Académique Documents

Professionnel Documents

Culture Documents

1.0 Objectives: Mass Transfer 2

Transféré par

Laila FaeizahDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1.0 Objectives: Mass Transfer 2

Transféré par

Laila FaeizahDroits d'auteur :

Formats disponibles

PLATE AND FRAME FILTER PRESS

1.0

OBJECTIVES

From this experiment, the objectives is to study the operation of filter press for

filtration by using calcium carbonate slurry. By the data obtained from this experiment, it can

be determined the filter medium resistancce and specific cake resistance from the filtration.

2.0

SUMMARY

In this experiment, the operation of filter press for filtration of calcium carbonate

slurry was determined. On the other hand, the filter medium resistance and specific cake

resistance from filtration data was obtained by the end of the experiment. The experiment was

achieved by following the manual instructions whereas the 5% of mixture between calcium

carbonate and water which become the slurry. On the other hand, the pressure drop used to get

the volume of filtrate is 30 psi. The sample of filtrate was taken at the different time intervals.

The results for weight and dry cake was collected for different tray and the different of total

of the weight is to be 0.8 kg. The time taken for the slurry to finished up inside the slurry tank

was taken. The results shows that the time taken for 100 L of slurry to finished is 22.46

minutes. Based on the tabulated result, the data for viscosity and density for three trays of

average differences filtrate collected at 20, 50 and 100 L. The differences in viscosity and

density of the different samples was affected by resistance in the tray. Futhermore, the graph

time per volume (s/L) vs filtrate volume has been plotted in order to analysed the t/V with the

filtrate volume and obtaining the straight line of graph. Moreover, the average of resistance of

filter medium resistance is 9.72x10^12 cm2/s while the average resistance for filter cake

resistance is 2.93x10^11 cm4/kg. In a nutshell, the efficiency of the filtration process is

determined by the filter medium resistance and also specific cake resistance in filter press

unit.

3.0

RESULTS

MASS TRANSFER 2

Page 1

PLATE AND FRAME FILTER PRESS

1. Weight fraction of calcium carbonate in slurry:

A. Weight of wet cake

5.00

Table 1.0 Weight of wet cake

Tray 1 :

4360 g

Tray 2 :

290 g

Tray 3 :

200 g

Total :

4850 g

B. Weight of dry cake

Table 1.1 The weight of dry cake

Tray 1 :

Tray 2 :

Tray 3 :

Total :

i.

ii.

iii.

iv.

v.

vi.

3910 g

120 g

50 g

4080 g

Weight ratio of wet cake to dry cake (mF/mC): 1.189 g

Density of calcium carbonate: 2.93 g/cm3

Total active filter area: 47 cm x 470 cm = 22090 cm2

Pressure drop (CP): 30 psi

Total filtration time: 1347.6 s

Total volume of filtrate: 100 litre

MASS TRANSFER 2

Page 2

PLATE AND FRAME FILTER PRESS

Table 1.2: Filtrate volume and Time Data

Filtrate volume, V

(litre, L)

Time, t

(s)

t/V

(s/L)

59

11.8

10

241.8

24.18

15

301.8

20.12

20

361.2

18.06

25

422.4

16.90

30

481.8

16.06

35

546.6

15.62

40

608.4

15.21

45

670.2

14.89

50

731.4

14.63

55

793.8

14.43

60

853.8

14.23

65

915.6

14.09

70

975

13.93

75

1036.2

13.82

80

1099.2

13.74

85

1161.6

13.67

90

1224

13.60

95

1286.4

13.54

100

1347.6

13.48

MASS TRANSFER 2

Page 3

PLATE AND FRAME FILTER PRESS

t/V versus V

Figure 1.0: Graph of t/V versus V

Table 1.3: Viscosity and Density of Filtrate at 5L, 40L and & 75L

Volume

Viscosity, (Pa.s)

20 L

0.001

50 L

0.0008

100 L

0.0008

Density, (g/cm3)

0.9972

0.9971

0.9971

Table 1.4: Filter medium resistance for three trays and average resistance

Rm1(20 L)

8.36 x10^12 cm2/s

Rm2 (50 L)

1.04x10^13 cm2/s

Rm3(100 L)

1.04x10^13 cm2/s

Average Rm

9.72x10^12 cm2/s

Table 1.5: Filter cake resistance for three trays and average resistance

1 (20 L)

2 (50 L)

3 (100 L)

Average

7.04 x 10^11 cm4/kg

8.80x10^10cm4/kg

8.80x10^10 cm4/kg

2.93x10^11 cm4/kg

MASS TRANSFER 2

Page 4

PLATE AND FRAME FILTER PRESS

4.0

DISCUSSION

In this experiment, the operation of filter press for filtration of calcium carbonate

slurry and filter medium resistance and specific cake resistance from filtration was obtained.

Basically, filtration is the removal of solid particles from a fluid by passing the fluid thrugh a

filtering medium on which the solid are deposited. Theoritically, filter press is a separation

process whereby employed by solid and liquid separation or known as slurry using the

principle of pressure drive. The pressure drive provided by a slurry pump. Filter press is a

fixed volume and batch operation. In this experiment, a liquidsolid filtration is carried out

which is often called cakefiltration.

The experiment was start up by dissolving 5 kg of calcium carbonate into a 100 litres

of water in the slurry tank. The mix of water and calcium carbonate known as slurry. The

slurry was let to be stirred in the tank for several minutes. After that, the filtration process was

done by starting up the pump and the slurry flowing through the filtering medium. The result

was collected and tabulated by taking its time for every 5 L for the filtration yield to

discharged from the filter press machine. The process continously ran until the slurry in the

tank is finished.

Based on table 1.2, the result obtained show that the the t/V is highest at the 10 L

which is at the 24.18 s/L. As the time increases, the t/v was decreasing over time. Basically,

the filter cakes are accumulated in each of the hollow frame. As the filter medium becoming

thicker due to the slurry stucked by, the resistance was also increased. Hence, the increasing

resistance will affecting the t/V to become highest. On the other hand, the plotted graph shows

that the t/V decreasing over time since as time volume increasing, the filter cake resistance is

increasing since the the calcium carbonate in the slurry are retained on the surface of the

medium where they build up, forming an increasing thicker cake. However, the fluctuation of

the graph at 5 L to 10 L is due to the mechanical problem. The pump was suddenly stop after

5 L reading hence the time taken for the next 10 L was increasing since the pressure drive of

slurry to the filter medium is zero.

MASS TRANSFER 2

Page 5

PLATE AND FRAME FILTER PRESS

For the cake filtration, the effeciency of the filtering medium was being obtained and

analysed. Based on the result, it can be seen that the highest weight of wet cake is at the first

tray of the filter medium. The weight obtained is 4.36 kg while for the second and third tray is

0.29 kg and 0.20 kg respectively. This result shows that the effeciency of filtration is

decreasing as passing the tray. On the other hand, Table 1.3 shows a results of the viscosity

and density of filtrate at 20, 50 and 100 L. The result obtained shows that the the highest

viscosity and density is at the first 20 L. This is due to the filter cake build up at the tray

affecting the viscosity and density. Theoritically, viscosity is measure of how the fluid flows

or the thickness of the fluid while density is a degree of compactness of the substances. As

the slurry passing by the filter more cake resistance were build up at the tray and become

resistance hence make just a fewer particle succeed to tresspassing the filter. This situation

make the viscosity and density at 50 L and 100 L are decreasing.

Table 1.4 shows the filter medium resistance for three trays and average resistance

while table 1.5 shows the filter cake resistance for three trays and average resistance. The

higher resistance shows at the 20 L which is 8.36 x10 ^12 cm2/s compared to the 100 L which is

9.72x10^12 cm2/s. On the other hand, the filter cake resistance shows that the higher number is

at 20 L which is 7.04 x 10^11 cm4/kg. In addition, the amount of the filtrate should be same as

the feed. Basically, the filtrate which is in the dry cake should be same as the feed which is 5

kg of calcium carbonate. Based on result, the dry cake obtained is 4.08 kg from 4.85 kg of wet

cake after the drying process. This is due to the filtration of the calcium carbonate was not

100% fully achieved. Futhermore, a straight line which connecting all of the points will

determined the 100% effeciency of the filtration process. Some of the erros might be due to

the error during running the experiment such as the failure of the pump and also the deposit

and blocking of the calcium carbonate in the experiment.

MASS TRANSFER 2

Page 6

PLATE AND FRAME FILTER PRESS

5.0

CONCLUSION

Based on the experiment, it can be concluded that the filter press instrument filtering a

solid particles from a fluid by using a filtering medium on which solid are deposited. As the

more deposited cake on the filtering medium, the higher the resistance was. Futhermore, the

average filter medium resistance and specific cake resistance had been determined by

referring to the graph. On the other hand, the weight of wet and dry cake has been determined

where it shows the percentage of the filtration process. Moreover, the pressure drop, filter

medium and also the size of particles affecting the average filter medium resistance and

specific cake resistance.

The recommendation for the experiment in order to get the accurate result is by

monitoring the pump so it would not be stop a certain time thus affecting the time taken for

each volume. Other than that, the mixture of the calcium carbonate and water or sluury should

be mixed well before going through the filtration process. Futhermore, as the reading of

viscosity are too slightly different, hece the test by using viscosity meter should use the

medium spindle and the speed should be less than 50 mm/s in order to get the accurate

reading. As a conclusion, the objectives of this experiment in order to study on how filtration

works on the operation of filter press for filtration calcium carbonate slurry and its filter

medium resistance and specific cake resistance was succesfully achieved.

MASS TRANSFER 2

Page 7

PLATE AND FRAME FILTER PRESS

6.0

APPENDIX

APPENDIX

Graph and Calculation

1. Plot the data relating

versus V to obtain a straight line graph.

2. The slope of each line is

in seconds per litre and

from the intercept of the line.

Linear equation

t/V = (Kc / 2)V + 1/qo

y = - 0.0569 + 18.287

-Find Kc

Because m =

, so unit for

MASS TRANSFER 2

Page 8

PLATE AND FRAME FILTER PRESS

, Kc = 28450

Find qo

= y-intercept

qo = 0.0547 x

qo = 5.468 x

3. Find the value of filter medium resistance (Rm) and cake resistance () from the equation:

Table 7: Viscosity of filtrate ()

At V= 20 L : 0.001 Pa.s

At V= 50 L :

0.0008 Pa.s

At V= 100 L:

0.0008 Pa.s

Pressure drop = 30 psi [(1.01325 105Pa) / 14.696psi] = 206841.998 Pa

=

A = 22090 cm2 = 2.209 m2

=

= 8.36 1012 m-1

MASS TRANSFER 2

Page 9

PLATE AND FRAME FILTER PRESS

Table 5: Calculated filter medium resistance for three trays.

Rm1(20 L)

8.36 x10^12 cm2/s

Rm2 (50 L)

1.04x10^13 cm2/s

Rm3(100 L)

1.04x10^13 cm2/s

Rm = Rm1 + Rm2 + Rm3

= 9.72x10^12 cm2/s

4. Finding the value of cake resistance ( ) using value () from table 7:

c =

=

=

= 40.8

=

=

= 7.04 1011 m/kg

Table 6: Calculated filter cake resistance for three trays.

1 (20L)

2 (50L)

3 (100L)

7.04 x 10^11 cm4/kg

8.80x10^10cm4/kg

8.80x10^10 cm4/kg

MASS TRANSFER 2

Page 10

PLATE AND FRAME FILTER PRESS

=

= 2.93x10^11 cm4/k

MASS TRANSFER 2

Page 11

PLATE AND FRAME FILTER PRESS

7.0

REFERENCES

1. Plate and Frame Filter Press Construction and Working Theory

Retrieved from: http://www.leofilterpress.com/filter_press/?555.html

2. Trebal, R. E. (1980). Chemical Engineering Series: Mass Transfer Operation. 3rd

Edition International Editions in Related Fields: Mcgraw-Hill.

3. Filter Press Operation

Retrieved from: http://www.industry animated.org/teachers

%20notes/filter_press_pdf.pdf

MASS TRANSFER 2

Page 12

Vous aimerez peut-être aussi

- Scientific American Supplement, No. 446, July 19, 1884D'EverandScientific American Supplement, No. 446, July 19, 1884Pas encore d'évaluation

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityD'EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityÉvaluation : 5 sur 5 étoiles5/5 (2)

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 3: Plate and Frame Filter Press Full Lab ReportDocument13 pagesCPB 20104 Mass Transfer 2 UniKL MICET Experiment 3: Plate and Frame Filter Press Full Lab ReportSiti Hajar Mohamed100% (4)

- Filtration (Final Report)Document13 pagesFiltration (Final Report)Noel Jeffrey PintonPas encore d'évaluation

- Discussion Exp 1 Plate & FrameDocument1 pageDiscussion Exp 1 Plate & FrameNur AsiahPas encore d'évaluation

- Filterability TestDocument8 pagesFilterability Testmgamal1080Pas encore d'évaluation

- SLE Experiment (REPORT)Document8 pagesSLE Experiment (REPORT)Kuknesvary PuniamurthyPas encore d'évaluation

- Cross FlowDocument14 pagesCross FlowFoong Shiuh HaurPas encore d'évaluation

- Lab Experiment 12 Filter PressDocument10 pagesLab Experiment 12 Filter PressRafique Ahmed AbroPas encore d'évaluation

- ACT 9 Filter Grp1Document8 pagesACT 9 Filter Grp1Junn Edgar LibotPas encore d'évaluation

- Jar Test Lab ReportDocument7 pagesJar Test Lab ReportTeCkMunPas encore d'évaluation

- Centrifugation of Fresh Milk and Acetic AcidDocument6 pagesCentrifugation of Fresh Milk and Acetic AcidNah Ee Lin100% (12)

- Filtration Questions)Document8 pagesFiltration Questions)Evan CarniyanPas encore d'évaluation

- Rotary Drum FilterDocument6 pagesRotary Drum FilterSiraj AL sharifPas encore d'évaluation

- Filter Ability Index Unit b9Document8 pagesFilter Ability Index Unit b9zzayannaPas encore d'évaluation

- Dewatering of Iron Ore Slurry by A Ceramic Vacuum Disc FilterDocument6 pagesDewatering of Iron Ore Slurry by A Ceramic Vacuum Disc FilterReynan Giacomin Borlini100% (1)

- Rotary Vacum Drum Filter (Jurnal)Document7 pagesRotary Vacum Drum Filter (Jurnal)Shofiyah Bannan100% (2)

- Chee Lab 2 FinalDocument26 pagesChee Lab 2 FinalOLEBOGENG RATLHOGOPas encore d'évaluation

- Batch Sedimentation Post-Laboratory Experiment 4Document8 pagesBatch Sedimentation Post-Laboratory Experiment 4Kat-kat GrandePas encore d'évaluation

- MO T6 ProbDocument3 pagesMO T6 ProbYashesh DarjiPas encore d'évaluation

- Water Jar TestDocument8 pagesWater Jar TestNurin Adlina100% (1)

- Sepa and PartechDocument5 pagesSepa and Partechdiana bunagan0% (1)

- Lab Session III. Filtration: Abstract-For This Practice, A Filtration Process Was Carried OutDocument3 pagesLab Session III. Filtration: Abstract-For This Practice, A Filtration Process Was Carried OutPaula HernandezPas encore d'évaluation

- Xevvumle 4289Document1 pageXevvumle 4289Dwaipayan PradhanPas encore d'évaluation

- Vacuum Filtration ExperimentDocument26 pagesVacuum Filtration Experimentdrami9433% (3)

- Plate and Frame Filter Press PDFDocument8 pagesPlate and Frame Filter Press PDFjamaiiicaPas encore d'évaluation

- Plate and Frame Filter PressDocument6 pagesPlate and Frame Filter PressLissa Hannah100% (2)

- Rotary DrumDocument7 pagesRotary Drumjeas grejoy100% (1)

- Filtration ControlDocument9 pagesFiltration ControlAlexandra Pity100% (1)

- API Filtration Test: API High-Pressure/High Temperature (HPHT) Filter PressDocument6 pagesAPI Filtration Test: API High-Pressure/High Temperature (HPHT) Filter PressAakriti Bhandari100% (2)

- Pressure Filtration PracticalDocument15 pagesPressure Filtration PracticalServeshan Naidoo33% (3)

- Gravimetric Determination of Moisture and Phosphorus Content in Fertilizer SamplesDocument8 pagesGravimetric Determination of Moisture and Phosphorus Content in Fertilizer SamplesanaperturesciencePas encore d'évaluation

- Water Jar TestDocument7 pagesWater Jar TestMuhammad AkmalPas encore d'évaluation

- 04apr31 PDFDocument10 pages04apr31 PDFAhmad Farid EhsanPas encore d'évaluation

- MT4 Lab FinalDocument19 pagesMT4 Lab FinalAmelia MaharajPas encore d'évaluation

- CG5082 Advanced Transport Processes - W.kwapinski Spring 2013Document11 pagesCG5082 Advanced Transport Processes - W.kwapinski Spring 2013WilliamLoobyPas encore d'évaluation

- MLSS VSS DeterminationDocument3 pagesMLSS VSS DeterminationAnonymous lVbhvJfPas encore d'évaluation

- Coagulation and Flocculation ReportDocument13 pagesCoagulation and Flocculation Reportdrami94100% (2)

- Jar Test ReportDocument8 pagesJar Test ReportRuvindran VasuPas encore d'évaluation

- Exp 3Document1 pageExp 3Harsh TekriwalPas encore d'évaluation

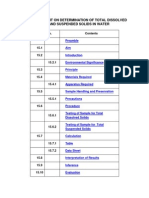

- 15.0 Experiment On Determination of Total Dissolved and Suspended Solids in WaterDocument15 pages15.0 Experiment On Determination of Total Dissolved and Suspended Solids in Waterhero100% (2)

- Jar Test ReportDocument8 pagesJar Test ReportHeLmi Hendrix75% (4)

- Vacuum Leaf FilterDocument2 pagesVacuum Leaf FilterGangadharan NagappanPas encore d'évaluation

- Tutorial 3 - FiltrationDocument4 pagesTutorial 3 - FiltrationDinesh Kumar VijeyanPas encore d'évaluation

- Advantage Mud Manual PDFDocument408 pagesAdvantage Mud Manual PDFEduardo Guajardo100% (2)

- Exp. No : University of Zakho College of Engineering Mechanical Engineering Dep. Drilling Lab 3 StageDocument7 pagesExp. No : University of Zakho College of Engineering Mechanical Engineering Dep. Drilling Lab 3 StageAbdullwahid AhmedPas encore d'évaluation

- Conclusion and Recommendation - Expt. FiltrationDocument1 pageConclusion and Recommendation - Expt. FiltrationArima KouseiPas encore d'évaluation

- Filtration ExperimentDocument15 pagesFiltration Experimentkudzai100% (1)

- Jar TestingDocument4 pagesJar TestingVel MuruganPas encore d'évaluation

- Particle Mech Assgmnt2Document3 pagesParticle Mech Assgmnt2Michael Kang'eriPas encore d'évaluation

- Determination of Total Suspended SolidsDocument2 pagesDetermination of Total Suspended Solidstanmay_envs100% (1)

- Lab 2 - Suspended Solids (Full)Document8 pagesLab 2 - Suspended Solids (Full)NorhazerahYussopPas encore d'évaluation

- Contoh Report Jar TestDocument12 pagesContoh Report Jar TestIzzat75% (4)

- Jar Test Dcc40172 Alif, Anis, ZulianaDocument10 pagesJar Test Dcc40172 Alif, Anis, ZulianaAnis NurdiniPas encore d'évaluation

- Mozley TableDocument6 pagesMozley TableZulqayyim Noor Azizul100% (2)

- Rapid Sand FilterDocument7 pagesRapid Sand FilterAjmal Khan67% (3)

- Standard methods for the examination of water and sewageD'EverandStandard methods for the examination of water and sewagePas encore d'évaluation

- O Level Biology Practice For Structured Questions Movement Of SubstancesD'EverandO Level Biology Practice For Structured Questions Movement Of SubstancesPas encore d'évaluation

- Methods and Instruments Used in Brewing Control - Selected QuestionsD'EverandMethods and Instruments Used in Brewing Control - Selected QuestionsPas encore d'évaluation

- Upsr Model Test 1: PAPER 013Document14 pagesUpsr Model Test 1: PAPER 013Laila FaeizahPas encore d'évaluation

- The Feasibility of Carbon Capturing, Storage and UtilizationDocument6 pagesThe Feasibility of Carbon Capturing, Storage and UtilizationLaila FaeizahPas encore d'évaluation

- CO2 Emissions From Fuel Combustion Highlights 2015Document152 pagesCO2 Emissions From Fuel Combustion Highlights 2015Laila FaeizahPas encore d'évaluation

- Low Carbon Cities Framework and Assessment SystemDocument91 pagesLow Carbon Cities Framework and Assessment SystemLaila Faeizah100% (1)

- Playbook PG Students 2019 1 PDFDocument82 pagesPlaybook PG Students 2019 1 PDFLaila FaeizahPas encore d'évaluation

- Building Sentences ModuleDocument76 pagesBuilding Sentences ModuleAireen Azura100% (1)

- Co2 Utilization ReviewDocument20 pagesCo2 Utilization ReviewLaila FaeizahPas encore d'évaluation

- KeyWorld Statistics 2015 PDFDocument81 pagesKeyWorld Statistics 2015 PDFLaila FaeizahPas encore d'évaluation

- Food PoisoningDocument18 pagesFood PoisoningLaila FaeizahPas encore d'évaluation

- Citations Referencing SlidesDocument54 pagesCitations Referencing SlidesLaila FaeizahPas encore d'évaluation

- POLY-MTL 2017-Winter RI BrochureDocument47 pagesPOLY-MTL 2017-Winter RI BrochureLaila FaeizahPas encore d'évaluation

- Environmental Issues Waste Management (CPB 40103) BriefingDocument2 pagesEnvironmental Issues Waste Management (CPB 40103) BriefingLaila FaeizahPas encore d'évaluation

- 3.4 DeodorizationDocument33 pages3.4 DeodorizationLaila FaeizahPas encore d'évaluation

- Data StreamDocument9 pagesData StreamLaila FaeizahPas encore d'évaluation

- Ammonia HAZARDDocument6 pagesAmmonia HAZARDLaila FaeizahPas encore d'évaluation

- Pergamon: Optimal Design of An Ammonia Synthesis Reactor Using Genetic AlgorithmsDocument6 pagesPergamon: Optimal Design of An Ammonia Synthesis Reactor Using Genetic AlgorithmsLaila FaeizahPas encore d'évaluation

- Result Exp2Document4 pagesResult Exp2Laila FaeizahPas encore d'évaluation

- CEB 40603 - Lab ManualDocument21 pagesCEB 40603 - Lab ManualLaila FaeizahPas encore d'évaluation

- Buffer DiscussDocument4 pagesBuffer DiscussLaila FaeizahPas encore d'évaluation

- Atr SelectivityDocument9 pagesAtr SelectivityLaila FaeizahPas encore d'évaluation

- Secondary ReformerDocument50 pagesSecondary Reformerwaheed_bhatti50% (2)

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaPas encore d'évaluation

- Design INFODocument2 pagesDesign INFOLaila FaeizahPas encore d'évaluation

- A Filter PressDocument0 pageA Filter Pressraneshkumar1992Pas encore d'évaluation

- 1.5 Quality Control AssuranceDocument7 pages1.5 Quality Control AssuranceLaila FaeizahPas encore d'évaluation

- 1.6 PomeDocument22 pages1.6 PomeLaila FaeizahPas encore d'évaluation

- Solid-State Fermentation: Ashok PandeyDocument4 pagesSolid-State Fermentation: Ashok PandeycarloscarinelliPas encore d'évaluation

- Citations Referencing SlidesDocument54 pagesCitations Referencing SlidesLaila FaeizahPas encore d'évaluation

- EnergyUpdate 2011 REPORTDocument16 pagesEnergyUpdate 2011 REPORTLaila FaeizahPas encore d'évaluation

- Laminar Premixed Flames 6Document78 pagesLaminar Premixed Flames 6rcarpiooPas encore d'évaluation

- Curry PowderDocument8 pagesCurry PowderMahendar Vanam100% (1)

- Probset 3 KeyDocument7 pagesProbset 3 KeyhoneyschuPas encore d'évaluation

- Training Structure - Thinkific Plus TemplateDocument7 pagesTraining Structure - Thinkific Plus TemplateQIONG WUPas encore d'évaluation

- The Role of IT in TQM L'Oreal Case StudyDocument9 pagesThe Role of IT in TQM L'Oreal Case StudyUdrea RoxanaPas encore d'évaluation

- Chemistry For Changing Times 14th Edition Hill Mccreary Solution ManualDocument24 pagesChemistry For Changing Times 14th Edition Hill Mccreary Solution ManualElaineStewartieog100% (50)

- Abhishek Parmar: Personal DetailsDocument2 pagesAbhishek Parmar: Personal DetailsabhishekparmarPas encore d'évaluation

- Practical Research 2 Group 11 RRL, Proposed Title and Answers To The QuestionsDocument14 pagesPractical Research 2 Group 11 RRL, Proposed Title and Answers To The QuestionsFeby Margaret AngPas encore d'évaluation

- VRealize Operations Manager Installation and Configuration Guide For Linux and WindowsDocument98 pagesVRealize Operations Manager Installation and Configuration Guide For Linux and Windowsamdusias67Pas encore d'évaluation

- ESG Conundrum PDFDocument30 pagesESG Conundrum PDFVijay Kumar SwamiPas encore d'évaluation

- Origins - and Dynamics of Culture, Society and Political IdentitiesDocument4 pagesOrigins - and Dynamics of Culture, Society and Political IdentitiesJep Jep Panghulan100% (1)

- Sheridan Specialized Building Products LLC - Queue Solutions Commercial Proposal by SeQure TechnologiesDocument6 pagesSheridan Specialized Building Products LLC - Queue Solutions Commercial Proposal by SeQure Technologiessailesh psPas encore d'évaluation

- Nurses Guide To Family Assessment and InterventionDocument9 pagesNurses Guide To Family Assessment and InterventionKaye CorPas encore d'évaluation

- Microcontrollers DSPs S10Document16 pagesMicrocontrollers DSPs S10Suom YnonaPas encore d'évaluation

- Reaffirmed 1998Document13 pagesReaffirmed 1998builconsPas encore d'évaluation

- Hamza Akbar: 0308-8616996 House No#531A-5 O/S Dehli Gate MultanDocument3 pagesHamza Akbar: 0308-8616996 House No#531A-5 O/S Dehli Gate MultanTalalPas encore d'évaluation

- Sullivan's Interpersonal TheoryDocument27 pagesSullivan's Interpersonal TheoryJezalen GonestoPas encore d'évaluation

- Viking 062293Document8 pagesViking 062293Lukman ZakariyahPas encore d'évaluation

- Hydrotest Test FormatDocument27 pagesHydrotest Test FormatRähûl Prätäp SïnghPas encore d'évaluation

- Elad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086Document61 pagesElad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086james wrightPas encore d'évaluation

- Proposal For A Working Procedure To Accurately Exchange Existing and New Calculated Protection Settings Between A TSO and Consulting CompaniesDocument9 pagesProposal For A Working Procedure To Accurately Exchange Existing and New Calculated Protection Settings Between A TSO and Consulting CompaniesanonymPas encore d'évaluation

- Dokumen - Tips - Dominick Salvatore Microeconomics Wwwpdfsdocuments2comd38dominick SalvatorepdfDocument2 pagesDokumen - Tips - Dominick Salvatore Microeconomics Wwwpdfsdocuments2comd38dominick SalvatorepdfIshan SharmaPas encore d'évaluation

- R917007195 Comando 8RDocument50 pagesR917007195 Comando 8RRodrigues de OliveiraPas encore d'évaluation

- Chapter 4 PDFDocument26 pagesChapter 4 PDFMeloy ApiladoPas encore d'évaluation

- Ahu 1997 22 1 95Document15 pagesAhu 1997 22 1 95Pasajera En TrancePas encore d'évaluation

- MGN815: Business Models: Ajay ChandelDocument38 pagesMGN815: Business Models: Ajay ChandelSam RehmanPas encore d'évaluation

- Time-Temperature Charge Function of A High Dynamic Thermal Heat Storage With Phase Change MaterialDocument15 pagesTime-Temperature Charge Function of A High Dynamic Thermal Heat Storage With Phase Change Materialgassoumi walidPas encore d'évaluation

- Lesson Tasks: Lesson Plan: Addition and Subtraction To 20Document2 pagesLesson Tasks: Lesson Plan: Addition and Subtraction To 20Марина СтанојевићPas encore d'évaluation

- Grade 8 Science Text Book 61fb9947be91fDocument289 pagesGrade 8 Science Text Book 61fb9947be91fNadarajah PragatheeswarPas encore d'évaluation

- Cooperative LinuxDocument39 pagesCooperative Linuxrajesh_124Pas encore d'évaluation