Académique Documents

Professionnel Documents

Culture Documents

FT 3360501

Transféré par

Kartik DesaiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FT 3360501

Transféré par

Kartik DesaiDroits d'auteur :

Formats disponibles

Fertilizer Technology

Course Code: 3360501

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

COURSE TITLE: FERTILIZER TECHNOLOGY

(COURSE CODE: 3360501)

Diploma Programme in which this course is offered

Chemical Engineering

Semester in which offered

Sixth

1.

RATIONALE

Indian economy is dominated by agriculture sector. Synthetic fertilizers are must for

producing good crops. Hence it is needed to provide comprehensive and balanced

understanding of essential link between chemistry and the synthetic fertilizer industry. It is

therefore vital for chemical engineers to understand for each fertilizer product, its flow

diagram for Industry production. For this purpose chemical engineers should have skills for

arranging treatment, reaction and separation steps in a flow diagram for variety of fertilizers

including Nitrogenous fertilizers, Phosphatic fertilizer, Potash Fertilizer, Complex fertilizer

and Bio fertilizers is essential. Hence this course is designed to achieve this objective.

2.

COMPETENCY

The course content should be taught and curriculum should be implemented with the aim to

develop required skills in the students so that they are able to acquire the following

competencies:

Supervise the different stages in fertiliser production.

3.

COURSE OUTCOMES (COs)

The theory should be taught and practicals should be carried out in such a manner that

students are able to acquire different learning outcomes in cognitive, psychomotor and

affective domain:

i.

Use reactions and unit operations steps in manufacturing of various fertilizers

ii.

Characterize fertilizers on the basis of different properties.

iii.

Identify engineering problems in fertilizer manufacturing.

iv.

Handle the fertilizers.

v.

Select appropriate synthesis fertilizer.

4.

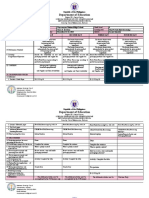

TEACHING AND EXAMINATION SCHEME

Teaching Scheme

(In Hours)

Total Credits

(L+T+P)

Examination Scheme

Theory

Marks

Practical Marks

ESE

PA

ESE

PA

06

70

30

20

30

Total Marks

150

Legends: L Lecture, T -Tutorial/Teacher Guided Student Activity, P Practical, C Credit, ESE - End

Semester Examination, PA -Progressive Assessment

GTU/NITTTR/Bhopal/14

Gujarat State

1

Fertilizer Technology

5.

Course Code: 3360501

COURSE CONTENT DETAILS

Major Learning Outcomes

Topics and Sub-topics

(In Cognitive Domain)

1a.

Justify

the need for synthetic

1.1 Synthetic fertilizers, Classification

Unit I

fertilizer

of fertilizers

Overview

1b. Categorize fertilizers

1.2 Role of essential Elements in plant

of

Growth,

Fertilizers 1c. Explain role of essential elements

for plant growth

1.3 Macro elements and Micro

elements

1d. Select the relevant fertilizers for

1.4 Application of fertilizers

the different types of crops

considering Nutrient

1.5 Balance and types of crop

Unit

2a. Describe different properties of

Unit II

Ammonia

Nitrogeneo

2b. Prepare synthesis path for

us

manufacturing synthesis gas

Fertilizers

2c. Differentiate various Ammonia

converter

2d. Differentiate various Ammonia

manufacturing process

2e. Describe the engineering

problems of ammonia

manufacturing

2f. Describe various properties of

Nitric Acid

2g. Estimate concentration of Nitric

acid

2h. Describe the problems in

manufacturing of Nitric Acid

2i. Describe various properties of

Urea

2j. Describe the major engineering

problems of Urea Manufacturing

2k. Describe the manufacturing

process of Ammonium Nitrate

GTU/NITTTR/Bhopal/14

2.1 Ammonia: Physical, chemical

properties and applications

2.2 Synthesis gas by Catalytic partial

oxidation Steam Hydrocarbon

reforming

2.3 Ammonia converters: Single bed

and multi-bed converter

2.4 Manufacturing of ammonia by

Linde Ammonia concept process

2.5 M. W. Kellogg process and Haldor

Topsoe process

2.6 Storage and Transportation of

Ammonia

2.7 Nitric acid: Chemical, physical

properties and applications

2.8 Manufacturing of Nitric Acid by

Pressure ammonia oxidation

process and Intermediate pressure

ammonia oxidation process

2.9 Concentration of Nitric acid by

Mg(NO3)2

2.10 Urea : Physical, chemical

properties

2.11 Manufacturing of Urea by

Stamicarbon's CO2 stripping

process, Montecatini Solution

recycle process Toyo-Koatsu total

recycle process

2.12 Manufacturing of Ammonium

nitrate by Prilling process,

Ammonium sulphate from

Ammonium carbonate and gypsum

Ammonium chloride from

Ammonium sulphate and sodium

chloride

Gujarat State

Fertilizer Technology

Unit

3a.

Unit III

Phosphatic

Fertilizer

3b.

3c.

3d.

Course Code: 3360501

Major Learning Outcomes

(In Cognitive Domain)

Describe various physical and

chemical properties Phosphorus

and Phosphoric acid

Describe the manufacturing

process of Phosphorus by Electric

furnace method

Describe the manufacturing

process of phosphoric acid by

Wet Process

Describe the manufacturing

Strong Sulphuric Acid Leaching

Hydrochloric Acid Leaching

Electric Furnace Process

4a. Describe physical and chemical

Unit IV

properties

Potassic

Fertilizers 4b. Explain manufacturing of

Potassium Chloride from

sylvinite

4c. Describe the of Preparation of

Potassium nitrate, Potassium

sulphate

Topics and Sub-topics

3.1 Physical, chemical properties and

applications of Phosphorus and

Phosphoric acid

3.2 Manufacturing of elemental

phosphorous by Electric furnace

method

3.3 Manufacturing phosphoric acid by

Wet Process

3.4 Strong Sulphuric Acid Leaching

Hydrochloric Acid Leaching

Electric Furnace Process

4.1 Physical, chemical properties and

uses of Potassium Chloride,

Potassium nitrate, Potassium

sulphate

4.2 Manufacturing of potassium

chloride from sylvinite

4.3 Preparation of Potassium nitrate,

Potassium sulphate

Unit V

Complex

Fertilizer

and Bio

Fertilizer

5a. Explain the manufacturing of

5.1 Manufacturing of NPK,

complex fertilizers with sketches

Ammonium Sulphate Phosphate

6a. Justify the need for biofertilizers

(ASP), Calcium Ammonium

and its benefits

Nitrate(CAN)

6b. Describe the Nitrogen fixing and 6.1 Types of Biofertilizers

Phosphate solubilising

6.2 Biofertilizers Nitrogen-fixing

biofertilizers

biofertilizers Phosphate6c. Explain preparation a

solubilizing biofertilizers

biofertilizers

6.3 Preparation of a biofertilizers

6.

SUGGESTED SPECIFICATION TABLE WITH HOURS & MARKS (Theory)

Unit

Teaching

Distribution of Theory

Unit Title

No.

Hours

Marks

R

U

A

Total

Level Level Level

Overview of Fertilizers

1

06

02

04

02

08

Nitrogeneous Fertilizers

2

22

06

09

06

21

Phosphatic Fertilizers

3

10

03

06

03

12

Potassic Fertilizers

4

06

03

05

03

11

Complex Fertilizers and Bio Fertilizers

5

12

06

06

06

18

TOTAL

56

20

30

20

70

Legends: R = Remember, U = Understand, A= Apply and above Level (Blooms revised

taxonomy)

GTU/NITTTR/Bhopal/14

Gujarat State

3

Fertilizer Technology

Course Code: 3360501

Note: This specification table shall be treated as a general guideline for students and teachers.

The actual distribution of marks in the question paper may vary slightly from above table.

7.

SUGGESTED PRACTICAL / EXERCISES

The practical/exercises should be properly designed and implemented with an attempt to develop

different types of skills (outcomes in psychomotor and affective domain) so that students are

able to acquire the competencies/programme outcomes. Following is the list of practical

exercises for guidance.

Note: Here only outcomes mainly in psychomotor domain are listed as practical/exercises.

However, if these practical/exercises are completed appropriately, they would also lead to

development of certain outcomes in affective domain which would in turn lead to development

of Course Outcomes related to affective domain. Thus over all development of Programme

Outcomes (as given in a common list at the beginning of curriculum document for this

programme) would be assured.

Faculty should refer to that common list and should ensure that students also acquire outcomes

in affective domain which are required for overall achievement of Programme

Outcomes/Course Outcomes.

S. Unit

No. No.

1

II

II

II

II

7

8

II

II

9

10

11

12

13

14

15

II

III

III

IV

IV

V

V

Practical/Exercise

(Outcomes in Psychomotor Domain)

Prepare chart for fertilizer classification with chemical formula and

nutrient content

Estimate nutrient content (% N, %P2O, % K2O) in different

fertilizers from their chemical formula

Estimate percentage of Nitrogen in Ammonium chloride by

substitution method

Estimate percentage of Nitrogen in Ammonium sulfate by

substitution method

Estimate percentage of Nitrogen in Ammonium chloride by back

titration

Estimate percentage of Nitrogen in Ammonium sulphate by back

titration

Analysis of Urea by Formaldehyde method

Estimate percentage of Nitrogen in Ammonium Chloride/Sulphate

by Kjeldhal's method

Estimate biuret content in Urea sample by colour comparison

Estimate percentage of Nitrogen in DAP by Formaldehyde method

Estimate percentage of Nitrogen in DAP by Kjeldhal's method

Prepare potassium sulphate

Prepare potasium chloride

Estimate ratio from Ammonia to Phosphoric acid in DAP

Prepare potassium nitrate

GTU/NITTTR/Bhopal/14

Approx.

Hours

Required

02

02

02

02

02

02

02

02

02

02

02

02

02

02

02

Gujarat State

Fertilizer Technology

S. Unit

No. No.

16

VI

Course Code: 3360501

Practical/Exercise

(Outcomes in Psychomotor Domain)

Prepare bio-fertilizer

Total

Approx.

Hours

Required

02

32

8.

SUGGESTED STUDENT ACTIVITIES

Following is the list of proposed student activities. These could be individual or group-based.

i. Prepare course/topic based presentations using internet

ii. Make a report on fertiliser plants in India/Gujarat with their capacity of production

and technology being used.

iii. Participate in MCQ/Quiz.

9.

i.

ii.

iii.

iv.

10.

SPECIAL INSTRUCTIONAL STRATEGY (IF ANY)

Show video/animation films about fertilizer production plants.

Arrange Visit to nearby fertilizer production plant

Arrange expert lectures

Arrange MCQ/Quiz arrange in normal term period.

SUGGESTED LEARNING RESOURCES

A)

Books

Title of Book

S. No.

1

Dryden's Outlines of

Chemical Technology,

2

Shreves Chemical Process

Industries, 5th edition

3

Chemical Technology

-Vol. I and II, 2nd edition

4

B)

i.

ii.

iii.

iv.

v.

vi.

Biofertilizers in Agriculture,

2nd edition

Author

M. Gopala Rao

Sitting Marshall

Austin G.T.

Pandey G.N. and

Shukla

N. S. Subba Rao

Publication

Affiliated East West Press

(Pvt) Ltd, 3rd Ed., New Delhi

McGraw Hill publication, New

Delhi

Vani Books Company

- Hyderabad

Oxford & IBH Publishing

Company, New Delhi 1988

Major Equipment / Instrument with Broad Specifications

Glassware: Conical flask, burette, pipette, RBF, measuring cylinder, beaker

Glass Assembly: RBF, reaction vessel, condenser, separating vessel

Burner

Weight balance (minimum 0.1gm)

Heating and cooling bath

Kjeldhal Assembly

C)

i.

ii.

iii.

iv.

v.

vi.

Software/Learning Websites

http://nptel.ac.in/courses/103107086/4

http://ijset.com/ijset/publication/v1s6/285-291%20IJSET_PK%20JAGA.pdf

www.gses.com/images/pressreleases/Manufacturing-Process-Fertilizer.pdf

http://nzic.org.nz/ChemProcesses/production/1A.pdf

http://tnau.ac.in/eagri/eagri50/SSAC222/lec12.pdf

www.fnca.mext.go.jp/bf/bfm/pdf/Biofertilizer_Manual.pdf

11.

COURSE CURRICULUM DEVELOPMENT COMMITTEE

GTU/NITTTR/Bhopal/14

Gujarat State

5

Fertilizer Technology

Course Code: 3360501

Faculty Members from Polytechnics

Prof. N. N. Hansalia, Lecturer in Chemical Engineering, Government

Rajkot

Prof. R. P. Hadiya, Lecturer in Chemical Engineering, Government

Rajkot

Prof.Rakesh R Vasava, Lecturer in Chemical Engineering, Shri K. J.

Bharuch

Prof. M. R. Aacharya, Lecturer in Chemical Engineering, Government

Gandhinagar

Polytechnic,

Polytechnic,

Polytechnic,

Polytechnic,

Coordinator andFaculty Members from NITTTR Bhopal

Dr. Abhilash Thakur. Associate Professor, Department of Applied Sciences

Dr. Joshua Earnest, Professor, Department of Electrical & Electronics Engineering.

GTU/NITTTR/Bhopal/14

Gujarat State

6

Vous aimerez peut-être aussi

- Fertilizer TechDocument3 pagesFertilizer TechNeel ShelatPas encore d'évaluation

- Fertilizer TechnologyDocument3 pagesFertilizer Technology2020001873.gcetPas encore d'évaluation

- Fertilizer TechnologyDocument6 pagesFertilizer TechnologySehjad khan BalochPas encore d'évaluation

- Microbial Sensing in FermentationD'EverandMicrobial Sensing in FermentationSatinder K. BrarPas encore d'évaluation

- CHE-0905554 Fertilizers Technology-Sep-2014-FallDocument4 pagesCHE-0905554 Fertilizers Technology-Sep-2014-FalllaminarsPas encore d'évaluation

- Jeevika DOCU 46Document199 pagesJeevika DOCU 46Anuj Kumar0% (1)

- Project Report at Cumene PDFDocument103 pagesProject Report at Cumene PDFDiv Savaliya100% (2)

- Semester-V: 2. CompetencyDocument8 pagesSemester-V: 2. CompetencyCliches inPas encore d'évaluation

- Food Processing By-Products and their UtilizationD'EverandFood Processing By-Products and their UtilizationAnil Kumar AnalPas encore d'évaluation

- 1601 - Indus Chem Lab ManualDocument46 pages1601 - Indus Chem Lab ManualChristy Joy Retanal100% (1)

- Principles and Applications of Fermentation TechnologyD'EverandPrinciples and Applications of Fermentation TechnologyArindam KuilaPas encore d'évaluation

- Bioethanol Production from Food Crops: Sustainable Sources, Interventions, and ChallengesD'EverandBioethanol Production from Food Crops: Sustainable Sources, Interventions, and ChallengesPas encore d'évaluation

- Lignocellulosic Biomass to Value-Added Products: Fundamental Strategies and Technological AdvancementsD'EverandLignocellulosic Biomass to Value-Added Products: Fundamental Strategies and Technological AdvancementsPas encore d'évaluation

- Biofuels: Alternative Feedstocks and Conversion ProcessesD'EverandBiofuels: Alternative Feedstocks and Conversion ProcessesÉvaluation : 3 sur 5 étoiles3/5 (1)

- Latest Edited 1 PDFDocument95 pagesLatest Edited 1 PDFDiv SavaliyaPas encore d'évaluation

- New Polymers for Encapsulation of Nutraceutical CompoundsD'EverandNew Polymers for Encapsulation of Nutraceutical CompoundsJorge Carlos Ruiz RuizPas encore d'évaluation

- Chemical Process TechnologyDocument9 pagesChemical Process TechnologyRITZCOOL FOR YOUPas encore d'évaluation

- Reactor Design For PetrochemicalDocument40 pagesReactor Design For Petrochemicalsinwei93Pas encore d'évaluation

- Biofuels and Bioenergy: Opportunities and ChallengesD'EverandBiofuels and Bioenergy: Opportunities and ChallengesBaskar GurunathanPas encore d'évaluation

- Advances in Physicochemical Properties of Biopolymers: Part 2D'EverandAdvances in Physicochemical Properties of Biopolymers: Part 2Pas encore d'évaluation

- 2017CHE003 FinalPaper Draft 8 1Document90 pages2017CHE003 FinalPaper Draft 8 1Evan DulayPas encore d'évaluation

- Emerging Areas in BioengineeringD'EverandEmerging Areas in BioengineeringHo Nam ChangPas encore d'évaluation

- Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food ProductionD'EverandPlant Factory: An Indoor Vertical Farming System for Efficient Quality Food ProductionÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Production of L-Glutamic Acid Using Submerged and Solid-State Fermentations by Utilizing Agro - Industrial WastesDocument15 pagesProduction of L-Glutamic Acid Using Submerged and Solid-State Fermentations by Utilizing Agro - Industrial WastesImmanuelrajPas encore d'évaluation

- SyllabusDocument6 pagesSyllabusAbhishek Gond100% (1)

- Isi Kandungan SinaDocument1 pageIsi Kandungan SinaMohd HafiezPas encore d'évaluation

- Production of 20 000 MTPD of Methyl Tertiary Butyl Ether From Methanol and Butylenes by Catalytic ConversionDocument177 pagesProduction of 20 000 MTPD of Methyl Tertiary Butyl Ether From Methanol and Butylenes by Catalytic ConversioniffatPas encore d'évaluation

- Dissertation OutlineDocument2 pagesDissertation OutlineweiwenPas encore d'évaluation

- Resume: Professional ObjectiveDocument3 pagesResume: Professional ObjectivepratikPas encore d'évaluation

- Sugar and Food Technology: Course Code: 3360505Document5 pagesSugar and Food Technology: Course Code: 3360505Nishit ShahPas encore d'évaluation

- Report On NFLDocument38 pagesReport On NFLanand DoliaPas encore d'évaluation

- Physiologically Based Pharmacokinetic Modeling: Science and ApplicationsD'EverandPhysiologically Based Pharmacokinetic Modeling: Science and ApplicationsPas encore d'évaluation

- Handbook of Composites from Renewable Materials, Nanocomposites: Science and FundamentalsD'EverandHandbook of Composites from Renewable Materials, Nanocomposites: Science and FundamentalsPas encore d'évaluation

- Handbook of Marine Macroalgae: Biotechnology and Applied PhycologyD'EverandHandbook of Marine Macroalgae: Biotechnology and Applied PhycologyÉvaluation : 1 sur 5 étoiles1/5 (1)

- Process Design Strategies for Biomass Conversion SystemsD'EverandProcess Design Strategies for Biomass Conversion SystemsPas encore d'évaluation

- Malathion 2013Document80 pagesMalathion 2013Arifin R HidayatPas encore d'évaluation

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerD'EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerPas encore d'évaluation

- Marine Algae Extracts: Processes, Products, and ApplicationsD'EverandMarine Algae Extracts: Processes, Products, and ApplicationsPas encore d'évaluation

- Advances in Dairy ProductsD'EverandAdvances in Dairy ProductsFrancesco ContoPas encore d'évaluation

- Cumene Project ReportsDocument42 pagesCumene Project ReportsDiv Savaliya100% (3)

- FPNB 19Document220 pagesFPNB 19Viktoria VonaPas encore d'évaluation

- D4.3 A Downstream Processing Protocol of Enzymes PurificationDocument6 pagesD4.3 A Downstream Processing Protocol of Enzymes PurificationUyen HuynhPas encore d'évaluation

- Intergrating Green Chemistry and Sustainable EngineeringD'EverandIntergrating Green Chemistry and Sustainable EngineeringPas encore d'évaluation

- Biotechnology of Microbial Enzymes: Production, Biocatalysis and Industrial ApplicationsD'EverandBiotechnology of Microbial Enzymes: Production, Biocatalysis and Industrial ApplicationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- 19ag423 - Bio-Energy System Design and ApplicationsDocument4 pages19ag423 - Bio-Energy System Design and Applicationsdevdixit1915Pas encore d'évaluation

- Microbial Services in Restoration EcologyD'EverandMicrobial Services in Restoration EcologyJay Shankar SinghPas encore d'évaluation

- 3360508Document5 pages3360508DivyamPas encore d'évaluation

- Ajeet Singh Iffco ReportDocument53 pagesAjeet Singh Iffco ReportNaveen DikshitPas encore d'évaluation

- Bioprocessing Technologies in Biorefinery for Sustainable Production of Fuels, Chemicals, and PolymersD'EverandBioprocessing Technologies in Biorefinery for Sustainable Production of Fuels, Chemicals, and PolymersPas encore d'évaluation

- Imidacloprid 08Document41 pagesImidacloprid 08kittyhawk88Pas encore d'évaluation

- Bioresource Technology: Sumit Kumar, Neerja Yadav, Lata Nain, Sunil Kumar KhareDocument4 pagesBioresource Technology: Sumit Kumar, Neerja Yadav, Lata Nain, Sunil Kumar KhareJosé BeltránPas encore d'évaluation

- Sugarcane-based Biofuels and BioproductsD'EverandSugarcane-based Biofuels and BioproductsIan O'HaraPas encore d'évaluation

- Fao Specifications and Evaluations For Agricultural PesticidesDocument44 pagesFao Specifications and Evaluations For Agricultural Pesticidesivanjose09Pas encore d'évaluation

- Microbial Pentose Utilization: Current Applications in BiotechnologyD'EverandMicrobial Pentose Utilization: Current Applications in BiotechnologyPas encore d'évaluation

- Ag Report UreaDocument40 pagesAg Report UreaVakul AgarwalPas encore d'évaluation

- Jivan Samruddhi June 2018Document1 pageJivan Samruddhi June 2018Kartik DesaiPas encore d'évaluation

- 3350503Document2 pages3350503Kartik Desai100% (1)

- GATE 2017 Admit Card: Instructions To The CandidateDocument1 pageGATE 2017 Admit Card: Instructions To The CandidateKartik DesaiPas encore d'évaluation

- Chapter 4 PDFDocument24 pagesChapter 4 PDFMd. Badrul IslamPas encore d'évaluation

- 2Document4 pages2Kartik DesaiPas encore d'évaluation

- Career GuidanceDocument65 pagesCareer GuidanceKartik DesaiPas encore d'évaluation

- A Manual On Wildlife Species in Trade: Manual On Medicinal Plants - Naresh KadyanDocument16 pagesA Manual On Wildlife Species in Trade: Manual On Medicinal Plants - Naresh KadyanNaresh KadyanPas encore d'évaluation

- Teacher & School DetailDocument1 pageTeacher & School DetailKartik DesaiPas encore d'évaluation

- Neem TreeDocument10 pagesNeem TreemandaremPas encore d'évaluation

- Chapter-2 Screen AnalysisDocument18 pagesChapter-2 Screen AnalysisKartik DesaiPas encore d'évaluation

- 3350501Document5 pages3350501Kartik DesaiPas encore d'évaluation

- Chapter 8 MixingDocument20 pagesChapter 8 MixingKartik DesaiPas encore d'évaluation

- PHT 3360507Document5 pagesPHT 3360507Kartik DesaiPas encore d'évaluation

- Enggquest 2012: N. G. Patel PolytechnicDocument1 pageEnggquest 2012: N. G. Patel PolytechnicKartik DesaiPas encore d'évaluation

- Chemical Technology-Mod3 PDFDocument83 pagesChemical Technology-Mod3 PDFSata AjjamPas encore d'évaluation

- Chapter-1 Intro & Properties of Particulate SolidsDocument11 pagesChapter-1 Intro & Properties of Particulate SolidsKartik DesaiPas encore d'évaluation

- DyesDocument65 pagesDyesKartik DesaiPas encore d'évaluation

- 8 Sci Worksheet 1agriculture 22-4-14Document2 pages8 Sci Worksheet 1agriculture 22-4-14Kartik DesaiPas encore d'évaluation

- Lyrics& ChordsDocument10 pagesLyrics& ChordsKartik DesaiPas encore d'évaluation

- Enggquest 2012: Who Is Popularly Known As 'Father of Indian Constitution'?Document15 pagesEnggquest 2012: Who Is Popularly Known As 'Father of Indian Constitution'?Kartik DesaiPas encore d'évaluation

- 5.2 Curriculam RelevanceDocument1 page5.2 Curriculam RelevanceKartik DesaiPas encore d'évaluation

- Flowsheet LabsDocument10 pagesFlowsheet LabsNisaMardiyahPas encore d'évaluation

- Petrochemicals FlowchartDocument1 pagePetrochemicals FlowchartKartik Desai50% (4)

- Science ExperimentsDocument97 pagesScience Experimentsemailstomelvin100% (5)

- Paranjay Practice of ComputerDocument2 pagesParanjay Practice of ComputerKartik DesaiPas encore d'évaluation

- Longman's Encyclopedia - ReptilesDocument40 pagesLongman's Encyclopedia - Reptilesrengachen100% (8)

- Feedback For SchoolDocument1 pageFeedback For SchoolKartik DesaiPas encore d'évaluation

- 02 Newton's Garden PDFDocument2 pages02 Newton's Garden PDFKartik DesaiPas encore d'évaluation

- 02 Newton's Garden PDFDocument2 pages02 Newton's Garden PDFKartik DesaiPas encore d'évaluation

- Socialisation Sheet RevisionDocument1 pageSocialisation Sheet Revisionapi-235423294Pas encore d'évaluation

- Fallarme Vs Sanjuan de DiosDocument14 pagesFallarme Vs Sanjuan de DiosCyber QuestPas encore d'évaluation

- Haarmann: Northwest Missouri State University (Northwest) Maryville, MissouriDocument2 pagesHaarmann: Northwest Missouri State University (Northwest) Maryville, MissouriabbyhaarmannPas encore d'évaluation

- The Lean Transformation RoadmapDocument22 pagesThe Lean Transformation Roadmapkfkms1Pas encore d'évaluation

- A. Patel, Resume 6.20Document2 pagesA. Patel, Resume 6.20Anika PatelPas encore d'évaluation

- DLL-Food Fish Processing 9-Q2-W6Document4 pagesDLL-Food Fish Processing 9-Q2-W6IlY-MyraTorresDeJesusPas encore d'évaluation

- Strategic ThinkingDocument23 pagesStrategic ThinkingJay Lewis100% (6)

- Reimagining Language Competence: On Professionalism: Ahmar Mahboob, University of SydneyDocument7 pagesReimagining Language Competence: On Professionalism: Ahmar Mahboob, University of SydneyNathalie RojasPas encore d'évaluation

- DEPED School FormsDocument30 pagesDEPED School FormsMayette ManigosPas encore d'évaluation

- Why Rural MattersDocument153 pagesWhy Rural MattersThe Washington PostPas encore d'évaluation

- Interrelation Between TEVT and General EducationDocument9 pagesInterrelation Between TEVT and General EducationLokuliyanaNPas encore d'évaluation

- PG Cert ELT and Professional Practice/ Delta Lesson Plan: Commented (A1) : Please Refer To The File Named Syllabus'Document8 pagesPG Cert ELT and Professional Practice/ Delta Lesson Plan: Commented (A1) : Please Refer To The File Named Syllabus'Nguyễn Hoài Anh ThưPas encore d'évaluation

- Editan Jan 2017 New-1Document128 pagesEditan Jan 2017 New-1arin0% (3)

- ArtcoBell Catalog SmallDocument36 pagesArtcoBell Catalog SmallseedrprimaryPas encore d'évaluation

- MlibDocument55 pagesMlibSamuel DavisPas encore d'évaluation

- Peace Corps Program and Training Assistant (PTA) Community Health (HE)Document1 pagePeace Corps Program and Training Assistant (PTA) Community Health (HE)Accessible Journal Media: Peace Corps DocumentsPas encore d'évaluation

- BRACU Scholarship PolicyDocument3 pagesBRACU Scholarship PolicyTanvirAritroPas encore d'évaluation

- HRM Lecture Notes For PUDocument36 pagesHRM Lecture Notes For PUVs SivaramanPas encore d'évaluation

- The Five-Dimensional Framework For Authentic Assessment: Educational Technology Research and Development September 2004Document22 pagesThe Five-Dimensional Framework For Authentic Assessment: Educational Technology Research and Development September 2004Midsy De la CruzPas encore d'évaluation

- RPASTDocument10 pagesRPASTJackylou SaludesPas encore d'évaluation

- Health Careers in Nunavut EnglishDocument12 pagesHealth Careers in Nunavut EnglishNunatsiaqNewsPas encore d'évaluation

- Countable - Uncountable, A, Some, Any, Much, Many, A Lot ofDocument2 pagesCountable - Uncountable, A, Some, Any, Much, Many, A Lot ofgrzincic7623Pas encore d'évaluation

- Exploring The Relationships Among Metalearning, Cognitive Holding Power and English Writing Skills of Pre-Service Teachers in EgyptDocument13 pagesExploring The Relationships Among Metalearning, Cognitive Holding Power and English Writing Skills of Pre-Service Teachers in EgyptIJ-ELTSPas encore d'évaluation

- Self - Apprisal FormatDocument6 pagesSelf - Apprisal Formatyogesh3663Pas encore d'évaluation

- HKICM PA Guidance Notes For CandidatesDocument7 pagesHKICM PA Guidance Notes For CandidatesJasmine TsoPas encore d'évaluation

- 2011 Peppler Nirvana Effect PDFDocument30 pages2011 Peppler Nirvana Effect PDFCarlos LuzPas encore d'évaluation

- DLL3 Math 7 Week 2Document3 pagesDLL3 Math 7 Week 2Angela Camille PaynantePas encore d'évaluation

- Physical Science SyllabusDocument3 pagesPhysical Science Syllabusapi-236865387Pas encore d'évaluation

- Dr. Wolf and The "Ancient Roots": Neoshamanism in SerbiaDocument20 pagesDr. Wolf and The "Ancient Roots": Neoshamanism in SerbiaNoel PutnikPas encore d'évaluation

- ENG 5 Q2 MODULE 1 Weeks 1 2 APPROVED FOR PRINTINGDocument24 pagesENG 5 Q2 MODULE 1 Weeks 1 2 APPROVED FOR PRINTINGMariel SalazarPas encore d'évaluation