response of the pressure in clutch cylinder.

Substituting the parameter values and determining the

stability of established shifting operation system, the

result shows that the system is stable, and proves the

rationality of the designed hydraulic operation system.

PC

XV

KC Cip

PC

X V s 2 2 h

s

s 1

1

2

h

r

rad/s,

where Mttotal mass of the piston and the load, kg,

Kspring stiffness of load, N/m,

FLany external load force, N.

The Laplace transformation of formula (8) is

G(s)

where

Ignored transient fluid dynamic, steady-state flow

force and viscous damping force during the process of

hydraulic cylinder movement, then the force balance

equation of the hydraulic cylinder is got

d2XP

1 ,

2

2

D12 q

(13)

The equivalent radius is calculated as

Rd

D

D2 D1

, c 1

D2

4

(14)

Taken formula (13) and (14) into formula (12) and got

maximum friction torque of the clutch

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

2951

Figure 4. Simulation model of shifting operation system

Mm M

2

16

D 1 c

3

2

1 c zk

0

(15)

where D1inside diameter of friction plate, m,

D2outside diameter of friction plate, m,

utilization area coefficient of friction plates,

[q]allowable specific pressure.

The actual transmitted friction torque Mm when the

clutch in the working process is

M m' P' Rd zk0

(16)

The clamping force P is calculated as

P' P

2

2

D12

(17)

where Pthe instantaneous pressure of clutch piston.

Taken formula (14) and (17) into formula (16)

M m'

16

P D22 D12 D1 D2 zk0

(18)

Form formula (18), it can be seen for shift clutch of

structure determined, friction torque is only related with

clutch piston supported instant pressure proportionally at

the shifting moment. Therefore, the changing pressure

influenced on shifting is the main content of research and

analysis in this paper.

III.

SIMULATION RESULTS

AMESim simulation model is set up, and the design

philosophy of AMESim is based on bond graph modeling

approach, compared to using transfer function described

the dynamic system, it takes into account the friction, the

oil itself characteristics, environmental temperature and

so on some parts difficult to model, which reduces the

error brought by these factors. The established model can

visually reflect the dynamic characteristics of hydraulic

system. Compared with traditional hydraulic system

design and analysis methods, it saves a lot of time and

2013 ACADEMY PUBLISHER

efforts and clearly observes the parameters of each

component influenced on the dynamic characteristics of

the hydraulic system. The combination and separation of

the clutch oil pressure curves of hydraulic cylinder during

the shifting process are obtained in order to verify

dynamic oil pressure changing consistent with the

theoretical design requirements.

Fig. 4 is shown shift control system simulation model

in the AMESim, established most valve model by using

HCD (shift control system simulation mode), and given

shift signal by using truth table in the drive library. Main

oil pressure in the system is provided by metering pump,

controlled the main oil pressure between 1.2 to 1.48MPa,

metering pump speed from 0 to 2100r/min, flow is

250L/min, fine oil filter relief valve opening pressure is

0.14 MPa, using PTF-2 hydraulic transmission oil.

A. Analysis Forward Upshifts of Simulation Results

Fig. 5 is shown that upshift signal from neutral

position, first gear to sixth gear, each gear

electromagnetic valve receives signal as shown in Table 1.

Fig.6 is shown oil pressure curves of low speed clutch

and low gear brake when neutral position up to the first

gear, it can be seen low speed clutch is jointed at neutral

position, shifting electromagnetic valve M3 received

electromagnetic signal promotes gear valve III so that

low gear brake begin to filling oil and joints when given

the first signal at 5 seconds. Oil pressure rising

characteristic of low gear brake hydraulic cylinder due to

the effect of stationary combination valve, is divided into

three stages obviously, and the first stage is rapidly filled

oil in the clutch cavity and establishes a certain pressure

to eliminate the gap between the clutch friction plates.

The second stage is buffer boost stage, which is a key

part of the shift quality, and there is no change with the

flow rate in the clutch hydraulic cylinder, only with rising

of pressure from friction plates compacted and staring

passing on friction torque to the clutch jointed completely.

If the buffer time is too short, it will produce the shift

shock, inversely, if the buffer time is too long, it will

2952

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

results in slipping friction overlength, slipping friction

work increased, the temperature rising, wear and tear

intensified. The third stage is step boost stage, in which

the friction between clutch plates changes from dynamic

friction to static friction, the oil pressure rise time of

clutch hydraulic cylinder is very short and easy to

produce dynamic loads, resulting in shift shock, however,

high retention oil pressure provides a certain torque

reserve during the process of transmission torque, which

prevents clutch slipping caused by mutation load.

Through the above analysis, dynamic hydraulic shift

changes consistent with the theoretical design

requirements.

Figure 5.

changes of torque and rotational speed. Both of two

conditions can generate shift shock, therefore timing

control should be taken when clutch combined during

shifting to achieve the ideal synchronization shift.

Fig. 8 is shown that hydraulic cylinder oil pressure

curves of low speed clutch, high speed brake, low gear

brake and middle gear brake when the second gear up to

the third gear. The curves indicate that oil pressure of

high speed brake and low gear brake rapidly reduced,

while low speed clutch and middle gear brake begin to

joint when given the shift signal at 15seconds. Low speed

clutch engages earlier than middle gear brake, this is

because low speed clutch is direction control element and

middle gear brake is shift control element. Oil pressure of

middle gear brake obviously lags behind the low speed

clutch due to throttle valve 7 in shift operation system.

Going forward gear signal

Figure 7. Clutch pressure from first speed to second speed

Figure 6. Clutch pressure from neutral gear to first speed

Fig. 7 is shown that hydraulic cylinder oil pressure

curves of low speed clutch, high speed brake and low

gear brake when the first gear up to the second gear. The

curves show that low speed clutch begins to separate, at

the same time high speed brake begins to joint and low

gear brake is always in the joint state when the signal up

to the second gear is given at 10 seconds until the end of

shifting process at 10.26s. This process is divided into

two stages, the first stage is low gear torque phase, which

the system is still running at low gear with the oil

pressure of low speed clutch decreased but still jointed,

however, the oil pressure of high speed brake has began

to rise, slip and transfer torque. The second stage is high

gear inertia phase that has been completed shifting with

low speed clutch into complete separation state and high

gear brake from slipping into fully jointed [19]. Torque

phase and the inertia phase indicate that there exist power

overlap phenomenon during the process of shifting, while

it avoids galloping caused by power interruption, but

too much overlap may cause clutch is not completely

separated then appears double shifts to cause dramatic

2013 ACADEMY PUBLISHER

Figure 8. Clutch pressure from second speed to third speed

Figure 9. Clutch pressure from third speed to fourth speed

Fig. 9 is shown that hydraulic cylinder oil pressure

curves of low speed clutch, high speed brake and middle

gear brake when the third gear up to the fourth gear.

Fig.10 is shown that hydraulic cylinder oil pressure

curves of low speed clutch, high speed brake, middle gear

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

brake and high gear clutch when the fourth gear up to the

fifth gear. Fig. 11 is shown that hydraulic cylinder oil

pressure curves of low speed clutch, high speed brake and

high gear clutch when the fifth gear up to the sixth gear.

The oil pressure changing principle of each clutch, brake

is same, so it will not do a detailed explanation.

2953

clutch begins to fill oil. Fig.14 is shown that hydraulic

cylinder oil pressure curves of low speed clutch, high

speed clutch, middle gear brake and high gear brake

when fifth gear reduced to fourth gear. The curves

indicate that when given the signal of fifth gear down to

fourth gear at 10 seconds, high gear clutch and low speed

clutch begin to drain oil, while middle gear brake and

high speed brake begin to fill oil. Also because of the

effect of throttle 7, oil pressure of middle gear brake rises

behind high speed brake.

Figure 10. Clutch pressure from fourth speed to fifth speed

Figure 13. Clutch pressure from sixth speed to fifth speed

Figure 11. Clutch pressure from fifth speed to sixth speed

Figure 14. Clutch pressure from fifth speed to fourth speed

Figure 12. Downing forward gear signal

B. Analysis of Forward Downshifts Simulation Results

Equations

Fig. 12 is given the signal from sixth gear down to first

gear sequentially then to the neutral gear. Fig.13 is shown

that hydraulic cylinder oil pressure curves of low speed

clutch, high speed brake and high gear brake when the

sixth gear down to fifth gear. The curves indicate that

high speed brake is jointed earlier than high gear clutch

also because of the effect of throttle 7 when given the

sixth gear signal at 0 seconds in order to ensure direction

control element jointed earlier and speed control element

jointed later. After downshifts signal is given at 5 seconds,

high gear clutch keeps working condition unchanged,

while high speed brake begins to drain oil and low speed

2013 ACADEMY PUBLISHER

Figure 15. Clutch pressure from fourth speed to third speed

Fig. 15 is shown that hydraulic cylinder oil pressure

curves of low speed clutch, high speed brake and middle

gear brake when the fourth gear down to third gear. Fig.

16 is shown that hydraulic cylinder oil pressure curves of

low speed clutch, high speed brake, high gear brake and

low gear brake when the third gear down to second gear.

Fig. 17 is shown that hydraulic cylinder oil pressure

curves of low speed clutch, high speed brake and low

gear brake when the second gear down to first gear.

Fig.18 is shown that hydraulic cylinder oil pressure

curves of low speed clutch and low gear brake when the

2954

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

first gear down to neutral gear. From the figures it can be

seen oil pressure changing of each clutch conforms to

shifting logic. This method accurately reflects the shifting

process of hydraulic control system for the design and

optimization of the hydraulic system providing a strong

basis.

characteristic curves of each actuator based on simulation

results, so that the combination and separation of actuator

is more convenient and reliable, which ensures that the

vehicle can achieve fast and accurate shift operation

during the starting process, and which indicates that the

design of the shift operation system has good starting

performance.

Figure 16. Clutch pressure from third speed to second speed

Figure 19. Reverse gear signal

Figure 17. Clutch pressure from second speed to first speed

Figure 20. Oil pressure change from neutral gear to reverse gear then to

neutral gear

IV.

Figure 18. Clutch pressure from first speed to neutral gear

C. Analysis of Reverse Gear Simulation Results

Given signal of neutral gear-reverse gear-neutral gear

shown in Figure 19, in this signal hydraulic cylinder oil

pressure curves of low speed clutch and reverse gear

brake are shown in Figure 20. It can be seen after given

reverse gear signal at 5 seconds, oil pressure of low speed

clutch decreased, while oil pressure of reverse gear brake

is rising. After both reaching about 6bar, two actuators oil

pressure together rise smoothly under the action of

stationary combination valve, until two actuators are fully

engaged. Reverse gear brake rapidly separates and low

speed clutch remains jointed state when given the signal

of reverse gear back to neutral gear at 10 seconds. There

does not exist overlap phenomenon in the hydraulic

2013 ACADEMY PUBLISHER

CONCLUSIONS

(1) Shift operation system of some heavy-duty

hydrodynamic mechanical automatic transmission is

designed and its working principle is explained, while a

simplified mathematical model of the system is

established, then analyzing the dynamic characteristics.

The results show that the designed operation system is

reasonable.

(2) Simulation model of shift operation system is

established based on AMEsim software platform. The

simulation results show that shift timing of shift operation

system is correct, meets the design requirements, and

joint oil pressure is stable during shifting process so that

shifting is stable, while avoiding power interruption or

double shifts. The established simulation platform

provides a reasonable solution for study of shift schedule

and shift quality.

(3) In this paper, the method to establish dynamic

simulation model can be used by changing one or more

parameters to change the dynamic characteristics of

hydraulic system, which saves a lot of manpower,

resources and time. This model can provide the basis for

the design and optimization of automatic transmission

hydraulic system.

JOURNAL OF NETWORKS, VOL. 8, NO. 12, DECEMBER 2013

2955

REFERENCES

[1] Bo Liang, Yuren Li, and Rensuo Li, Research on

Simulation of Aircraft Electro-Hydrostatic Actuator(EHA)

Anti-Skid Braking System, JOURNAL OF COMPUTERS,

vol. 6, no. 12, pp. 26682674, December 2011.

[2] Fachao Jiang, Molin Wang, and Lin Li, Software Design

of Engine Characteristic Simulation, JOURNAL OF

SOFTWARE, vol. 7, no. 2, pp. 316321, February 2012.

[3] Jian Wu, Zhiming Cui, Jianming Chen, and Guangming

Zhang, A Survey on Video-based Vehicle Behavior

Analysis Algorithms, JOURNAL OF MULTIMEDIA, vol.

7, no. 3, pp. 223230, June 2012.

[4] Hao Yang, Qingmin Meng, Xiong Gu, and Baoyu Zheng,

Image-based Position Estimation and Adaptive

Modulation Coding in Vehicular Communication,

JOURNAL OF NETWORKS, vol. 6, no. 12, pp. 17541759,

December 2011.

[5] Zhenkun Dai, Xiangyang Xu, Yanfang Liu, and Shuhan

Wang, Closed-loop Slip Control of Clutches in Hydraulic

Automatic Transmission, Automotive Engineering, vol. 34,

no. 8, pp. 718722, 2012.

[6] Jinyue Tian, Vehicle automatice transmission structure

principle and design method, Peking University Press,

2009.

[7] Hiroshi Tsutsui, Takayuki Hisano, Akitomo Suzuki,

Makoto Hijikata, and Masatoshi Taguchi, ElectroHydraulic Control System for AISIN AWNew 6-Speed

Automatic Transmission, Society of Automotive

Engineers, 2004-01-1638.

[8] Shuhan Wang, Xiangyang Xu, Yanfang Liu, and Peter

Tenberge, Design and dynamic simulation of hydraulic

system for AT, Journal of Beijing University of

Aeronautics and Astronautics, vol. 35, no. 7, pp. 860864,

2009.

[9] Juan Wang, Huiyan Chen, Gang Tao, and Peng Gong,

Research on Shift Quality of Automatic Transmission,

Transctions of the Chinese Society for Agricultural

Machinery, vol. 39, no. 2, pp. 3842, 2008.

[10] Bingli Zhang, Mingwei Ji, and Youhuang Zhang,

Research on the Shift Quality of Automatic Transmission

Vehicles, China Journal of Highway and Transport, vol.

25, no. 3, pp. 141146, May 2012.

[11] Fei Meng, Gang Tao, and Huiyan Chen, A Study on the

Dynamic Response Characteristics of Electro-hydraulic

Proportional Valve for the Shift of Automatic

Transmission, Automotive Engineering, vol. 35, no. 3, pp.

229233, 2013.

[12] Hyoun-Woo Lee, Baek-Hyun Cho, Won-Hi Lee, A Study

on Response Improvement of Proportional Control

Solenoid Valve for Automatic Transmission, Seoul 2000

2013 ACADEMY PUBLISHER

[13]

[14]

[15]

[16]

[17]

[18]

[19]

FISITA World Automotive Congress (FISITA 2000), pp.

463-468, 2000.

Yanying Wang, Kraska M., Ortmann W., Dynamic

modeling of a variable force solenoid and a clutch for

hydraulic control in vehicle transmission system,

American Control Conference, pp. 1789-1793, 2001.

Osh ima K, K imu raH, M iyataH, et al, Control system

development with large flow small linear solenoid for the

new Toyota 6-speed transaxle, Transmission and Drive

line of SAE, 2006-01-1478.

Jack S.P. Liu and Paul W. Erlandson, A Nonlinear

Transient CAE Method for Vehicle Shift Quality

Prediction, Society of Automotive Engineers, 2006-011640.

Yong Chen, New Development and Trend of Automatic

Transmission Technologies, Automotive Engineering, vol.

30, no. 10, pp. 938945, 2008.

Zongyi Huang and Xinghua Li, Engineering machinery

hydraulic transmission (sixth speak) Electro-hydraulic

control of transmission (2), Construction Machinery and

Equipment, vol. 38, no. 6, pp. 7073, 2007.

Lidui Dong, Simulation Analysis of ZL50 Transmission

Shift Change Hydraulic System, Jilin University, 2009.

Xinghua Li, Wei Ye, and Zongyi Huang, Dynamic

Analysis of Automatic Transmission during Shifting,

Journal Of Tongji University, vol. 31, no. 5, pp. 576580,

May 2003.

Yan Zhang was born in Harbin, Heilongjiang province, China,

May 1987, and received her BS degree in Mechanical design

manufacturing and automation from Northeast Dianli University

of China in June 2006. She is now pursuing the Ph.D degree at

Institute of Mechanical Science and Engineering, Jilin

University, China. Her research interests include computer

simulation and automatic transmission.

Wenxing Ma was born in Lishu, Jilin province, China, Aug

1962. He received his BS degree in 1983, Master degree in

1986 and Ph.D. degree in 1991, in mechanical engineering from

Jilin University of Technology, Changchun, China. He is a

Professor in the College of Mechanical Science and Engineering

at Jilin University, Changchun, Jilin, China. His research

interests and publications have been focused on hydraulic

transmission and automatic transmission, mechanical

engineering and intelligent control.

Xuesong Li was born in 1978. Now she is a in the station

postdoctoral and a lecturer. Her research direction is hydraulic

transmission and automatic transmission theory.

Vous aimerez peut-être aussi

- Control of DC Motor Using Different Control StrategiesD'EverandControl of DC Motor Using Different Control StrategiesPas encore d'évaluation

- Control of Gear Shifts in Dual Clutch Transmission PowertrainsDocument14 pagesControl of Gear Shifts in Dual Clutch Transmission PowertrainsOday AliPas encore d'évaluation

- DC Motor Position Control EMDAP CVTDocument11 pagesDC Motor Position Control EMDAP CVTzulfikarzaidPas encore d'évaluation

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorD'EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorPas encore d'évaluation

- Actuators: Position Control of Pneumatic Actuators Using Three-Mode Discrete-Valued Model Predictive ControlDocument15 pagesActuators: Position Control of Pneumatic Actuators Using Three-Mode Discrete-Valued Model Predictive Controlsakthiya ramPas encore d'évaluation

- Modelling of An Automated Manual Transmission SystemDocument19 pagesModelling of An Automated Manual Transmission SystemJEFFERSSON DAVID BASTIDAS GAONAPas encore d'évaluation

- Multi-Functional Loader Steering Hydraulic System Model Construction and Simulation Based On Power Bond GraphsDocument7 pagesMulti-Functional Loader Steering Hydraulic System Model Construction and Simulation Based On Power Bond GraphsDeniezRamadhanPas encore d'évaluation

- A Control-Oriented Linear Parameter-Varying Model of A Commercial Vehicle Air Brake SystemDocument20 pagesA Control-Oriented Linear Parameter-Varying Model of A Commercial Vehicle Air Brake SystemkomklavePas encore d'évaluation

- Effect of Bulk Modulus On Performance of A HydrostDocument15 pagesEffect of Bulk Modulus On Performance of A HydrostEVCYPas encore d'évaluation

- Modeling Torque ConvDocument11 pagesModeling Torque ConvDiego HidalgoPas encore d'évaluation

- 68 - Numerical Modeling of Hydraulic Power Steering SystemDocument6 pages68 - Numerical Modeling of Hydraulic Power Steering SystemGalal RabiePas encore d'évaluation

- Jjmie: Performance Analysis and Behaviour Characteristics of CVD (Semi Active) in Quarter Car ModelDocument5 pagesJjmie: Performance Analysis and Behaviour Characteristics of CVD (Semi Active) in Quarter Car ModelGaby GhiuzanPas encore d'évaluation

- Shift Dynamics and Control of Dual-Clutch Transmissions: Mechanism and Machine TheoryDocument15 pagesShift Dynamics and Control of Dual-Clutch Transmissions: Mechanism and Machine Theorydarshan911Pas encore d'évaluation

- Jesr20101604v16s01a0004 PDFDocument8 pagesJesr20101604v16s01a0004 PDFNedim BabicPas encore d'évaluation

- Imaaca2013 44Document8 pagesImaaca2013 44mohammad ghaderzadehPas encore d'évaluation

- Speed Control of DC Motor Using Sliding Mode Control ApproachDocument5 pagesSpeed Control of DC Motor Using Sliding Mode Control ApproachIOSRjournalPas encore d'évaluation

- Mechanical Systems and Signal Processing: Fei Meng, Peng Shi, Hamid Reza Karimi, Hui ZhangDocument13 pagesMechanical Systems and Signal Processing: Fei Meng, Peng Shi, Hamid Reza Karimi, Hui ZhangWilber Pari ReyesPas encore d'évaluation

- Challenges and Opportunities in Automotive Transmission ControlDocument6 pagesChallenges and Opportunities in Automotive Transmission ControlArnabGhoshPas encore d'évaluation

- Sliding ModeDocument13 pagesSliding ModeSiva Ganesh MallaPas encore d'évaluation

- Modeling and Parameter Identification For Active Lubricated Hydrostatic Bearing-Rotor SystemDocument11 pagesModeling and Parameter Identification For Active Lubricated Hydrostatic Bearing-Rotor SystemhacenePas encore d'évaluation

- Modeling and Optimal Shift Control of A Planetary Two-Speed TransmissionDocument16 pagesModeling and Optimal Shift Control of A Planetary Two-Speed TransmissionEduardo DelfinoPas encore d'évaluation

- Research Paper 5Document1 pageResearch Paper 5abrakadabra2401Pas encore d'évaluation

- 2011control Strategy of Disc Braking Systems For Downward Belt ConveyorsDocument4 pages2011control Strategy of Disc Braking Systems For Downward Belt ConveyorsSanjiv Kumar SinghPas encore d'évaluation

- Final SynopsisDocument9 pagesFinal SynopsisUttkarsh ShelarPas encore d'évaluation

- Research Paper 4Document1 pageResearch Paper 4abrakadabra2401Pas encore d'évaluation

- Torque EstimationDocument19 pagesTorque EstimationOmnaath GupthaPas encore d'évaluation

- Control Optimo de EngranesDocument20 pagesControl Optimo de EngranesJosé Alberto PadillaPas encore d'évaluation

- Application of Adaptive Controlnext Term To The Fluctuation of Engine Speed at IdleDocument15 pagesApplication of Adaptive Controlnext Term To The Fluctuation of Engine Speed at IdleIkhwanul KhairiPas encore d'évaluation

- Actuators: Motion Characteristics of A Clutch Actuator For Heavy-Duty Vehicles With Automated Mechanical TransmissionDocument25 pagesActuators: Motion Characteristics of A Clutch Actuator For Heavy-Duty Vehicles With Automated Mechanical TransmissionNgọc ĐạiPas encore d'évaluation

- Pushbelt CVT Efficiency Improvement Potential of Servo-Electromechanical Actuation and Slip ControlDocument7 pagesPushbelt CVT Efficiency Improvement Potential of Servo-Electromechanical Actuation and Slip ControlSoumya PrasadPas encore d'évaluation

- Abec - Steer by Wire PDFDocument4 pagesAbec - Steer by Wire PDFKatherine DukePas encore d'évaluation

- Advanced Design For Crankshafts and Sliding Bearings in Reciprocating EnginesDocument9 pagesAdvanced Design For Crankshafts and Sliding Bearings in Reciprocating EnginessajeedshaikPas encore d'évaluation

- Modelling and Simulation of DC-Motor Electric Drive Control System With Variable Moment of InertiaDocument6 pagesModelling and Simulation of DC-Motor Electric Drive Control System With Variable Moment of InertiaIDESPas encore d'évaluation

- Sliding Mode Control of Induction Motor ThesisDocument6 pagesSliding Mode Control of Induction Motor Thesiss0kuzej0byn2100% (2)

- CONAT 2010 Tamba AndreiDocument8 pagesCONAT 2010 Tamba AndreiAdelin SimtinicaPas encore d'évaluation

- Adaptive IM ControlDocument16 pagesAdaptive IM ControlAli AltahirPas encore d'évaluation

- Working of Gear TransmissionDocument6 pagesWorking of Gear TransmissionTechmate TechnologiesPas encore d'évaluation

- Simulated and Experimental Study of Hydraulic Anti-Lock Braking System Using Sliding-Mode PWM ControlDocument21 pagesSimulated and Experimental Study of Hydraulic Anti-Lock Braking System Using Sliding-Mode PWM ControlLêĐạiHiệpPas encore d'évaluation

- Engine Torque Ripple Cancellation With An Integrated Starter Alternator in A Hybrid Electric Vehicle: Implementation and ControlDocument6 pagesEngine Torque Ripple Cancellation With An Integrated Starter Alternator in A Hybrid Electric Vehicle: Implementation and Controlstefanovicana1Pas encore d'évaluation

- Speed Regulation of Induction Motor Using Sliding Mode Control SchemeDocument5 pagesSpeed Regulation of Induction Motor Using Sliding Mode Control SchemeranaateeqPas encore d'évaluation

- Design of Single Acting Pulley Actuator (SAPA) Continuously Variable Transmission (CVT)Document9 pagesDesign of Single Acting Pulley Actuator (SAPA) Continuously Variable Transmission (CVT)Benjamin F ZavalaPas encore d'évaluation

- Matrix AdvantagesDocument14 pagesMatrix AdvantagesAdeline WinsterPas encore d'évaluation

- Electro HydraulicDocument20 pagesElectro HydraulicAnkit KumarPas encore d'évaluation

- PD Fuzzy Ratio Control EMDAP CVTDocument7 pagesPD Fuzzy Ratio Control EMDAP CVTzulfikarzaidPas encore d'évaluation

- Transient Characteristics of A Hydraulically Interconnected Suspension System PDFDocument12 pagesTransient Characteristics of A Hydraulically Interconnected Suspension System PDFmanteghPas encore d'évaluation

- PMSM Position ControlDocument29 pagesPMSM Position ControlMounir YasniPas encore d'évaluation

- Simulation of Vehicle Working Conditions With Hydrostatic Pump and Motor Control AlgorithmDocument7 pagesSimulation of Vehicle Working Conditions With Hydrostatic Pump and Motor Control Algorithm113BOAPas encore d'évaluation

- 10 18038-Aubtda 340798-351378Document11 pages10 18038-Aubtda 340798-351378ayesha siddiqaPas encore d'évaluation

- Study of Automatic Transmission Based On Electronic Control SystemDocument10 pagesStudy of Automatic Transmission Based On Electronic Control SystemHusseenPas encore d'évaluation

- Ijcs 35 2 05Document9 pagesIjcs 35 2 05Ari NugrohoPas encore d'évaluation

- Cylinder Pressure and Combustion Heat Release Estimation Using Nonlinear Sliding ObserversDocument9 pagesCylinder Pressure and Combustion Heat Release Estimation Using Nonlinear Sliding Observerskumar_yogesh223881Pas encore d'évaluation

- Controller Design of A New Active Front Steering SystemDocument11 pagesController Design of A New Active Front Steering SystemENIC-AITCGPas encore d'évaluation

- 1637-Article Text-3036-1-10-20230929Document12 pages1637-Article Text-3036-1-10-20230929Freddy KurniawanPas encore d'évaluation

- Estimation of Gasoline-Engine Parameters Using Higher Order Sliding ModeDocument8 pagesEstimation of Gasoline-Engine Parameters Using Higher Order Sliding ModeenginehardwarePas encore d'évaluation

- Design and Analysis of Torque ConverterDocument32 pagesDesign and Analysis of Torque ConverterSaravanan SPas encore d'évaluation

- Electric Power Steering Simulation Analyze Based On Fuzzy PID Current Tracking ControlDocument8 pagesElectric Power Steering Simulation Analyze Based On Fuzzy PID Current Tracking ControlMspavan RaoPas encore d'évaluation

- 1 s2.0 S0888327017305654 MainDocument10 pages1 s2.0 S0888327017305654 MainchinnavenkateswarluPas encore d'évaluation

- Time Management Conference 2019Document28 pagesTime Management Conference 2019Matthew SmithPas encore d'évaluation

- 6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Document8 pages6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Matthew SmithPas encore d'évaluation

- C 20 MTT 1 2 SemDocument165 pagesC 20 MTT 1 2 SemMatthew SmithPas encore d'évaluation

- Maths 3 CompressedDocument208 pagesMaths 3 CompressedMatthew SmithPas encore d'évaluation

- C 20 MY 3 4 SemDocument80 pagesC 20 MY 3 4 SemMatthew SmithPas encore d'évaluation

- Basic Thermo 3Document65 pagesBasic Thermo 3Matthew SmithPas encore d'évaluation

- Study of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueDocument10 pagesStudy of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueMatthew SmithPas encore d'évaluation

- Combustion in Si EnginesDocument36 pagesCombustion in Si Enginesrgopi_83Pas encore d'évaluation

- BTD - QBDocument25 pagesBTD - QBMatthew SmithPas encore d'évaluation

- Front-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningDocument25 pagesFront-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningMatthew SmithPas encore d'évaluation

- MP 3Document69 pagesMP 3Matthew SmithPas encore d'évaluation

- Applied Thermodynamics Unit-Ic Engines Assaignment - 01: Bharath .A, Lecturer, Dsce, BangaloreDocument4 pagesApplied Thermodynamics Unit-Ic Engines Assaignment - 01: Bharath .A, Lecturer, Dsce, BangaloreMatthew Smith0% (1)

- Describe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesDocument3 pagesDescribe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesMatthew SmithPas encore d'évaluation

- Types of Chassis LayoutDocument8 pagesTypes of Chassis LayoutMatthew SmithPas encore d'évaluation

- 6 CNC PDFDocument42 pages6 CNC PDFOgnjenOklobdzijaPas encore d'évaluation

- Audi Engine Management SystemsDocument185 pagesAudi Engine Management SystemsHri Vitalion100% (12)

- Geh 6839Document50 pagesGeh 6839Ayoade Lanre BexPas encore d'évaluation

- Course Brochure 94Document2 pagesCourse Brochure 94Gopi BvPas encore d'évaluation

- Edwards Probe Heat DetectorDocument1 pageEdwards Probe Heat DetectoracforofficeusePas encore d'évaluation

- RC-300 System Update ProcedureDocument3 pagesRC-300 System Update Procedure_GodfatherPas encore d'évaluation

- 2324model Proposal Report 1Document21 pages2324model Proposal Report 1Han hoPas encore d'évaluation

- HE Readboard: D E C E 1Document5 pagesHE Readboard: D E C E 1Abdullah ShahidPas encore d'évaluation

- Unicorn 150Document2 pagesUnicorn 150Nirmal GorePas encore d'évaluation

- Factory Simulation Software System: Software Requirements Specification (SRS)Document24 pagesFactory Simulation Software System: Software Requirements Specification (SRS)Majety S LskshmiPas encore d'évaluation

- Ford Ranger Spare PartsDocument2 pagesFord Ranger Spare PartsNgila João AndréPas encore d'évaluation

- TSPC Logic A Circuit For All SeasonsDocument4 pagesTSPC Logic A Circuit For All SeasonsJaya Chandra ManchalaPas encore d'évaluation

- Install Manual BloombergDocument18 pagesInstall Manual BloombergHrishikesh GandhePas encore d'évaluation

- Oracle Application Express (APEX) Training Course OutlineDocument5 pagesOracle Application Express (APEX) Training Course OutlinevineetPas encore d'évaluation

- SmartHDM Brochure English A4Document6 pagesSmartHDM Brochure English A4dawitPas encore d'évaluation

- Matrix Pro PlusDocument7 pagesMatrix Pro PlussimonesongsPas encore d'évaluation

- Hall Ticket - CCC-Saurashtra University, RajkotDocument2 pagesHall Ticket - CCC-Saurashtra University, RajkotChirag radiyaPas encore d'évaluation

- AF 1 SixpackDocument20 pagesAF 1 SixpackJay ManPas encore d'évaluation

- MELC - EPP 5 Entrep ICT MELCDocument2 pagesMELC - EPP 5 Entrep ICT MELCChristian GranadaPas encore d'évaluation

- Bsbinm601 Copy 1Document13 pagesBsbinm601 Copy 1sayan goswami75% (4)

- Heriot Watt FeesDocument3 pagesHeriot Watt FeesAtkins GonesePas encore d'évaluation

- Nokia MorphDocument22 pagesNokia MorphSai Manoj K RPas encore d'évaluation

- 1MRK504051-UEN - AM RET670 IEC 1pBDocument430 pages1MRK504051-UEN - AM RET670 IEC 1pBJOSEPas encore d'évaluation

- Analysis of @darealbubu - Whotwi Graphical Twitter AnalysisDocument1 pageAnalysis of @darealbubu - Whotwi Graphical Twitter Analysisdeer muPas encore d'évaluation

- Elna User Manual Xpressive SoftwareDocument230 pagesElna User Manual Xpressive SoftwareRelu GarbanPas encore d'évaluation

- Communication Engineering 1Document11 pagesCommunication Engineering 1Azza24 Azize24Pas encore d'évaluation

- IS40/Triton System: Installation ManualDocument19 pagesIS40/Triton System: Installation ManualJITHESH KPas encore d'évaluation

- IT Skill Lab-2: Raj School of Management & SciencesDocument38 pagesIT Skill Lab-2: Raj School of Management & Sciencesindia cybercafePas encore d'évaluation

- UPS - Netpro Operation Manual 0k6 1k5 VaDocument13 pagesUPS - Netpro Operation Manual 0k6 1k5 VagoroonPas encore d'évaluation

- Cloud Pathology Demo TRXDocument3 pagesCloud Pathology Demo TRXshubham redlawarPas encore d'évaluation

- Program Evaluation Documents (Table 1 To 16)Document14 pagesProgram Evaluation Documents (Table 1 To 16)Cristina CarpioPas encore d'évaluation

- Phaser 5500 5550 SRVC Manual PDFDocument573 pagesPhaser 5500 5550 SRVC Manual PDFfmr_setdiPas encore d'évaluation

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionD'EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AD'EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&APas encore d'évaluation

- Bulk Material Handling: Practical Guidance for Mechanical EngineersD'EverandBulk Material Handling: Practical Guidance for Mechanical EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CD'EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CPas encore d'évaluation

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- The Laws of Thermodynamics: A Very Short IntroductionD'EverandThe Laws of Thermodynamics: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedD'EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedÉvaluation : 5 sur 5 étoiles5/5 (1)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)D'EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Évaluation : 4 sur 5 étoiles4/5 (12)

- Basic Digital Signal Processing: Butterworths Basic SeriesD'EverandBasic Digital Signal Processing: Butterworths Basic SeriesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsD'EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsPas encore d'évaluation

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataD'EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataPas encore d'évaluation

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseD'EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseÉvaluation : 4.5 sur 5 étoiles4.5/5 (51)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsD'EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongPas encore d'évaluation

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionD'EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionPas encore d'évaluation

- Safety Theory and Control Technology of High-Speed Train OperationD'EverandSafety Theory and Control Technology of High-Speed Train OperationÉvaluation : 5 sur 5 étoiles5/5 (2)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsD'EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (9)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeD'EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeÉvaluation : 4 sur 5 étoiles4/5 (9)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsD'EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsD'EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Mechanical Vibrations and Condition MonitoringD'EverandMechanical Vibrations and Condition MonitoringÉvaluation : 5 sur 5 étoiles5/5 (1)