Académique Documents

Professionnel Documents

Culture Documents

CH 05 Turbofan Cycle Cantwell

Transféré par

CrashCoolTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CH 05 Turbofan Cycle Cantwell

Transféré par

CrashCoolDroits d'auteur :

Formats disponibles

CHAPTER 5

THE TURBOFAN CYCLE

5.1

TURBOFAN THRUST

The figure below illustrates two generic turbofan engine designs.

Commercial Turbofan

reference

r

m a

fan

m a

core

diffuser

d

1.5

fan nozzle

1n

fan

1c

18

13

1e

burner

b

compressor

c

turbine

t

nozzle

n

m a

core

+ m f

2.5

4.5

m f

Military Turbofan

reference

r

diffuser

d

1.5

fan

1c

compressor

c

burner

b turbine

t

2.5

afterburner

a

nozzle

4.5

Figure 5.1 Engine numbering and component notation

The upper figure shows a modern high bypass ratio engine designed for long distance cruise at

subsonic Mach numbers around 0.83 typical of a commercial aircraft. The fan utilizes a single

stage composed of a large diameter fan (rotor) with wide chord blades followed by a single

bjc

5.1

1/4/10

Turbofan thrust

nozzle stage (stator). The bypass ratio is 5.8 and the fan pressure ratio is 1.9. The lower figure

shows a military turbofan designed for high performance at supersonic Mach numbers in the

range of 1.1 to 1.5. The fan on this engine has three stages with an overall pressure ratio of about

6 and a bypass ratio of only about 0.6. One of the goals of this chapter is to understand why

these engines look so different in terms the differences in flight condition for which they are

designed. In this context we will begin to appreciate that the thermodynamic and gasdynamic

analysis of these engines defines a continuum of cycles as a function of Mach number. We had

a glimpse of this when we determined that the maximum thrust turbojet is characterized by

!c

max thrust

!"

= --------- .

!r

(5.1)

For fixed turbine inlet temperature and altitude, as the Mach number increases the optimum

compression decreases and at some point it becomes desirable to convert the turbojet to a ramjet. We will see a similar kind of trend emerge for the turbofan where it replaces the turbojet as

the optimum cycle for lower Mach numbers. Superimposed on all this is a technology trend

where, with better materials and cooling schemes, the allowable turbine inlet temperature

increases. This tends to lead to an optimum cycle with higher compression and higher bypass

ratio at a given Mach number.

The thrust equation for the turbofan is similar to the usual relation except that it includes the

thrust produced by the fan.

T = m a ( U e U 0 ) + m a ( U 1e U 0 ) + m f U e + ( P e P 0 ) A e + ( P 1e P 0 ) A 1e (5.2)

core

fan

The total air mass flow is

m a = m a

+ m a .

core

fan

(5.3)

The fuel/air ratio is defined in terms of the total air mass flow.

m f

f = ------- .

m a

(5.4)

m a

fan

B = -----------------------------------m a + m a

(5.5)

m a

fan

# = --------------.

m a

(5.6)

The bypass fraction is defined as

fan

core

and the bypass ratio is

core

Note that

1/4/10

5.2

bjc

The ideal turbofan cycle

B

# = ------------1B

#

B = ------------- .

1+#

(5.7)

5.2 THE IDEAL TURBOFAN CYCLE

In the ideal cycle we will make the usual assumption of isentropic flow in the inlet, fan, compressor, turbine and fan and core nozzles as well as the assumption of low Mach number heat

addition in the burner. The fan and core nozzles are assumed to be fully expanded. The assumptions are

P 1e = P 0

$d = 1

$c =

%

-----------%1

!c

$b = 1

$ c1 =

Pe = P0

$n = 1

%

-----------%1

! c1

(5.8)

$ n1 = 1

(5.9)

%

-----------%1

!t

.

(5.10)

$t =

For a fully expanded exhaust the normalized thrust is

* Ue

+

* U 1e

+

0

1

T

------------- = M 0 . ( 1 B + f ) ( ------- 1) + B ( --------- 1) + f /

m a a 0

&U0

'

& U0

'

,

-

(5.11)

or, in terms of the bypass ratio with f 1

+

+1

0 1 * Ue

# * U 1e

T

------------- = M 0 . * -------------+ ( ------- 1) + * -------------+ ( --------- 1) / .

&

'

&

'

1 + # & U0

m a a 0

'

', 1 + # &U0

(5.12)

5.2.1

THE FAN BYPASS STREAM

First work out the velocity ratio for the fan stream

M 1e T 1e

U 1e

--------- = ---------- --------- .

M0 T 0

U0

(5.13)

The exit Mach number is determined from the stagnation pressure.

%1 2

P t1e = P 0 $ r $ c1 = P 1e * 1 + ------------ M 1e+

&

'

2

%

-----------%1

(5.14)

Since the nozzle is fully expanded and the fan is assumed to behave isentropically, we can write

%1 2

! r ! c1 = 1 + ------------ M 1e

2

bjc

5.3

(5.15)

1/4/10

The ideal turbofan cycle

therefore

2

M 1e

! r ! c1 1

---------- = ---------------------- .

2

!r 1

M0

(5.16)

The exit temperature is determined from the stagnation temperature.

%1 2

T te = T 0 ! r ! c1 = T 1e * 1 + ------------ M 1e+ .

&

'

2

(5.17)

Noting (5.15) we can conclude that for the ideal fan

T 1e = T 0 .

(5.18)

The exit static temperature is equal to the ambient static temperature. The velocity ratio of the

fan stream is

* U 1e+

( ---------)

& U0 '

5.2.2

! r ! c1 1

= ---------------------- .

!r 1

(5.19)

2

* M e+ T e

= ( --------) ------ .

& M 0' T 0

(5.20)

THE CORE STREAM

The velocity ratio across the core is

* U e+

( -------)

& U 0'

The analysis of the stagnation pressure and temperature is exactly the same as for the ideal

turbojet.

P te = P 0 $ r $ c $ t = P e * 1 +

&

%

-----------%

% 1 2+ 1

------------ M e

.

'

2

(5.21)

Since the nozzle is fully expanded and the compressor and turbine operate ideally the Mach

number ratio is

2

Me

* ! r ! c ! t 1+

-------- = ( ------------------------) .

2

& !r 1 '

M0

(5.22)

The temperature ratio is also determined in the same way in terms of component temperature

parameters

T te = T 0 ! r ! d ! c ! b ! t ! n .

1/4/10

5.4

(5.23)

bjc

The ideal turbofan cycle

In the ideal turbofan we assume that the diffuser and nozzle flows are adiabatic and so

%1 2

T te = T 0 ! r ! c ! b ! t = T e * 1 + ------------ M e+ = T e ! r ! c ! t

&

'

2

(5.24)

from which is determined

!"

Te

------ = ---------- .

T0

!r !c

(5.25)

* ! r ! c ! t 1+ ! "

= ( ------------------------) ---------- .

& !r 1 ' !r !c

(5.26)

The velocity ratio across the core is

* U e+

( -------)

& U 0'

5.2.3

TURBINE - COMPRESSOR - FAN MATCHING

The work taken out of the flow by the high and low pressure turbine is used to drive both the

compressor and the fan.

( m a

core

+ m f ) ( h t4 h t5 ) = m a ( h t3 h t2 ) + m a ( h t13 h t2 )

core

fan

(5.27)

Divide (5.27) by m a C p T 0 and rearrange. The work matching condition for a turbofan is

!r 0 1 B

1

B

! t = 1 ----- . ------------------------ ( ! c 1 ) + ------------------------ ( ! c1 1 ) / .

1B+ f

!" , 1 B + f

-

(5.28)

The approximation f 1 is generally a pretty good one for a turbofan. Using this approximation the work matching condition becomes

!r

! t = 1 ----- { ( ! c 1 ) + # ( ! c1 1 ) }

!"

(5.29)

where the bypass ratio # appears for the first time. If the bypass ratio goes to zero the matching

condition reduces to the usual turbojet formula.

5.2.4

FUEL/AIR RATIO

The fuel/air ratio is determined from the energy balance across the burner.

m f ( h f h t4 ) = m a ( h t4 h t3 ) .

core

(5.30)

Divide (5.30) by m a C p T 0 and rearrange. The result is

bjc

5.5

1/4/10

Maximum specific impulse ideal turbofan

1 !" !r !c

f = * -------------+ ---------------------- .

& 1 + #' ! !

f

"

(5.31)

5.3 MAXIMUM SPECIFIC IMPULSE IDEAL TURBOFAN

The specific impulse is

I sp g

g

T

1

T

---------- = * ----------+ * -----+ = * -------------+ * ---+ .

&

&

'

&

'

&

'

m a a 0 f '

m f g a 0

a0

(5.32)

Substitute (5.12) and (5.31) into (5.32). The result is

I sp g

* ! f !" + 0 * U e

+

* U 1e

+1

---------- = M 0 ( ----------------------) . ( ------- 1) + # ( --------- 1) / .

a0

& ! " ! r ! c' , & U 0

'

& U0

'-

(5.33)

The question is: what value of # maximizes the specific impulse? Differentiate (5.33) with

respect to # and note that # appears in (5.29). The result is

+

2 * I sp g+

2 * U e+ * U 1e

( ----------) =

( -------) + ( --------- 1) = 0 .

2 # & a0 '

2 # & U 0' & U 0

'

(5.34)

We can write (5.34) as

* 2+

+

1

2 ( U e ) * U 1e

--------------------------------- + ( --------- 1) = 0

2 ( U e U 0 ) 2 # ( U 2) & U 0

'

& 0'

(5.35)

* ! " + 2! t

* U 1e

+

1

--------------------------- ( --------------)

= ( --------- 1) .

2 ( U e U 0 ) & ! r 1' 2 #

& U0

'

(5.36)

* ! r ( ! c1 1 )+

* U 1e

+

1

--------------------------- ( ----------------------------) = ( --------- 1) .

2 ( U e U 0 ) & !r 1 '

& U0

'

(5.37)

or

This becomes

From (5.19),the expression in parentheses on the left side of (5.37) is

2

* * U 1e+

+

* U 1e

+

1

--------------------------- ( ( ---------) 1) = ( --------- 1) .

2(Ue U0) && U0 '

'

& U0

'

1/4/10

5.6

(5.38)

bjc

Maximum specific impulse ideal turbofan

Factor the left side of (5.38) and cancel common factors. The velocity condition for a maximum

impulse ideal turbofan is

* U 1e

+

* Ue

+

( --------- 1) = 2 ( ------- 1) .

& U0

'

&U0

'

(5.39)

According to this result for an ideal turbofan one would want to design the turbine such that the

velocity increment across the fan was twice that across the core in order to achieve maximum

specific impulse. Recall that U e U 0 depends on # through (5.29) (and weakly though (5.31)

which we neglect). The value of # that produces the condition (5.39) corresponding to the maximum impulse ideal turbofan is

1

# max impulse ideal turbofan = ----------------------

( ! c1 1 )

0

+

3 * !"

- 1) ( ! c 1 ) +

. ( --------'

3 & !r !c

,

!"

---------- ( ! r 1 )

2

!r !c

1.

12

+3

1 * ! r 1+ * * ! r ! c1 1+

--- ( --------------) ( ( ----------------------)

+ 1) /

4 & !r ' & & !r 1 '

'3

-

(5.40)

The figure below shows how the optimum bypass ratio (5.40) varies with flight Mach number

for a given set of engine parameters.

# max impulse ideal turbofan

20

! c = 2.51

17.5

! c1 = 1.2

15

! " = 8.4

12.5

10

7.5

5

2.5

1.5

2.5

3.5

4.5

!r

Figure 5.2 Ideal turbofan bypass ratio for maximum specific impulse as a function

of Mach number.

bjc

5.7

1/4/10

Turbofan thermal efficiency

It is clear from this figure that as the Mach number increases the optimum bypass ratio

decreases until a point is reached where one would like to get rid of the fan altogether and convert the engine to a turbojet. For the ideal cycle the turbojet limit occurs at an unrealistically

high Mach number of approximately 3.9. Non-ideal component behavior reduces this Mach

number considerably.

The next figure provides another cut on this issue. Here the optimum bypass ratio is plotted

versus the fan temperature (or pressure) ratio. Several curves are shown for increasing Mach

number.

# max impulse ideal turbofan

10

! r = 1.02

8

! " = 8.4

! r = 1.2

! c = 2.51

! r = 1.6

! r = 2.5

4

! r = 3.5

1.5

2.5

3.5

4.5

! c1

Figure 5.3 Ideal turbofan bypass ratio for maximum specific impulse as a function

of fan temperature ratio. Plot shown for several Mach numbers

It is clear that increasing the fan pressure ratio leads to an optimum at a lower bypass ratio. The

curves all seem to allow for optimum systems at very low fan pressure ratios and high bypass

ratios. This is an artifact of the assumptions underlying the ideal turbofan. As soon as non-ideal

effects are included the low fan pressure ratio solutions reduce to much lower bypass ratios. To

see this we will compute several non-ideal cases.

5.4 TURBOFAN THERMAL EFFICIENCY

Recall the definition of thermal efficiency from Chapter 2.

5 kinetic energy of air 5 kinetic energy of fuel

Power to the vehicle + ------------------------------------------------------- + --------------------------------------------------------second

second

4 th = --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------m f h f

1/4/10

5.8

(5.41)

bjc

Turbofan thermal efficiency

For a turbofan with a core and bypass stream the thermal efficiency is

2

4 th

2

2

m a

(Ue U0)

m a ( U 1e U 0 )

m f ( U e U 0 )

m f ( U 0 )

core

fan

T U 0 + ---------------------------------------------- + ---------------------------------------------- + ------------------------------------ ---------------------2

2

2

2

= ----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------m f h f

If both exhausts are fully expanded so that P e = P 0 ;

becomes

(5.42)

P 1e = P 0 the thermal efficiency

( m a

( U e U 0 ) + m a ( U 1e U 0 ) + m f U e )U 0

core

fan

4 th = -------------------------------------------------------------------------------------------------------------------------------- +

m f h f

2

2

2

m a

(Ue U0)

m a ( U 1e U 0 )

m f ( U e U 0 )

m f ( U 0 )

core

fan

---------------------------------------------- + ---------------------------------------------- + ------------------------------------ ---------------------2

2

2

2

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------m f h f

(5.43)

which reduces to

2

4 th

U

U 2 U 2

U 1e 2 U 0 2

* ------e- ------0- + + m ------e- + m

* --------m a

------- +

a

f 2

2 '

2 '

fan & 2

core & 2

= ----------------------------------------------------------------------------------------------------------------------------------m f h f

(5.44)

We can recast (5.44) in terms of enthalpies using the following relations

m f ( h f h t4 ) = m a ( h t4 h t3 )

core

2

Ue

h t5 = h e + ------2

(5.45)

U 1e

h t13 = h 1e + --------2

where the fan and core nozzle streams are assumed to be adiabatic. Now

[ m a

( ( h t 5 h e ) ( h t 0 h 0 ) ) + m a ( ( h t 13 h 1e ) ( h t 0 h 0 ) ) + m f ( h t 5 h e ) ]

core

fan

4 th = ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------( m f + m a

)h t 4 m a

ht 3

core

(5.46)

core

Rearrange (5.46) to read

bjc

5.9

1/4/10

Turbofan thermal efficiency

( m a

+ m f )h t 5 + m a h t 13 ( m a

+ m a )h t 0

core

fan

core

fan

4 th = ---------------------------------------------------------------------------------------------------------------------------------------

( m f + m a

)h t 4 m a

ht 3

core

core

(5.47)

( h e h 0 ) + m a ( h 1e h 0 ) + m f h e

m a

core

fan

-----------------------------------------------------------------------------------------------------------( m f + m a

)h t 4 m a

ht 3

core

core

Recall the turbofan work balance (5.27). This relation can be rearranged to read

( m f + m a

core

)h t 4 m a

core

h t 3 = ( m a

core

+ m f )h t 5 + m a

fan

h t 13 ( m a

core

+ m a

fan

(5.48)

)h t 0

where it has been assumed that the inlet is adiabatic h t2 = h t0 . Now use (5.48) to replace the

numerator or denominator in the first term of (5.47). The thermal efficiency finally reads

( m a

+ m f ) ( h e h 0 ) + m a ( h 1e h 0 ) + m f h 0

Q rejected during the cycle

core

fan

4 th = 1 ---------------------------------------------------- = 1 -------------------------------------------------------------------------------------------------------------------------------Q input during the cycle

( m f + m a

)h t 4 m a

ht 3

core

(5.49)

core

The expression in (5.49) for the heat rejected during the cycle,

Q rejected during the cycle = ( m a

+ m f ) ( h e h 0 ) + m a ( h 1e h 0 ) + m f h 0

core

fan

(5.50)

brings to mind the discussion of thermal efficiency in Chapter 2. The heat rejected comprises

heat conduction to the surrounding atmosphere from the fan and core mass flows plus physical

removal from the thermally equilibrated nozzle flow of a portion equal to the added fuel mass

flow. From this perspective the added fuel mass carries its fuel enthalpy into the system and the

exhausted fuel mass carries its ambient enthalpy out of the system and there is no net mass

increase or decrease to the system.

The main assumptions underlying (5.49) are that the engine operates adiabatically, the shaft

mechanical efficiency is one and the burner combustion efficiency is one. Engine components

are not assumed to operate ideally - they are not assumed to be isentropic.

5.4.1

THERMAL EFFICIENCY OF THE IDEAL TURBOFAN

For the ideal cycle assuming constant C p equation (5.49) becomes, in terms of temperatures,

4t h

ideal turbofan

Te

* ( 1 + ( 1 + # ) f ) ----- 1 +)

(

T0

( 1 + ( 1 + # ) f )T e T 0

1

= 1 -------------------------------------------------------------- = 1 * ----------+ ( -----------------------------------------------------------)

& ! r ! c' (

)

!"

( 1 + ( 1 + # ) f )T t 4 T t 3

( ( 1 + ( 1 + # ) f ) --------- 1)

!r !c

&

'

(5.51)

Using (5.25) Equation (5.51) becomes

4 th

1/4/10

ideal turbofan

1

= 1 * ----------+

&! ! '

(5.52)

r c

5.10

bjc

The non-ideal turbofan

which is identical to the thermal efficiency of the ideal turbojet. Notice that for the ideal turbofan with h 1e = h 0 the heat rejected by the fan stream is zero. Therefore the thermal efficiency

of the ideal turbofan is independent of the parameters of the fan stream.

5.5 THE NON-IDEAL TURBOFAN

The fan, compressor and turbine polytropic relations are

% 4 pc'

------------%1

$ c1 = ! c1

% 4 pc

-----------%1

$c = !c

$t =

%

--------------------------( % 1 ) 4 pe

!t

(5.53)

where 4 pc' is the polytropic efficiency of the fan. The polytropic efficiencies 4 pc , 4 pc' and

4 pe are all less than one. The inlet, burner and nozzles all operate with some stagnation pressure loss.

$d < 1

$ n1 < 1

$n < 1

$b < 1 .

(5.54)

5.5.1

NON-IDEAL FAN STREAM

The stagnation pressure ratio across the fan is

%1 2

P t1e = P 0 $ r $ d $ $ n1 = P 1e * 1 + ------------ M 1e+

&

'

c1

2

%

-----------%1

(5.55)

The fan nozzle is still assumed to be fully expanded and so the Mach number ratio for the nonideal turbofan is

2

M 1e

---------2

M0

%1

-----------4 pc'

%

! r ! c1 ( $ d $ n1 )

1

= ---------------------------------------------------------- .

!r 1

(5.56)

The stagnation temperature is (assuming the inlet and fan nozzle are adiabatic)

%1

------------

4 pc'

%1 2

%

T t1e = T 0 ! r ! c1 = T 1e * 1 + ------------ M 1e+ = T 1e ! r ! c1 ( $ d $ n1 )

&

'

2

(5.57)

and

1 4 pc'

! c1

T 1e

--------- = ------------------------------- .

%1

T0

-----------( $ d $ n1 )

bjc

5.11

(5.58)

1/4/10

The non-ideal turbofan

Now the velocity ratio across the non-ideal fan is

*

1 4 pc' +

2

(

)

U 1e

!

1 (

c1

--------- = -------------- ! r ! c1 -------------------------------) .

2

% 1)

!r 1 (

------------)

U0

(

%

( $ d $ n1 )

&

'

(5.59)

5.5.2

NON-IDEAL CORE STREAM

The stagnation pressure across the core is.

%

-----------%

1

%1 2

P te = P 0 $ r $ d $ c $ b $ $ n = P e * 1 + ------------ M e+

.

&

'

t

2

(5.60)

The core nozzle is fully expanded and so the Mach number ratio is

2

1

%1

-------------------4 pc 4 pe

%

!r !c !t ( $d $b $n )

1

Me

-------- = ------------------------------------------------------------------------ .

2

!r 1

M0

(5.61)

In the non-ideal turbofan we continue to assume that the diffuser and nozzle flows are adiabatic

and so

1

%1

-------------------4 pc 4 pe

%

T te = T 0 ! r ! c ! b ! t = T e ! r ! c ! t ( $ d $ b $ n )

(5.62)

from which is determined

Te

------ =

T0

1 +

* 1 -------4 pe'

1 4 pc &

!c

!t

!"

------------------------------------------------ .

%1

-----------%

!r !c ( $d $b $n )

(5.63)

The velocity ratio across the core is

*

1 +

1 --------*

4 pe' +

1 4 pc &

2

(

!c

!t

! ")

* U e+

1 (

-) .

( -------) = -------------- ( ! " ! t ----------------------------------------------% 1)

!r 1

& U 0'

------------ )

(

%

!r !c ( $d $b $n )

&

'

(5.64)

The work balance across the engine remains essentially the same as in the ideal cycle

1/4/10

5.12

bjc

The non-ideal turbofan

!r

! t = 1 ------------- { ( ! c 1 ) + # ( ! c1 1 ) }

4m !

(5.65)

"

where a shaft mechanical efficiency has been introduced defined as

m a ( h t3 h t2 ) + m a ( h t13 h t2 )

core

fan

4 m = --------------------------------------------------------------------------------------------.

( m a

+ m f ) ( h t4 h t5 )

(5.66)

core

5.5.3

MAXIMUM SPECIFIC IMPULSE NON-IDEAL CYCLE

Equation (5.35) remains the same as for the ideal cycle.

* 2+

+

1

2 ( U e ) * U e1

--------------------------------- + ( --------- 1) = 0 .

(

)

2

2(Ue U0) 2# U

U

'

& 0' & 0

(5.67)

# max impulse turbofan

30

! " = 8.4

25

! r = 1.162

ideal cycle

! c = 2.51

20

non - ideal cycle

15

10

5

1.1

1.2

1.3

1.4

1.5

! c1

Figure 5.4 Turbofan bypass ratio for maximum specific impulse as a function of

fan temperature ratio comparing the ideal with a non-ideal cycle. parameters of the nonideal cycle are $ d = 0.95 , 4 pc1 = 0.86 , $ n1 = 0.96 ,

4 pc = 0.86 , $ b = 0.95 , 4 m = 0.98 , 4 pe = 0.86 , $ n = 0.96 .

bjc

5.13

1/4/10

The non-ideal turbofan

The derivative is

*

(

(

* U 2+

!

(

!

1

)

2 ( e)

r c1

------- = ------------------------------- ( 1

4m ( !r 1 ) (

2 # ( U 2)

(

& 0'

(

&

-+

1 4 pc -------4 pe)

1 +

* 1 -------- !

!t )

&

4 pe' c

------------------------------------------------------------) .

%1 )

------------ )

%

!r !c ( $d $b $n )

)

'

(5.68)

Equations (5.59), (5.64), (5.65) and (5.68) are inserted into (5.67) and the optimal bypass ratio

for a set of selected engine parameters is determined implicitly. A typical numerically determined result is shown in Figure 5.4 and Figure 5.5.

# max impulse turbofan

20

ideal cycle

! " = 8.4

17.5

non - ideal cycle

15

! c1 = 1.2

! c = 2.51

12.5

10

7.5

5

2.5

1.2

1.4

1.6

1.8

!r

Figure 5.5 Turbofan bypass ratio for maximum specific impulse as a function of

Mach number comparing the ideal with a non-ideal cycle. Parameters of

the nonideal cycle are $ d = 0.95 , 4 pc1 = 0.86 , $ n1 = 0.96 ,

4 pc = 0.86 , $ b = 0.95 , 4 m = 0.98 , 4 pe = 0.86 , $ n = 0.96 .

These figures illustrate the strong dependence of the optimum bypass ratio on the non-ideal

behavior of the engine. In general as the losses increase, the bypass ratio optimizes at a lower

value. But note that the optimum bypass ratio of the non-ideal engine is still somewhat higher

than the values generally used in real engines. The reason for this is that our analysis does not

include the optimization issues connected to integrating the engine onto an aircraft where there

is a premium on designing to a low frontal area so as to reduce drag while maintaining a certain

clearance between the engine and the runway.

1/4/10

5.14

bjc

Problems

Nevertheless our analysis helps us to understand the historical trend toward higher bypass

engines as turbine and fan efficiencies have improved along with increases in the turbine inlet

temperature.

5.6 PROBLEMS

Problem 1 - Assume % = 1.4 , R = 287 M2/(sec2-K), C p = 1005 M2/(sec2-K). The

7

fuel heating value is 4.28 10 J/Kg. Where appropriate assume f 1 . The ambient tem4

perature and pressure are T 0 = 216K and P 0 = 2 10 N M . Consider a turbofan

with the following characteristics.

M 0 = 0.85 ;

! " = 8.0 ;

$ c = 30 ;

$ c1 = 1.6 ;

# = 5.

(5.69)

The compressor, fan and turbine polytropic efficiencies are

4 pc = 0.9 ;

4 pc1 = 0.9 ;

4 pt = 0.95 .

Let the burner efficiency and pressure ratio be 4 b = 0.99 ;

(5.70)

$ b = 0.97 . Assume the shaft

efficiency is one. Both the fan and core streams use ideal simple convergent nozzles. Determine

the dimensionless thrust T ( P 0 A 0 ) , specific fuel consumption and overall efficiency. Suppose

the engine is expected to deliver 8,000 pounds of thrust at cruise conditions. What must be the

area of the fan face, A 2 ?

Problem 2 - Use Matlab or Mathematica to develop a program that reproduces Figure 5.4

and Figure 5.5.

Problem 3 - An ideal turbofan operates with a heat exchanger at its aft end.

m a

fan

m a

core

2.5

bjc

5.15

1/4/10

Problems

The heat exchanger causes a certain amount of thermal energy Q (Joules/sec) to be transferred

from the hot core stream to the cooler fan stream. Let the subscript x refer to the heat exchanger.

Assume that the heat exchanger operates without any loss of stagnation pressure

$ x = $ x' = 1.0 and that both nozzles are fully expanded. Let ! x = T te T t5 and

! x' = T te' T t5' . The thrust is given by

T = m a a 0 M 0 { ( U 6 U 0 1 ) + # ( U 6' U 0 1 ) }

core

(5.71)

where we have assumed f 1 .

1) Derive an expression for T ( m a

core

a 0 ) in terms of ! ", ! r, ! c, ! c', # and ! x, ! x' .

2) Write down an energy balance between the core and fan streams. Suppose an amount of heat

Q is exchanged. Let ! x = 1 6 where 6 = Q ( m a C p T t5 ) , Q > 0 . Show that

core

* !" !t +

! x' = 1 + ( ---------------) 6 .

& #! r ! c''

(5.72)

3) Consider an ideal turbofan with the following characteristics.

T 0 = 216K ; M 0 = 0.85 ; ! " = 7.5 ; $ c = 30 ; $ c' = 1.6 ; # = 5 .

Plot T ( m a

core

(5.73)

a 0 ) versus 6 for 0 < 6 < 6 max where 6 max corresponds to the value of 6

such that the two streams are brought to the same stagnation temperature coming out of the heat

exchanger.

Problem 4 - The figure below shows a turbojet engine supplying shaft power to a lift fan.

Assume that there are no mechanical losses in the shaft but the clutch and gear box that

transfers power to the fan has an efficiency of 80%. That is, only 80% of the shaft power

is used to increase the enthalpy of the air flow through the lift fan. The air mass flow rate

1/4/10

5.16

bjc

Problems

through the lift fan is equal to twice the air mass flow rate through the engine

m Lift Fan = 2m a . The polytropic efficiency of the lift fan is 4 p Lift Fan = 0.9 and the air

flow through the lift fan is all subsonic. The flight speed is zero.

m Lift Fan

P0 T 0

m

a

2f

3f

gear

box

Lift

Fan

clutch

A*4

M=1

A1throat

The ambient temperature and pressure are T 0 = 300K and P 0 = 1.01x10 N M . The

turbine inlet temperature is T t4 = 1800K and $ c = 25 . Relevant area ratios are

*

A 2 A 4 = 15 and A 1throat A 2 = 0.5 . Assume the compressor, burner and turbine all

operate ideally. The nozzle is a simple convergent design and stagnation pressure losses

due to wall friction in the inlet and nozzle are negligible. Assume f<<1. Let the nozzle area

be set so that P t5 P 0 = 3 .

1) Is there a shock in the inlet of the turbojet?

2) Determine the stagnation temperature and pressure ratio across the lift fan

T t3 LiftFan

! Lift Fan = ------------------------T t2 LiftFan

bjc

P t3 LiftFan

$ Lift Fan = -----------------------P t2 LiftFan

5.17

(74)

1/4/10

Problems

1/4/10

5.18

bjc

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- IEEE Power and Energy Magazine Volume 9 Issue 3 2011 (Doi 10.1109/mpe.2011.940579) Katiraei, K.F. Agüero, J.R. - Solar PV Integration ChallengesDocument10 pagesIEEE Power and Energy Magazine Volume 9 Issue 3 2011 (Doi 10.1109/mpe.2011.940579) Katiraei, K.F. Agüero, J.R. - Solar PV Integration Challengesjagadeeshkumar116100% (1)

- Large Field Refrigeration System-USMC Technical ManualDocument228 pagesLarge Field Refrigeration System-USMC Technical ManualbusybusybusyPas encore d'évaluation

- Cash FlowDocument14 pagesCash FlowCrashCoolPas encore d'évaluation

- Yogendra Kumar: Degree / Qualification Name of The Institute / School Examining Authority Marks Scored Year of PassingDocument3 pagesYogendra Kumar: Degree / Qualification Name of The Institute / School Examining Authority Marks Scored Year of PassingCrashCoolPas encore d'évaluation

- Missiles of The World - Missile ThreatMissile ThreaDocument3 pagesMissiles of The World - Missile ThreatMissile ThreaCrashCoolPas encore d'évaluation

- Shock Diamonds and Mach DisksDocument6 pagesShock Diamonds and Mach DisksCrashCoolPas encore d'évaluation

- A New Development in Completion Methods - The Limited Entry TechniqueDocument8 pagesA New Development in Completion Methods - The Limited Entry TechniqueJosé TimanáPas encore d'évaluation

- ProMax 3 BrochureDocument20 pagesProMax 3 BrochureNila Gama100% (2)

- Colfax Mechanical Seal LeakageDocument4 pagesColfax Mechanical Seal Leakagesoumya19800000000Pas encore d'évaluation

- Portal Frame ConstructionDocument2 pagesPortal Frame Constructionriz2010Pas encore d'évaluation

- RFP Iecc KochiDocument73 pagesRFP Iecc KochiCUBE ProjectsPas encore d'évaluation

- Frax22b Frax22d Drx32ddlmanualDocument18 pagesFrax22b Frax22d Drx32ddlmanualPawel Vlad LatoPas encore d'évaluation

- PV6000 Series Hydraulic Variable Pumps: Contact InformationDocument7 pagesPV6000 Series Hydraulic Variable Pumps: Contact InformationMauricio GuanellaPas encore d'évaluation

- Water Level Indicator Project PDFDocument7 pagesWater Level Indicator Project PDFSimranPas encore d'évaluation

- kx0804 PDFDocument519 pageskx0804 PDFstefan corjuc100% (7)

- CAT 323 DL 2013 LeafletDocument20 pagesCAT 323 DL 2013 LeafletLuka BornaPas encore d'évaluation

- Lab3E8 - Series and Parallel PumpDocument8 pagesLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- Decarbonization MagazineDocument86 pagesDecarbonization MagazineSynergy IndustriesPas encore d'évaluation

- Sugar Sector PDF - 1608046711Document29 pagesSugar Sector PDF - 1608046711Mustafa Farooq100% (1)

- GUF RDH4 SpecificationsDocument4 pagesGUF RDH4 SpecificationstachetachePas encore d'évaluation

- PHYSICS/FILIPINODocument2 pagesPHYSICS/FILIPINOMaLou Temblique EscartinPas encore d'évaluation

- Снимок экрана 2023-03-01 в 09.16.43Document48 pagesСнимок экрана 2023-03-01 в 09.16.43Maksim ZolotarjovPas encore d'évaluation

- ECM433 LAB 1 (Reference Update)Document10 pagesECM433 LAB 1 (Reference Update)Nina WalinPas encore d'évaluation

- 5456 de Filter PressDocument6 pages5456 de Filter PressmbhadelPas encore d'évaluation

- ConveyorDocument20 pagesConveyormatealoredana8015Pas encore d'évaluation

- 1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionDocument12 pages1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionwilliamPas encore d'évaluation

- Flare Gas Recovery RGBDocument4 pagesFlare Gas Recovery RGBAdriana_TorresPas encore d'évaluation

- Eat That Frog!: A Book Summary OnDocument17 pagesEat That Frog!: A Book Summary OnramranganPas encore d'évaluation

- Green Hotels and Sustainable Hotel Operations in India: ResearchgateDocument7 pagesGreen Hotels and Sustainable Hotel Operations in India: ResearchgateSanika AgrawalPas encore d'évaluation

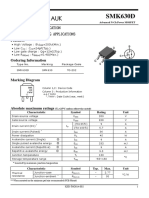

- SMK 630 DDocument8 pagesSMK 630 DMuhammad Chaidir FhadlyPas encore d'évaluation

- Kem R7005 Uc2 Ud2-541010Document18 pagesKem R7005 Uc2 Ud2-541010Anonymous C6Vaod9Pas encore d'évaluation

- Verified Carbon StandardDocument34 pagesVerified Carbon Standardkamlesh pardeshiPas encore d'évaluation

- 3rd Reviewer - Grade 6Document13 pages3rd Reviewer - Grade 6Joseph Bryan VictoriaPas encore d'évaluation

- Zentech Jackup Rig Design R 550D PDFDocument8 pagesZentech Jackup Rig Design R 550D PDFGiang Nguyen NinhPas encore d'évaluation