Académique Documents

Professionnel Documents

Culture Documents

SAC305 Lead Free Electrolytic Wave Solder Product Bulletin: Metallic Resources, Inc

Transféré par

muki10Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SAC305 Lead Free Electrolytic Wave Solder Product Bulletin: Metallic Resources, Inc

Transféré par

muki10Droits d'auteur :

Formats disponibles

SAC305 Lead Free Electrolytic

Wave Solder Product Bulletin

Purity Improves Process

Metallic Resources SAC305 Lead-free solder alloy is manufactured from electrolytically

processed tin and other elements to create solder so pure it far exceeds the most common

specifications. It has been independently tested to meet all restrictions on hazardous substances. It is RoHS compliant. The specific

alloy is Sn96.5/Ag3.0/Cu0.5 (commonly

referred to as SAC305 alloy). The melt point

is 217C and recommended operating temperature ranges are between 250-260C.

Other variations on the tin/copper, tin/silver

and tin/silver/copper combination alloys are

also available, depending upon customer preference. Standard packaging includes 50

pound boxes containing cast bars, ingots, or

feeder bars.

When copper content approaches 1.0%,

Metallic Resources offers a replenishment

alloy, SAC305-R to lower the copper content

of the solder bath.

Versatile Uses

Metallic Resources high purity SAC305

electrolytic alloy has been specially formulated

and designed for use in all wave soldering and

tin and dip soldering applications. It is ideally suited for the assembly of printed circuit

boards utilizing existing or new equipment

found in the electronics market.

Benefits

Metallic Resources high purity SAC305 alloy is

manufactured using an electrolytic process, which

creates an alloy that is lower in viscosity, which

improves the fluidity. Greater fluidity improves

the alloys wetting capability for better throughhole fill, and reduces necessary re-work including

bridging, icicling, cobwebbing and flagging.

High purity electrolytic solder is environmentally

friendly, and generates less dross compared to

other "virgin grade" Lead-free alloys. Less dross

generation results in a greater number of joints

per pound of solder consumed and greater costeffectiveness through less waste due to solder loss.

Energy savings, extended pot life, reduced thermal stress, and reduced potential of contamination are all benefits derived from the electrolytic

manufacturing process.

The electrolytic manufacturing process assures

batch-to-batch consistency for predictable performance in the solder pot. The process removes

most metallic and non-metallic impurities often

found in "virgin metals" to provide a purer solder alloy. This purity results in a smaller crystalline structure which exhibits a shinier, more

brilliant solder appearance when compared to

other SAC305 alloys.

METALLIC RESOURCES, INC.

2116 Enterprise Parkway Twinsburg, Ohio 44087 Phone: 330.425.3155 Fax: 330.425.2180

Certified

Metallic Resources SAC305 bar solder alloy

exceeds the requirements of Specification IPC JSTD-006B. Certificates of Conformance and

Analysis are provided with each shipment.

Physical Properties

Melting Point (C)

217

3

7.4

Density (g/cm )

Operating temp. (C)

250-260

Tensile Strength (M Pa)

52

Elongation

27

Thermal Conductivity (J/ms K)

64

Electrical Resistance ( m)

0.15

Thermal Shock

-10 to +100C

>1000 cycles

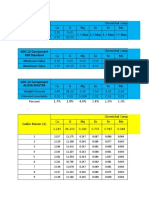

Alloy SAC305 (Sn96.5/Ag3.0/Cu0.5)

J-STD-006B

Sn

As

Sb

Au

Fe

Ni

Bi

Al

Cu

Ag

Zn

Cd

In

Pb

96.5000 (0.5)

0.0300

0.0500

0.0500

0.0200

0.0100

0.1000

0.0050

0.5000 (0.1)

3.0000 (0.2)

0.0030

0.0020

0.1000

0.1000

MRI Specs

96.3-96.8

0.0035 (max)

0.0250 (max)

0.0002 (max)

0.0050 (max)

0.0060 (max)

0.0100 (max)

0.0010 (max)

0.5000 (0.1)

3.0000 (0.2)

0.0010 (max)

0.0010 (max)

0.0100 (max)

0.0500 (max)

MRI Typical

Analysis

96.4600

0.0015

0.0150

0.0002

0.0030

0.0030

0.0040

0.0001

0.5000

3.0100

0.0005

0.0005

0.0050

0.0250

SAC305-0406

Recommendations made by this company and its representatives are based upon test data, experiments, and experience believed to be reliable. No guarantee

of accuracy is made, however. All products are sold upon the condition that the buyer will make his own tests and assume the responsibility for the suitability

of the product under his application and service conditions. Statements made herein will vary according to the nature of the surfaces to which the product

is applied, application technique, and service condition. We in no event assume liability beyound the purchase price of our products involved and make as a

condition of sale that we will refund the purchase price or replace materials proven to be defective and reported in a timely fashion, but no later than six (6)

months after shipment. No representative of the manufacturer and/or seller has the authority to alter or extend these conditions.

Vous aimerez peut-être aussi

- Alloy 625 Spec SheetDocument3 pagesAlloy 625 Spec SheetLinnie McleodPas encore d'évaluation

- Brass Material Property Data Sheet for Custom FastenersDocument2 pagesBrass Material Property Data Sheet for Custom FastenersMuzammil Ali KhanPas encore d'évaluation

- Technical Sheet Ag55Sn: The Above Data Are Subject To Change Without Notice by StellaDocument1 pageTechnical Sheet Ag55Sn: The Above Data Are Subject To Change Without Notice by StellaAntonis VentourisPas encore d'évaluation

- Data SAF2205 04Document8 pagesData SAF2205 04il_yoo_1Pas encore d'évaluation

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667Pas encore d'évaluation

- Sandvik SAF 2205: Duplex Stainless SteelDocument8 pagesSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciPas encore d'évaluation

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Document6 pagesDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanPas encore d'évaluation

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanPas encore d'évaluation

- Sac 305 Lead Free No CleanDocument2 pagesSac 305 Lead Free No CleanBenjamin HQPas encore d'évaluation

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerPas encore d'évaluation

- Case Study On The Validation of SAC305 and SnCu Based Solders in SMT Wave and Hand Soldering at The Contract Assembler LevelDocument8 pagesCase Study On The Validation of SAC305 and SnCu Based Solders in SMT Wave and Hand Soldering at The Contract Assembler LevelJoel JacoboPas encore d'évaluation

- Welding Stainless SteelDocument4 pagesWelding Stainless SteelJohan ZraghozPas encore d'évaluation

- Effectsof Metallic ImpuritiesDocument7 pagesEffectsof Metallic ImpuritiesJoel JacoboPas encore d'évaluation

- Oil & Gas Pipeline PDFDocument12 pagesOil & Gas Pipeline PDFrolandobtPas encore d'évaluation

- Duplex Stainless SteelsDocument25 pagesDuplex Stainless Steelspym1506gmail.comPas encore d'évaluation

- Technical Data Sheet: Stainless Steel: SuperausteniticDocument5 pagesTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicPas encore d'évaluation

- Joining Copper-Nickel Alloys GuideDocument9 pagesJoining Copper-Nickel Alloys GuidehboodhaiPas encore d'évaluation

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- Final Poster PPT of ERWDocument1 pageFinal Poster PPT of ERWMaksudur Rahman SumonPas encore d'évaluation

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraPas encore d'évaluation

- A Primer on Duplex Stainless SteelsDocument51 pagesA Primer on Duplex Stainless SteelsAnonymous GE8mQqxPas encore d'évaluation

- Bohler Subarc t85 - Uv 421 TT en 1Document1 pageBohler Subarc t85 - Uv 421 TT en 1Dragan JerčićPas encore d'évaluation

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031Pas encore d'évaluation

- SpringDocument4 pagesSpringarun123123Pas encore d'évaluation

- 380.1 PropiedadesDocument3 pages380.1 PropiedadesNini CortesPas encore d'évaluation

- Echnical ATA Heet: Lead-Free Bar SolderDocument2 pagesEchnical ATA Heet: Lead-Free Bar SolderEduardoPas encore d'évaluation

- 2205 InfoDocument6 pages2205 InfoMave75Pas encore d'évaluation

- High Strength Duplex Stainless Steel 2507 PropertiesDocument3 pagesHigh Strength Duplex Stainless Steel 2507 Propertiessudish mishraPas encore d'évaluation

- Norma Aws Er70s6Document2 pagesNorma Aws Er70s6Nathan CantelliPas encore d'évaluation

- Advances in Wear Resistant Alloys and ApplicationsDocument56 pagesAdvances in Wear Resistant Alloys and ApplicationsMilanWaPas encore d'évaluation

- URB25Document4 pagesURB25malika_00Pas encore d'évaluation

- 160210144213Document26 pages160210144213Abdul Wajid AliPas encore d'évaluation

- New A5Document7 pagesNew A5Yas kiPas encore d'évaluation

- Alloy304-304L-APR2013Document3 pagesAlloy304-304L-APR2013J A S JASPas encore d'évaluation

- RA151 28pgDocument31 pagesRA151 28pgpipedown456Pas encore d'évaluation

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezPas encore d'évaluation

- Data Sheet For BRASS SPECIFICATIONS PDFDocument5 pagesData Sheet For BRASS SPECIFICATIONS PDFvkmsPas encore d'évaluation

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradePas encore d'évaluation

- Ferritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesDocument4 pagesFerritic 9Cr1Mo Alloy Selected for PFBR Steam Generator TubesrkukgPas encore d'évaluation

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyPas encore d'évaluation

- Alloy 625 Wire & Rod: U.S. Alloy CoDocument1 pageAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraPas encore d'évaluation

- Esab DublexDocument8 pagesEsab DublexSuphi YükselPas encore d'évaluation

- ASM Material Data SheetDocument3 pagesASM Material Data SheetAscanio BarbosaPas encore d'évaluation

- Zinc CoatingsDocument16 pagesZinc CoatingsShojikuriakoseT100% (2)

- Avesta MA 253Document2 pagesAvesta MA 253Alif Nur FirdausPas encore d'évaluation

- Principal of DPTDocument5 pagesPrincipal of DPTJhandu KumarPas encore d'évaluation

- SS 302HQ, Type 302HQ, WNR 1.4567, UNS S30430, AISI 302HQ, Grade 302HQDocument3 pagesSS 302HQ, Type 302HQ, WNR 1.4567, UNS S30430, AISI 302HQ, Grade 302HQpierocarnelociPas encore d'évaluation

- ALPHA SACX PLUS 0307 Wave SolderDocument5 pagesALPHA SACX PLUS 0307 Wave SolderVimal Kumar VarmaPas encore d'évaluation

- Alloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelDocument2 pagesAlloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelManoj PaneriPas encore d'évaluation

- Cut FasterDocument5 pagesCut Fasterpipedown456Pas encore d'évaluation

- Arc Welding Cracks SolidificationDocument3 pagesArc Welding Cracks SolidificationShaher YarPas encore d'évaluation

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasPas encore d'évaluation

- Urea 25 22 2 20030603Document4 pagesUrea 25 22 2 20030603Ghulam AhmadPas encore d'évaluation

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkD'EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkPas encore d'évaluation

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsD'EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsPas encore d'évaluation

- Wear Mechanism of Exhaust ValveDocument8 pagesWear Mechanism of Exhaust Valvemuki10Pas encore d'évaluation

- Yogesh Aghav 2Document7 pagesYogesh Aghav 2pranjalbaruah8Pas encore d'évaluation

- Wear and Wear Mechanism Simulation of Heavy-Duty Engine Intake Valve and Seat InsertsDocument13 pagesWear and Wear Mechanism Simulation of Heavy-Duty Engine Intake Valve and Seat Insertsmuki10Pas encore d'évaluation

- Combating automotive engine valve recession through testing and modelingDocument4 pagesCombating automotive engine valve recession through testing and modelingmuki10100% (1)

- Technical Data Sheet: Persang Alloy Industries Pvt. LTDDocument2 pagesTechnical Data Sheet: Persang Alloy Industries Pvt. LTDmuki10Pas encore d'évaluation

- Engine Combustion Deposit PDFDocument16 pagesEngine Combustion Deposit PDFMomina AliPas encore d'évaluation

- Understanding Valve Design and AlloysDocument6 pagesUnderstanding Valve Design and Alloysmuki10Pas encore d'évaluation

- Thermal Shock Corrosion of Valve SteelsDocument13 pagesThermal Shock Corrosion of Valve Steelsmuki10Pas encore d'évaluation

- Transient Thermal Analysis of Engine Exhaust ValveDocument20 pagesTransient Thermal Analysis of Engine Exhaust Valvemuki10Pas encore d'évaluation

- Valve Face BurningDocument2 pagesValve Face BurningMomina AliPas encore d'évaluation

- 7-Failure Analysis of InternalDocument9 pages7-Failure Analysis of Internalrajeshsrajan1974Pas encore d'évaluation

- Wear Behaviour of Engine ValveDocument5 pagesWear Behaviour of Engine Valvemuki10Pas encore d'évaluation

- Lead-Free Comparison of AlloysDocument11 pagesLead-Free Comparison of Alloysmuki10Pas encore d'évaluation

- Effects of High Temperature On The Microstructure of Engine ValvesDocument5 pagesEffects of High Temperature On The Microstructure of Engine ValvesMomina AliPas encore d'évaluation

- Add To Study GuideDocument16 pagesAdd To Study Guidemuki10Pas encore d'évaluation

- Gas Lift Paper ResearchDocument15 pagesGas Lift Paper Researchmuki10Pas encore d'évaluation

- SAC ALLOY 305 MaterialDocument2 pagesSAC ALLOY 305 Materialmuki10Pas encore d'évaluation

- Nodal Analysis for Improving Gas Lift Wells ProductionDocument10 pagesNodal Analysis for Improving Gas Lift Wells ProductionSeth CheathamPas encore d'évaluation

- SAC ALLOY 305 MaterialDocument2 pagesSAC ALLOY 305 Materialmuki10Pas encore d'évaluation

- SAC 305 Bar Solder Data SheetDocument2 pagesSAC 305 Bar Solder Data Sheetmuki10Pas encore d'évaluation

- Wellbore Cleanout ReportDocument2 pagesWellbore Cleanout Reportmuki10Pas encore d'évaluation

- Ultrapure K100LD Bar SolderDocument2 pagesUltrapure K100LD Bar Soldermuki10Pas encore d'évaluation

- Reference LetterDocument2 pagesReference Lettermuki10Pas encore d'évaluation

- Gas Lift Paper 1Document12 pagesGas Lift Paper 1muki10Pas encore d'évaluation

- CNG Blasts Kill Two, Injure 10 in Peshawar, NowsheraDocument3 pagesCNG Blasts Kill Two, Injure 10 in Peshawar, Nowsheramuki10Pas encore d'évaluation

- ME4Document12 pagesME4muki10Pas encore d'évaluation

- Technical Data Sheet: Persang Alloy Industries Pvt. LTDDocument2 pagesTechnical Data Sheet: Persang Alloy Industries Pvt. LTDmuki10Pas encore d'évaluation

- Metal Foam Heat ExchangerDocument16 pagesMetal Foam Heat Exchangermuki10Pas encore d'évaluation

- Demister EfficiencyDocument9 pagesDemister EfficiencyHastelloy MonelPas encore d'évaluation

- Crouse Hinds Unf Unl Uny Unions El Elbows Catalog PageDocument4 pagesCrouse Hinds Unf Unl Uny Unions El Elbows Catalog PagewillytPas encore d'évaluation

- Manufacturing Process of Train Wheel and Automobile Wheel RimDocument14 pagesManufacturing Process of Train Wheel and Automobile Wheel RimUsamah Abdul Latif79% (14)

- Bare Overhead Transmission Conductors ": Selection and Application"Document23 pagesBare Overhead Transmission Conductors ": Selection and Application"Adnan KhanPas encore d'évaluation

- Bender Plans 2011Document15 pagesBender Plans 2011tehdevo100% (5)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- High Nitrogen Martensitic Steels A New Family of Martensitic Corrosion Resistant Steels For Improved Aerospace Bearing PerformanceDocument5 pagesHigh Nitrogen Martensitic Steels A New Family of Martensitic Corrosion Resistant Steels For Improved Aerospace Bearing PerformanceJim SmithPas encore d'évaluation

- BS en 15266-2007Document56 pagesBS en 15266-2007Rachid MounirPas encore d'évaluation

- Heap Construction and Solution ApplicationDocument17 pagesHeap Construction and Solution ApplicationChristy Alexandra Solano GavelánPas encore d'évaluation

- F1325 91 (2016)Document2 pagesF1325 91 (2016)masoudPas encore d'évaluation

- 4.3 ESAB Product Catalogue 2013Document301 pages4.3 ESAB Product Catalogue 2013SAIL ISP Blast FurnacePas encore d'évaluation

- Hardness Conversion Chart: ConversionsDocument1 pageHardness Conversion Chart: ConversionsQuốc Trí LêPas encore d'évaluation

- Excel - CCC - Soft Weld Metal - Gas ConsumptionDocument6 pagesExcel - CCC - Soft Weld Metal - Gas ConsumptionOctavian PanteaPas encore d'évaluation

- Effect of D.C. Polarity On SMAWDocument9 pagesEffect of D.C. Polarity On SMAWhp PCPas encore d'évaluation

- Một số lỗi về mạDocument11 pagesMột số lỗi về mạĐình Khoa PhanPas encore d'évaluation

- Q1, Module 1, Lesson 2Document10 pagesQ1, Module 1, Lesson 2Jerome A. GomezPas encore d'évaluation

- AISI 4130 alloy steel guideDocument2 pagesAISI 4130 alloy steel guideALEX MURPHYPas encore d'évaluation

- Centennial College: Milestone - 1 Project: - Hand Power SawDocument14 pagesCentennial College: Milestone - 1 Project: - Hand Power Sawanmol singhPas encore d'évaluation

- ADC12 Composition Check SheetDocument4 pagesADC12 Composition Check SheetevanPas encore d'évaluation

- MP Lab ReportDocument4 pagesMP Lab ReportAbdul RehmanPas encore d'évaluation

- Certified Reference Materials (CRM) : Csir-National Metallurgical Laboratory JAMSHEDPUR-831007, INDIADocument7 pagesCertified Reference Materials (CRM) : Csir-National Metallurgical Laboratory JAMSHEDPUR-831007, INDIASai dineshPas encore d'évaluation

- Total HBF 4Document1 pageTotal HBF 4htPas encore d'évaluation

- Forming and Shaping Processes and Equipment: Manufacturing Engineering Technology in SI Units, 6 EditionDocument35 pagesForming and Shaping Processes and Equipment: Manufacturing Engineering Technology in SI Units, 6 EditionRodger OlynPas encore d'évaluation

- Microestructura y Propiedades Mecánicas Del Acero AISI 1016 Calibrado Procesado Por ECAPDocument8 pagesMicroestructura y Propiedades Mecánicas Del Acero AISI 1016 Calibrado Procesado Por ECAPjorgeelr09Pas encore d'évaluation

- Acceptance Criteria For WelderDocument3 pagesAcceptance Criteria For WelderAkhtarcmti1342Pas encore d'évaluation

- Vrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH EkudDocument14 pagesVrir Y?Kqñr Dkczu Blikr DH PKNJ, Oa Iùkh: HKKJRH Ekudsunil kumar sharmaPas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilPas encore d'évaluation

- Questions and Answers on Welding Processes, Defects, and StandardsDocument12 pagesQuestions and Answers on Welding Processes, Defects, and StandardspremPas encore d'évaluation

- Chapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 14 EdDocument10 pagesChapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 14 EdINNOBUNo7Pas encore d'évaluation

- Carta Maestra de Soldadura y CortDocument7 pagesCarta Maestra de Soldadura y CortAlejandro Del Valle TovarPas encore d'évaluation

- Red 403 Red 503Document1 pageRed 403 Red 503mt1742k4Pas encore d'évaluation