Académique Documents

Professionnel Documents

Culture Documents

Design and Fabrication of A Spring Constant Testing Machine and Determination of Spring Constant of A Compression Spring

Transféré par

Innovative Research PublicationsTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design and Fabrication of A Spring Constant Testing Machine and Determination of Spring Constant of A Compression Spring

Transféré par

Innovative Research PublicationsDroits d'auteur :

Formats disponibles

International Journal of Engineering Research

Volume No.4, Issue No.10, pp : 573-577

ISSN:2319-6890)(online),2347-5013(print)

01 Oct. 2015

Design and Fabrication of a Spring Constant Testing Machine and

Determination of Spring Constant of a Compression Spring

Muhammad Abu Rahat1, Muhammad Ferdous Raiyan2, MD. Safayet Hossain3, J.U. Ahamed4, Nahed

Hassan Jony5

Department of Mechanical Engineering, CUET, Chittagong, Bangladesh

Rahatmechanical07@gmail.com1, muhammadferdousraiyan@gmail.com2, safayet_shawon@ymail.com3,

jamal293@yahoo.com4, jonyme09@gmail.com5

Abstract: The main objective of this project is to determine the

stiffness which is commonly known as spring constant of a

compression spring under various load.The kit which has been

built into a machine to stretch or compress test springs, while

measuring load and displacement is called spring testing kit. It

tests springs and finds their properties good for mechanical

workshops use. It includes a set of different springs to compare

spring rates and effect of different spring sizes. It has wide

range and variety of experiments. Easy-to-use, compact

instrument that fits on a small bench or desktop and as a spring

force constant determination as a learning tool for graphing

and modeling. Compression of a spring in a spring constant

testing machine is an example of a loading that can be treated

as a combination of a direct shear load and a torsional load.

This project is just a prototype which can be improved for

implementation in industrial work.

Keywords: Spring testing kit, hooks law, stiffness, shear

stress, Wahl factor.

I.

INTRODUCTION

A kit that builds into a machine to stretch or compress test

springs, while measuring load and displacement. The kit

includes a spring for tensile tests and a different spring for

compression tests. A spring is an elastic object used to store

mechanical energy. Springs are usually made out of spring steel.

Small springs can be wound from pre-hardened stock, while

larger ones are made from annealed steel and hardened after

fabrication. Some non-ferrous metals are also used including

phosphor bronze and titanium for parts requiring corrosion

resistance and beryllium copper for springs carrying electrical

current (because of its low electrical resistance).

When a spring is compressed or stretched, the force it exerts is

proportional to its change in length. The rate or spring constant of

a spring is the change in the force it exerts, divided by the change

in deflection of the spring. That is, it is the gradient of the force

versus deflection curve. An extension or compression spring has

units of force divided by distance, for example lbfin or N/m.

Torsion springs have units of force multiplied by distance divided

by angle, such as rad or /degree. The inverse of spring rate is

compliance that is: if a spring has a rate of 10 Nmm, it has pliance

of 0.1 mmN. The stiffness (or rate) of springs in parallel is

additive, as is the compliance of springs in series.

Depending on the design and required operating environment, any

material can be used to construct a spring, so long as the material

has the required combination of rigidity and elasticity:

technically, a wooden bow is a form of spring.

IJER@2015

Compression of a helical spring is an example of a loading that

can be treated as a combination of a direct shear load and a

torsion load. The relationship between the load and deflection of

the spring is referred to as the spring constant, with units of load

per deflection. With load plotted along the Y-axis and

deformation plotted along the X-axis, the spring constant is

determined as the slope of the straight line.

Various research works were done and also many experiments

were conducted for the determination of spring constant. A

method for determining the spring constant of cantilevers for

atomic force microscopy was conducted by [1]. Experiment

regarding effect of spring stiffness to check the suspension

capability as shock absorber in a bus was carried out by [2]. There

are springs with controllable stiffness and test was done on

controllable stiffness by [3]. Design and manufacturing of

hydraulic spring stiffness testing machine was done by [4].

Variable stiffness coil spring for vehicle was optimized, designed

and calculated by [5]. Further researches were also conducted on

the determination of spring constant. Determination of spring

constant as a learning tool for graphing and modeling was done

by [6]. A simplified dynamic model for constant force

compression spring was developed by [7]. The spring constant

testing kit which we developed in this experiment will be able to

determine the value of stiffness for spring. Calibration of torsional

spring constants was compared by different methods by using

torsional photo detector. [8]. Research were performed for design,

analysis and optimization of leaf spring where spring stiffness

was also calculated [9]. Spring constant for helical spring was

found by finite element method and abacus script [10].

II.

MATERIAL AND METHODOLOGY

A kit that builds into a machine to stretch or compress test

springs, while measuring load and displacement. At first

assemble the spring tester on a task frame (MF, separately). The

kit includes a spring for tensile tests and a different spring for

compression tests. Then apply a compressive or tensile force to

the spring by turning an adjustment screw. A load cell (available

separately) shows the force applied to the spring. By moving

freely with the load cell, scales behind the spring directly measure

the spring extension or compression. From the value of load,

displacement we can easily measure the spring constant using

Hooke`s Law.

A complete list of essential equipment is given below:

A.

Spring

The test includes a compression spring.

B. Frame

Page 573

International Journal of Engineering Research

Volume No.4, Issue No.10, pp : 573-577

ISSN:2319-6890)(online),2347-5013(print)

01 Oct. 2015

High quality, specially made frames that provides a sturdy base to

set up experiments. There are two frames. The larger Upright

Frame comes with feet and clamps. The feet allow the frame to

stand on a workbench or table.

The Mini Frame shown in Fig.1 is for smaller and more compact

TASK experiments.

Fig.4 Spring Testing Kit

IV.

EXPERIMENT AND ANALYSIS

To determine the spring constant and properties of a compression

spring using Hooks law.

THEORY: If a weight, W = mg, is applied on an ordinary spring,

causing it to stretch a distance x, then an equal and opposite force,

F, is created in the spring which opposes the pull of the weight. If

Fig.2 Mini frame

W is not so large as to permanently distort the spring, then this

force, F, will restore the spring to its original length after the load

C. Load Cell(LC)

is removed. The magnitude of this restoring force is directly

Load cell Fig.3 is the method of choice for weighing applications. proportional to the stretch; this relationship for elastic behaviour

An easy-to read scale that measure force (load).

is known as Hooke's law and is described by

F=kx

(eq. 1)

Where k is the constant of proportionality called the spring

constant. The springs restoring force acts in the opposite

direction to its elongation, denoted by the negative sign. For a

system such as the spring's compression, (x x-0), is dependent

upon the spring constant, k, and the weight of a mass, mg, that

compress the spring. If the system of forces is in equilibrium (i.e.,

it has no relative acceleration), then the sum of the forces down

(the weight) is equal and opposite to the sum of the forces acting

upward (the restoring force of the spring), or

mg=k(x-x0)

(eq. 2)

Comparing equation 2 with the form for the equation of a straight

line (y = mx + b), we can see that if we plot the force produced by

different masses (mg) as a function of the displacement from

equilibrium (x-x0), the data should be linear and the slope of the

line will be equal to the spring constant, k, whose standard metric

Fig.3 Load cell

units are N/m.

D.

The maximum stress in the wire may be computed by

E. Scale

By moving freely with the load cell, scale behind the spring superposition of the shear stress is given by the equation 3.

T=8WD(d3F)

(eq.3)

directly measures the spring extension or compression.

Where, W = (4C-1) / (4C-4) + 0.615/C is the Wahl factor of a

compression spring.

III.COMPLETE MODEL OF SPRING TESTING KIT

After assembling the load cell, spring, scale and mini frame we

V.

PROCEDURE

will get the complete model of spring testing kit. The complete

1. Firstly, place a spring on the angled plate bar.

model of Spring Testing Kit Fig.5 is given below.

IJER@2015

Page 574

International Journal of Engineering Research

Volume No.4, Issue No.10, pp : 573-577

2.

3.

4.

5.

VI.

ISSN:2319-6890)(online),2347-5013(print)

01 Oct. 2015

Attach a mass hanger directly to the bottom of the spring

and record the position of the bottom of the mass relative

to a meter stick.

Add masses to the spring and record the position of the

bottom of the mass hanger.

A load cell shows the force applied to the spring. By

moving freely with the load cell, scale behind spring

directly measures the spring compression. And thus by

getting the load and displacement we can measure spring

constant of the compression spring.

Repeat for other masses.

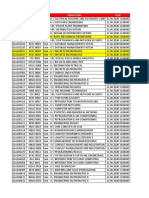

DATA COLLECTION

In this experiment we determine the spring constant of

compression spring by using three springs. Here we use Hooks

law to determine the spring constant. We make three experiments

and there is some error in every step.

Sample 1:

Lfree=8 in; D = 2.1 in; d = 5.4 mm;

Lwire = 78.9 in; = 7500kg/m3; M = 0.344kg;

C = D/d= 9.9

Fig. 5. Force vs. displacement for sample 1

Sample 2:

Lfree=6 in; D=1.7 in; d=6.35 mm;

Table 1: Experimental Data for sample 1

Lwire = 48.9 in; =7500kg/m3; M = 0.295kg; C = D/d= 6.8

No of obs.

Mass

(kg)

Force

(N)

Table 2. Experimental data for sample 2

1.

2.

3.

4.

5.

25

30

35

40

45

245

294

343

392

441

Initial

dis, X

(m)

0.2032

0.2032

0.2032

0.2032

0.2032

Final dis, X0(m)

0.1473

0.1372

0.127

0.1168

0.1067

Table 1 (continued)

No of

obs.

1.

2.

3.

4.

5.

Change

of dis,

(X-X0)

(m)

0.05588

0.06604

0.07620

0.08636

0.09652

IJER@2015

Wahl

Factor,

W

Shear

Stress,

(MPa)

Spring

constant,

K (KN/m)

1.15

1.15

1.15

1.15

1.15

243.04

291.65

340.25

388.86

437.47

4.384

4.451

4.501

4.539

4.569

No of obs.

Mass

(kg)

Force(N)

1.

2.

3.

4.

5.

30

40

50

60

70

294

392

490

588

686

Initial

dis, X

(m)

0.1524

0.1524

0.1524

0.1524

0.1524

Final dis, X0(m)

0.1423

0.1397

0.1372

0.1346

0.1321

Table 2 (continued)

No of obs.

Change

Wahl

Shear

Spring constant,

Of dis,

Factor,

Stress,

K (KN/m)

(X-X0)

(MPa)

1.

2.

3.

4.

(m)

0.01016

0.01270

0.01524

0.01778

1.22

1.22

1.22

1.22

154.03

205.37

256.72

308.06

28.94

30.87

32.15

33.07

5.

0.02032

1.22

359.41

33.75

Page 575

International Journal of Engineering Research

Volume No.4, Issue No.10, pp : 573-577

ISSN:2319-6890)(online),2347-5013(print)

01 Oct. 2015

Average Spring Constant,K=22.4445=4.489KNm

Error =4.628-4.4894.628100=3.0%

From, Sample-2 and Table-2

Ideal condition, spring at rest

Spring constant,K=d4G8D3n

Where, D=0.04318 m=(0.0065)4(79.3109)8(0.04318)3(6)

= 33.364 KN/m, n = 6

Actual condition,

1. Spring constant,K=2940.01016=28.94KNm

2. Spring constant,K=3920.01270=30.87KNm

3. Spring constant,K=4900.01524=32.15KNm

4. Spring constant, K= 5880.01778=33,07 KNm

Fig.6 Force vs. displacement for sample 2

Average Spring Constant,K=158.785=31.76KNm

Sample 3:

Lfree = 5.85 in; D = 1.7 in; d = 6.1 mm;

3

Lwire = 66 in; =7500kg/m ; M = 0.367kg; C = D/d = 7.08

Error =33.36-31.7633.36100=4.7%

= 4.7%

From, Sample-3,

Ideal condition, spring at rest

Spring constant,K=d4G8D3n

Where, D=0.04318 m=(0.0065)4(79.3109)8(0.04318)3(6)

= 15.49 KN/m, n=11

Average Spring Constant,K=76.445=15.29KNm

Error =15.49-15.2915.49100=1.3%

Fig.7 Force vs. displacement for sample 3

VII.

CALCULATION

The calculation of the experiment is given below:

From, Sample-1 and Table-1

Ideal condition, spring at rest

Spring constant, K=d4G8D3n

where D=0.5334 m=(0.0054)4(79.3109)8(0.05334)3(12)

= 4.628 KN/m=12

Actual condition,

1. Spring constant,K=2450.05588=4.384KNm

2. Spring constant,K=2940.06604=4.451KNm

3. Spring constant,K=3430.07620=4.501KNm

4. Spring constant,K=3920.08636= 4.539KNm

5. Spring constant,K=4410.09652= 4.569KNm

IJER@2015

VIII.

RESULTS AND DISCUSSIONS

At first assemble the spring tester on a task frame (MF,

separately). The kit includes a spring for compression tests. Then

apply a compressive force to the spring by turning an adjustment

screw. A load cell (available separately) shows the force applied

to the spring. By moving freely with the load cell, scales behind

the spring directly measure the spring extension or compression.

From the value of load, displacement we can easily measure the

spring constant using Hook`s Law. We know Hooks Law states

that as the extension so is the force.

IX.

SUMMARY RESULTS

The summary result of this experiment is given below.

1. Average Spring Constant,K=4.489KNm

Error=3.0%

2.

Average Spring Constant,K=31.76KNm

Error=4.7%

3.

Average Spring Constant,K=15.29KNm

Error=1.3%

Page 576

International Journal of Engineering Research

Volume No.4, Issue No.10, pp : 573-577

ISSN:2319-6890)(online),2347-5013(print)

01 Oct. 2015

iv. Avdhut R. Jadhav, Gajendra J Pol and Amit A Desai, Design

and Manufacturing of a Hydraulic Spring Stiffness Testing Machine,

International Journal of Emerging Engineering Research and

Technology, Vol.2, No.7, pp 184-190, 2014.

v. Qu Xian and Zhao Shu-en,,Optimization , Design and

Calculation of the Variable Stiffness Coil Spring Applied to Vehicles ,

International Journal of Science and Research, Vol.3, No.4, pp 25622565, 2014.

vi. Newton, I. Galilei, G. and Einstein, Spring Force Constant

Determination as a Learning Tool for Graphing and Modeling, NCSU

Physics 205 Section 11, 2002.

vii. Ikechukwu Celestine UGWUOKE, A Simplified Dynamic

Model for Constant-Force Compression Spring, Leonardo Journal of

i. Akihiro Torii, Minoru Sasakir, Kazuhiro Hane and Shigeru Sciences, Issue.13, pp. 30-43, 2008.

viii. Torbjorn Pettersen, Niklas Nordgren, Mark W. Rutland, Adam

Okuma, A method for determining the spring constant of cantilevers for

atomic force microscopy, Measurement Science and Technology, Vol.7, Feiler.Comparison of different methods to calibrate torsional spring

constant and photodetector for atomic force microscopy friction

No.2, 1995.

ii. Dragan Sekulic, Vlastimir Dedovic, The Effect of Stiffness measurement in air and liquid, American Institute of Physics.

ix. Dhiraj K. Bhandarkar, Sanjay P. Shekhawat, Design,

and Damping of the Suspension System Elements on the Optimization of

the Vibrational Behavior of a Bus, International Journal of Traffic and Analysis and Optimization of Leaf Spring, International Journal of

Innovative Research in Science, Engineering and Technology, Vol.3,

Transport Engineering, Vol.1, No.4, pp 231-244, 2011.

iii. Waldemar Razcka, Testing of a spring with Controllable Issue 6, 2014.

x. Biswajit Banaerjee, Finding the Spring Constant of a Helical

Stiffness, MECHANICS, AGH University of Science and Technology,

Spring,

January 2012, imeccanica.org/files/helical spring.

Vol.25, No.2, 2006.

X.

DISCUSSIONS ON RESULTS

In this experiment, we determine the spring constant of a

compression spring using Hooks Law. We took three springs of

different sizes. But every steps some error occurred. For first

spring error is 3 %, for second spring error 4.7% and for third

spring error 1.3 %. The sources of error in this part of the

experiment are due to the precision of the location measurement

using the meter stick and the accuracy of the slotted masses. The

meter stick was mounted vertically and behind the spring .By

plotting the value of force and displacement on the graph a

straight line is found.

REFERENCES

IJER@2015

Page 577

Vous aimerez peut-être aussi

- Differential Transformation Method for Mechanical Engineering ProblemsD'EverandDifferential Transformation Method for Mechanical Engineering ProblemsPas encore d'évaluation

- Rfactor Calculation InstructionsDocument6 pagesRfactor Calculation InstructionsACTRPas encore d'évaluation

- Brake Design 2Document3 pagesBrake Design 2Aakash SharmaPas encore d'évaluation

- Math (F5) - Gradient and Area Under A GraphDocument26 pagesMath (F5) - Gradient and Area Under A GraphRoszelan MajidPas encore d'évaluation

- 2011 REV SAE Suspension Kiszco PDFDocument112 pages2011 REV SAE Suspension Kiszco PDFRushik KudalePas encore d'évaluation

- MF52 EquationManualDocument41 pagesMF52 EquationManualFelipe100% (1)

- Real Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDocument47 pagesReal Time Simulation and Parametric Optimization Applied To Racing Cars The BMW Team Brasil Case PDFDebra JacksonPas encore d'évaluation

- CG Height Calculator - Automotive Brake System Calculator - BRAKE POWERDocument2 pagesCG Height Calculator - Automotive Brake System Calculator - BRAKE POWERAnonymous QiMB2lBCJLPas encore d'évaluation

- SAE Mini BAJA: Suspension and Steering: Concept GenerationDocument16 pagesSAE Mini BAJA: Suspension and Steering: Concept GenerationPrashant DubeyPas encore d'évaluation

- Drenth Display Unit USB Manual 2013-5Document20 pagesDrenth Display Unit USB Manual 2013-5Lucas Nicolás MartinezPas encore d'évaluation

- Brake Force CalculationDocument25 pagesBrake Force CalculationVicky TjPas encore d'évaluation

- Team Teaching Presentation How Car Suspension WorksDocument17 pagesTeam Teaching Presentation How Car Suspension Worksmsaad19103564Pas encore d'évaluation

- Development and Experimental Verification of A Parametric Model of An Automotive DamperDocument126 pagesDevelopment and Experimental Verification of A Parametric Model of An Automotive DamperMrudula Amar WardePas encore d'évaluation

- Analysis of Davis Steering Gear Mechanism For Four Wheels and Six WheelsDocument5 pagesAnalysis of Davis Steering Gear Mechanism For Four Wheels and Six WheelsIJIRSTPas encore d'évaluation

- Optimumt Product Description: Key FeaturesDocument6 pagesOptimumt Product Description: Key FeaturesPierre LalsingPas encore d'évaluation

- 2014 FSAE Structural Equivalency Spreadsheet V1.2Document103 pages2014 FSAE Structural Equivalency Spreadsheet V1.2Homer SilvaPas encore d'évaluation

- Geneva MechanismDocument12 pagesGeneva Mechanismsarodesarang4750Pas encore d'évaluation

- Vehicle AerodynamicsDocument31 pagesVehicle AerodynamicsNimisha Singh100% (1)

- Vehicle Suspension Modeling NotesDocument25 pagesVehicle Suspension Modeling Notesahmetlutfu100% (2)

- Roll Center MysteryDocument7 pagesRoll Center MysteryMrudula Amar WardePas encore d'évaluation

- IJREI - Vibration Analysis and Response Characteristics of A Half Car Model Subjected To Different Sinusoidal Road ExcitationDocument6 pagesIJREI - Vibration Analysis and Response Characteristics of A Half Car Model Subjected To Different Sinusoidal Road ExcitationIjrei JournalPas encore d'évaluation

- Frame Design & Load Calculations PDFDocument5 pagesFrame Design & Load Calculations PDFRrdbjdPas encore d'évaluation

- AC Worksheet v016Document82 pagesAC Worksheet v016Игорь БелецкийPas encore d'évaluation

- The Magic Formula Tyre ModelDocument19 pagesThe Magic Formula Tyre ModelgholmalikPas encore d'évaluation

- Driveline Dynamics NotesDocument19 pagesDriveline Dynamics NotesprabhjotbhangalPas encore d'évaluation

- Tutorial 1 - Importing Data: 1. Loading A FileDocument9 pagesTutorial 1 - Importing Data: 1. Loading A FileDavid López AlmirallPas encore d'évaluation

- Assignment ClutchDocument624 pagesAssignment ClutchSubhash KPas encore d'évaluation

- Slip Angle Explained Race Logic PDFDocument8 pagesSlip Angle Explained Race Logic PDFyeshwantamburePas encore d'évaluation

- Ground Effect (Aircraft)Document5 pagesGround Effect (Aircraft)Mohd Anuar50% (2)

- Research Paper SuspensionDocument7 pagesResearch Paper SuspensionAnirudh GuptaPas encore d'évaluation

- Ahmed BodyDocument15 pagesAhmed Bodyk sai krishnaPas encore d'évaluation

- Theoretical Analysis of Stress and Design of Piston Head Using CATIA & ANSYSDocument10 pagesTheoretical Analysis of Stress and Design of Piston Head Using CATIA & ANSYSinventionjournalsPas encore d'évaluation

- Ackermann Steering For Performance Race Cars PDFDocument22 pagesAckermann Steering For Performance Race Cars PDFr2d23Pas encore d'évaluation

- Porsche Chassis DevelopmentDocument18 pagesPorsche Chassis DevelopmentArif OthmanPas encore d'évaluation

- Automotive Transmission - Lecture Notes CompleteDocument156 pagesAutomotive Transmission - Lecture Notes CompleteAkshay PundePas encore d'évaluation

- RCE4Document3 pagesRCE4Ketan JainPas encore d'évaluation

- A Tool For Lap Time Simulation PDFDocument5 pagesA Tool For Lap Time Simulation PDFRodrigo BobPas encore d'évaluation

- Aerodynamics of Gurney Flaps On A Wing in Ground EffectDocument9 pagesAerodynamics of Gurney Flaps On A Wing in Ground EffectVyssionPas encore d'évaluation

- (電動機械L30補充教材) ITU - Vehicle FundamentalsDocument53 pages(電動機械L30補充教材) ITU - Vehicle Fundamentalsdeepak_gupta_pritiPas encore d'évaluation

- Report On Four Bar Mechanism of Sewing MachineDocument8 pagesReport On Four Bar Mechanism of Sewing MachineshazedislamPas encore d'évaluation

- CFD of Clubman Roll CagesDocument18 pagesCFD of Clubman Roll CagesJoel ForbesPas encore d'évaluation

- Mechanics of Pneumatic TiresDocument88 pagesMechanics of Pneumatic Tiressaddleman100% (1)

- Chassis Newsletter 2010.8Document3 pagesChassis Newsletter 2010.8Ganesh ShanmugamPas encore d'évaluation

- Integration of Magic Formula Tire Model With Vehicle Handling ModelDocument7 pagesIntegration of Magic Formula Tire Model With Vehicle Handling ModelFabio Bazakas ZetolaPas encore d'évaluation

- Suspension and Chassis GlossaryDocument9 pagesSuspension and Chassis GlossaryHemantPas encore d'évaluation

- Literature ReviewDocument11 pagesLiterature ReviewDharmendra PrajapatiPas encore d'évaluation

- Finite Element Analysis of Fatigue Life of Suspension Coil SpringDocument6 pagesFinite Element Analysis of Fatigue Life of Suspension Coil SpringSameer SinghPas encore d'évaluation

- 253 Suspension Calc ExplainedDocument1 page253 Suspension Calc ExplainedholaqPas encore d'évaluation

- Cam MechDocument24 pagesCam MechmarcglebPas encore d'évaluation

- Vehicle Roll EstimatorDocument10 pagesVehicle Roll EstimatorRaja Amer AzimPas encore d'évaluation

- Deep Bed Filter Unit: Technical Teaching EquipmentDocument3 pagesDeep Bed Filter Unit: Technical Teaching EquipmentJennifer MaamaryPas encore d'évaluation

- All You Need To Know About Differentials PDFDocument107 pagesAll You Need To Know About Differentials PDFJay100% (1)

- Tire-Road Friction CoefficientDocument11 pagesTire-Road Friction CoefficientAnonymous Hy5Ir9QXPas encore d'évaluation

- SusProg3D PDFDocument299 pagesSusProg3D PDFyagoegay100% (1)

- Design and Analysis of Disc Brake and Caliper of Four WheelerDocument5 pagesDesign and Analysis of Disc Brake and Caliper of Four WheelerIJSTEPas encore d'évaluation

- 3.study of Ignition SystemDocument10 pages3.study of Ignition SystemShridhar RaskarPas encore d'évaluation

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationD'EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationPas encore d'évaluation

- Ijer 2015 1013Document6 pagesIjer 2015 1013Subu ManiPas encore d'évaluation

- Helical Spring RevisedDocument5 pagesHelical Spring RevisedJubaer RabbyPas encore d'évaluation

- Case Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageDocument6 pagesCase Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageInnovative Research PublicationsPas encore d'évaluation

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDocument5 pagesThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsPas encore d'évaluation

- Power Transformer Protection Using Fuzzy Logic Based ControllerDocument5 pagesPower Transformer Protection Using Fuzzy Logic Based ControllerInnovative Research PublicationsPas encore d'évaluation

- Computational EconomicsDocument2 pagesComputational EconomicsInnovative Research PublicationsPas encore d'évaluation

- 3D Modeling of Complex Structure Based On AutoCAD VBADocument3 pages3D Modeling of Complex Structure Based On AutoCAD VBAInnovative Research PublicationsPas encore d'évaluation

- Information EngineeringDocument2 pagesInformation EngineeringInnovative Research PublicationsPas encore d'évaluation

- Surveillance NetworksDocument2 pagesSurveillance NetworksInnovative Research PublicationsPas encore d'évaluation

- Role of Coaching Institutes in IndiaDocument5 pagesRole of Coaching Institutes in IndiaInnovative Research PublicationsPas encore d'évaluation

- Online Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Document2 pagesOnline Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Innovative Research PublicationsPas encore d'évaluation

- Wearable ComputingDocument3 pagesWearable ComputingInnovative Research PublicationsPas encore d'évaluation

- Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesDocument3 pagesComparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesInnovative Research PublicationsPas encore d'évaluation

- Computational ElectromagneticsDocument3 pagesComputational ElectromagneticsInnovative Research PublicationsPas encore d'évaluation

- Information Security in Cloud Computing: A Systematic Literature Review and AnalysisDocument6 pagesInformation Security in Cloud Computing: A Systematic Literature Review and AnalysisInnovative Research PublicationsPas encore d'évaluation

- CFD Analysis of A 210 MW Tangential Fired BoilerDocument6 pagesCFD Analysis of A 210 MW Tangential Fired BoilerInnovative Research PublicationsPas encore d'évaluation

- Experimental Study About Soil Improvement With Glass FibersDocument5 pagesExperimental Study About Soil Improvement With Glass FibersInnovative Research PublicationsPas encore d'évaluation

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDocument6 pagesA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsPas encore d'évaluation

- The Lower Parts of The Lock Stitch Sewing MachineDocument3 pagesThe Lower Parts of The Lock Stitch Sewing MachineHazelAnnCandelarioVitug20% (5)

- Danh M C AHTN 2017 - HS Code 2017 PDFDocument564 pagesDanh M C AHTN 2017 - HS Code 2017 PDFBao Ngoc Nguyen100% (1)

- 12.1 ANSYS CompositePrepPostDocument2 pages12.1 ANSYS CompositePrepPostLakmal ArandaraPas encore d'évaluation

- Cracked Tooth Syndrome. Part 1 Aetiology and DiagnosisDocument17 pagesCracked Tooth Syndrome. Part 1 Aetiology and Diagnosisfloressam2000Pas encore d'évaluation

- Anish Pandey ResumeDocument4 pagesAnish Pandey ResumeAnubhav ChaturvediPas encore d'évaluation

- Modeling Plastics in ANSYS (Compatibility Mode) PDFDocument14 pagesModeling Plastics in ANSYS (Compatibility Mode) PDFashutosh.srvPas encore d'évaluation

- Blank BPSU TemplateDocument6 pagesBlank BPSU TemplateClarina Alviz BergantePas encore d'évaluation

- MHT-CET 2021 Question Paper: 25 September 2021Document3 pagesMHT-CET 2021 Question Paper: 25 September 2021Sank DamPas encore d'évaluation

- Samsung Bd-p4600 SMDocument101 pagesSamsung Bd-p4600 SMIonel CociasPas encore d'évaluation

- Block-1 BLIS-03 Unit-2 PDFDocument15 pagesBlock-1 BLIS-03 Unit-2 PDFravinderreddynPas encore d'évaluation

- Lecture2 v1Document69 pagesLecture2 v1c.ronaldo2012777Pas encore d'évaluation

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocument8 pagesAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- 06ESL37 Analog Electronics Lab MANUALDocument70 pages06ESL37 Analog Electronics Lab MANUALSan AngadiPas encore d'évaluation

- CSA Pre-Test QuestionnaireDocument16 pagesCSA Pre-Test Questionnairedaniella balaquitPas encore d'évaluation

- Know Thyself - Jnana Yoga - Par - Omraam Mikhael AivanhovDocument314 pagesKnow Thyself - Jnana Yoga - Par - Omraam Mikhael AivanhovPedro Ribeiro100% (5)

- Salmonella - Methods and Protocols.-springer-Verlag New York (2020)Document215 pagesSalmonella - Methods and Protocols.-springer-Verlag New York (2020)Yudith ParamitadeviPas encore d'évaluation

- O221771s - Mil Pipe Pro 450 RFC PDFDocument84 pagesO221771s - Mil Pipe Pro 450 RFC PDFJavier Isaac Berrocal Torres100% (1)

- SDS Super PenetrantDocument5 pagesSDS Super Penetrantaan alfianPas encore d'évaluation

- Pastor O. I. Kirk, SR D.D LIFE Celebration BookDocument63 pagesPastor O. I. Kirk, SR D.D LIFE Celebration Booklindakirk1100% (1)

- Construction Companies in AlbaniaDocument17 pagesConstruction Companies in AlbaniaPacific HRPas encore d'évaluation

- Engineering Drawings and Plans: Engr. Rolly S. TambeDocument4 pagesEngineering Drawings and Plans: Engr. Rolly S. TambeFred Joseph G. AlacayanPas encore d'évaluation

- Brewing With New Hop VarietiesDocument70 pagesBrewing With New Hop VarietiesFelipe BaronyPas encore d'évaluation

- Content For Essay and Paragraph Writing On Maritime HistoryDocument15 pagesContent For Essay and Paragraph Writing On Maritime HistoryRaju KumarPas encore d'évaluation

- Staff Code Subject Code Subject Data FromDocument36 pagesStaff Code Subject Code Subject Data FromPooja PathakPas encore d'évaluation

- 159 SnackDocument97 pages159 SnackGuy PlaterPas encore d'évaluation

- The Practice of Veterinary Anesthesia - Small Animals, Birds, Fish, and ReptilesDocument382 pagesThe Practice of Veterinary Anesthesia - Small Animals, Birds, Fish, and ReptilesMárcio MoreiraPas encore d'évaluation

- Ingles y Español Unidad 7Document9 pagesIngles y Español Unidad 7Pier Jhoani Ñañez LlanosPas encore d'évaluation

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDocument10 pagesSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaPas encore d'évaluation

- Naskah Soal PeroranganDocument16 pagesNaskah Soal PeroranganRiza FatimahPas encore d'évaluation

- Environmental and Sustainability Issues - 1Document21 pagesEnvironmental and Sustainability Issues - 121. PLT PAGALILAUAN, EDITHA MPas encore d'évaluation